"Chairman Kaga" (mike-mckinnon)

"Chairman Kaga" (mike-mckinnon)

02/16/2015 at 11:27 • Filed to: None

0

0

11

11

"Chairman Kaga" (mike-mckinnon)

"Chairman Kaga" (mike-mckinnon)

02/16/2015 at 11:27 • Filed to: None |  0 0

|  11 11 |

I'm pretty sure I dropped a valve seat. That's best case scenario. I also have a theory the previous owner's decision to use RTV to affix the valve covers to the heads is a contributing factor. I've ready many stories about RTV degrading under heat and oil, then the little bits that seeped out from under the cover get lodged into oil journals and passages, preventing flow. Reduced lubrication up top, cooked valvetrain. This problem is compounded by the fact I've never been able to remove the valve covers to so much as adjust the valves as the RTV has become epoxylike, with not even a razor blade's width of tolerance between the cover and head. All aluminum so force is limited. I'm now in the process of destroying them to remove them, regardless. Then explore rebuild vs replace. I know a guy with a MIlano Verde 3.0 for sale. Might be the cheaper and simpler option.

HammerheadFistpunch

> Chairman Kaga

HammerheadFistpunch

> Chairman Kaga

02/16/2015 at 11:34 |

|

That sucks man... then bangs...then blows, but not as good as it should. Sorry.

RamblinRover Luxury-Yacht

> Chairman Kaga

RamblinRover Luxury-Yacht

> Chairman Kaga

02/16/2015 at 11:43 |

|

I've seen valve covers stuck in place with actual glues - one step beyond RTV. There are some poor "fixes" out there. Is the original gasket even there anymore, or is the RTV an all-encompassing substitute?

brianbrannon

> Chairman Kaga

brianbrannon

> Chairman Kaga

02/16/2015 at 13:18 |

|

Sounds like rod knock from the video

RallyWrench

> Chairman Kaga

RallyWrench

> Chairman Kaga

02/16/2015 at 13:24 |

|

No good, I'm sorry to hear that. A strategically used rubber mallet might help dislodge those cam covers without damage. Let us know what you find.

Chairman Kaga

> RamblinRover Luxury-Yacht

Chairman Kaga

> RamblinRover Luxury-Yacht

02/16/2015 at 13:33 |

|

No gasket whatsoever. I bought a complete set of gaskets about a year ago and have been trying to work out a way to get the damned things off without warping them or galling the head, but as of yet don't have an answer. Heat, prying, razor blades, hot razor blades, chisels, mallets, intense vibration, etc. No luck.

Chairman Kaga

> RallyWrench

Chairman Kaga

> RallyWrench

02/16/2015 at 13:35 |

|

Nope. I've tried mallets, heat, blades, fishing line, vibration, and nothing. I don't want to gall the heads and was trying not to warp the covers, but it seems my only choice now is to crack them in the middle and pry them off working to the edge. Whee.

Chairman Kaga

> brianbrannon

Chairman Kaga

> brianbrannon

02/16/2015 at 13:38 |

|

I'm worried the RTV might be causing oil starvation. I started reading lots of threads where other folks experienced total destruction after someone had used liquid gasket in a part of the engine where oil flows. The petroleum breaks down the RTV and bits collect in the pickup screen, in the journals, etc and eventually the engine croaks. My oil pressure has been good according to the gauge. Which is 33 years old. And Italian.

I probably would be better off just getting a new engine. We'll see once I get into this thing a little deeper. Most rebuilds are $2k. I can get a 2.5 out of another GTV6 or Milano for $400 and install it with my neighbor's help and a rented hoist.

RamblinRover Luxury-Yacht

> Chairman Kaga

RamblinRover Luxury-Yacht

> Chairman Kaga

02/16/2015 at 13:41 |

|

Unserious recommendation: block all PCV orifices, pressurize. Serious recommendation: more heat. I know you've heated them before, but RTV's breakdown temp is still way below that of aluminum unless it's ultra high-temp rated, and even if, not for long. If you can get an acetylene torch near without burning everything, you can keep safe and not risk blowout by sooting the covers with a dirty flame, and then heating until the affected areas start to burn. That's the procedure for annealing aluminum (~650F), so it will take you just short of blowing out, and then stop. The annealing would soften your valve covers (so you might need to tap them with a light hammer to re-harden them), but that would also keep them from cracking as long as it was relatively even...

RallyWrench

> Chairman Kaga

RallyWrench

> Chairman Kaga

02/16/2015 at 13:52 |

|

Wow, I don't think I've ever had one that bad. Best of luck, I hope the necessary damage is minimal.

Buick Mackane

> Chairman Kaga

Buick Mackane

> Chairman Kaga

10/03/2015 at 15:07 |

|

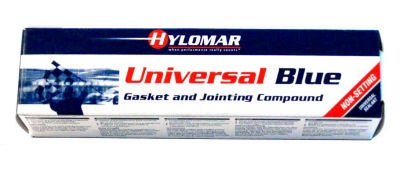

You might want to try Hylomar Blue, excellent sealer.

Hylomar Universal Blue

is the world standard for a non-setting sealant. It is used by many of the worlds automotive manufacturers, major airlines, compressor manufacturers, heavy equipment manufacturers, various OEMs and racing teams. It is a polyester urethane based viscous putty blended with a solvent to make it easy to apply, whether pumped, applied in a tube, or sprayed in an aerosol. It was a revolutionary sealant when it was introduced over 40 years ago, a development product out of Rolls Royce that was used to seal the flanges in gas turbine engines and withstand the high temperatures and intense vibration of a jet engine. A non-setting sealant, it doesn’t harden, even at 250oC. It has a unique curtaining action. As flanges sealed with

Hylomar UniversalBlue

are pulled apart, the material stretches, and then breaks cohesively, leaving sealant on both sides. When the flanges return together, the putty reseals, a self-healing mechanism. This makes Universal Blue a particularly effective sealant on close fitting large flanges which are subject to extreme vibration, distortion, or joint movement, because while the seal may break for a microsecond, it reseals and the fluids remain contained.

Chairman Kaga

> Buick Mackane

Chairman Kaga

> Buick Mackane

10/05/2015 at 11:13 |

|

And that’s exactly what I did!