"Bullitt417" (Bullitt417)

"Bullitt417" (Bullitt417)

08/29/2013 at 10:35 • Filed to: None

1

1

19

19

"Bullitt417" (Bullitt417)

"Bullitt417" (Bullitt417)

08/29/2013 at 10:35 • Filed to: None |  1 1

|  19 19 |

Jalops,

I want your thoughts on something.

Per AutoBlog on the Volvo Concept Coupe

"A four-cylinder gasoline engine makes up half the plug-in hybrid powertrain, and Volvo promises power levels on par with current V8 engines through the use of both a turbocharger and a supercharger. Combined output from the 2.0-liter engine that powers the front wheels and the electric motor connected to the rear wheels is around 400 horsepower and 443 pound-feet of torque."

At first glance, 400hp and 443lb of torque are impressive numbers, especially from a 2.0L 4-cylinder engine; Now though, my gut reaction is making me less than impressed as I consider the complexity of the powertrain. Are they trying to keep the forced induction pressure down for reliability? Why would they need both methods? This just seems overly complicated.

LETS BREAK THIS DOWN

It's a plug-in Hybrid meaning there will be some sort of electric assist. Thinking conservatively, lets assume the electric motor makes about 50hp, leaving the turbocharged and supercharged engine to make 350hp.

No mention is made of direct injection but considering the turbo and small displacement, I am going to assume this has it. Now lets look at some comparable engines:

a) Ford 3.5L Ecoboost— Twin Turbo Direct Injected V6: 365hp 350ft-lbs torque

b) Ford 2.0L Ecoboost— Single Turbo Direct Injected 4Cyliner: 240hp, 270ft-lbs

c) Jaguar 3.0L V6— Supercharged V6: 340-380hp

We know we can make the power with either twin-turbos or a supercharger and a bigger motor. But if we can make 240hp with a single turbo, wouldn't it be easier to just add the second turbo rather than a supercharger? Then again, with only 4cylinders, it may dictate the size of the turbo used based on exhaust gas flow. Thinking about it further, the turbos would probably have to be set up as sequential, with a smaller turbo boosting lower RPMs that will feed into the larger turbo so that the turbos don't run out of steam. This would make a flat torque curve like the 3.5L ecoboost (which utilizes the same turbo set-up) but may not actually boost power to a 350hp level. Additionally, using sequential turbos would eliminate the turbo lag associated with using a larger turbo.

To be fair, I imagine turbo lag is the reason they decided to supercharge the engine, using the supercharger as the "small" turbo feeding boosted air into the larger one. I also understand that on an engine that small, the associated supercharger will probably not be able to boost power that much on its own (a la GM SCV6 engines from the 90's).

SO WHATS MY POINT?

Well to be completely honest, the more I think about what you need to pull 350hp out of a 2.0L engine, the more I think my gut reaction was wrong: its certainly not as easy as just doing one form of forced induction or the other. However, I still stand by my thoughts that this is a complicated way to set up an engine, especially considering all of the plumbing and cooling requirements.

ARE THERE ANY OTHER OPTIONS?

I don't actually know. I have an idea but I imagine that the supercharging and turbocharging path Volvo has embarked on is the more production acceptable solution to what I am about to propose. Still this is a concept car so why not think crazy.

The car is a plug in Hybrid- like everything else these days. But lets do this differently. No electric motor assist. Instead lets take a page from BMW and their new tri-turbo system and utilize electric turbochargers. Use the battery pack, the regenerative braking and associated hardware to run the turbos. In my mind, I am imagining three-turbos (so much for not complicating the engine): a true twin turbo set-up utilizing two small turbos to get the car off the line and feeding one larger turbo for max power. I expect the two smaller turbos to be electric as they will do the heavy lifting during stop and go traffic, with the larger turbo being a traditional design. It think this should give the low end torque typically missing out of small engines with the high end power associated with large turbo.

Still, I think creating what amounts to a battery powered turbo system is an interesting concept, even if I completely negated my point about the engine being too complicated. Plus I think it would be cool to see the battery packs utilized to power something other than an e-assist motor. As I said earlier, it is a concept car so Volvo should let their imagination run wild.

IN CONCLUSION

In a world where 400hp is becoming relatively normal, its easy to forget about hp per liter. 350hp from a 2.0L engine converts to 175hp per liter, an number unthinkable ten years ago, and still unbelievable today. Though I may have proved myself wrong in thinking that Volvo was needlessly complicating their engine, i'm glad I took the time to write this post. It allowed me to really evaluate the challenges involved in getting the power figures we have come to expect from our modern cars. At the very least, I am walking from this a little more impressed at the numbers Volvo has thrown down with their Concept Coupe.

Let me know what you all think in the comments below. I welcome you to point out flaws in my thought process and your thoughts on my engine design. Lastly I apologize for how long winded this post became; I didn't originally intend to prove myself wrong when I started.

Casper

> Bullitt417

Casper

> Bullitt417

08/29/2013 at 10:44 |

|

You will see more and more compound systems as time goes by. What we consider incredibly complex today will be nothing tomorrow. Just look at current engines, they have more computing power controlling them than took people to the moon. We are also constantly improving material sciences that allow us greater flexibility in implementation.

I have always wanted to design a compound turbo system that was virtually instant power, and thanks to new VVT and composite turbo materials, we are there. Electric assist would just be icing on the cake for a very large system.

Joe_Limon

> Bullitt417

Joe_Limon

> Bullitt417

08/29/2013 at 10:44 |

|

My input on the matter is, a sequential setup, doesn't eliminate lag. It changes it from a sudden sharp bolt of power into a more linear build up of torque. The lag is still there, it's just not gonna make you shit your pants when your 2.0 goes from putting out ~200hp to putting out 350-400hp.

If fuel economy wasn't an issue, I'd simply make a high revving supercharged motor. But with fuel economy being an issue, high revs are bad, supercharger draws are bad, and lag from getting full power of a turbo is bad. So the setup somewhat justifies itself like you said.

Speedmonkey

> Bullitt417

Speedmonkey

> Bullitt417

08/29/2013 at 10:46 |

|

It's a fantastic idea. Driven a ton of turbocharged cars recently and all have turbolag to one degree or another. Volvo's supercharger acts only in low rev range until turbo comes online. That engine will be known as the T6 - even thought it's only got 4-cylinders

Supercharged Jaaaaaag engines are sublime

AbigGRNboot

> Bullitt417

AbigGRNboot

> Bullitt417

08/29/2013 at 10:48 |

|

Not that I know anything, but isn't there less plumbing involved in a supercharger.

I would think that a small belt driven SC would be easier to fit than a second turbo.

deekster_caddy

> Bullitt417

deekster_caddy

> Bullitt417

08/29/2013 at 10:48 |

|

My wife's car is an '08 Passat 2.0 T. It's rated at 220 or 240 HP. I also spent a lot of time with modified GM SC 3800s. Twincharging is awesome when it's done right because you get the instant torque of a supercharger on the low end plus the turbo push on the high end. It makes for an amazing driving experience. Combine that with stop-start, hybrid style and a small electric boost and you get big engine performance from a fuel efficient 2.0. My wife's Passat Wagon is fun to drive but you sometimes wish there was a little more oomph off the line. But pulling off 32 MPG hwy in a car that big I'm not complaining.

Aya, Almost Has A Cosmo With Toyota Engine Owned by a BMW.

> Bullitt417

Aya, Almost Has A Cosmo With Toyota Engine Owned by a BMW.

> Bullitt417

08/29/2013 at 10:52 |

|

Hmm

Mitshubishi has done the concept of 2L i4 400hp before by gigantic turbo, eh?

You know, this one:

Bullitt417

> Speedmonkey

Bullitt417

> Speedmonkey

08/29/2013 at 10:52 |

|

Thanks for the link! I didn't know about the T-6 line. Like I said in the article, it was a gut reaction to the thought of both systems. I think the more interesting question is How much evaluation and thought process did they go through before the realized that this twin set-up was the best option?

Casper

> AbigGRNboot

Casper

> AbigGRNboot

08/29/2013 at 10:53 |

|

It is easier, that's why it's done a lot. It's also less efficient due to drags and heat (not to mention order of operations). If you wanted to use an SC to charge a large turbo, you would have to use something like a Vortec style SC... which is basically a turbo with half the housing replaced by a pulley and belt. The question becomes, if you are doing all that plumbing anyway, why not go with a higher efficiency VVT turbo instead?

I think you will see the "part time" supercharger systems go by the way side as they have in the past.

Speedmonkey

> Bullitt417

Speedmonkey

> Bullitt417

08/29/2013 at 10:58 |

|

Strange that it's on petrol though. Evoque and XC90 turbodiesels with auto gearboxes have epic turbo lag when pulling away from a junction

Bullitt417

> Casper

Bullitt417

> Casper

08/29/2013 at 10:59 |

|

I definitely agree with your sentiment and I imagine compound systems will just be the norm in the next decade. However, I am not sold on e-assist yet but that has more to do with battery power and weight than anything else. Still instant torque is awesome. doing it in an innovative but relatively simple way would be even better. Its one thing to apply technology. It's another to apply it smartly.

Fl1ngstam

> Bullitt417

Fl1ngstam

> Bullitt417

08/29/2013 at 10:59 |

|

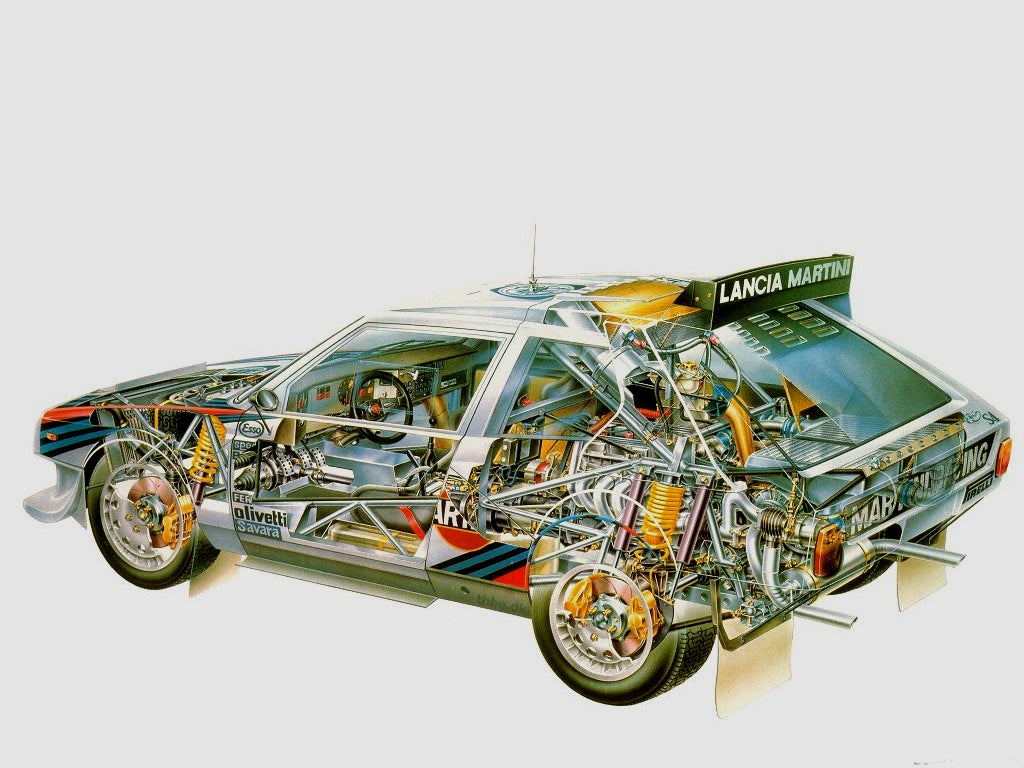

Group B monster, baby! ~650bhp from a 1.8 I4:

However, there's also this, which had ~108bhp from a 0.93 I4:

So, it's not really a new idea...

kouryuuk

> Fl1ngstam

kouryuuk

> Fl1ngstam

08/29/2013 at 11:01 |

|

Ahhh when a Lancia was a Lancia, not some sort of aborted Chrysler-FIAT baby.

kouryuuk

> Aya, Almost Has A Cosmo With Toyota Engine Owned by a BMW.

kouryuuk

> Aya, Almost Has A Cosmo With Toyota Engine Owned by a BMW.

08/29/2013 at 11:02 |

|

With devastating turbo lag mid corner, that's why supercharging and turbocharging make sense, now you don't have to worry about turbo lag because it doesn't exist.

Group B-raaaaaaaaaap!

> Bullitt417

Group B-raaaaaaaaaap!

> Bullitt417

08/29/2013 at 11:03 |

|

Twincharging (Symbiotic supercharger/turbocharger system) has been used with a relative degree of success since the mid 1980's, when Lancia used a Twincharger system in their Group B Delta S4 rally car, and in the street version called the Delta S4 Stradale. The Audi A1 also uses a version of the VW 1.4L TFSI twin charger system. It's a good option for performance oriented small displacement engines which would otherwise suffer from turbo lag.

Casper

> Bullitt417

Casper

> Bullitt417

08/29/2013 at 11:05 |

|

I don't know if I buy e-assist at the engine level but I think it makes sense at the turbo level. You only need a fraction of the power to pre-spin a turbo. You could even use compressed air, only electronically powering the compressor.

The real problem is more revolving around durability. Cars with instant torque tend to break more stuff.

BoxerFanatic, troublesome iconoclast.

> Bullitt417

BoxerFanatic, troublesome iconoclast.

> Bullitt417

08/29/2013 at 11:09 |

|

1: it is a technology showcase, to show "that we can."

2: They are trying to get maximum energy out of the fuel they do burn. More power output from a given displacement.

3: they are trying to average out and somewhat split the operational system into two modes.

Most people don't use max power very often, but want it for a very short time on demand. Building an engine for that max power tends to be thirstier 90% of the time, at cruising and low-speed maneuvering where much less power is required.

Building an engine that is smooth and efficient at cruising and low speeds tends not to provide the max power output that sells cars, magazines, and makes headlines to get attention.

So they try to do both.

With turbocharging, supercharging, or electric supplemental drive... or in this case, all three.

And frankly 'all-three' somewhat cancels each other out.

compound Turbo-Supercharging is a way to get positive intake pressure at all RPMS. Positive intake pressure, (Boost) and a bit more fuel, especially if metered precisely by gasoline direct injection, gets more power output than relying on the engine to suck in it's own air (vacuum)

Turbos rely on engine speed to produce gas flow, heat, and thus pressure to spin up the turbocharger... it doesn't spin up early, or by itself.

A Supercharger doesn't lag like that, it is mechanically driven, and depending on gear ratio in the supercharger, or a variable drive, can spin up pretty much from idle and above, but something geared that way, and small enough to make pressure at low volume, runs out of breath at the upper end of the RPM range.

So combining a small supercharger with no lag, and a bigger turbocharger with bigger high-RPM lungs, you get a complimentary system that isn't quite as complex, as a sequential dual turbo system, and positive pressure across the RPM range.

With variable vane turbos, and variable traction-drive superchargers, they can be managed to somewhat disengage when not needed, and fuel can be metered back accordingly, for fuel-efficient cruising, as well. Power on demand, essentially.

The thing is... using electrical drivetrain for boosting torque to the wheels somewhat mitigates the need for such a wide RPM range. If you are going to have the weight and complexity of a hybrid system, it makes more sense for low-speed maneuvering to be handled by an electric traction motor, and the engine to default into a steady-state generator role at a constant power-efficient throttle level, to supply the electricity, rather than jumping up and down trying to drive the car in stop-and-go traffic.

At higher speeds where the electric traction motor gets hot, and requires more and more current, it starts to make more sense to kinetically engage the fuel-burning engine...

The thing is...that doesn't really require lugging the engine near idle, and sort of defeats the purpose of the complication of combining a supercharger with a turbocharger.

This concept is likely to be a "throw everything we can do into it, to show off our chops" sort of arrangment.

Bullitt417

> BoxerFanatic, troublesome iconoclast.

Bullitt417

> BoxerFanatic, troublesome iconoclast.

08/29/2013 at 11:15 |

|

Nice Write-up. I definitely agree with the idea of the concept engine being a lets throw everything at it to prove we can do it. I like the idea of using the electric motor around town. I just wonder if you can get the same efficiency with lighter weight by using the electric turbos I mentioned.

BoxerFanatic, troublesome iconoclast.

> Bullitt417

BoxerFanatic, troublesome iconoclast.

> Bullitt417

08/29/2013 at 11:35 |

|

I am a bit skeptical of electric turbos...

Simply because it is easier and less 'lossy' to directly drive a supercharger, rather than converting kinetic energy to electrical energy, and then turning that electrical energy back into kinetic energy in an air compressor.

Electric turbos seem like fancy-fied leaf blowers strapped to an engine, and plugged into the alternator.

Turbos are energy recovery devices... using waste thermal energy.

Superchargers are direct drive devices... using kinetic energy directly, without conversion process losses.

Electric... seems superfluous and comparatively needlessly complex, as it doesn't really add much that a Turbo or a supercharger can't already do.

Turbineguy: Nom de Zoom

> Bullitt417

Turbineguy: Nom de Zoom

> Bullitt417

08/29/2013 at 12:29 |

|

VW's Twincharger works the same way AFAIK. The blower turns at crank speed so there's no lag, but as the rpms rise the turbo spools up and provides boost (assumingly without a gap)