"f86sabre" (f86sabre)

"f86sabre" (f86sabre)

07/31/2015 at 13:25 • Filed to: planelopnik

14

14

13

13

"f86sabre" (f86sabre)

"f86sabre" (f86sabre)

07/31/2015 at 13:25 • Filed to: planelopnik |  14 14

|  13 13 |

As opposed to positing in the noise !!!error: Indecipherable SUB-paragraph formatting!!! , I wanted to provide some clarification to the article written over on Gawker. They say they have identified the flaperon because it bares part number 657BB. 657BB is not a part number. It is a panel number used to identify removable panels that are used to access underlying systems and structures. That said, it is a valid panel number for a 777 flaperon leading edge. Boeing part numbers for the 777 typically look something like this: 111W2222-3. Where the first three digits identify the zone of the aircraft, the W is the fleet type designation (W=777, N=757, T=767, A=737NG), the second four digits are the assembly number and the number after the dash is called, amazingly enough, the dash number that specifies specific parts. This whole sequence makes up what is traditionally referred to as “the part number”. The flaperon should have a data plate on the end rib with a part number and serial number. That data should more closely be able to tie the part to an airframe. If that is missing then the assembly can be taken apart and you can look at more detailed part stampings on the inside, and on many of the piece parts, to drive you to a high probability call on build date and what tail the part was delivered on.

In the picture above, that bit just outboard of the inboard faring is the flaperon. The funny name comes from the fact that it acts as both a flap during times when high lift is needed as well as the inboard, high speed aileron.

For Sweden

> f86sabre

For Sweden

> f86sabre

07/31/2015 at 13:28 |

|

Welcome to my life yesterday. Literally no journalist understands part number vs. panel number vs. serial number.

f86sabre

> For Sweden

f86sabre

> For Sweden

07/31/2015 at 13:33 |

|

Some of us peeps do, but we are vary rare. I would imagine the authorities asked those on the ground in Reunion to look for externally visible markings and to not touch anything else. Makes sense.

On an unrelated topic, I had a good conversation with our SMS guru about the Virgin Galactic NTSB findings. The tone of the published notes were interesting, especially since SMS is intended to drive you to the “what could happens if someone did something crazy”. WE also talked about automation vs human controlled items and how that impacts your failsafe designs.

Moves-Like-Senna

> f86sabre

Moves-Like-Senna

> f86sabre

07/31/2015 at 13:36 |

|

Thanks for the clarification and the picture! An ANA 777 used between Tokyo and LA/SF/Washington etc!

The Powershift in Steve's '12 Ford Focus killed it's TCM (under warranty!)

> f86sabre

The Powershift in Steve's '12 Ford Focus killed it's TCM (under warranty!)

> f86sabre

07/31/2015 at 13:36 |

|

Excellent overview. I know enough about aviation part numbering schemes to know that wasn’t the part number, but I didn’t know enough to know what it actually meant...and now I do.

For Sweden

> f86sabre

For Sweden

> f86sabre

07/31/2015 at 13:38 |

|

Virgin is an interesting case, as no other civilian aircraft operation has the same kind of Buck Rodgers “I’ve got the Right Stuff!” feel about it.

For Sweden

> f86sabre

For Sweden

> f86sabre

07/31/2015 at 13:42 |

|

Also, OF COURSE Scaled Composites used PowerPoint to communicate the risk of unlocking the feathering mechanism too early.

PowerPoint: Crashing spacecraft since 2003!

Jayhawk Jake

> The Powershift in Steve's '12 Ford Focus killed it's TCM (under warranty!)

Jayhawk Jake

> The Powershift in Steve's '12 Ford Focus killed it's TCM (under warranty!)

07/31/2015 at 13:44 |

|

The number format will be different for different manufacturers as well. Our parts at Cessna don't follow that numbering convention.

f86sabre

> Jayhawk Jake

f86sabre

> Jayhawk Jake

07/31/2015 at 13:47 |

|

Yep, everyone does it different.

Racescort666

> f86sabre

Racescort666

> f86sabre

07/31/2015 at 14:02 |

|

Maybe you can answer this, maybe not, does the entire aircraft industry follow a dash number/semi-smart part number system? I seem to remember that being common when I worked in aircraft but I didn’t deal with many other manufacturers than the one I worked for.

Now that I’m in automotive, dash numbers and, to some degree, smart part numbers are somewhat of a novelty.

ttyymmnn

> For Sweden

ttyymmnn

> For Sweden

07/31/2015 at 14:08 |

|

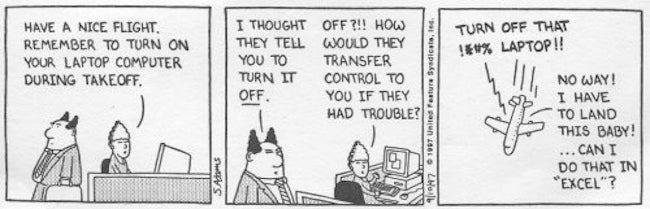

You sure it isn’t Excel?

The Powershift in Steve's '12 Ford Focus killed it's TCM (under warranty!)

> Jayhawk Jake

The Powershift in Steve's '12 Ford Focus killed it's TCM (under warranty!)

> Jayhawk Jake

07/31/2015 at 14:19 |

|

The avionics company I worked for had a 1x-11111-1 format. The first number and letter indicated assembly level/part type. The next five digits were a unique part number. The dash number indicated a the part variation, with odd numbers being the typical variations and the even numbers being alternate versions of the odds. Usually the evens were cockpit- or airframe-side-specific (for example, -1 being pilots side and -2 being FO’s versions of mechanically identical LRUs loaded with different software, or -1 and -2 instrument panels that were mirrors of each other).

ttyymmnn

> f86sabre

ttyymmnn

> f86sabre

07/31/2015 at 14:20 |

|

Excellent clarification. Thanks.

f86sabre

> Racescort666

f86sabre

> Racescort666

07/31/2015 at 15:47 |

|

Each vendor has its own methods. The base number/dash number way of doing things seems to exist among Boeing (including legacy Douglas products) and Airbus. Many subtier vendors do that as well. There are some vendors who use other PN standards, such as letters instead of dashes and other things. Each part needs a unique identifier, but the FAA allows people to set their own standard. There is clear guidance on who parts need to be marked as far as legibility though.