"Santiago of Escuderia Boricua" (sdiglesias)

"Santiago of Escuderia Boricua" (sdiglesias)

10/31/2015 at 01:11 ē Filed to: None

1

1

17

17

"Santiago of Escuderia Boricua" (sdiglesias)

"Santiago of Escuderia Boricua" (sdiglesias)

10/31/2015 at 01:11 ē Filed to: None |  1 1

|  17 17 |

Seriously... The tech isnít there yet.

I spent about seven hours fucking around with my solidoodle press. I thought it was printing first try, so I left it to finish while I went to crossfit. It must have frozen as I left, mid print. This means I have to take the extruder apart to clean out the stuck plastic

Then I do some googling and see that they released fixing instructions for how bad they fucked up the preorder units like mine. OK, grab the multimeter, adjust potentiometer voltages on the motors. Then flash fresh firmware. Relatively simple. Also updated the printing software.

Well the firmware fucked up the whole thing. When it starts a print, itís supposed to do limit tests with touch sensors to zero itself. Well it would no longer deploy the vertical touch sensor or even try to calibrate Z, so it would either print in midair or smash the print bed into the extruder.

Tried a few different print software versions to no avail. Figure I should try firmware. Well, fucking solidoodle doesnít have any old versions online. What the fucking fuck. Eventually I find the 1.0 firmware on a forum, which can actually fucking print.

Anyway, hereís what I made. Itís a fake utility belt buckle for my Jedi costume. I seem to have lost the original while moving and thought this would be easy...

TheHondaBro

> Santiago of Escuderia Boricua

TheHondaBro

> Santiago of Escuderia Boricua

10/31/2015 at 01:20 |

|

No. Youíre just a victim of Solidoodle.

Tohru

> Santiago of Escuderia Boricua

Tohru

> Santiago of Escuderia Boricua

10/31/2015 at 01:24 |

|

I donít recommend fucking your 3D printer - thereís a lot of moving parts and some of them will cause

tromoly

> Santiago of Escuderia Boricua

tromoly

> Santiago of Escuderia Boricua

10/31/2015 at 01:27 |

|

Sounds about right.

I ran into an issue with a Makerbot Replicator 2X that would randomly jam the nozzle every time, tried a new feed roller design, new thermocouples, new hot end blocks, new nozzles, and it only marginally improved.

People get so excited when they see them, but in reality theyíre so much work.

DrJohannVegas

> Tohru

DrJohannVegas

> Tohru

10/31/2015 at 01:36 |

|

ToyDeathbot

> Santiago of Escuderia Boricua

ToyDeathbot

> Santiago of Escuderia Boricua

10/31/2015 at 01:42 |

|

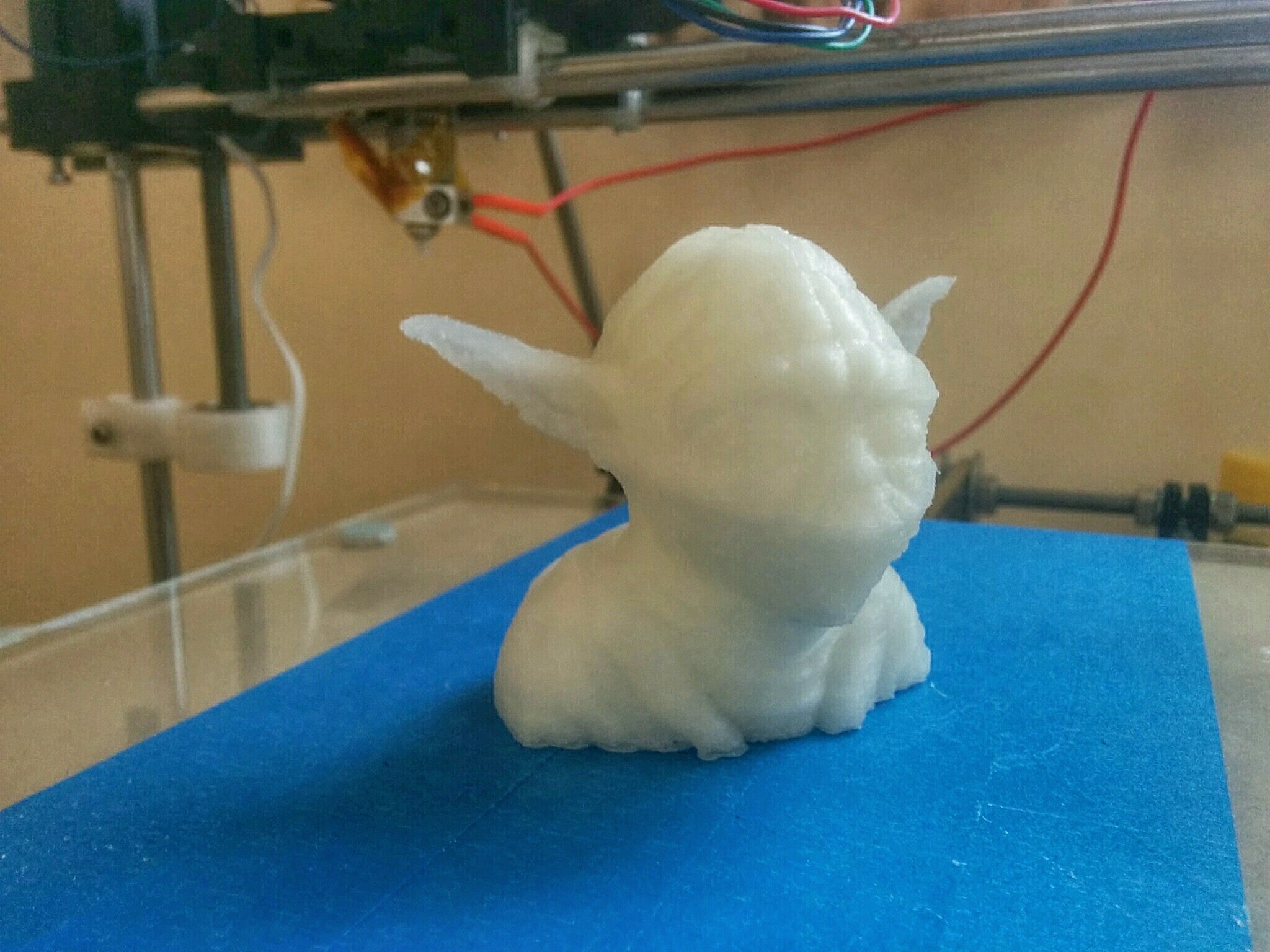

heh, at least youíve got it as a kit with *some* support. My reprap is full of issues, and I havenít had too much time to go over them. The only successful stuff itís ever printed are things made to improve the prints (like z-axis stabilizers, the white thing in the background) and the odd Yoda.

Satoshi "Zipang" Katsura

> Santiago of Escuderia Boricua

Satoshi "Zipang" Katsura

> Santiago of Escuderia Boricua

10/31/2015 at 02:05 |

|

At least you don't have to deal with a laptop that somehow requires you to disable GPU mode to work with 3D printers - all of a sudden, my laptop performs like a really old Pentium M CPU and none of the onboard SSDs are helping.

RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

> tromoly

RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

> tromoly

10/31/2015 at 07:45 |

|

Weíve got a Makerbot Replicator 2 at the local library where I work under grants on occasion and once we solved our issues (replace the original set-screw drive block with the spring-loaded one - re-wire a frayed cable that leads to the X-axis motor), itís been fine since as long as you tweak the settings for each print.

Iíve got Ď98 Ford Escort ZX2 rims on my DD Ď09 Hyundai Accent for my summer tires and custom printed 4 Hyundai center caps for them to replace the OEM Ford ones with almost no issues (again, as long as Iíve had the settings tweaked):

Sam

> Santiago of Escuderia Boricua

Sam

> Santiago of Escuderia Boricua

10/31/2015 at 07:57 |

|

Thatís less a problem with 3d printers and more a problem with low quality 3d printers.

If you had an old Land Rover that broke down all the time, you wouldnít assume that all cars are unreliable.

Santiago of Escuderia Boricua

> tromoly

Santiago of Escuderia Boricua

> tromoly

10/31/2015 at 08:08 |

|

The main issue I would see before was that the print would stop in the middle of a job like I unplugged it. Then the nozzle would jam from plastic sitting hot too long

Santiago of Escuderia Boricua

> Satoshi "Zipang" Katsura

Santiago of Escuderia Boricua

> Satoshi "Zipang" Katsura

10/31/2015 at 08:09 |

|

That doesnít even make sense! How could that even interfere with it?

Santiago of Escuderia Boricua

> Sam

Santiago of Escuderia Boricua

> Sam

10/31/2015 at 08:12 |

|

The press was advertised as a plug and play system. Mass produced, even.

Iíd put it closer to a Yugo or something. I did punch it a few times before it started working

GK27V6

> tromoly

GK27V6

> tromoly

10/31/2015 at 09:29 |

|

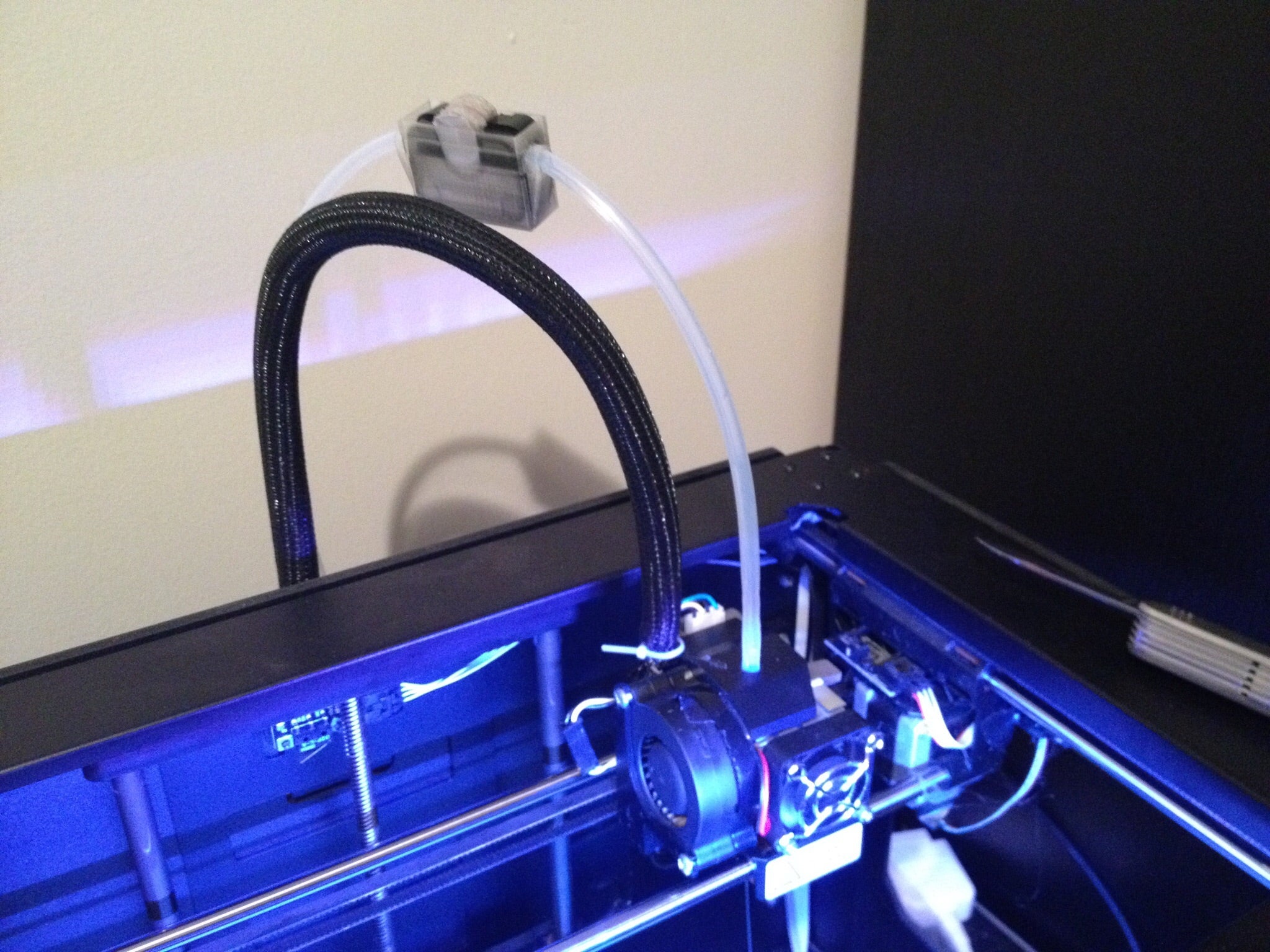

I modified my Rep2 to run a coating of canola oil on the filament before it goes into the extruder. ZERO filament jams since. I had everything, you name it, fail on my Rep2. Replaced it all and at the end still had filament jams but it wasnít until I made that mod that I had zero issues with my bot anymore.

shop-teacher

> RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

shop-teacher

> RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

10/31/2015 at 10:15 |

|

I have two Reclicator 2ís in my classroom. I had the exact same issues, among others. Iíve been incredibly disappointed in the build quality of them. Theyíre really built like crap.

RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

> shop-teacher

RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

> shop-teacher

10/31/2015 at 10:51 |

|

Other than misfitting plastic panels that screw on with the hex screws, ours has been fine for months with no issues? I donít think the quality is that bad at all...at least compared to some of the others out there. The library also has two Printrbot Simple Metals which are much cheaper and more manually-controlled....a lot harder to dial in for prints, but they seem to have decent build quality.

On the subject of bad quality, NEVERRRRRRRR get a CubeX product....library has one of those too and itís ABSOLUTE GARBAGE. Weíve ďsuccessfullyĒ printed something on it 3 times in 3 years. Support from the company and responses to problems are nonexistant. A lot like a ďtake the money and runĒ situation on their part...

Manwich - now Keto-Friendly

> Santiago of Escuderia Boricua

Manwich - now Keto-Friendly

> Santiago of Escuderia Boricua

10/31/2015 at 15:55 |

|

Probably shitty software/drivers.

shop-teacher

> RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

shop-teacher

> RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

10/31/2015 at 18:05 |

|

Iíve only used our Makerbots, so I have nothing to compare to. Thatís good to know about CubeX. I have a sneaking suspicion that as the original poster said, all the cheaper commercial printers rather suck.

Iíve had to tear down my Makerbots several times for various things. Iíve found freyed wires, striped screws, crushed parts, a backwards cooling fan, etc, etc. Not the kind of workmanship I expect from an American made product. Customer service has been very hit or miss. Often forgetting to send parts that theyíve promised.

The design of the base is very flimsy, so the outer quarter on each side is pretty useless, as the table wonít stay level under pressure when it makes a part on the sides.

I will say that when the Makerbots are working, they are very easy to use.

Satoshi "Zipang" Katsura

> Santiago of Escuderia Boricua

Satoshi "Zipang" Katsura

> Santiago of Escuderia Boricua

10/31/2015 at 19:45 |

|

I have no freaking clue. Iím just hoping that I donít get this laptop shipped/repaired... Again.