"My bird IS the word" (mybirdistheword)

"My bird IS the word" (mybirdistheword)

03/12/2018 at 13:43 ē Filed to: None

5

5

15

15

"My bird IS the word" (mybirdistheword)

"My bird IS the word" (mybirdistheword)

03/12/2018 at 13:43 ē Filed to: None |  5 5

|  15 15 |

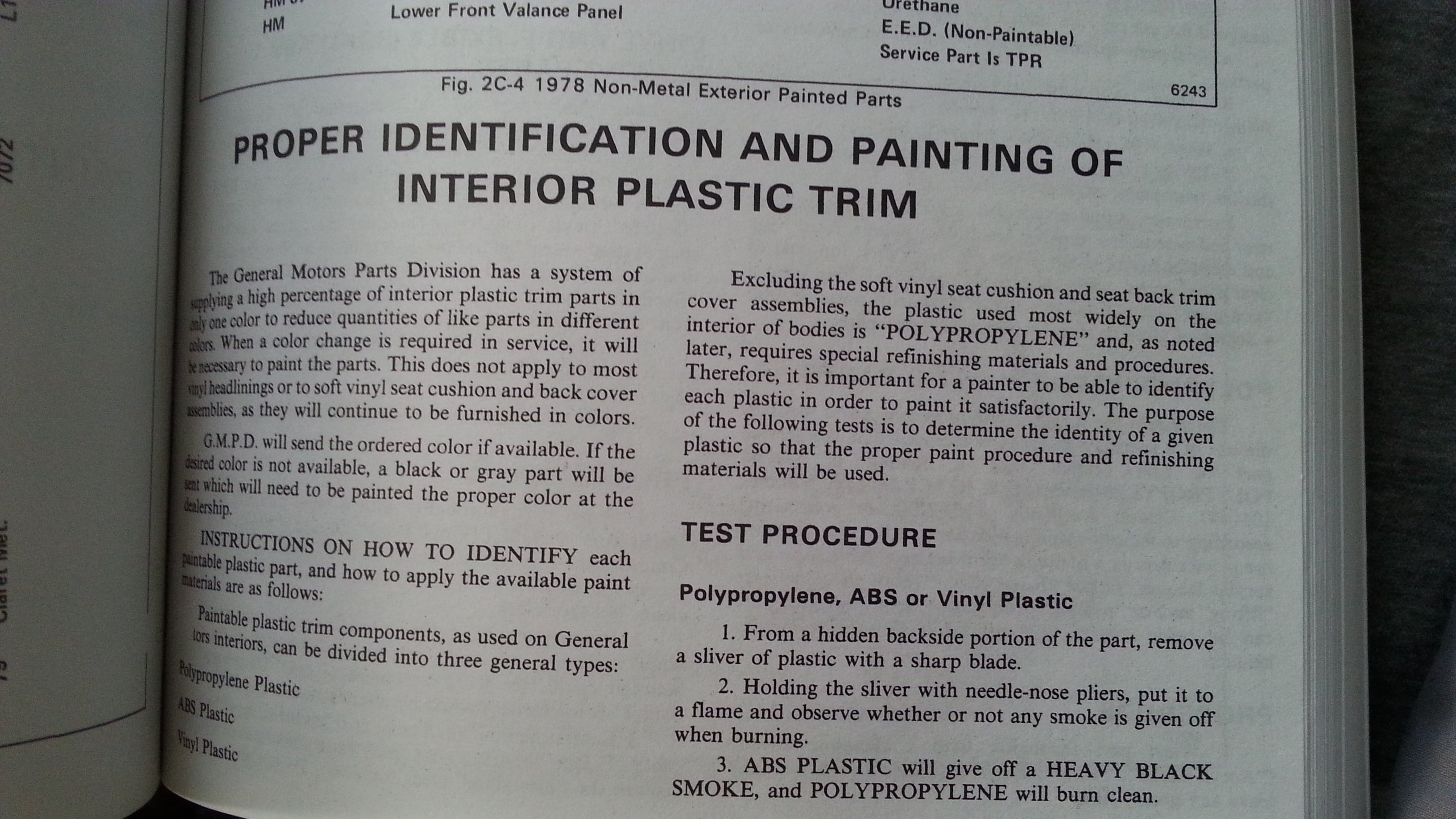

While looking for body torque specs.

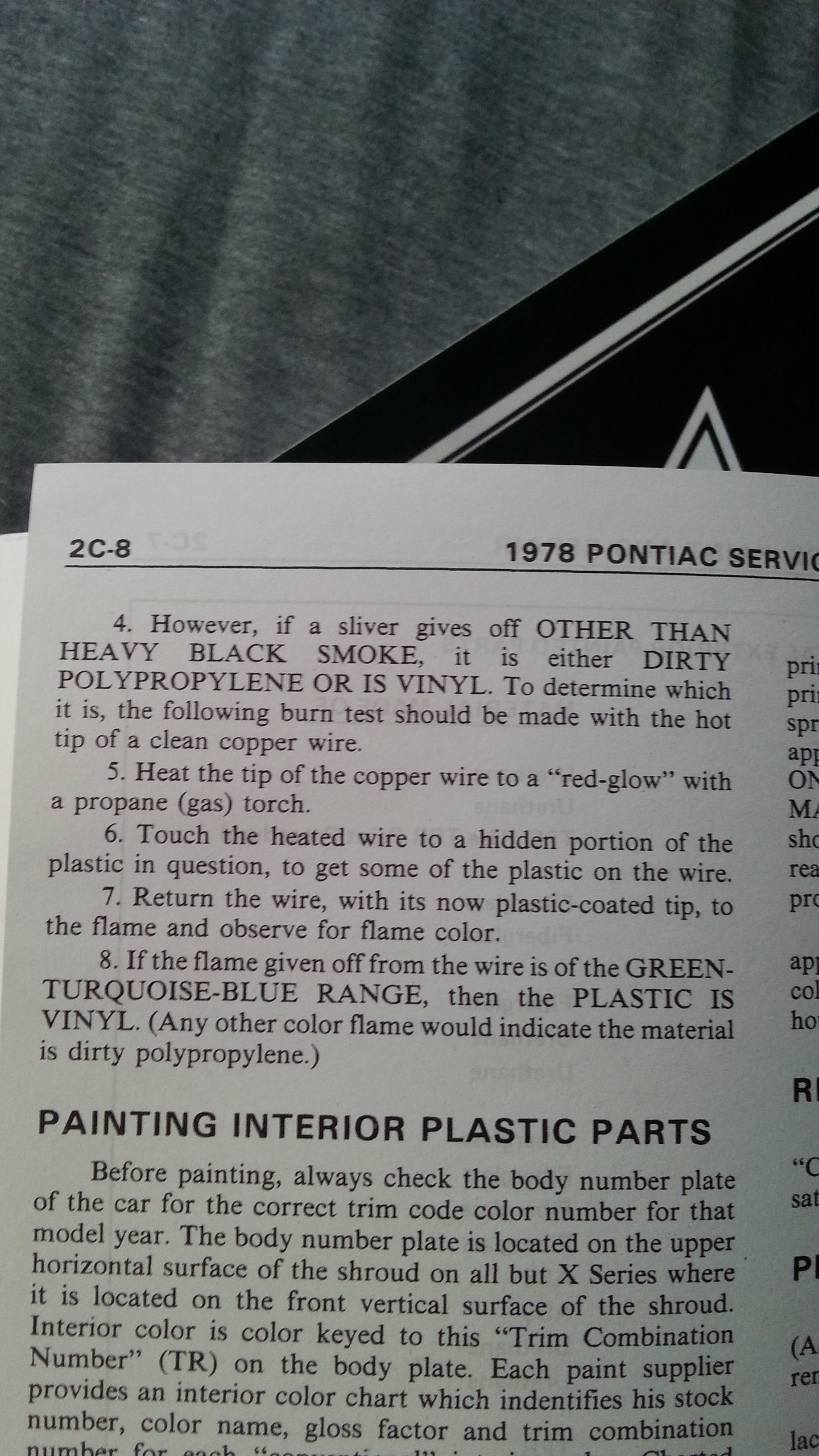

In order to determine the type of plastic, please set it on fire.

instead of gm, you know, labeling the parts in the mold. Since, you know, itís plastic.

That would make far too much sense.

random001

> My bird IS the word

random001

> My bird IS the word

03/12/2018 at 13:55 |

|

Thatís amazing.

e36Jeff now drives a ZHP

> random001

e36Jeff now drives a ZHP

> random001

03/12/2018 at 13:57 |

|

Amazing doesnít cover it.

My bird IS the word

> random001

My bird IS the word

> random001

03/12/2018 at 14:01 |

|

For Sweden

> My bird IS the word

For Sweden

> My bird IS the word

03/12/2018 at 14:04 |

|

Gem?

MasterMario - Keeper of the V8s

> My bird IS the word

MasterMario - Keeper of the V8s

> My bird IS the word

03/12/2018 at 14:06 |

|

What GM would end up doing is using the same mold for either type of plastic and have it labeled, ďMade of Polypropylene or VinylĒ

Also, this has all the makings of an ďInstructions unclear, car now on fireĒ story

My bird IS the word

> For Sweden

My bird IS the word

> For Sweden

03/12/2018 at 14:06 |

|

G(e)M

user314

> My bird IS the word

user314

> My bird IS the word

03/12/2018 at 14:11 |

|

Imagine if we had to do this for recycling.

My bird IS the word

> MasterMario - Keeper of the V8s

My bird IS the word

> MasterMario - Keeper of the V8s

03/12/2018 at 14:13 |

|

so bizarre. that canít cost less than making it from one type of material.

My bird IS the word

> user314

My bird IS the word

> user314

03/12/2018 at 14:13 |

|

it would sure make the kids more interested

Urambo Tauro

> My bird IS the word

Urambo Tauro

> My bird IS the word

03/12/2018 at 14:15 |

|

Yeah, they taught us this technique in plastic welding class. You donít always have access to a stamping, or a specific part number to look up more information on the material used on a product. So you cut off a piece of material (since youíre going to weld it back together anyway) and light it before selecting your repair rod. Here ís a pretty good flow chart of what to look for.

MasterMario - Keeper of the V8s

> My bird IS the word

MasterMario - Keeper of the V8s

> My bird IS the word

03/12/2018 at 14:15 |

|

Switched which type of plastic they use depending on whatís cheaper?

My bird IS the word

> Urambo Tauro

My bird IS the word

> Urambo Tauro

03/12/2018 at 14:19 |

|

I mean that part does make sense (if it is somewhat amusing) but GM can control mold stampings and these are large pieces.

My bird IS the word

> MasterMario - Keeper of the V8s

My bird IS the word

> MasterMario - Keeper of the V8s

03/12/2018 at 14:21 |

|

Thatís a good question. No idea about materials cost or the manufacturing differences.

Urambo Tauro

> My bird IS the word

Urambo Tauro

> My bird IS the word

03/12/2018 at 15:16 |

|

Yeah itís not that hard.

pip bip - choose Corrour

> My bird IS the word

pip bip - choose Corrour

> My bird IS the word

03/13/2018 at 07:05 |

|

GM at itís finest.