"Spanfeller is a twat" (theaspiringengineer)

"Spanfeller is a twat" (theaspiringengineer)

02/09/2018 at 00:00 ē Filed to: SHITPOSTING WITH TEH ASPIRING ENGINEER

0

0

20

20

"Spanfeller is a twat" (theaspiringengineer)

"Spanfeller is a twat" (theaspiringengineer)

02/09/2018 at 00:00 ē Filed to: SHITPOSTING WITH TEH ASPIRING ENGINEER |  0 0

|  20 20 |

Because some of you have much more experience with cars than I do... but I thought about something....

The only thing I calculated about this build is the displacement, the rest is just supposing that symmetry will do its job... I donít have the knowledge (or time since this isnít a real proyect) to carry out all the necesary calculations so that the engine actually runs at this time. So again, take it easy... its more of a thought experiment than a final design.

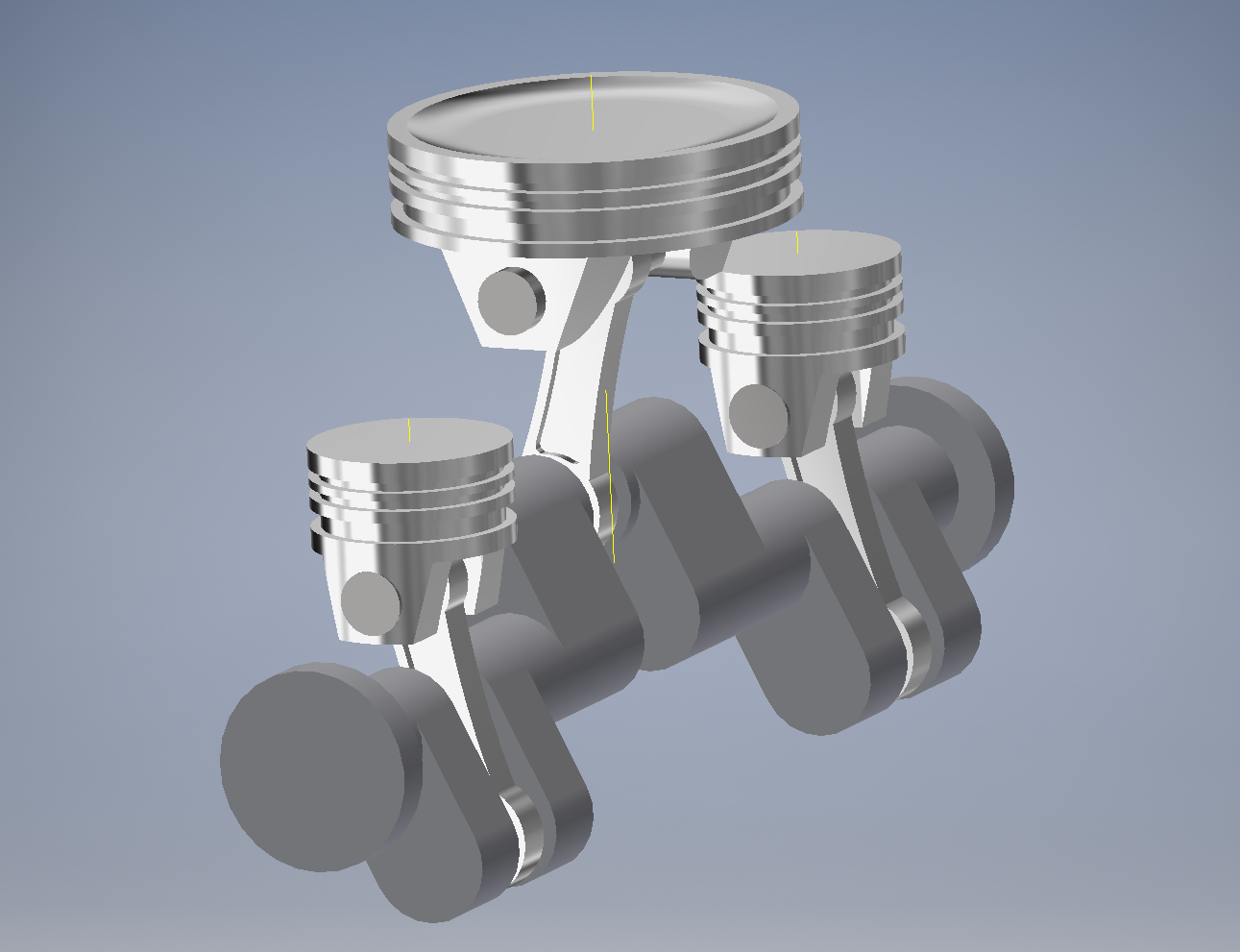

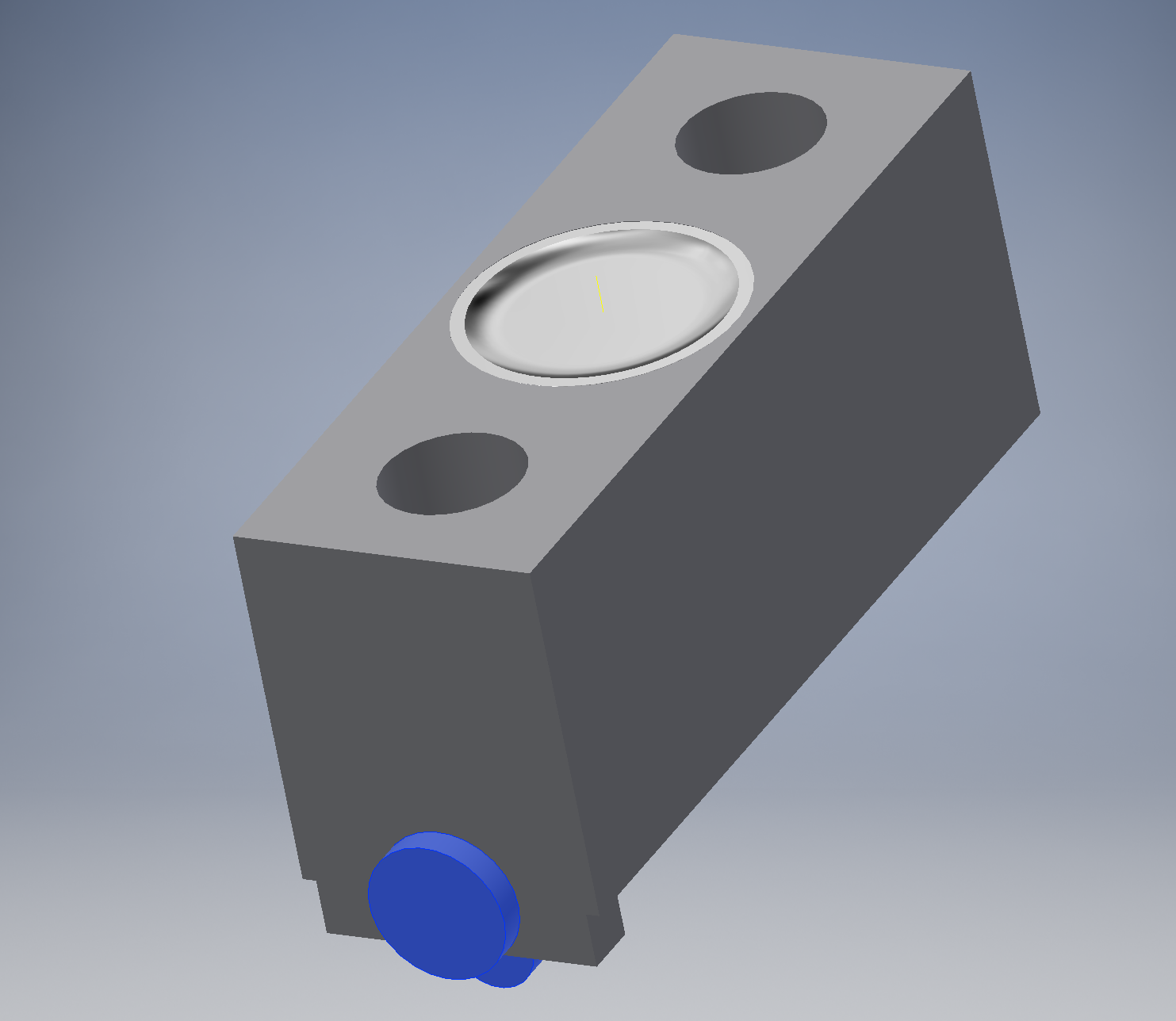

Why not have a 3 cylinder engine with a flat plane crank?

the advantage is that you remove the rocking motion as the firing order would be 1-3, 2; the center piston is made so that its displacement is exactly the same as the two smaller ones combined. I kept the stroke the same on both cylinders, I only reduced the bore of 1 and 3 to 70mm (the pictures donít show it correctly)... in the end it should displace about a litre, with a stroke of 64mm.

In terms of rotating mas, in order to balance the crank, you do need to add more weight, in order to balance the cylinders you also need to have the mass of all the components of cylinder 2 (connecting rod, pin, piston rings... etc) be equal to the mass of all the components of the first and last cylinder. two cylinders will be almost square, meaning that it will have a turbulent power curve. my thoughts are that it would work like a 2 cyl engine, and at that stage it would make sense to reduce complexity and just make it a two cylinder motor.

its a very wierd build, and it is at a basic stage right now, just a passing thought I had today.... I also want to design an engine with pistons alike the Honda NR.

WilliamsSW

> Spanfeller is a twat

WilliamsSW

> Spanfeller is a twat

02/09/2018 at 00:09 |

|

My engineering degree is extremely stale, but I canít see any benefit to designing an engine this way, instead of just making it a 2 cylinder - but I can see lots of downsides.

Spanfeller is a twat

> WilliamsSW

Spanfeller is a twat

> WilliamsSW

02/09/2018 at 00:25 |

|

It would a pain in the ass, the more I thought about it the less sense it made..

But I think that the primary and secondary forces would be balanced and thatís good, other than that, well... A lot of stuff I donít know (yet!) Probably influences how it would behave... Iím probably not the first person to think about it and given that all engines have the same cylinder sizes I can understand why itís done that way and not this way....

Berang

> Spanfeller is a twat

Berang

> Spanfeller is a twat

02/09/2018 at 01:02 |

|

You would be adding a bunch more moving parts (and thus expense) to do something a boxer twin could do (except minus the rocking couple).

Eric @ opposite-lock.com

> WilliamsSW

Eric @ opposite-lock.com

> WilliamsSW

02/09/2018 at 01:43 |

|

This was almost exactly my thought. Youíd get the same result with two while reducing weight, friction, and complexity.

Spanfeller is a twat

> Berang

Spanfeller is a twat

> Berang

02/09/2018 at 01:44 |

|

A lot more moving parts than a 2 cyl yes.. but it wouldnít need a balancing shaft like a 2 or 3 cyl.... I think?

Spanfeller is a twat

> Eric @ opposite-lock.com

Spanfeller is a twat

> Eric @ opposite-lock.com

02/09/2018 at 02:06 |

|

Whereís Collin Chapman when I need inspiration?

Distraxi's idea of perfection is a Jagroen

> Spanfeller is a twat

Distraxi's idea of perfection is a Jagroen

> Spanfeller is a twat

02/09/2018 at 03:42 |

|

Assuming youíre designing for 4 stroke, the basic problem here is that the firing interval is 720 degrees. Which means if you want even firing your cylinders should be 360 degrees apart not 180. Which means youíll need a crank counterweight for primary balance and your secondary is even more f*cked up than a regular I2. I doubt the improvement in tertiary (rocking) is a net win, even aside from the complexity.

Berang

> Spanfeller is a twat

Berang

> Spanfeller is a twat

02/09/2018 at 04:34 |

|

Well you donít really need a balance shaft in a boxer twin.

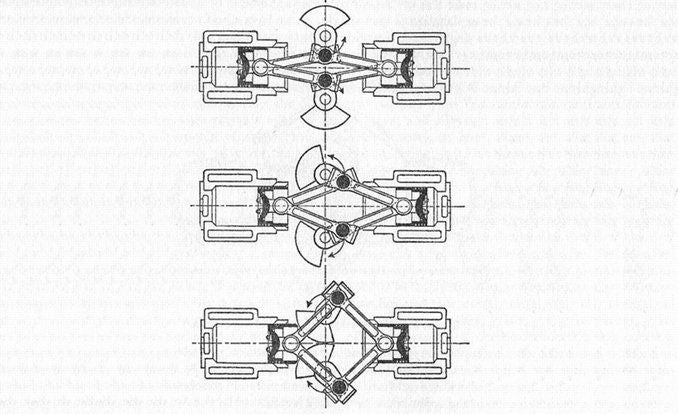

Although, hereís another idea:

Two piston, non-boxer. The pistons both move in the same direction, but have counter weights to achieve balance - each piston has three connecting rods (two outer rods go to the crank that the inner rod from the opposite piston connects to - eliminating the rocking couple).

These engines were used in early Lanchesters, which were also mid-engined, because apparently somebody at the factory was obsessed with balance.

bob and john

> Spanfeller is a twat

bob and john

> Spanfeller is a twat

02/09/2018 at 07:32 |

|

...why?

Putting undue stress on the crank for...what purpose? 3 cylinders are normally VERY smooth to begin with. And now you will have some EXTREMELY weird revving characteristics as well.

Spanfeller is a twat

> bob and john

Spanfeller is a twat

> bob and john

02/09/2018 at 08:09 |

|

I know this engine makes no sense...its more of a thought experiment.

Idk, Iím just playing around, I think that at least symetrically it doesnít put added stress (as the forces of pistons 1 and 3 are canceled by piston 2) in reality it would remove some stress because it would (symetrically) have forces of same magnitude in opposing directions, thus canceling out primary and secondary forces, removing the need for a balancing shaft.

It would rev wierdly because the center piston will want to go faster than the other due to the different stroke to bore ratio (which in the smaller pistons is almost 1:1)

triples tend to be smooth because of their size, itíd be weird to see a 3 cylinder engine larger than 1.5 liters, so theyíre easy to balance with a small shaft.... I think that as size increases so must cylinder count or else balancing the engine is a bigger nightmare (I think)

Spanfeller is a twat

> Distraxi's idea of perfection is a Jagroen

Spanfeller is a twat

> Distraxi's idea of perfection is a Jagroen

02/09/2018 at 08:11 |

|

I was thinking about it too! it would work as a 2 stroke but as a 4 stroke its a lost battle!

Demon-Xanth knows how to operate a street.

> Spanfeller is a twat

Demon-Xanth knows how to operate a street.

> Spanfeller is a twat

02/09/2018 at 08:51 |

|

For some reason I want to make a gas powered air compressor using a Corvairís engine with one side being engine and the other being compressor. Iíve seen one completely turned into an air compressor, and Grimmer Schmidt used a Ford 302 as an I-4+4 cylinder compressor.

†

punkgoose17

> Berang

punkgoose17

> Berang

02/09/2018 at 10:01 |

|

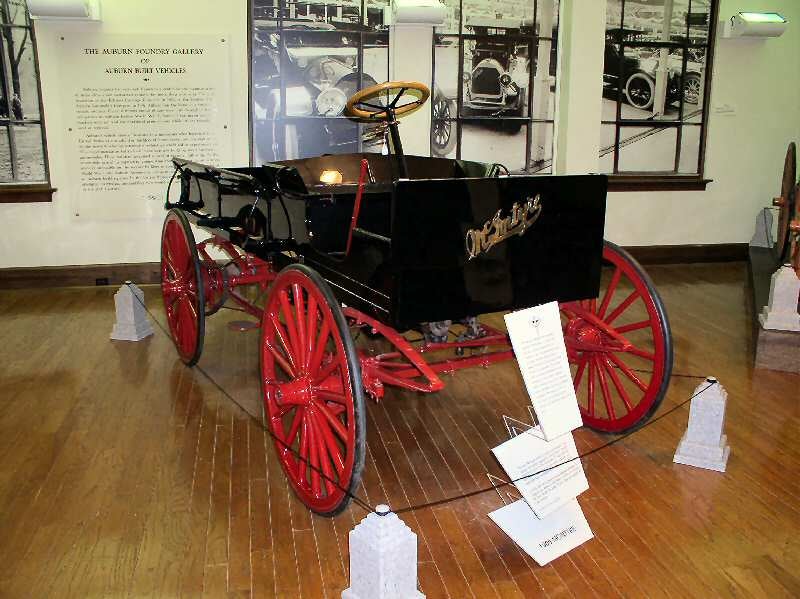

Very cool. McIntyre from Auburn Indiana made mid-engined passenger cars and trucks using a horizontally mounted boxer twins.

1909 McIntyre model 251 truck, 90 ci, 20 hp, $800

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> Spanfeller is a twat

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> Spanfeller is a twat

02/09/2018 at 10:04 |

|

As the owner of several tractors, I have two 3-cylinder diesels, the 1.5 litre engine has a moderately sized dedicated ballance-shaft and is as smooth as a diesel ever gets, like v12 smooth. The 2.8 litre engine uses itís accessory drives as counter balances and is only marginally less-smooth.

Bman76 (hates WS6 hoods, is on his phone and has 4 burners now)

> Spanfeller is a twat

Bman76 (hates WS6 hoods, is on his phone and has 4 burners now)

> Spanfeller is a twat

02/09/2018 at 11:54 |

|

Youíve basically built a 2 cylinder but with unnecessary friction losses...

Spanfeller is a twat

> Bman76 (hates WS6 hoods, is on his phone and has 4 burners now)

Spanfeller is a twat

> Bman76 (hates WS6 hoods, is on his phone and has 4 burners now)

02/09/2018 at 11:56 |

|

Yup. Starting to realize that two 0.5l pistons would do better in that respect.

And weight.

And maintenance.

And manufacturability.

Berang

> punkgoose17

Berang

> punkgoose17

02/09/2018 at 20:41 |

|

Lots of early American cars were mid engined. Fords, Buicks, and Cadillacs were all the same way. Less common layout in Europe though.

Stephenson Valve Gear

> Spanfeller is a twat

Stephenson Valve Gear

> Spanfeller is a twat

02/10/2018 at 22:42 |

|

When I first saw that, I suspected that you were making a compound engine. The exhaust gasses from each of the two small cylinders is expanded further in the center cylinder. The 2x volume, crankpin positions, and placement of the big cylinder in between the two smaller cylinders are perfect for a compound application. It was done way-back-when in the early days of the automobile, and there have been experiments in recent times, but nothing in production in the modern era. Compounding is very common in marine steam applications, and not unheard of in railroad steam locomotives, but relatively uncommon in internal combustion engines.

But, it is instead an unusual 3-cylinder engine. Not disappointed, and I give you extra credit for thinking outside the box. Although, isnít there a story of a race team running a V8 with on small cylinder? The story is that the tech team always measured the same cylinder to make sure the engine displacement didnít exceed what was allowed in the rules, so they came up with the idea of making the other 7 larger for more power. Or maybe I dreamed that...

Spanfeller is a twat

> Stephenson Valve Gear

Spanfeller is a twat

> Stephenson Valve Gear

02/11/2018 at 00:54 |

|

Thanks! Wouldíve never thought about a compound engine (though I think that using exhaust gases from other cylinders canít be good for emissions).

CAD lets me do so many wacky things in such little time, just this afternoon I designed an engine with 8 valves per cylinder, with cylinders alike the ones in the Honda NR.

It would require a triple overhead camshaft or a Freevalve system to work, but... it still makes the engine run more efficient, rev higher, and be able to compress much more. Also sealing an NR piston is mostly impossible...

About the cylinder.... I wouldnít know.. but it would certainly be an interesting story!

Recovering Gaijin

> Demon-Xanth knows how to operate a street.

Recovering Gaijin

> Demon-Xanth knows how to operate a street.

02/16/2018 at 17:57 |

|

The guy on whose farm I store my partscars has an old ( WWII I believe ) 6-cylinder radial airplane engine which was modified so 3 cylinders run it and the other 3 compress air. His dad started a machine shop after the war and that was their air source. Last ran in the late Ď70s he said. Pretty cool, I thought.

Every other cylinder, btw: not 1/2 & 1/2