"benjrblant" (benjblant)

"benjrblant" (benjblant)

06/10/2020 at 16:47 ē Filed to: None

3

3

12

12

"benjrblant" (benjblant)

"benjrblant" (benjblant)

06/10/2020 at 16:47 ē Filed to: None |  3 3

|  12 12 |

Truthfully, itís getti ng kind of old at this point. Iíd so much rather have a job and be working, but Iíve had absolutely zero prospects. Itís been a weird mental shift from ďhow can i do this efficientlyĒ to ďf-it, Iíve got all the time in the world and doing it this way saves me $3.Ē I feel that Iím making excellent use of my college education.

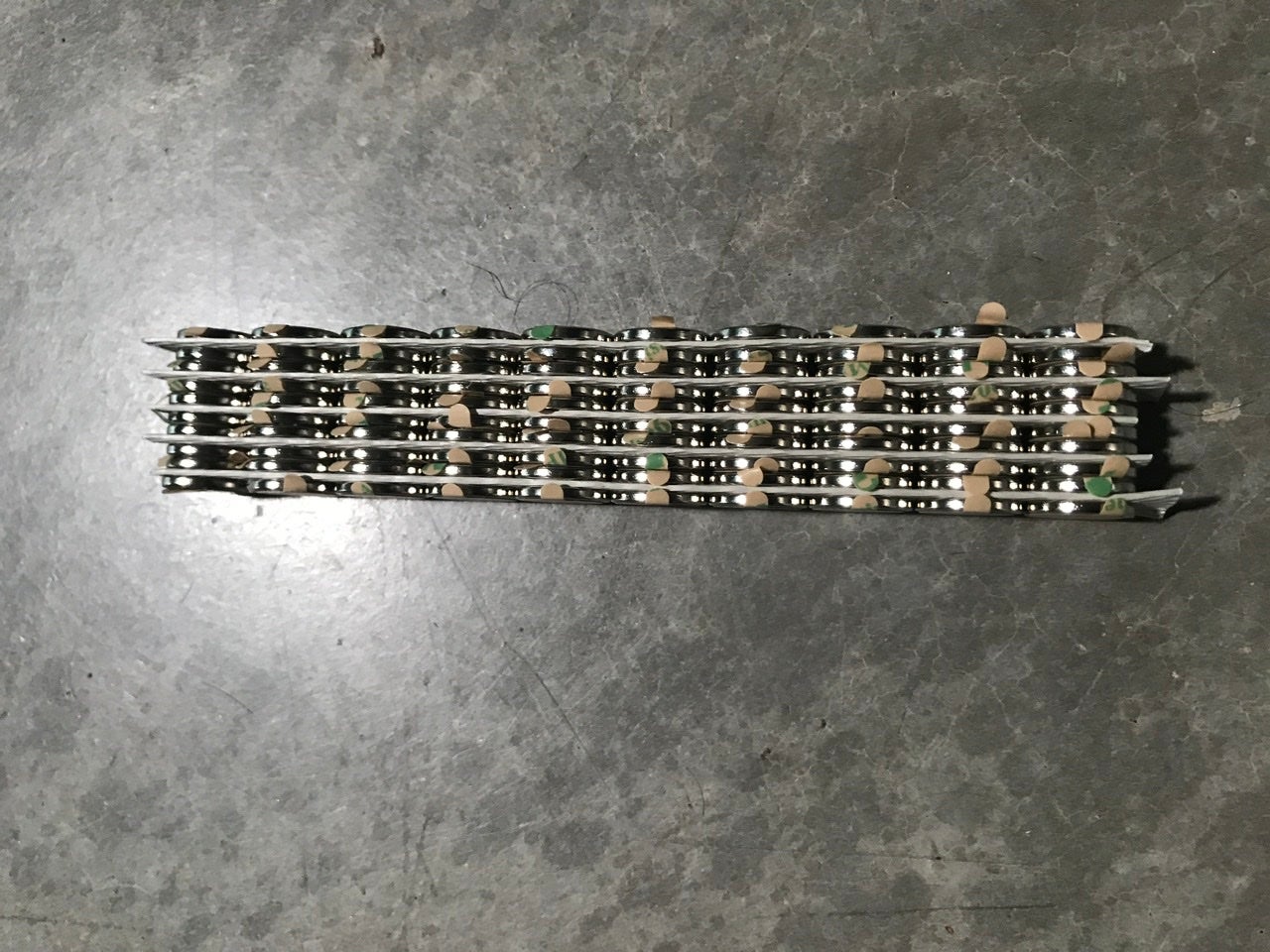

Pictured: stack of beams to hopefully make into a workbench because... Iím pretty much running out of things to do at this point.

Sovande

> benjrblant

Sovande

> benjrblant

06/10/2020 at 16:57 |

|

That's some nice looking wood. Long bar clamps and glue it all together?†

benjrblant

> Sovande

benjrblant

> Sovande

06/10/2020 at 17:07 |

|

Thanks, theyíre beams for residential construction, 11 7/8" wide x 1 3/4" thick. These leftovers are about 8' long, so Iím thinking the benchtop will be two beams wide and Iíll rip one down for legs.

TheRealBicycleBuck

> benjrblant

TheRealBicycleBuck

> benjrblant

06/10/2020 at 17:14 |

|

Those beams will make for one sturdy table. I need something more portable, so I built a Paulk compact workbench. Itís been surprisingly handy. The torsion box design provides a place to set tools down without cluttering the bench top (I clutter it up anyway) and the edge has been great for clamping down items. I plan to get holes drilled for bench dogs eventually. The plans call for custom saw horses but Iím thinking a pair of folding legs with casters will work better for me.

Mineís currently sitting on a couple of cabinets. I turned them sideways last week so the bench surface is about the same height as my table saw and it can act as an outfeed table.

Are you going to follow a set of plans or just wing it?

phenotyp

> benjrblant

phenotyp

> benjrblant

06/10/2020 at 17:16 |

|

I just bought a bunch of magnets (US-based) to make a knife rack or 10.

I might have overbought, magnet-wise.

Should be able to use my friendís shop on Friday or Saturday and take her scrap wood and make a few.†

benjrblant

> TheRealBicycleBuck

benjrblant

> TheRealBicycleBuck

06/10/2020 at 17:27 |

|

Nice! That looks efficient. Bench dogs are the way to go if youíre working with long stock.

I used to do detailing and engineering, so Iíll stick with a custom design for mine.

TheRealBicycleBuck

> benjrblant

TheRealBicycleBuck

> benjrblant

06/10/2020 at 17:34 |

|

I look forward to the finished product!

Sovande

> benjrblant

Sovande

> benjrblant

06/10/2020 at 17:35 |

|

I want to make tables out of it. Are they oak? This is a solid slab of oak I split down the center and then glued back together. It's just over 2" thick. The butterflies are walnut.†

benjrblant

> Sovande

benjrblant

> Sovande

06/10/2020 at 17:37 |

|

The beams are plywood, doug fir or pine, IIRC. Theyíre quite knotty with a lot of glue seams- definitely construction product.

Thatís a really nice looking table! It takes some skill to do butterflies well, nice work.

66P1800inpieces

> benjrblant

66P1800inpieces

> benjrblant

06/10/2020 at 17:37 |

|

What field and region are you in?

benjrblant

> 66P1800inpieces

benjrblant

> 66P1800inpieces

06/10/2020 at 17:40 |

|

Iím in Denver. Previous employment was here: https://oppositelock.kinja.com/and-thats-a-wrap-1842428125

Sovande

> benjrblant

Sovande

> benjrblant

06/10/2020 at 19:02 |

|

Thanks. I had a nice template and some strong tape.†

Oh! I didnít realize those were laminated beams, thatís pretty cool. They are doing some amazing things with engineered beams these days. There is a construction company called Katerra which is trying to really push that technology. They are having limited success, but its pretty interesting stuff. Cross laminated timber is the technical name, I think.†

functionoverfashion

> benjrblant

functionoverfashion

> benjrblant

06/10/2020 at 20:55 |

|

It would be hard to convince me not to build some sweet mountain bike obstacles out of all that. Iím starting to build some of that into my trails, now that the kids have enough singletrack to keep them busy; I need impossible stuff to try to get up and over to keep myself entertained.†