"Dash-doorhandle-6 cyl none the richer" (dash-doorhandle-and-bondo)

"Dash-doorhandle-6 cyl none the richer" (dash-doorhandle-and-bondo)

08/11/2020 at 21:57 ē Filed to: None

4

4

7

7

"Dash-doorhandle-6 cyl none the richer" (dash-doorhandle-and-bondo)

"Dash-doorhandle-6 cyl none the richer" (dash-doorhandle-and-bondo)

08/11/2020 at 21:57 ē Filed to: None |  4 4

|  7 7 |

little pinholes to weld up in the tub, and a little trimming on the inside and this bit will be done.

minus this bit.

a big section sliced out.

Iíll trim to fit when I attach a big chunk of rocker panel to it.

VincentMalamute-Kim

> Dash-doorhandle-6 cyl none the richer

VincentMalamute-Kim

> Dash-doorhandle-6 cyl none the richer

08/11/2020 at 22:21 |

|

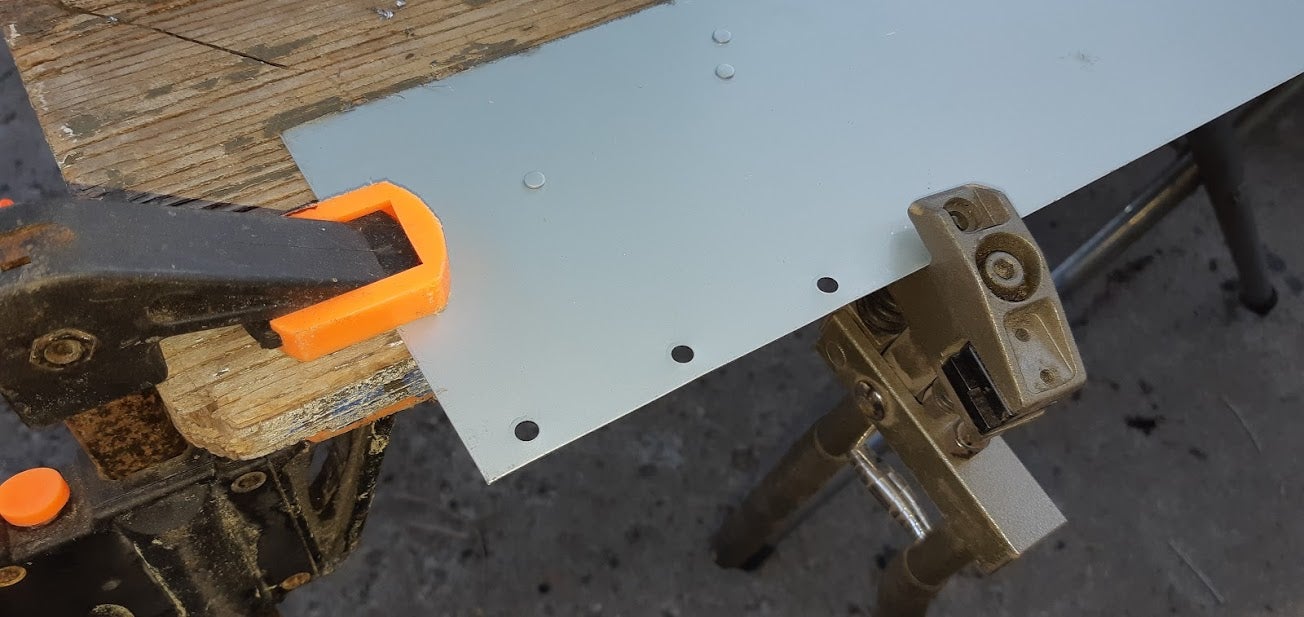

Dang.† Whatís the tool in the second to last photo?† Only thing I can think of is some kind of Cleco?

ranwhenparked

> Dash-doorhandle-6 cyl none the richer

ranwhenparked

> Dash-doorhandle-6 cyl none the richer

08/11/2020 at 22:25 |

|

Are you sure you aren't secretly Scott Newstead in disguise?

Dash-doorhandle-6 cyl none the richer

> VincentMalamute-Kim

Dash-doorhandle-6 cyl none the richer

> VincentMalamute-Kim

08/11/2020 at 22:28 |

|

It is a punch and joggle tool.

it also makes a little step down in sheet metal so you can lap one panel behind the other and weld flush.

VincentMalamute-Kim

> Dash-doorhandle-6 cyl none the richer

VincentMalamute-Kim

> Dash-doorhandle-6 cyl none the richer

08/11/2020 at 22:43 |

|

Thank you. TIL.

I imagine most Oppos are amazed at people who do

body work.

Nom De Plume

> Dash-doorhandle-6 cyl none the richer

Nom De Plume

> Dash-doorhandle-6 cyl none the richer

08/11/2020 at 23:06 |

|

This is lowkey the best project going on here.

sony1492

> Dash-doorhandle-6 cyl none the richer

sony1492

> Dash-doorhandle-6 cyl none the richer

08/11/2020 at 23:12 |

|

Is there a particular issue with using a thicker gauge sheet ?

When doing this Z Iíve been using 18ga sheet, they cool differently but welding an entire sea m warps the panel anyways

Dash-doorhandle-6 cyl none the richer

> sony1492

Dash-doorhandle-6 cyl none the richer

> sony1492

08/11/2020 at 23:21 |

|

This repair panel stuff is much thinner than 18ga probably about right for N issan, or any more modern car. on this car the steel is much thicker than the repair panel. Very nice patch by the way.