"glemon" (glemon)

"glemon" (glemon)

02/07/2019 at 23:52 ē Filed to: None

5

5

11

11

"glemon" (glemon)

"glemon" (glemon)

02/07/2019 at 23:52 ē Filed to: None |  5 5

|  11 11 |

3 Degrees out and only slightly warmer in my now heated, but not yet sealed up and insulated shop, work on the 97 Ranger continues. The bolts for the rusted on brackets have to attach to the frame, there is no back access because of the gas tank. I considered taking off the tank, but of course I had just filled it, and no doubt the bolts holding the gas tank straps †were as badly rusted as everything else so I decided not to go down that road.

So I fished a wire through the hole, fiddled around until I could get it to peek out from between the frame and the tank, attached the bolt to the wire and pulled it through.

A little finesse to get the bolt through, and great care not to push it out once in. I started with 6 bolts, 2 were lost in the abyss, which left me with the 4 I needed.

The impact wrench took care of torqueing down the nuts without a wrench on the bolts. A little fun with levers and leaf springs to get the eye bolt in and we are back on the road.

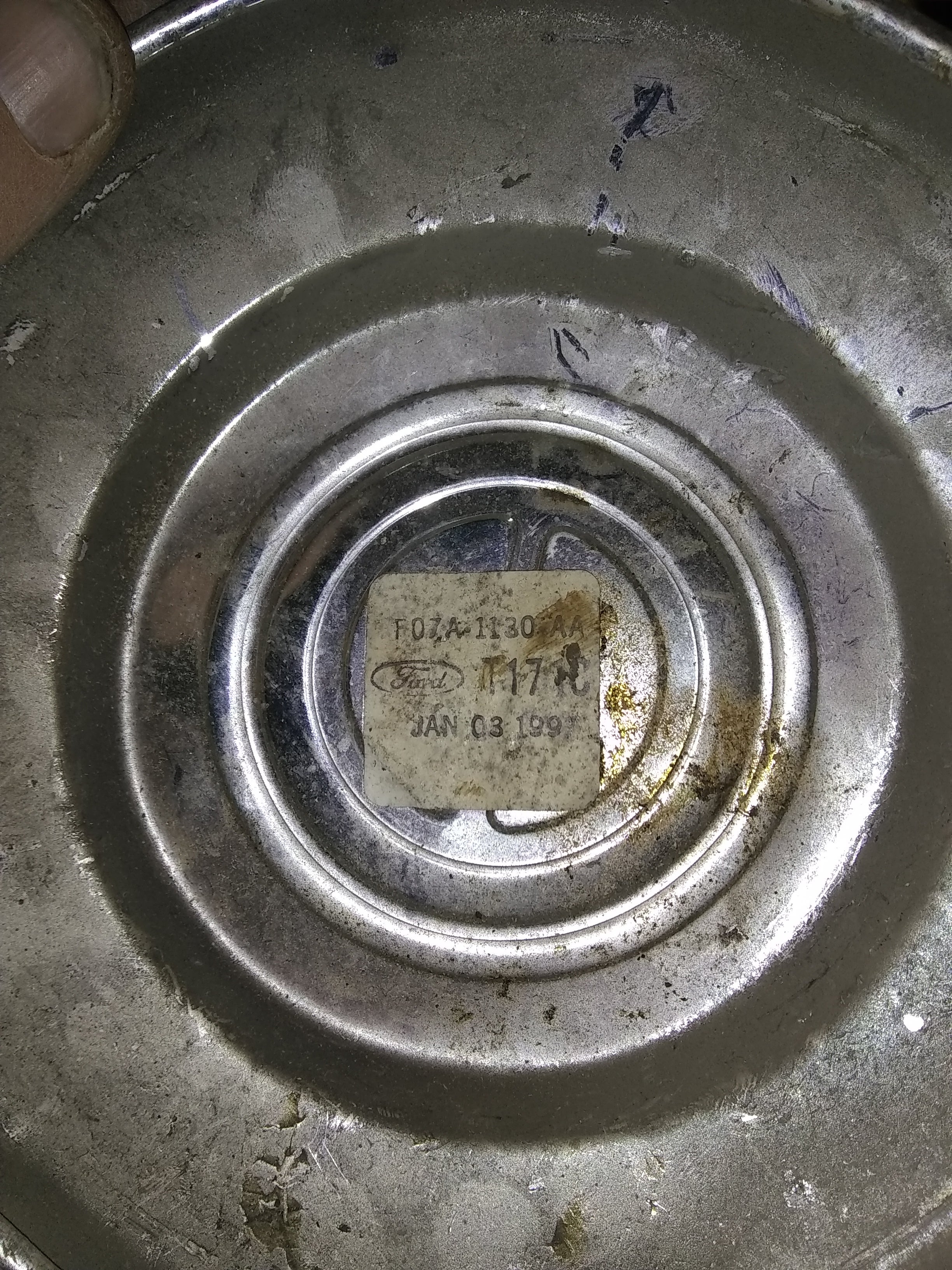

Guess my truck was born in January.

pip bip - choose Corrour

> glemon

pip bip - choose Corrour

> glemon

02/08/2019 at 01:19 |

|

what a colossal pain in the arse that appears to be.

hope you warmed yourself up by a fire with alcohol

glemon

> pip bip - choose Corrour

glemon

> pip bip - choose Corrour

02/08/2019 at 01:28 |

|

Cheers!

Future Heap Owner

> glemon

Future Heap Owner

> glemon

02/08/2019 at 02:29 |

|

Great idea, excellent execution. Very good work. Iím gonna have to remember this trick.

Nick- Professional Car Destroyer

> glemon

Nick- Professional Car Destroyer

> glemon

02/08/2019 at 06:38 |

|

I donít miss doing these jobs.

At a shop I used to work for I was the ďshackle masterĒ because I was the only one dumb enough to volunteer to do them, but I could get shackles and brackets done in about an hour and a half or so on the rangers.

shop-teacher

> glemon

shop-teacher

> glemon

02/08/2019 at 07:07 |

|

What a huge PITA!

Urambo Tauro

> glemon

Urambo Tauro

> glemon

02/08/2019 at 08:05 |

|

Sorry I missed your earlier post. I know what you nee- uh... could have us ed . One of these:

D idnít even realize unti l I looked for a video that these fish wires were available separately. Iím used to seeing them packaged with hitch installation kits and thrown away at the end of th e job.

You donít need to buy one though. Just coil your wire around the threads about 5-6 times and it will have enough thread engagement to pull the bolt through without fussing over a knot of wire hanging up on the hole. If youíre worried that your wire is relaxing too much after coiling , and is fitting the threads too loosely, just wrap it arou nd a smaller bolt first.

Ah, well. Maybe next time.

glemon

> Urambo Tauro

glemon

> Urambo Tauro

02/08/2019 at 09:20 |

|

Thanks, didn't know you could buy stuff like that or it was even a thing.† When I tried to get a utube video on the job at hand all I came up with was pull the gas tank or some nebulous reference to magnets.† I came up with the fish wire as I have been doing a lot of electrical work on the house and garage lately.

glemon

> Nick- Professional Car Destroyer

glemon

> Nick- Professional Car Destroyer

02/08/2019 at 09:24 |

|

Mine took a look at the longer than that, learning as I went. Didnít help that the bulk of my tools are off-site, grabbed what I thought I needed, but there were things I could have used to make the job easier. It is a cheap old truck, I did not want to spend much money on it, but a cheap †bracket was not the hill I thought it should die on either.

glemon

> shop-teacher

glemon

> shop-teacher

02/08/2019 at 09:26 |

|

Yes it was, middle of the job I was actually questioning life choices, buying cheap vehicles, fixing them myself.† But when I got done it all felt pretty good.

Nick- Professional Car Destroyer

> glemon

Nick- Professional Car Destroyer

> glemon

02/08/2019 at 09:40 |

|

Yeah, the weakest point on those is the bracket and shackles.

My first one took me a couple hours, and was mostly spent learning and trying different things to get it apart.

I know little tricks now to get everything apart, using torches of course, but I even was able to do the leaf spring bushing without a press or any removal of the springs.

shop-teacher

> glemon

shop-teacher

> glemon

02/08/2019 at 10:52 |

|

Thatís pretty much how most every DIY job goes for me :)