"Tareim - V8 powered" (tareimgaml)

"Tareim - V8 powered" (tareimgaml)

05/15/2020 at 16:05 ē Filed to: Classic Car, V8, TR7

7

7

2

2

"Tareim - V8 powered" (tareimgaml)

"Tareim - V8 powered" (tareimgaml)

05/15/2020 at 16:05 ē Filed to: Classic Car, V8, TR7 |  7 7

|  2 2 |

A lot has happened since I last posted about my TR7V8, I took it to an AutoSolo on boxing day last year and ended up snapping a rear tie rod during my 2nd run, tried repairing using a lot of cables ties but unfortunately that didnít hold the V8 torque

managed to get that fixed after getting recovery home, then on new years day I went to a classic car meet (photo from my previous post) where it decided none of the dash clocks wanted to work, didnít seem to want to run right and also started steaming as I tried to find somewhere to park, after all that I opted not to go on the long cruise they usual do following the meet as I didnít want to get stranded.

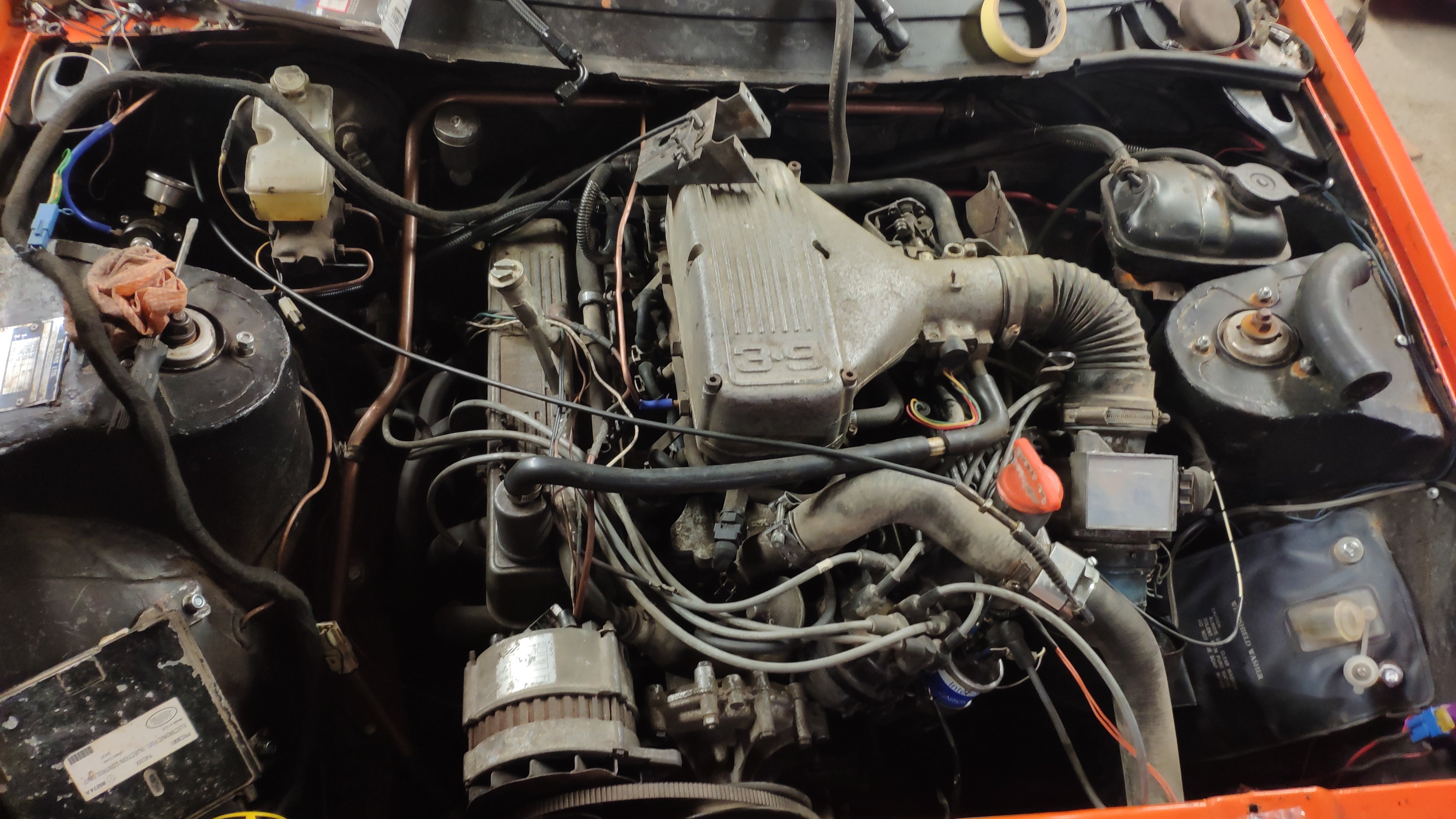

a couple weeks later I decided that I had enough of the 3.5 carbíd V8 for not running right (more on that shortly) so decided to look for engine alternatives from the almost common as muck 1UZ engine swap that everyone is doing now to a Jag V8 from the xk8, in the end I settled for the simplest of options and upgraded to the Rover 3.9 EFI engine as didnít need to change engine mounts or gearbox etc.

cue the donor vehicle, an offroader built on a Range Rover Classic chassis, it came with an autobox that mustíve been slipping or has been modded in the weird way as it took sooo long to change gear and when it did it felt like getting kicked in the back by a donkey, I had test drove it down a narrow country lane with ditches either side, I felt like the kick from the gear change was going to put me in either ditch so backed out of it quickly. here is the said beast I bought for relatively cheap

couple weeks later after getting that beast it was bolted in to the TR7, and then a couple of months dealing with various niggles that cropped up, the biggest issue was sorting out the fuel line issue as the tank only had 1 fuel pipe coming from it (output as no return lines on a carb engine) in the end we found someone willing to weld in a new fitting for a return line without blowing themselves up from igniting any old fumes still in the tank (a risk factor that Iím told of)

whilst finishing off the final bits to allow me to drive it again we looked at the 3.5 and came across this twisted/bent fuel line which would explain the poor running, no idea how we missed that

Cut to today where I drove it home from the workshop and got a brief clip of how it sounds

!!! UNKNOWN CONTENT TYPE !!!

hopefully youíve made it this far, if so well done you! and thanks for taking the time to read it

TheRealBicycleBuck

> Tareim - V8 powered

TheRealBicycleBuck

> Tareim - V8 powered

05/15/2020 at 16:31 |

|

ď... in the end we found someone willing to weld in a new fitting for a return line without blowing themselves up from igniting any old fumes still in the tank (a risk factor that Iím told of)...Ē †

Itís a big risk factor. My best friendís dad was killed this way. He was one of the few truck mechanics willing to work on tankers. The normal process was to power-wash the interior of the tank, then start working immediately. He had one prepped for work when an emergency repair rolled in. He made that repair, then went back to the tanker. He should have power-washed it a second time, but he thought the fumes wouldnít have built up again after the first wash. He was wrong. He was leaning over the open manhole when he started welding a crack. The fumes caught, burning him and throwing him into the air. He hit one of the joists in the shop on the way up before he fell to the concrete floor below. My friend called 911, then did CPR until the ambulance arrived. He was declared dead at the scene.

A smaller tank might not have the same force, but I certainly wouldnít want to be anywhere near one when someone was welding on it.

Tareim - V8 powered

> TheRealBicycleBuck

Tareim - V8 powered

> TheRealBicycleBuck

05/15/2020 at 16:33 |

|

shit that sounds awful, sorry to hear that