"Just wear your damn mask..." (jimal)

"Just wear your damn mask..." (jimal)

07/17/2015 at 18:50 ē Filed to: None

2

2

3

3

"Just wear your damn mask..." (jimal)

"Just wear your damn mask..." (jimal)

07/17/2015 at 18:50 ē Filed to: None |  2 2

|  3 3 |

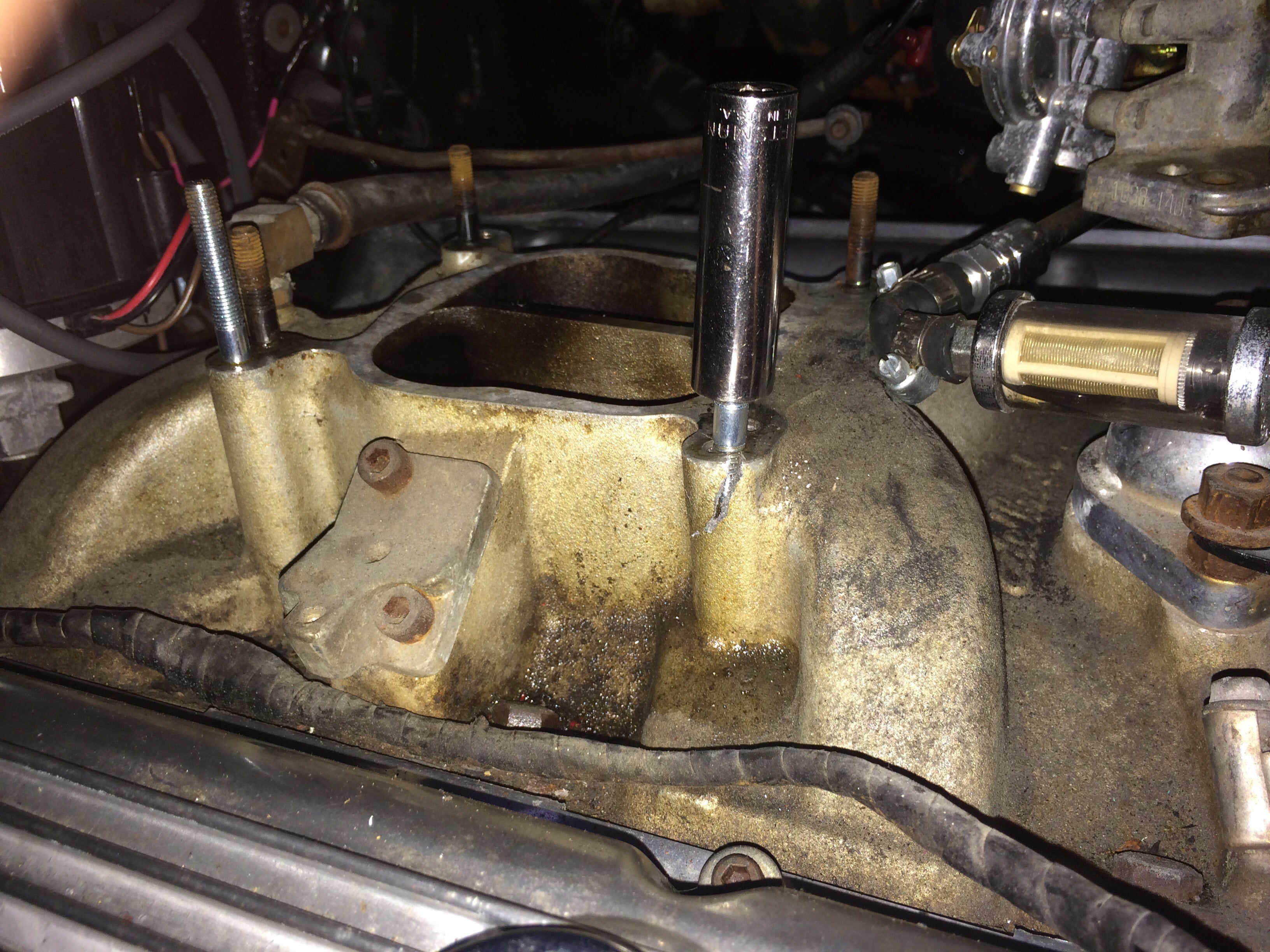

When we last left Captain Pedantic, he was beating himself up and ordering a new intake manifold after cracking his existing intake while installing studs. Despite chasing the previously unused threads with a tap, the stud didnít go in smooth and the aluminum gave.

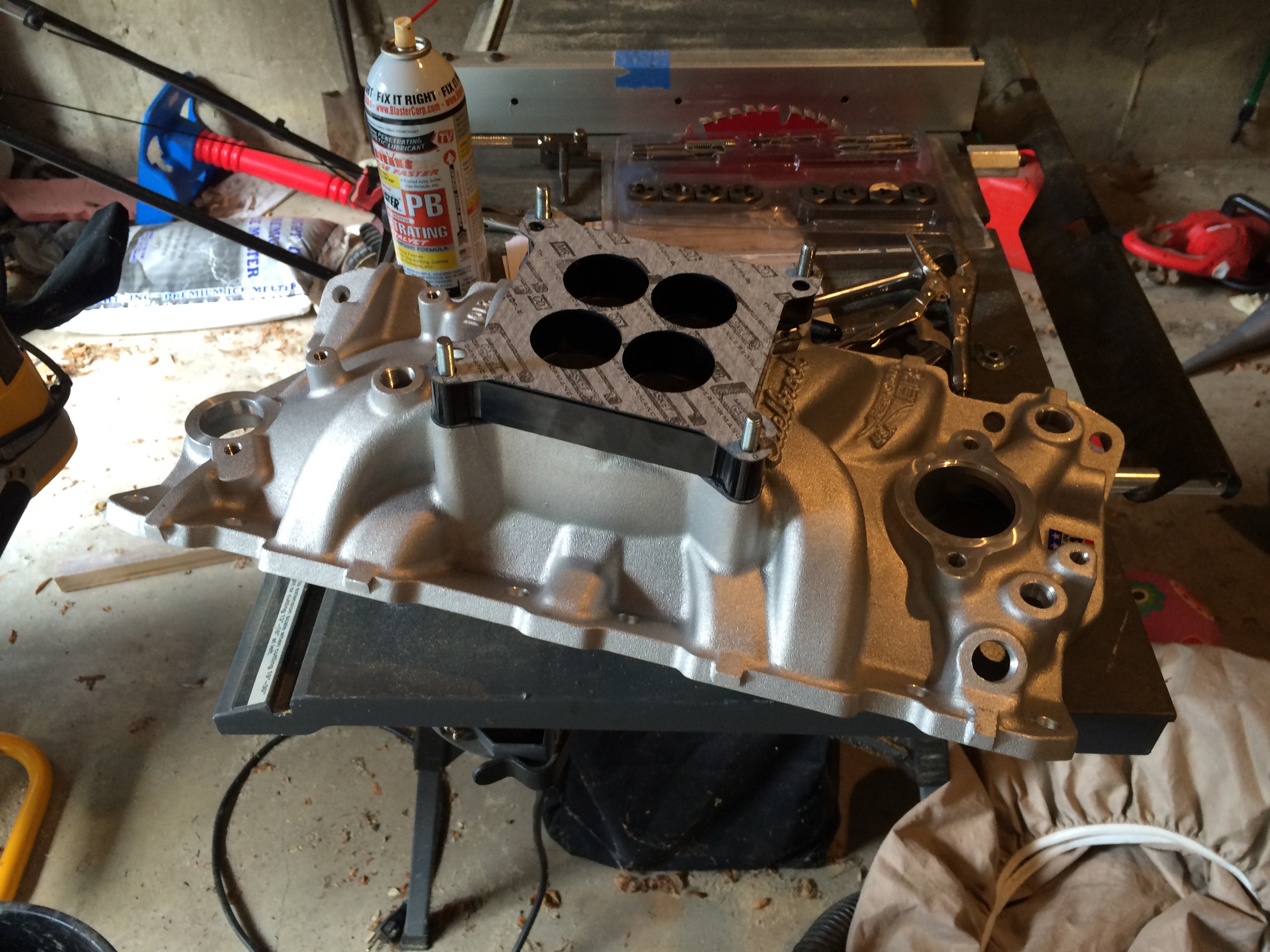

And here is my new manifold, with the studs and spacer installed. End of the story, right?

Wrong.

Turns out that the problem wasnít the threads I chased in the intake, but the threads on the shitty Made in Taiwan studs that came with the Mr. Gasket phenolic spacer I bought. I discovered this while trying to thread the new studs into the new intake, having them not go in clean, chasing the threads in the intake, and still not having them go in clean.

The solution? Chase the threads on the studs with a die

That problem solved, if the weather cooperates (and my new intake bolts arrive tomorrow) I will tackle the intake, and the heater hoses, and the serpentine belt system, all on Sunday.

tromoly

> Just wear your damn mask...

tromoly

> Just wear your damn mask...

07/17/2015 at 19:31 |

|

Lesson learned: Chase both sets of threads before re-assembly.

Donít ask about the time I forgot to do that and completely boogered the bolt hole in the alternator on my old Rambler and didnít realize until the temp gauge spiked and the lights started to flicker that something was wrong with the bolt holding the alternator tight which meant that the belt which runs for both the water pump and alternator was super loose.

Sometimes you only learn the hard way.

Just wear your damn mask...

> tromoly

Just wear your damn mask...

> tromoly

07/17/2015 at 19:53 |

|

I've never had something as basic as threads on new parts be bad like this. Lesson learned indeed.

boxrocket

> Just wear your damn mask...

boxrocket

> Just wear your damn mask...

07/17/2015 at 22:12 |

|

A few years ago, I replaced the front axles on a friendís Trailblazer (which are massive PsOS, BTW), and the splines from the ďOEM quality, guaranteed!í big-name axle company didnít match with the internal differential.

He sent them back and they sent him a replacement set, no problem, even paid for the shipping. Unfortunately, the second set also didnít fit, and one was very slightly bent. He exchanged those as well, and included a rubbing of the VIN, diff info, original axle info. The third set had the seemingly correct ends, but the axles were too short. At this point they offered him a full refund in addition to all the shipping charges refunded, which he accepted, and sent them back pictures of the inside of the diff, pictures of the axle next to a tape measure, and pictures of the hub where the axles connected.

Fourth set was finally the correct ones. It only took seven weeks. Installation went without a hitch.

They worked great for the week and a half the truck had left, before it got smeared (while parked and empty) by a dump truck.

You have my sympathy. Cheap parts suck.