"BJohnson11" (brettjohnson01)

"BJohnson11" (brettjohnson01)

11/25/2014 at 22:40 • Filed to: Machining Porn

7

7

8

8

"BJohnson11" (brettjohnson01)

"BJohnson11" (brettjohnson01)

11/25/2014 at 22:40 • Filed to: Machining Porn |  7 7

|  8 8 |

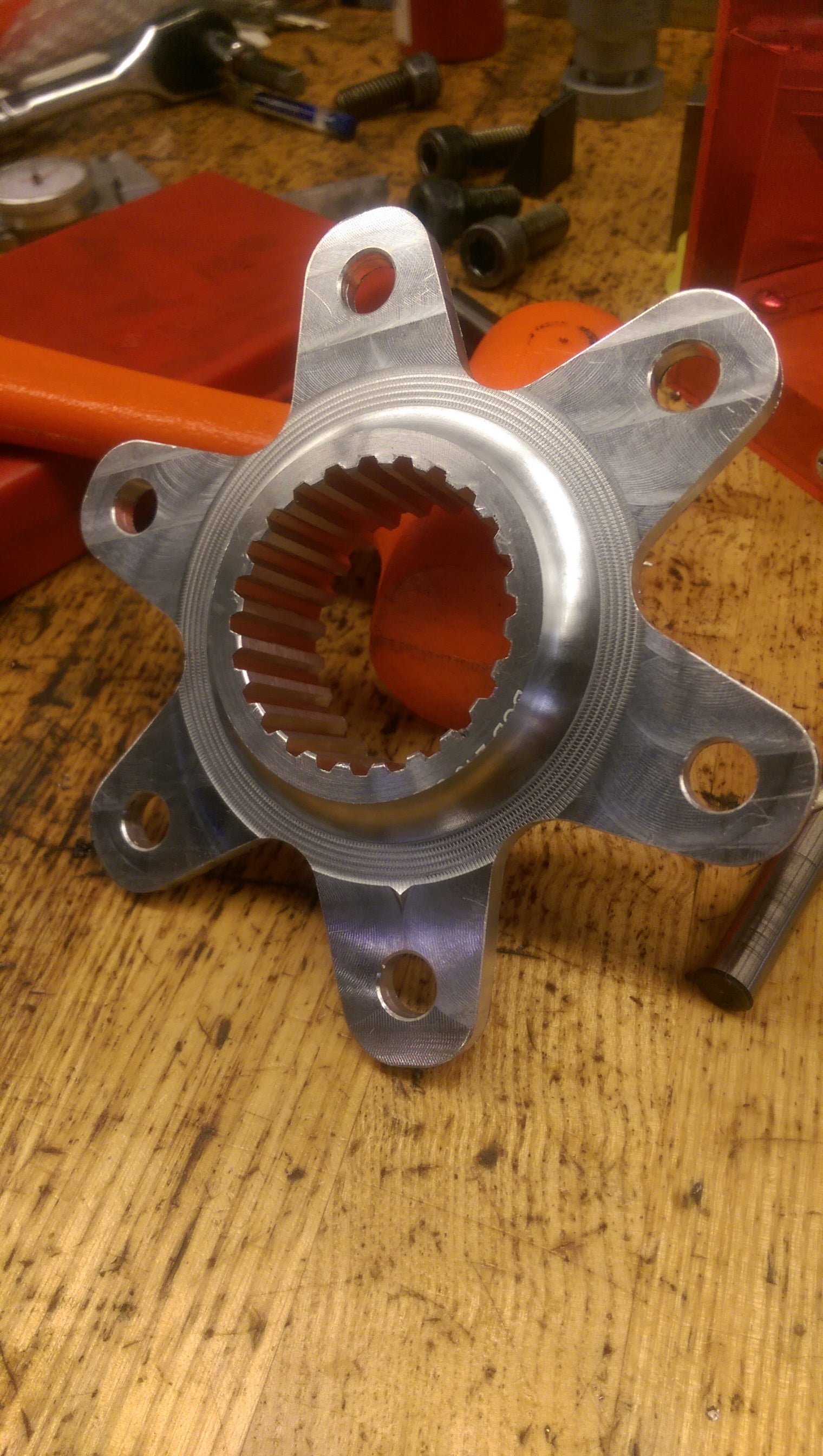

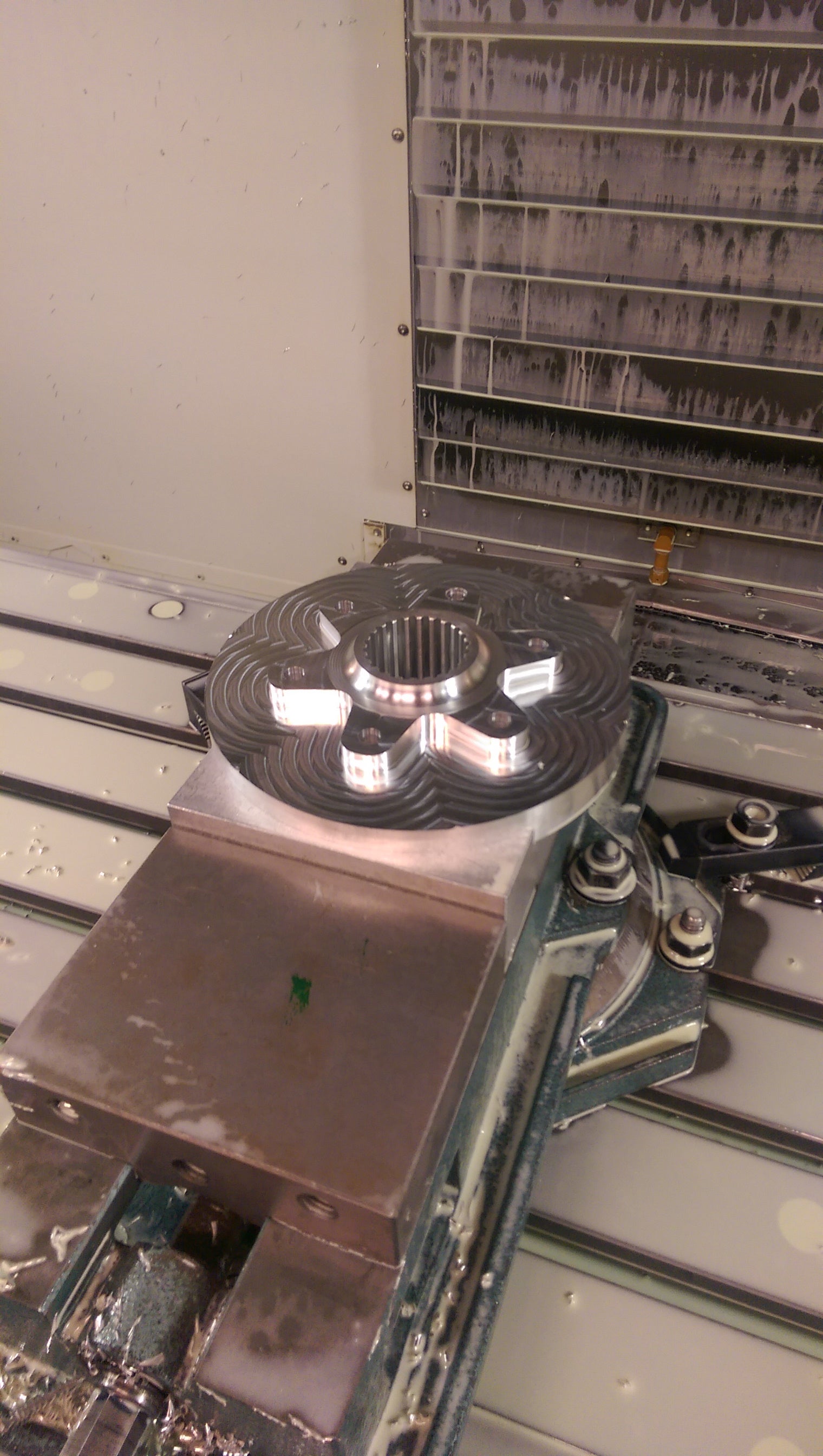

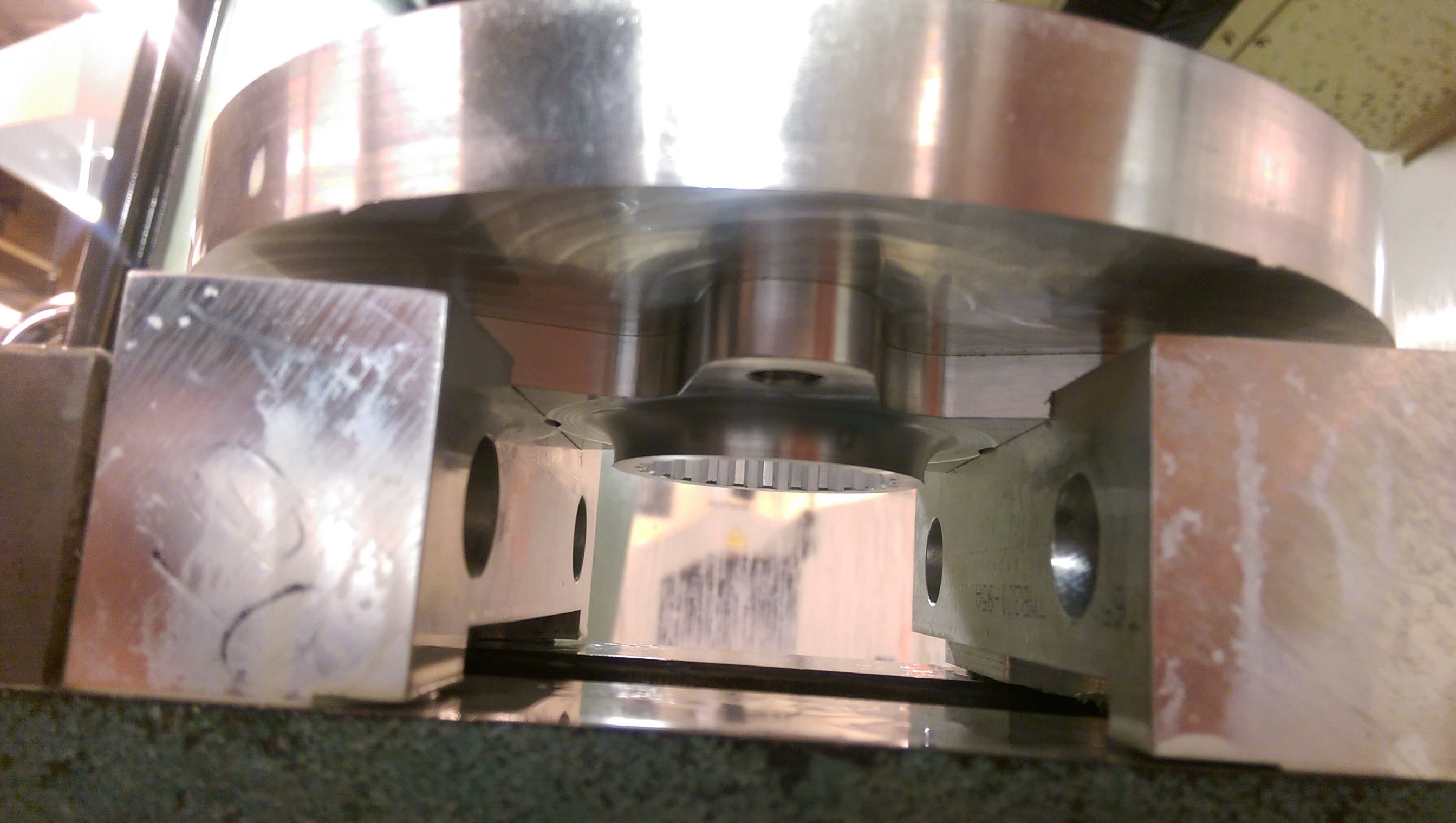

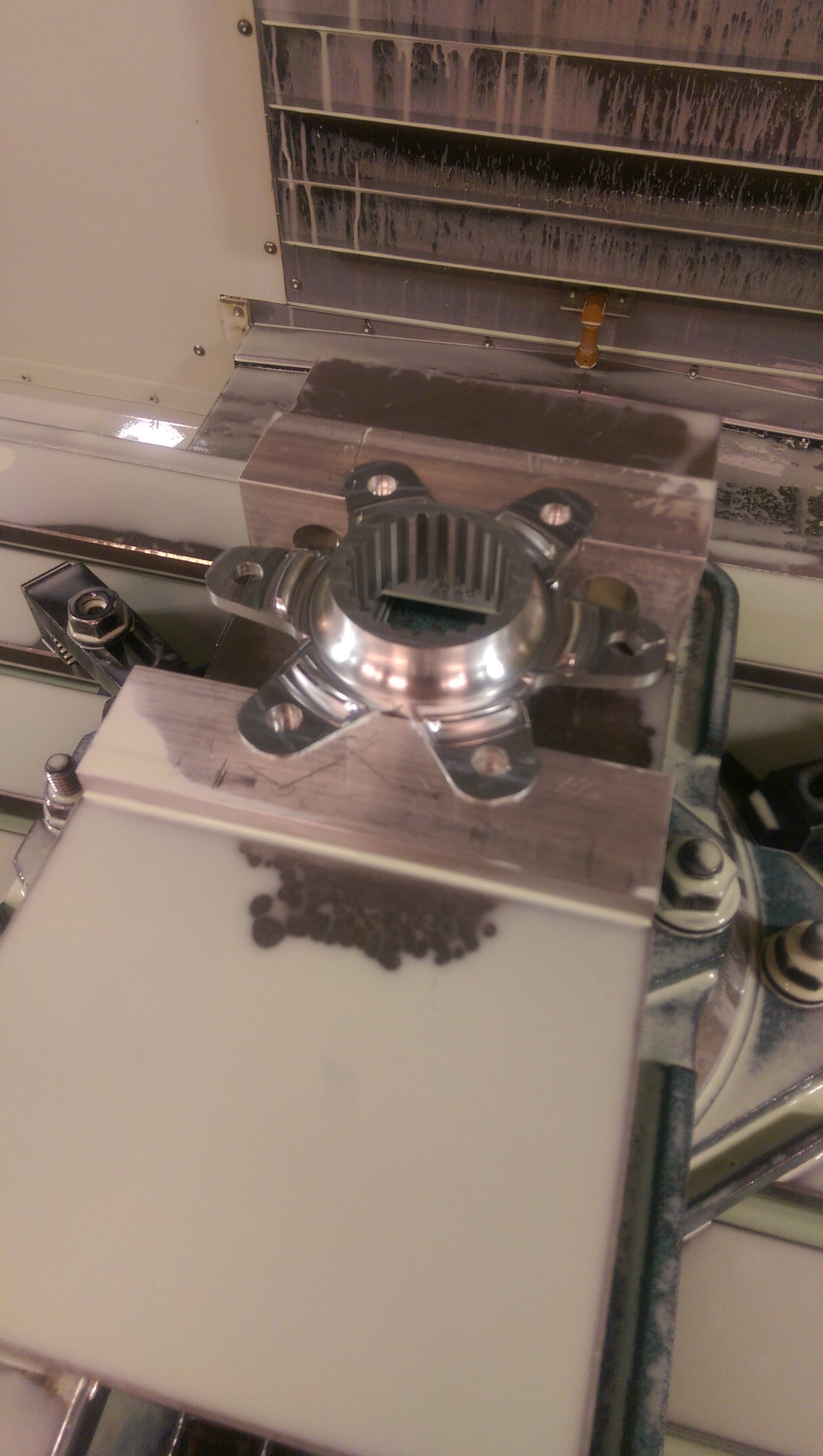

First time I ran our Haas VF3 in awhile. Cut the sprocket carrier for the formula electric team. Came out well, and only spent a few hours at the machine. Enjoy some machine porn.

LappingLuke

> BJohnson11

LappingLuke

> BJohnson11

11/25/2014 at 22:50 |

|

That's awesome!

gmctavish needs more space

> BJohnson11

gmctavish needs more space

> BJohnson11

11/25/2014 at 22:58 |

|

I briefly worked in a custom machine shop...just helping out/learning things. We had a couple Doosan lathes, but my friend was in a shop with a Haas, I'm told it was a cool thing

Stupidru

> BJohnson11

Stupidru

> BJohnson11

11/25/2014 at 23:09 |

|

Even as an engineer, I'm still in awe of what people can do machining

BJohnson11

> Stupidru

BJohnson11

> Stupidru

11/25/2014 at 23:17 |

|

It's a nifty skill to have. As an engineering student myself, it's always good to know how to make the parts you design so that you can respect the process of design to finished product.

dontbethatguy

> BJohnson11

dontbethatguy

> BJohnson11

11/26/2014 at 00:34 |

|

It also prevents you from designing something thats impossible to make.

Stupidru

> BJohnson11

Stupidru

> BJohnson11

11/26/2014 at 09:09 |

|

Exactly. I've always believed that any engineer should spend some time getting to know the machines & processes they have at their disposal before jumping behind the CAD system and designing some crazy part that either costs too much or is impossible to design

uofime

> BJohnson11

uofime

> BJohnson11

11/26/2014 at 09:51 |

|

how did you do the spline? looks like that was done beforehand, wEDM or do you have someone around who does broaching?

BJohnson11

> uofime

BJohnson11

> uofime

11/26/2014 at 13:47 |

|

The blank came to us splined from Drexler Motorsports (who makes the differential we use).