"MR2_FTW - Group J's resident Stig" (MR2_FTW)

"MR2_FTW - Group J's resident Stig" (MR2_FTW)

05/23/2019 at 11:30 ē Filed to: None

13

13

11

11

"MR2_FTW - Group J's resident Stig" (MR2_FTW)

"MR2_FTW - Group J's resident Stig" (MR2_FTW)

05/23/2019 at 11:30 ē Filed to: None |  13 13

|  11 11 |

With the car safely home from HPDE back in April, a few issues that had made themselves apparent now needed fixing.

The valve cover gaskets were seeping oil, so I went ahead and painted my spare set of covers and put them on with fresh gaskets. I love the white/black/red NASA-inspired color theme.

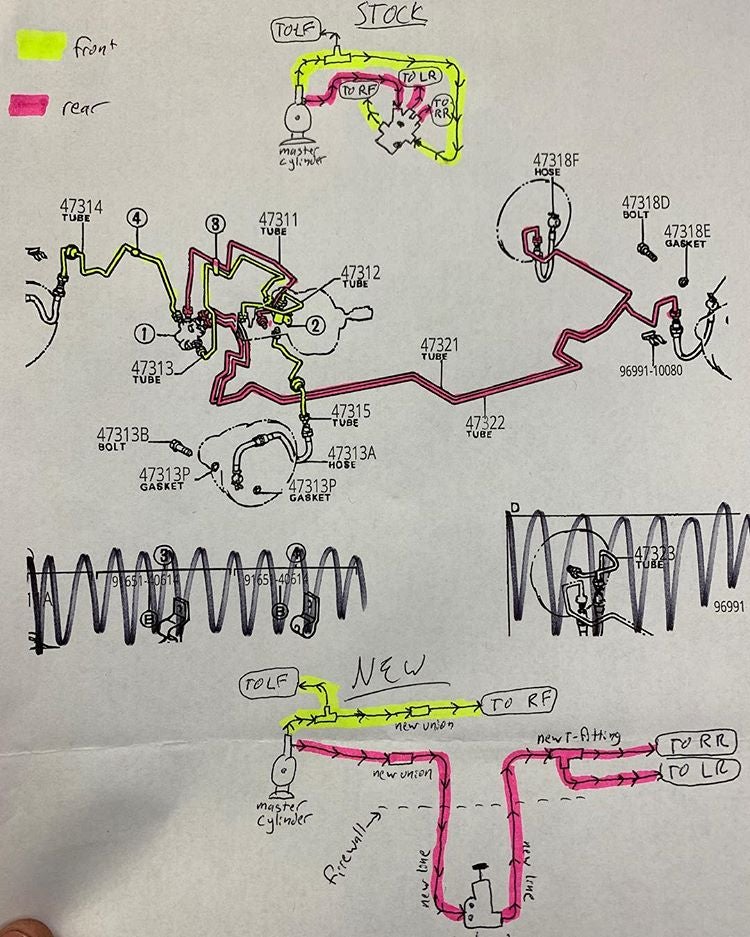

The biggest takeaway from HPDE was how much I was under-using the brakes, and needed to brake harder. By the end of the day the front brakes were pretty toasty, with the pads starting to glaze and the rotors starting to warp after the last sessionís cooldown. The rear brakes were basically like-new though.

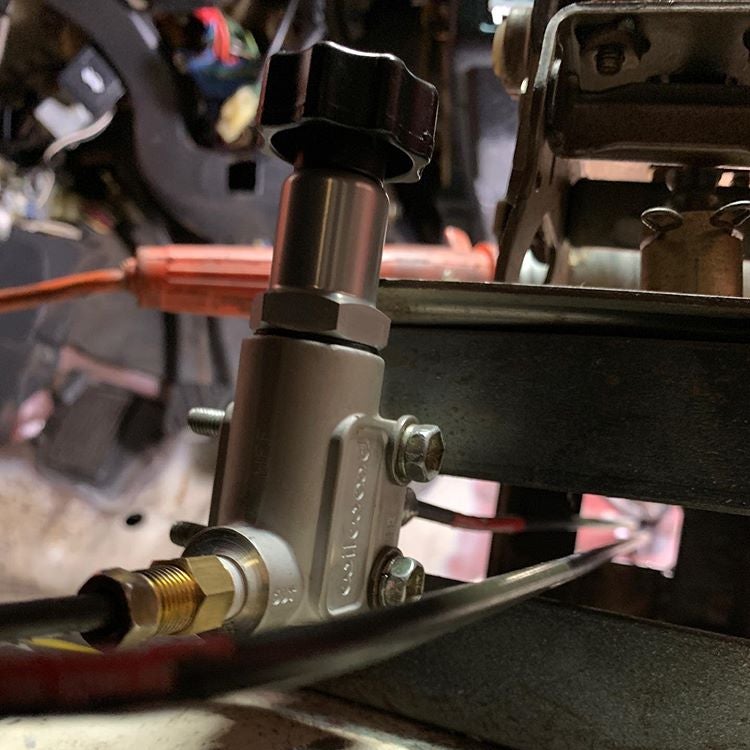

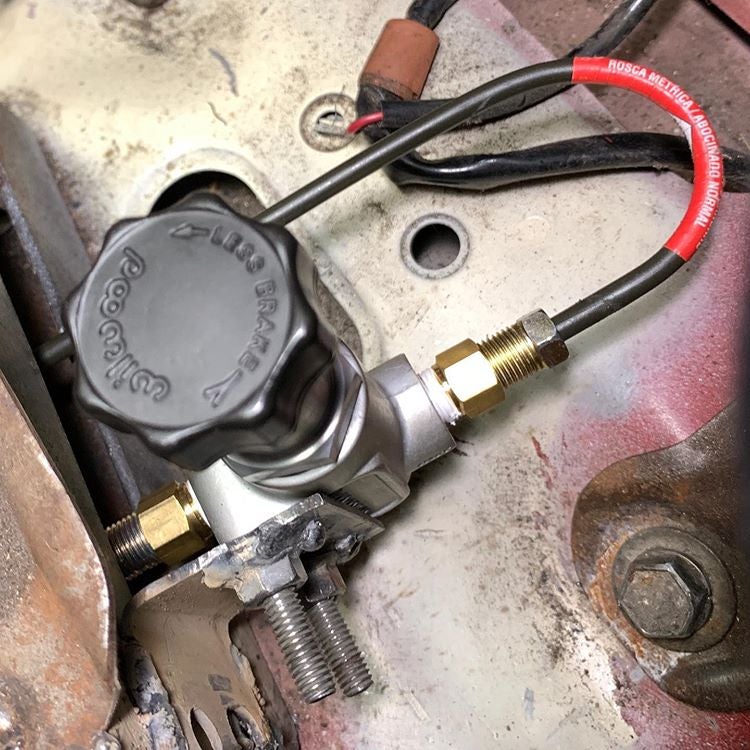

Solution: remove the stock proportioning valve and install an adjustable valve for the rear brakes. This will accomplish two things: allow me to fine tune how much force goes to the rear brakes, and split the front and rear circuits for safety/redundancy.

I wanted to be able to reach the adjuster knob from the driverís seat so I made a little mounting bracket and welded it to the shifter riser.

A couple adapters and two 4-foot sections of steel brake tubing complete this end of the circuit.

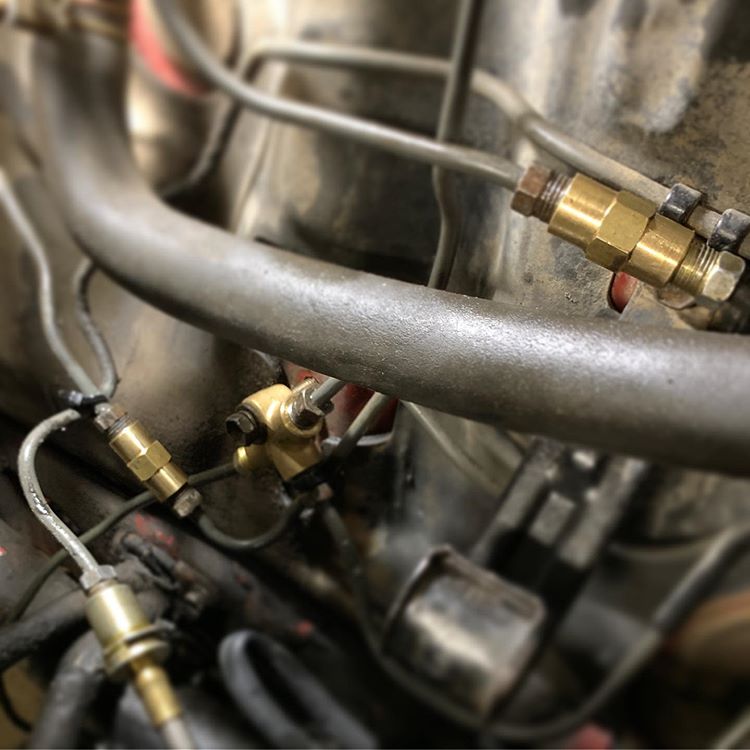

The lines run under the shifter and through a pre-existing grommet in the firewall.

Without much room to hand-bend the lines, itís not the prettiest install ever, but so far nothing leaks or rattles and it seems to work as intended. Fortunately all of this is hidden behind the engine so you donít have to look at it.

Iíd had a stainless clutch line laying around for a while, and this seemed as good a time as any to install it. Whatís one more bleeder valve when youíre already doing the brakes anyway?

If youíve been keeping up with this build so far itís probably pretty clear that this is a low-budget endeavor. That means funds for events are hard to come by, but Iím hoping to make it out to my first two-day HPDE event at Dominion in September. I canít wait!

Nibby

> MR2_FTW - Group J's resident Stig

Nibby

> MR2_FTW - Group J's resident Stig

05/23/2019 at 11:36 |

|

Bob Loblaw Made Me Make a Phoney Phone Call to Edward Rooney

> MR2_FTW - Group J's resident Stig

Bob Loblaw Made Me Make a Phoney Phone Call to Edward Rooney

> MR2_FTW - Group J's resident Stig

05/23/2019 at 11:37 |

|

Man I love this build so much. Glad to see it continuing!

Textured Soy Protein

> MR2_FTW - Group J's resident Stig

Textured Soy Protein

> MR2_FTW - Group J's resident Stig

05/23/2019 at 11:59 |

|

I fully endorse the embiggening of this post. Even if the current kinja borktification of oppo means we should be embiggening everything.†

DutchieDC2R

> MR2_FTW - Group J's resident Stig

DutchieDC2R

> MR2_FTW - Group J's resident Stig

05/23/2019 at 12:56 |

|

This is f*cking awesome! Keep on doing what you're doing, I sincerely hope you get the funds together for Dominion, I'd love to read about it.

MR2_FTW - Group J's resident Stig

> DutchieDC2R

MR2_FTW - Group J's resident Stig

> DutchieDC2R

05/23/2019 at 13:23 |

|

If youíd like to hear about the last HPDE day at Dominion, we did a nice commentary for an episode of our podcast.

!!! UNKNOWN CONTENT TYPE !!!

Also available on itunes, spotify, stitcher, pocketcasts, etc

MR2_FTW - Group J's resident Stig

> Textured Soy Protein

MR2_FTW - Group J's resident Stig

> Textured Soy Protein

05/23/2019 at 13:25 |

|

I havenít been around much in recent months, whatís the skinny on the new Kinja update?

MR2_FTW - Group J's resident Stig

> Bob Loblaw Made Me Make a Phoney Phone Call to Edward Rooney

MR2_FTW - Group J's resident Stig

> Bob Loblaw Made Me Make a Phoney Phone Call to Edward Rooney

05/23/2019 at 13:25 |

|

Thanks for the kind words!

66P1800inpieces

> MR2_FTW - Group J's resident Stig

66P1800inpieces

> MR2_FTW - Group J's resident Stig

05/23/2019 at 15:07 |

|

Is that steel with a yellow coating or brass? I know my vintage car has a brass union, but you may want to check on the burst strength since you are using it for track duty.

The spec below is for on road applications in the US, and is for hoses, but fittings are probably similar.

(b) Shall not rupture during a 2-minute, 4,000 psi pressure hold test, and;

(c) Shall not burst at a pressure less than 5,000 psi.

Code is FMVSS 116

https://www.law.cornell.edu/cfr/text/49/571.106

While brass fittings might be okay ( I am not really sure) you might want something stronger once you test out the new system to make sure it does what you want before buying another set of fittings.†

Textured Soy Protein

> MR2_FTW - Group J's resident Stig

Textured Soy Protein

> MR2_FTW - Group J's resident Stig

05/23/2019 at 15:39 |

|

No more post text on the desktop version of the site, only titles !

MR2_FTW - Group J's resident Stig

> Textured Soy Protein

MR2_FTW - Group J's resident Stig

> Textured Soy Protein

05/23/2019 at 16:16 |

|

Dumb

MR2_FTW - Group J's resident Stig

> 66P1800inpieces

MR2_FTW - Group J's resident Stig

> 66P1800inpieces

05/23/2019 at 16:17 |

|

I believe they are brass but they are all automotive grade parts from Autozone or off-road truck sites. I have no reason to suspect they would fail. Iíve seen far, far jankier things on track cars. Like a multiple- SCCA- champ- title holder running with vicegrips on his rear brake lines to keep the rears from locking.