"YSI-what can brown do for you" (ysi-what-can-brown-do-for-you)

"YSI-what can brown do for you" (ysi-what-can-brown-do-for-you)

07/16/2014 at 11:25 • Filed to: None

0

0

11

11

"YSI-what can brown do for you" (ysi-what-can-brown-do-for-you)

"YSI-what can brown do for you" (ysi-what-can-brown-do-for-you)

07/16/2014 at 11:25 • Filed to: None |  0 0

|  11 11 |

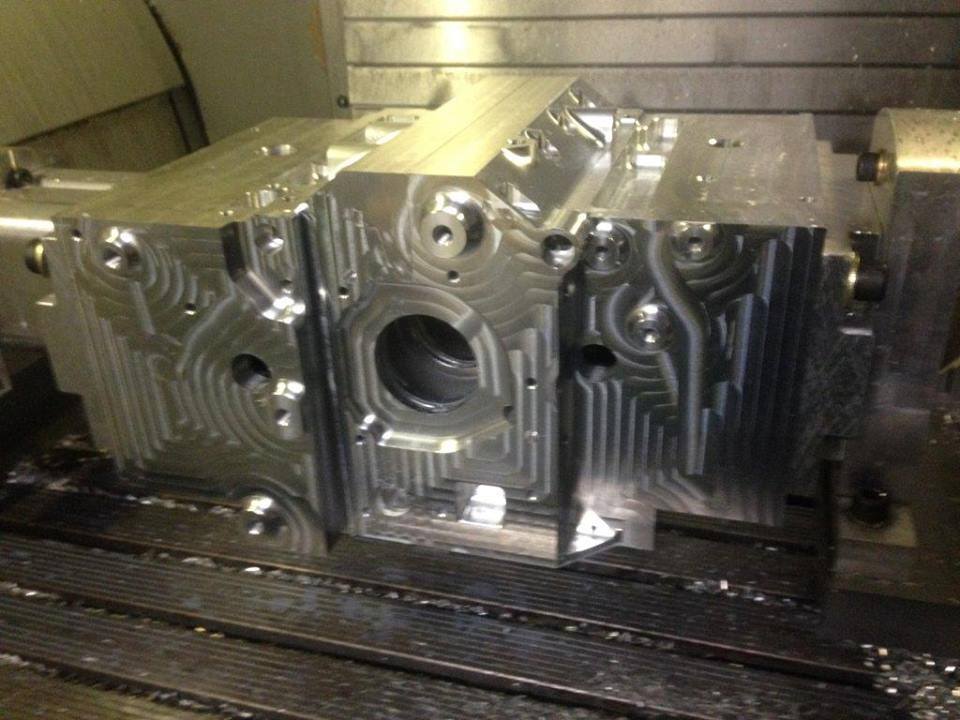

A LOT.

vdub_nut: scooter snob

> YSI-what can brown do for you

vdub_nut: scooter snob

> YSI-what can brown do for you

07/16/2014 at 11:29 |

|

I'd say around a mill....

cazzyodo

> vdub_nut: scooter snob

cazzyodo

> vdub_nut: scooter snob

07/16/2014 at 11:30 |

|

YSI-what can brown do for you

> vdub_nut: scooter snob

YSI-what can brown do for you

> vdub_nut: scooter snob

07/16/2014 at 11:32 |

|

Heh, Hehehe, Hehehehehehe

Übel

> vdub_nut: scooter snob

Übel

> vdub_nut: scooter snob

07/16/2014 at 11:33 |

|

What a lathey guess

MontegoMan562 is a Capri RS Owner

> cazzyodo

MontegoMan562 is a Capri RS Owner

> cazzyodo

07/16/2014 at 11:34 |

|

came here to post this guy

cazzyodo

> MontegoMan562 is a Capri RS Owner

cazzyodo

> MontegoMan562 is a Capri RS Owner

07/16/2014 at 11:41 |

|

My buddy made a bad pun last night and we both imitated this husky afterwards.

It was so bad it was good.

MontegoMan562 is a Capri RS Owner

> cazzyodo

MontegoMan562 is a Capri RS Owner

> cazzyodo

07/16/2014 at 11:49 |

|

I did it the other night and my wife was laughing her ass off. She thought the "bad joke husky face" was more entertaining than the pun haha

GhostZ

> YSI-what can brown do for you

GhostZ

> YSI-what can brown do for you

07/16/2014 at 11:52 |

|

Are there substantial strength / weight gains for cutting vs casting or forging? I know nothing about metalwork.

cazzyodo

> MontegoMan562 is a Capri RS Owner

cazzyodo

> MontegoMan562 is a Capri RS Owner

07/16/2014 at 12:06 |

|

TJDMAX

> GhostZ

TJDMAX

> GhostZ

07/16/2014 at 12:07 |

|

The strength answer is one thats a bit detailed. You can't have the same material for a casting, forging and billet. Let me rephrase. A material that has good castability won't be as strong as a material that has good forgability. So yes forging adds grain flow and is considered stronger than a cast part but thats mostly because of the material used for the forging is inherently stronger to begin with than the material for a casting.

With a billet because you aren't forming the material you can pick as strong of a material as you would like. So you can choose to pick a material stronger than the forging material and you would end up with a stronger part. On the flip side you can machine a much weaker material as your billet so could end up with a part that is weaker than a cast part. It just comes down to material. All steels are not created equal, same with aluminums etc.

TJDMAX

> YSI-what can brown do for you

TJDMAX

> YSI-what can brown do for you

07/16/2014 at 12:12 |

|

In all seriousness, i would bet the block itself would be around 20 grand. Assuming that you go to a shop that does this "regularly" instead of a job shop or something.