"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

07/23/2018 at 12:00 ē Filed to: saab 900, project, wrenching

2

2

6

6

"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

07/23/2018 at 12:00 ē Filed to: saab 900, project, wrenching |  2 2

|  6 6 |

You didnít think that a car could sit for ~13 years and not have rust issues, did you?

So Iíve been holding out on you a little, Oppo. Thereís just been so much else going on, and we werenít quite sure when or how we would be dealing with the rust. We knew it was going to need attention, and now that the engineís out, thereís no better time to do something about it.

Wounded as this car is, itís a survivor. Which is more than I can say for some of the !!!error: Indecipherable SUB-paragraph formatting!!! that Ron had to get rid of:

!!! UNKNOWN CONTENT TYPE !!!

Throughout all the wrenching weíve been doing these past few months, Iím pleased to say that very few fasteners have broken. There have been some casualties, the most expensive of which being the stuck bleeders on the rear brake calipers that necessitated sending them in as cores for rebuilt units.

But for the most part, the body has been in pretty good shape, rust-wise. Thereís a bit of rust bubbling up from behind the paint in a couple of spots, but all things considered its not terrible.

Saabís decision to route the rear brake line through the interior of the car has been a blessing, as well as their coated exterior brake lines. I was prepared to have to throw some !!!error: Indecipherable SUB-paragraph formatting!!! at this thing, but it appears that that wonít be necessary after all. Some spots of rust are peeking through, but itís far from the catastrophic flaking & breaking Iím used to seeing on domestic cars.

!!! UNKNOWN CONTENT TYPE !!!

Even the unberbody looks pretty good, for the most part. Not much that needs attention there, except for one hole in the trunk floor and maybe some exhaust heat shielding.

The worst of the rust can be found on some critical parts, though. Thanks to their close proximity with the ground as this car sat for so long, there is some substantial flaking on various suspension components. Perhaps not enough to warrant total replacement, as thereís still a LOT of material there, but enough to give it some attention before it rusts away any more so.

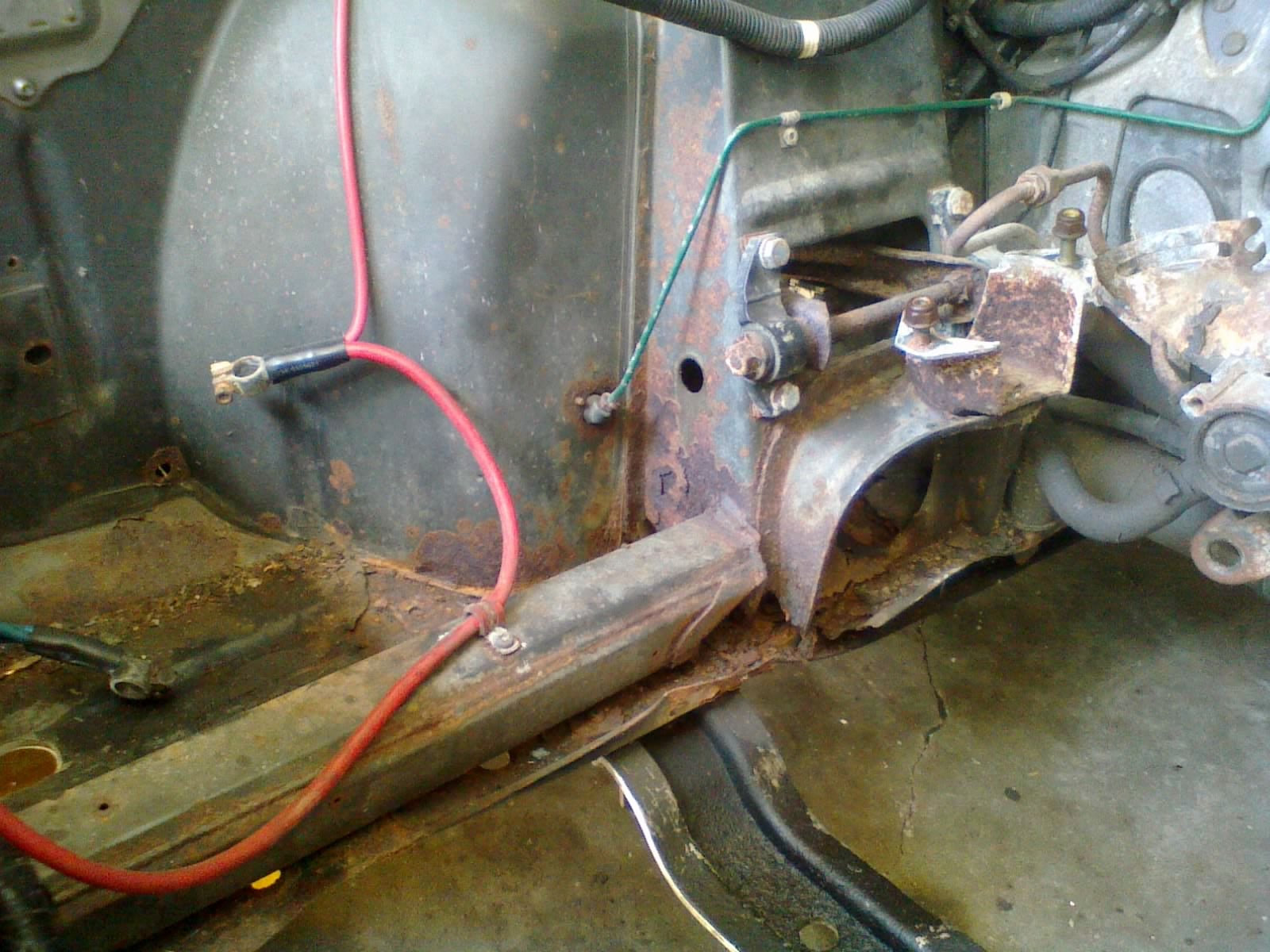

The most serious concern is the framework up front. The area where the RF lower control arm attaches to has all but rotten away. This CANNOT be ignored. Itís still holding on, and since the control arm hasnít torn away yet, we still have a chance to reinforce it before it goes. I couldnít help but cringe when I saw that area flexing as I jacked up that corner in order to pull the axle-shaft prior to engine removal.

It didnít have a battery when we got it, but I canít help but suspect that battery leakage may have contributed to this. Especially when you look at how relatively clean the left side is:

It could still use some reinforcement, though:

Come to find out, this is not unique to the car having sat for an estimated 13 years. This is apparently a common problem area on all classic 900s, regardless of whether theyíve been sitting in fields or driven through rain & salt. There are even

!!!error: Indecipherable SUB-paragraph formatting!!!

available that can be welded right in.

The classic 900 has a substantial design flaw that allows dirt and mud to collect inside the frame rail right where the lower control arm attaches. Add to that the location directly under the battery, and you have the potential for disaster. We have had them in here after the lower control has ripped right out of the frame. We designed this kit to repair that rusted area.

My brother might actually end up !!!error: Indecipherable SUB-paragraph formatting!!! his !!!error: Indecipherable SUB-paragraph formatting!!! panels, but itís nice to know that kits like this exist. We havenít finalized plans for just how much weíre going to have to clean up and/or cut out, but at least the work will be easier now weíve gone to all the trouble of taking the engine out.

Akio Ohtori - RIP Oppo

> Urambo Tauro

Akio Ohtori - RIP Oppo

> Urambo Tauro

07/23/2018 at 12:34 |

|

And another thing gets added to the TODO list.

Seriously Iím impressed at how little rust mine accumulated through sitting for 13 years under a tree, but also living 50% of its life in the Pacific Northwest.

Still, the battery tray had a lot of rust, but I didnít investigate further.† Maybe now is the time to do that...

Urambo Tauro

> Akio Ohtori - RIP Oppo

Urambo Tauro

> Akio Ohtori - RIP Oppo

07/23/2018 at 12:44 |

|

When you get a chance, w ould you mind taking some pics of your battery tray? Weíre going to have to find (or fabricate) one for this, as it didnít come with one. It doesnít look like theyíre available anymore, just universal ones.

I donít know what happened to it, but judging by the rust, I wouldnít be surprised if it sat with a leaking battery in it all this time, and when Ron went to take it out, whatever was left of the tray came with it. Just a hunch.

Akio Ohtori - RIP Oppo

> Urambo Tauro

Akio Ohtori - RIP Oppo

> Urambo Tauro

07/23/2018 at 14:38 |

|

Yeah I can do that.† Mine is missing the bracket and heat shield, sadly, but the tray is intact.

pip bip - choose Corrour

> Urambo Tauro

pip bip - choose Corrour

> Urambo Tauro

07/24/2018 at 07:07 |

|

burn it

Akio Ohtori - RIP Oppo

> Urambo Tauro

Akio Ohtori - RIP Oppo

> Urambo Tauro

07/26/2018 at 21:41 |

|

Urambo Tauro

> Akio Ohtori - RIP Oppo

Urambo Tauro

> Akio Ohtori - RIP Oppo

07/26/2018 at 21:54 |

|

Wow, thatís taller than I thought it was gonna

be. Looks like the platform is just about even with

t

he top of the square tube next to it.

We do ha

ve

the

correct

size battery, but

the cables just barely reach

t

he posts when itís in there without a tray. E

levating it up to that

stock height will easily eliminate the

stress on the battery cables. Good to know. Thanks!