"6cyl" (6cyl)

"6cyl" (6cyl)

08/15/2013 at 11:23 • Filed to: None

11

11

24

24

"6cyl" (6cyl)

"6cyl" (6cyl)

08/15/2013 at 11:23 • Filed to: None |  11 11

|  24 24 |

Trailers that lower to the ground for easy loading and unloading of race cars. Plus a built in air source for tires.

MonkeePuzzle

> 6cyl

MonkeePuzzle

> 6cyl

08/15/2013 at 11:29 |

|

agreed. 100% don't forget air tools too!

the design to get it down is really quite ingenious

gotta love the accent, and the fact that he's not using a TRUCK to tow his toy

Converse

> 6cyl

Converse

> 6cyl

08/15/2013 at 11:29 |

|

dinobot666

> 6cyl

dinobot666

> 6cyl

08/15/2013 at 11:33 |

|

But this great technology doesn't make for entertaining videos like trying to push a Honda Civic into the back of a U-Haul truck.

You know what comes next.

RB_XXV_Z

> 6cyl

RB_XXV_Z

> 6cyl

08/15/2013 at 11:34 |

|

I wonder if he is interested in a US based partnership. These would be awesome for drift cars.

6cyl

> RB_XXV_Z

6cyl

> RB_XXV_Z

08/15/2013 at 11:36 |

|

These would be awesome for all cars! Drift cars, show cars, race cars, "stance" cars, daily drivers... basically this seems like one of the best ways to move a car I can think of.

Josh Welton

> 6cyl

Josh Welton

> 6cyl

08/15/2013 at 11:42 |

|

In 2009 we ran into David Coker from Newstalgia while on the Power Tour.

Bike, car, and trailer were all bagged.

Casper

> 6cyl

Casper

> 6cyl

08/15/2013 at 11:49 |

|

I have seen bagged trailers before, but I like that design more other than the lack of redundancies. The biggest issue would be the fact it is such a light weight design I don't know if it would pass some of the certifications in the US. That trailer doesn't have real axles, which drastically limits it's capacity and rigidity. Also, what happens if the system fails? If the trailer drops with a car on it while traveling down the road you will have a very bad day.

I think I would need some extra safeties in place. Something to lock the trailer at transport height would be a good start. Even if it were just large metal ratchet locks like shipping containers have.

Mattbob

> Casper

Mattbob

> Casper

08/15/2013 at 12:12 |

|

Agreed. The first thing I thought was that it needs some kind of bumps stop that lock in place so once you are underway, it cant just drop all the way down. Other than that, it looks neat.

Casper

> Mattbob

Casper

> Mattbob

08/15/2013 at 12:18 |

|

Yeah, I'm sending the video to my buddy. I might just have to go to his shop this weekend and see if we can't come up with a way to make something like this ourselves.

Another issue I thought of after the fact was that you can't lower it while it's still attached to another vehicle. The tongue drops with the trailer, so you have to park, unhook, then lower the trailer. That would actually be rather annoying for track days where we throw the car and tools off, then move the other vehicle and trailer somewhere else.

Bird

> 6cyl

Bird

> 6cyl

08/15/2013 at 12:25 |

|

I would definitely buy a trailer from him! Check out his 'Midmounted Mazda Minitruck' project.

http://www.youtube.com/playlist?list=…

Bird

> Casper

Bird

> Casper

08/15/2013 at 12:37 |

|

What 'certifications' are you speaking of in the US? There's no federal standard or crash testing that needs to be met...

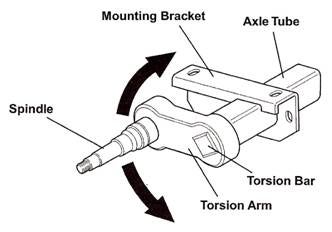

Lot's of trailer's don't have what you refer to as 'real' axles. I definitely wouldn't say it 'dramatically limits capacity and rigidity'. Axles don't make the trailer more rigid at all. Here's an example of a torsion bar swing arm set up:

As far as redundancy, it's built in. I can't say for sure, but I would imagine at the very least the front and rear pairs of wheels are on separate air circuits. Therefore you have the same redundancy as a dual axle trailer. If you get a leak on one circuit, it wouldn't automatically empty all four air bags. For even more redundancy, use four air valves and lines to each corner individually.

As far as locking it in place, no need. Do people with bagged cars lock their cars at ride height?

GreenN_Gold

> 6cyl

GreenN_Gold

> 6cyl

08/15/2013 at 12:49 |

|

So, umm, am I like the only one that's totally bummed that the video doesn't show the trailer lifting the car?

Casper

> Bird

Casper

> Bird

08/15/2013 at 12:59 |

|

DOT regulations for weight, crash safety, etc. If you follow an approved design it's easy. If you start changing it up, it's very different matter to be approved for sale. Selling something is much harder than simply getting it approved for road use... at least if you want to stay in business.

Yes, it does affect the structural stability and rigidity of the trailer. If a solid axle connects both points of the load balance, and the deck is connected to the axles through fixed mounts, it means each wheel is transferring energy to the other. The only way for the weight to shift is through give in the tires or the contents moving. Light trailers such as this do not have a large structure frame like for instance a standard trailer on a semi, so they are very dependent on dissipation of energy to the axles. Trailers with suspension typically have stringers or re-enforcement under the deck to stiffen them, that way the deck will stay "flat" even when the suspension is allowing it to travel.

I honestly can't believe you are stating that something connected solely to a frame tab is going to provide the same load capacity as something with a full axle tube. I don't even know why you are stating something like that, so I don't know whether to refute it with basic physics or capacity calculation sheets.

Yes, the air can be kept from leaking via multiple circuits. But there are several key issues. First, the Fed won't let you have axles that don't evenly deflate ( http://www.fmcsa.dot.gov/rules-regulati… ) but also the requirement varies by state. For instance, a car that lowers completely to the ground from deflation of it's air bags is not legal in some states but if the suspension components prevent it from contacting, it is legal. Another example, South Carolina has been known to ticket air bags on cars, but allow it on trucks as it's a work function. So getting 50 state compliance would be the hardest part. It would be a no brainier with a lock because there is a mechanical secondary to the system capable of operation regardless of complete air system failure.

Bird

> Casper

Bird

> Casper

08/15/2013 at 13:47 |

|

I thought those regulations are regarding 'motor carriers' not private use. I could be very wrong, and I won't argue that point.

I think you misunderstood my point on the axle. I'm saying a swingarm can be designed to work in this application. The trailer can be rigid without having a solid axle. It just means the design needs to be different. My statement of 'Axles don't make the trailer more rigid' was referring to the deck. Bad choice of words on my part. I should have said it could be designed to work without them.

You may be misreading the link you posted regarding how the air systems work.

The air suspension exhaust controls must not have the capability to exhaust air from the suspension system of one axle of a two-axle air suspension trailer unless the controls are either located on the trailer , or the power unit and trailer combination are not capable of traveling at a speed greater than 10 miles per hour while the air is exhausted from the suspension system.

You're allowed individual control. You just have to have the controls on the trailer or meet that speed requirement.

Also, you could design a system with multiple valves for redundancy that does not allow individual control.

As far as individual states are concerned, I'm sure that yes you would run afoul of a few state regulations in different areas. Again, I was referring to federal regulations on private use. I'm no expert and could be very wrong there.

Also after looking up this trailer, it does include a lock to prevent complete bottoming out while driving.

Casper

> Bird

Casper

> Bird

08/15/2013 at 14:42 |

|

Yeah, I was reading that differently.

Yes, then I misunderstood you. If you changed the design slightly, they could stiffen the trailer and make it much more rigid without a fixed solid axle. They could very well do as you suggest and stiffen the deck into a more "unibody" like design as they would on a vehicle and not rely on a connective axle for stability.

Well then, if it has a lock, the whole discussion is moot. All the regulatory issues that could arise would be negated by the lock to prevent the ride from lowering. The only reason it's an issue is because air systems constantly leak pressure and will fail over time without power. It would be a pretty big deal if you lost power to the trailer and rather than just losing lights, the whole thing decided to do a belly slide on the interstate.

MILK

> 6cyl

MILK

> 6cyl

08/15/2013 at 15:56 |

|

UH... Whats so hard about ramps?

6cyl

> MILK

6cyl

> MILK

08/15/2013 at 16:01 |

|

Clearance

MILK

> 6cyl

MILK

> 6cyl

08/15/2013 at 16:05 |

|

Easy...

List price is $16000 NZ call it $12000 USD, buy this instead. Take your $9600 and stuff stacks of $100's under the front tires until proper clearance is obtained. Step 3: profit.

Sethersm

> RB_XXV_Z

Sethersm

> RB_XXV_Z

08/16/2013 at 10:49 |

|

Would be awesome for boat trailers too.

Philbert/Phartnagle

> Casper

Philbert/Phartnagle

> Casper

11/09/2013 at 05:38 |

|

I agree Casper, I would also have some concern about how well the tires would stay aligned in that configuration after you hit a few potholes.

The overall thought and design are great, but I wonder how well it would hold up to heavy useage?

Dsscats

> 6cyl

Dsscats

> 6cyl

10/12/2014 at 02:50 |

|

How the hell does this have 2500 views?

6cyl

> Dsscats

6cyl

> Dsscats

10/15/2014 at 09:55 |

|

I have no idea!

RamtheCowy

> 6cyl

RamtheCowy

> 6cyl

02/12/2016 at 14:41 |

|

Can anyone tell me what the hell airbag suspension even is?

6cyl

> RamtheCowy

6cyl

> RamtheCowy

02/12/2016 at 16:44 |

|

it is an alternate way of cushioning a vehicle. Regular suspention uses springs. Air suspension uses bags (bladders) of compressed air. The advantage to using air is you can control the pressure to adjust the “spring rate”