"Santiago of Escuderia Boricua" (sdiglesias)

"Santiago of Escuderia Boricua" (sdiglesias)

03/07/2016 at 21:28 ē Filed to: None

0

0

49

49

"Santiago of Escuderia Boricua" (sdiglesias)

"Santiago of Escuderia Boricua" (sdiglesias)

03/07/2016 at 21:28 ē Filed to: None |  0 0

|  49 49 |

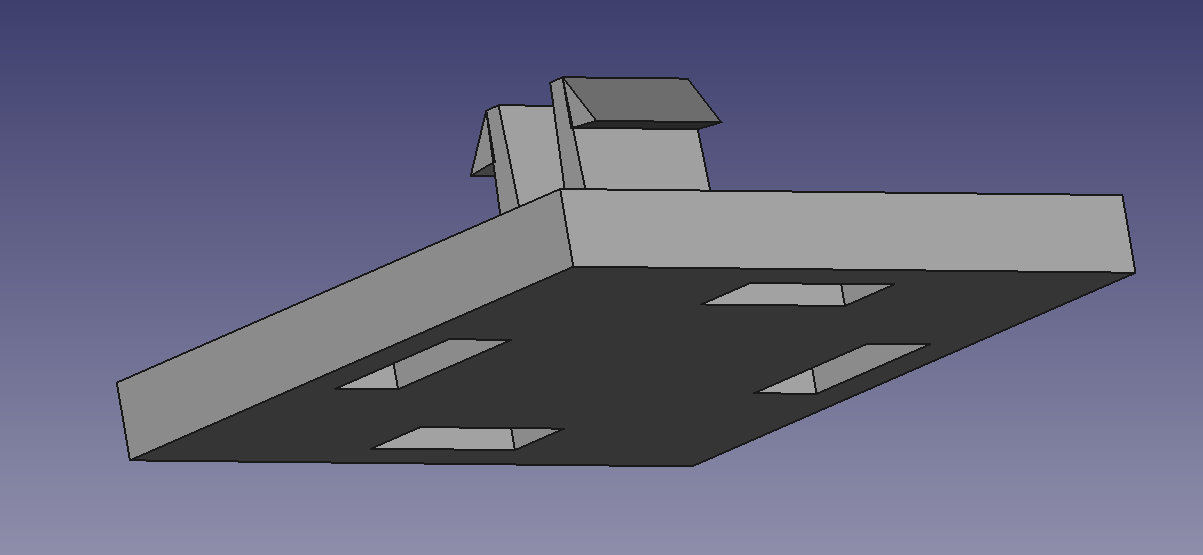

One hint: This will be 3D printed

Daily Drives a Dragon - One Last Lap

> Santiago of Escuderia Boricua

Daily Drives a Dragon - One Last Lap

> Santiago of Escuderia Boricua

03/07/2016 at 21:33 |

|

It has tabs to lock into something, but I donít know.

Blondude

> Santiago of Escuderia Boricua

Blondude

> Santiago of Escuderia Boricua

03/07/2016 at 21:34 |

|

A clippy thingy

ttyymmnn

> Santiago of Escuderia Boricua

ttyymmnn

> Santiago of Escuderia Boricua

03/07/2016 at 21:34 |

|

Something that clips into something so something can be clipped into it.

yamahog

> Santiago of Escuderia Boricua

yamahog

> Santiago of Escuderia Boricua

03/07/2016 at 21:34 |

|

a convenient wall mount for your favorite rubber fist

TheHondaBro

> Santiago of Escuderia Boricua

TheHondaBro

> Santiago of Escuderia Boricua

03/07/2016 at 21:36 |

|

A warp nacelle.

Flynorcal: pilot, offshore sailor, car racer and panty thief

> Santiago of Escuderia Boricua

Flynorcal: pilot, offshore sailor, car racer and panty thief

> Santiago of Escuderia Boricua

03/07/2016 at 21:37 |

|

Iíll take ďrobot chastity beltĒ for $200, Alex.

Levitas

> Santiago of Escuderia Boricua

Levitas

> Santiago of Escuderia Boricua

03/07/2016 at 21:44 |

|

Mmmmmmm CATIA.

And this part looks really familiar, just not sure what from

Dingers Ghost, Champion Jockey

> Santiago of Escuderia Boricua

Dingers Ghost, Champion Jockey

> Santiago of Escuderia Boricua

03/07/2016 at 21:54 |

|

Looks like a clip for something? Iím thinking either a trim piece or electrical connector?

Santiago of Escuderia Boricua

> Levitas

Santiago of Escuderia Boricua

> Levitas

03/07/2016 at 21:57 |

|

Iím using a program called FreeCAD, to try and be legit

‹bel

> Santiago of Escuderia Boricua

‹bel

> Santiago of Escuderia Boricua

03/07/2016 at 22:10 |

|

I know a buttplug when I see one

Shmevans

> Santiago of Escuderia Boricua

Shmevans

> Santiago of Escuderia Boricua

03/07/2016 at 22:14 |

|

Cell phone mount? Clips attach to heater vent slats? Grabby arms (that will poke through the holes) yet to be installed.

Santiago of Escuderia Boricua

> Santiago of Escuderia Boricua

Santiago of Escuderia Boricua

> Santiago of Escuderia Boricua

03/07/2016 at 22:31 |

|

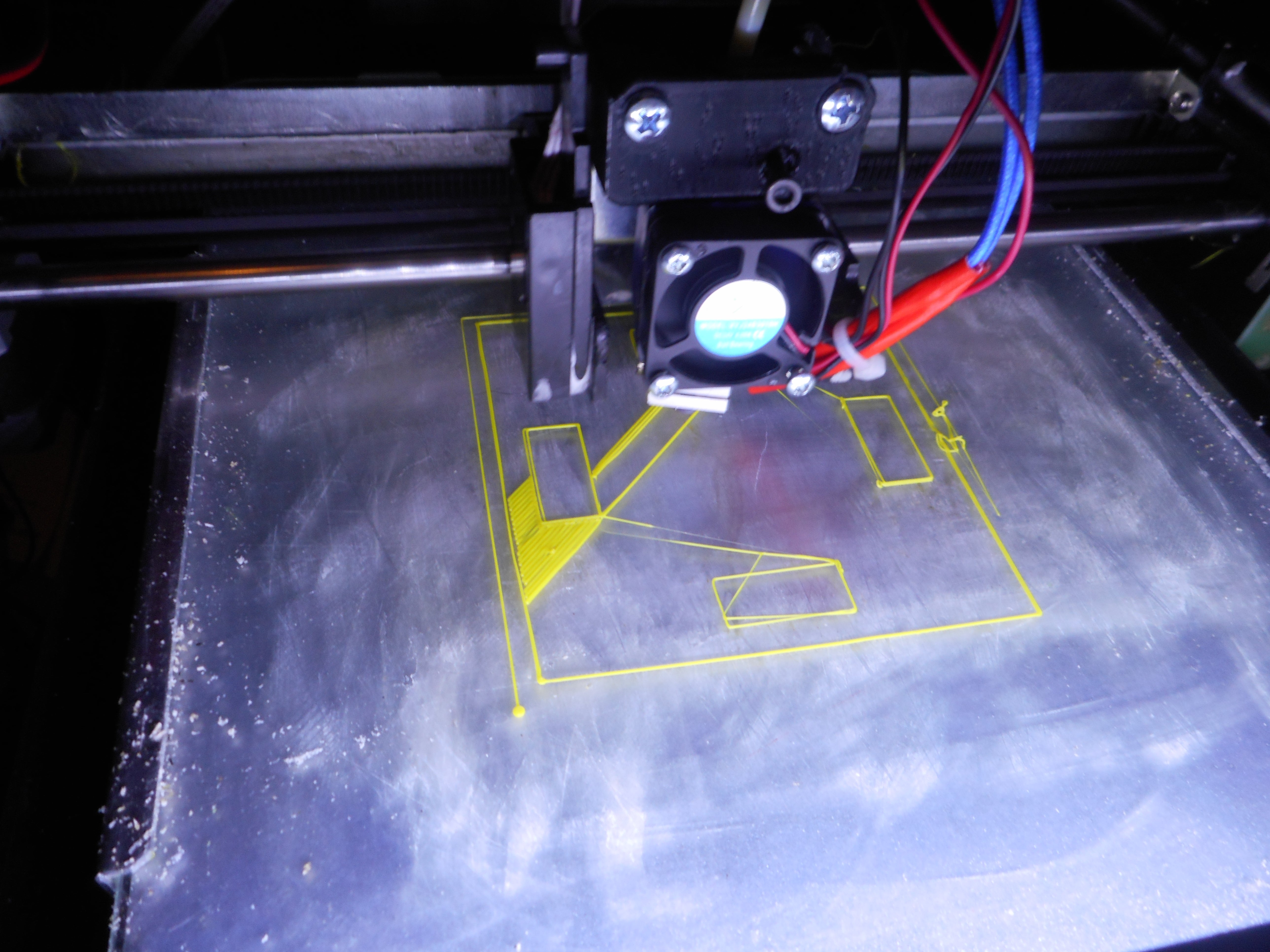

Printing

Santiago of Escuderia Boricua

> Daily Drives a Dragon - One Last Lap

Santiago of Escuderia Boricua

> Daily Drives a Dragon - One Last Lap

03/07/2016 at 22:33 |

|

It is for one of my cars....

Santiago of Escuderia Boricua

> Shmevans

Santiago of Escuderia Boricua

> Shmevans

03/07/2016 at 22:34 |

|

This is the first time Iím printing snap fits (the technical term for grabby arms).

But no, not for a phone or HVAC

You can tell a Finn but you can't tell him much

> ‹bel

You can tell a Finn but you can't tell him much

> ‹bel

03/07/2016 at 22:34 |

|

You've got a funny shaped butt man.

Daily Drives a Dragon - One Last Lap

> Santiago of Escuderia Boricua

Daily Drives a Dragon - One Last Lap

> Santiago of Escuderia Boricua

03/07/2016 at 22:34 |

|

I figured that much.

You can tell a Finn but you can't tell him much

> Santiago of Escuderia Boricua

You can tell a Finn but you can't tell him much

> Santiago of Escuderia Boricua

03/07/2016 at 22:35 |

|

Camera mount that will snap onto your cage?

Santiago of Escuderia Boricua

> Daily Drives a Dragon - One Last Lap

Santiago of Escuderia Boricua

> Daily Drives a Dragon - One Last Lap

03/07/2016 at 22:36 |

|

Between my cars and the shape, the purpose of this part should be discernable

Levitas

> Santiago of Escuderia Boricua

Levitas

> Santiago of Escuderia Boricua

03/07/2016 at 22:39 |

|

Oh interesting. Looks just like CATIA.

‹bel

> You can tell a Finn but you can't tell him much

‹bel

> You can tell a Finn but you can't tell him much

03/07/2016 at 22:43 |

|

I canít help that I have wide-set cheeks and a square butthole.

tromoly

> Santiago of Escuderia Boricua

tromoly

> Santiago of Escuderia Boricua

03/07/2016 at 22:44 |

|

You probably should calibrate your printer, the strings running around are not good for your prints.

Daily Drives a Dragon - One Last Lap

> Santiago of Escuderia Boricua

Daily Drives a Dragon - One Last Lap

> Santiago of Escuderia Boricua

03/07/2016 at 22:49 |

|

Itís for a rally car but I have no clue where youíd put it.

Santiago of Escuderia Boricua

> tromoly

Santiago of Escuderia Boricua

> tromoly

03/07/2016 at 22:54 |

|

I know. This is my first print since I switched my hotend to an e3dv6. Plus, in this application, Iím not concerned about first layer...

Santiago of Escuderia Boricua

> You can tell a Finn but you can't tell him much

Santiago of Escuderia Boricua

> You can tell a Finn but you can't tell him much

03/07/2016 at 22:54 |

|

Ah, but the snap fits would face the other way in that case, wouldnít they?

Santiago of Escuderia Boricua

> Daily Drives a Dragon - One Last Lap

Santiago of Escuderia Boricua

> Daily Drives a Dragon - One Last Lap

03/07/2016 at 22:55 |

|

It would take some above-average knowledge of the e36 platform to figure out

Santiago of Escuderia Boricua

> tromoly

Santiago of Escuderia Boricua

> tromoly

03/07/2016 at 22:55 |

|

A 0.1 or 0.2mm z offset correction should fix it, right?

Santiago of Escuderia Boricua

> Levitas

Santiago of Escuderia Boricua

> Levitas

03/07/2016 at 22:56 |

|

It is much clunkier than CATIA. Which is saying a lot.

I learned on Catia v5 in college and use Solidworks professionally. This software is usable, but not nearly as user friendly as even Catia.

Daily Drives a Dragon - One Last Lap

> Santiago of Escuderia Boricua

Daily Drives a Dragon - One Last Lap

> Santiago of Escuderia Boricua

03/07/2016 at 23:01 |

|

I have basically no knowledge of the e36 platform. Iíve never driven one, been in one, or worked on one. They look fun though. And theyíre cheaper than the E46 and E30.

Santiago of Escuderia Boricua

> Daily Drives a Dragon - One Last Lap

Santiago of Escuderia Boricua

> Daily Drives a Dragon - One Last Lap

03/07/2016 at 23:11 |

|

True, at least for now. They may be bottoming out right now

Shmevans

> Santiago of Escuderia Boricua

Shmevans

> Santiago of Escuderia Boricua

03/07/2016 at 23:33 |

|

Ha, no. The ďgrabby armsĒ would have come through the holes but are not yet pictured. Or at least thatís what I was imagining.

scoob

> ttyymmnn

scoob

> ttyymmnn

03/07/2016 at 23:46 |

|

No, something that gets something else clipped onto it, which also gets clipped onto something else.

tromoly

> Santiago of Escuderia Boricua

tromoly

> Santiago of Escuderia Boricua

03/07/2016 at 23:52 |

|

No, the stringing is nozzle-related whether it be too much pressure applied by the feed motor or incorrect nozzle temperature. A z-height change wonít fix that.

roflcopter

> Santiago of Escuderia Boricua

roflcopter

> Santiago of Escuderia Boricua

03/08/2016 at 00:03 |

|

Are you using Catia? That looks an awful lot like Catia.

BaconSandwich is tasty.

> Santiago of Escuderia Boricua

BaconSandwich is tasty.

> Santiago of Escuderia Boricua

03/08/2016 at 00:31 |

|

Iíve been meaning to try out FreeCAD. How is it? Usable?

Santiago of Escuderia Boricua

> tromoly

Santiago of Escuderia Boricua

> tromoly

03/08/2016 at 06:48 |

|

Hmm... This is my first print with this hot end. Lower temp then?

Santiago of Escuderia Boricua

> roflcopter

Santiago of Escuderia Boricua

> roflcopter

03/08/2016 at 06:50 |

|

FreeCAD

Santiago of Escuderia Boricua

> BaconSandwich is tasty.

Santiago of Escuderia Boricua

> BaconSandwich is tasty.

03/08/2016 at 06:51 |

|

Good enough. I wouldnít use it to make anything too complex, but I wouldnít be printing that anyway

gmporschenut also a fan of hondas

> Santiago of Escuderia Boricua

gmporschenut also a fan of hondas

> Santiago of Escuderia Boricua

03/08/2016 at 07:20 |

|

spare relay holder

You can tell a Finn but you can't tell him much

> Santiago of Escuderia Boricua

You can tell a Finn but you can't tell him much

> Santiago of Escuderia Boricua

03/08/2016 at 09:11 |

|

True, the snaps would face in unless you had a socket welded on to the cage ahead of time.

Based on your reply Iím going to say camera mount that will snap into the front bumper. Maybe where the cover for a tow point goes or where the trim would have snapped into.

uofime-2

> Santiago of Escuderia Boricua

uofime-2

> Santiago of Escuderia Boricua

03/08/2016 at 10:24 |

|

snap fits with fused filament... godspeed sir!

Santiago of Escuderia Boricua

> uofime-2

Santiago of Escuderia Boricua

> uofime-2

03/08/2016 at 10:36 |

|

Should be fine...?

I did read one thing that the max elongation in Z was reduced about 50% and the tensile strength is reduced by 20-30%. Good thing I can always make more prototypes

uofime-2

> Santiago of Escuderia Boricua

uofime-2

> Santiago of Escuderia Boricua

03/08/2016 at 10:47 |

|

Tensile strength in z is terrible, the kind of bending those tabs will have to do is the worst case scenario. youíll be OK as long as the deflection is small.

Point taken, youíve probably got 3 hours and 1$ on the part, things can be changed, more can be made.

Iím interested to see how it works.

Santiago of Escuderia Boricua

> uofime-2

Santiago of Escuderia Boricua

> uofime-2

03/08/2016 at 10:51 |

|

Once assembled, the tensile will be almost nothing. I can mess with the position and angles of the snap fits to keep them from breaking

uofime-2

> Santiago of Escuderia Boricua

uofime-2

> Santiago of Escuderia Boricua

03/08/2016 at 10:54 |

|

if you make a rev 2, You could build it like a molded part so the support material for the overhangs is on the platform instead of the part, might make it easier to remove.

Santiago of Escuderia Boricua

> uofime-2

Santiago of Escuderia Boricua

> uofime-2

03/08/2016 at 11:02 |

|

What do you mean by the platform instead of the part?

uofime-2

> Santiago of Escuderia Boricua

uofime-2

> Santiago of Escuderia Boricua

03/08/2016 at 11:10 |

|

Through the base of the part. Basically have a hole cut through the base of the part defined by the projection of the overhanging snaps.

Santiago of Escuderia Boricua

> uofime-2

Santiago of Escuderia Boricua

> uofime-2

03/08/2016 at 11:11 |

|

Ah, gotcha. From the snapfit design guides I found, isnít that weaker? Iím not too worried about cleaning up the support material

uofime-2

> Santiago of Escuderia Boricua

uofime-2

> Santiago of Escuderia Boricua

03/08/2016 at 11:15 |

|

Yea it would be weaker, you can have a fillet on the other side.

It is what we try to do in molding because it makes the feature easily moldable with just a simple open-shut mold.

STATICFRICTION

> Santiago of Escuderia Boricua

STATICFRICTION

> Santiago of Escuderia Boricua

04/11/2016 at 09:51 |

|

FreeCAD; Thanks for posting the name of the software, I am very interested.