"razorbeamteam" (razorbeamteam)

"razorbeamteam" (razorbeamteam)

09/28/2020 at 17:13 ē Filed to: None

4

4

25

25

"razorbeamteam" (razorbeamteam)

"razorbeamteam" (razorbeamteam)

09/28/2020 at 17:13 ē Filed to: None |  4 4

|  25 25 |

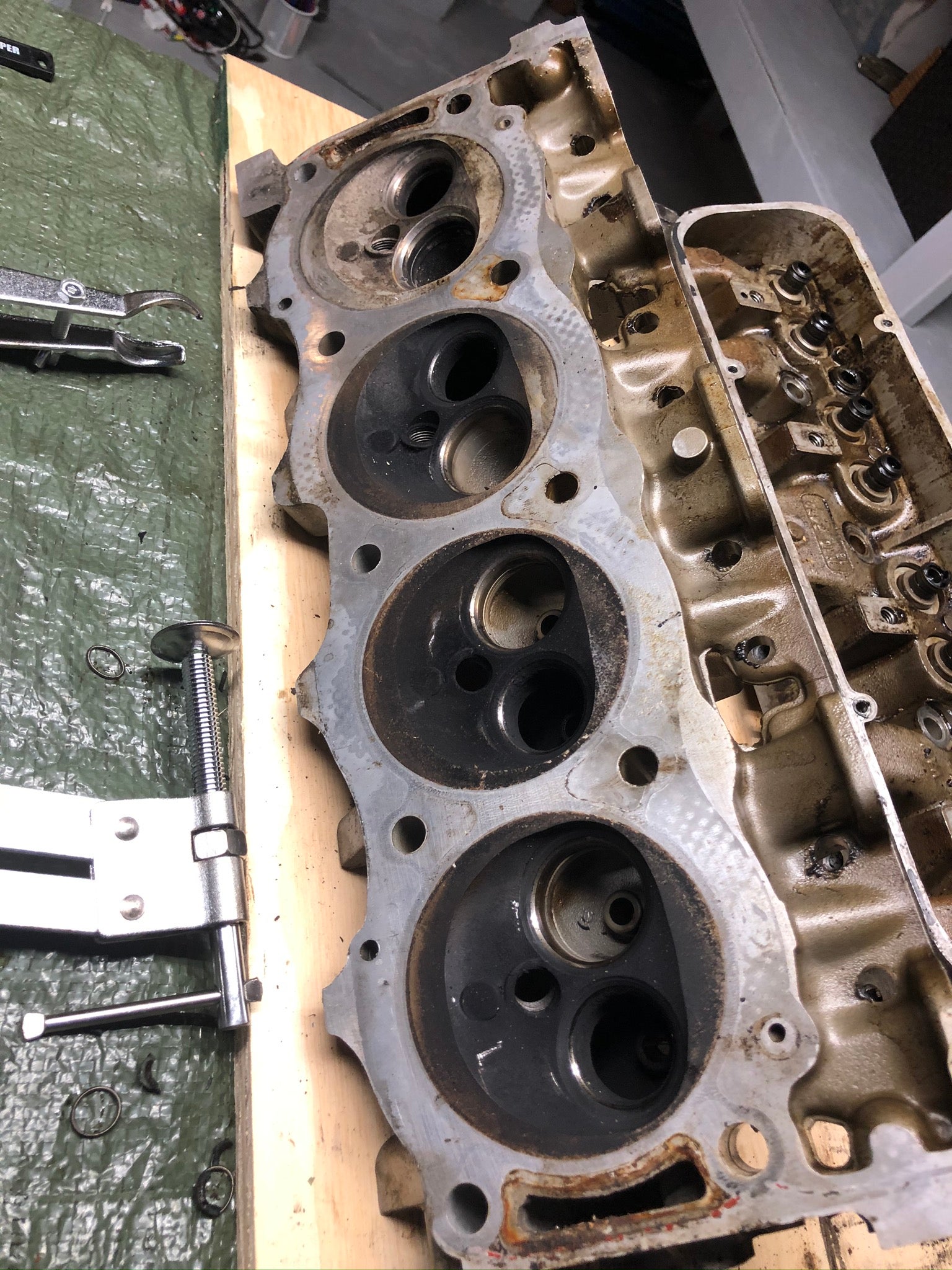

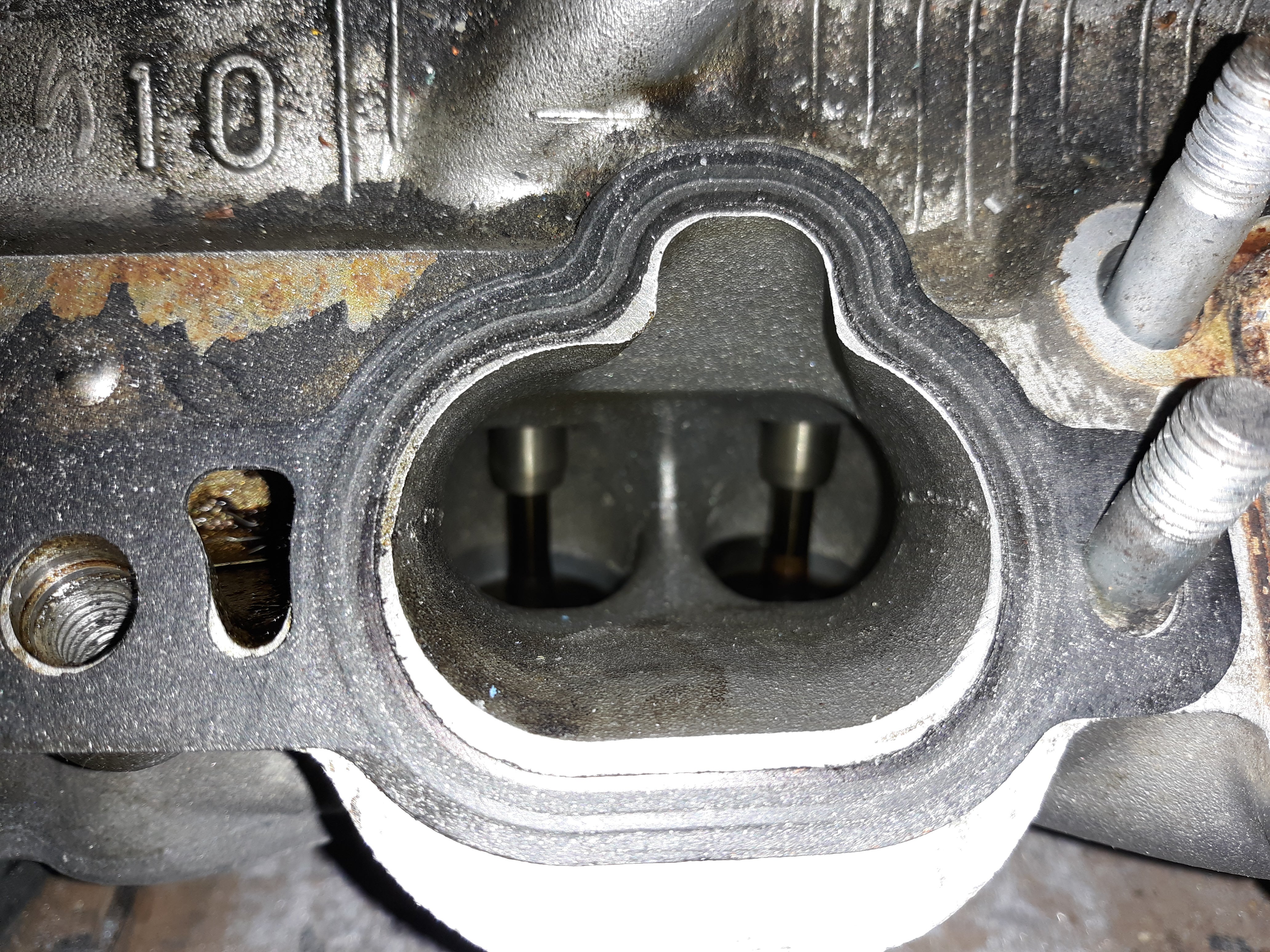

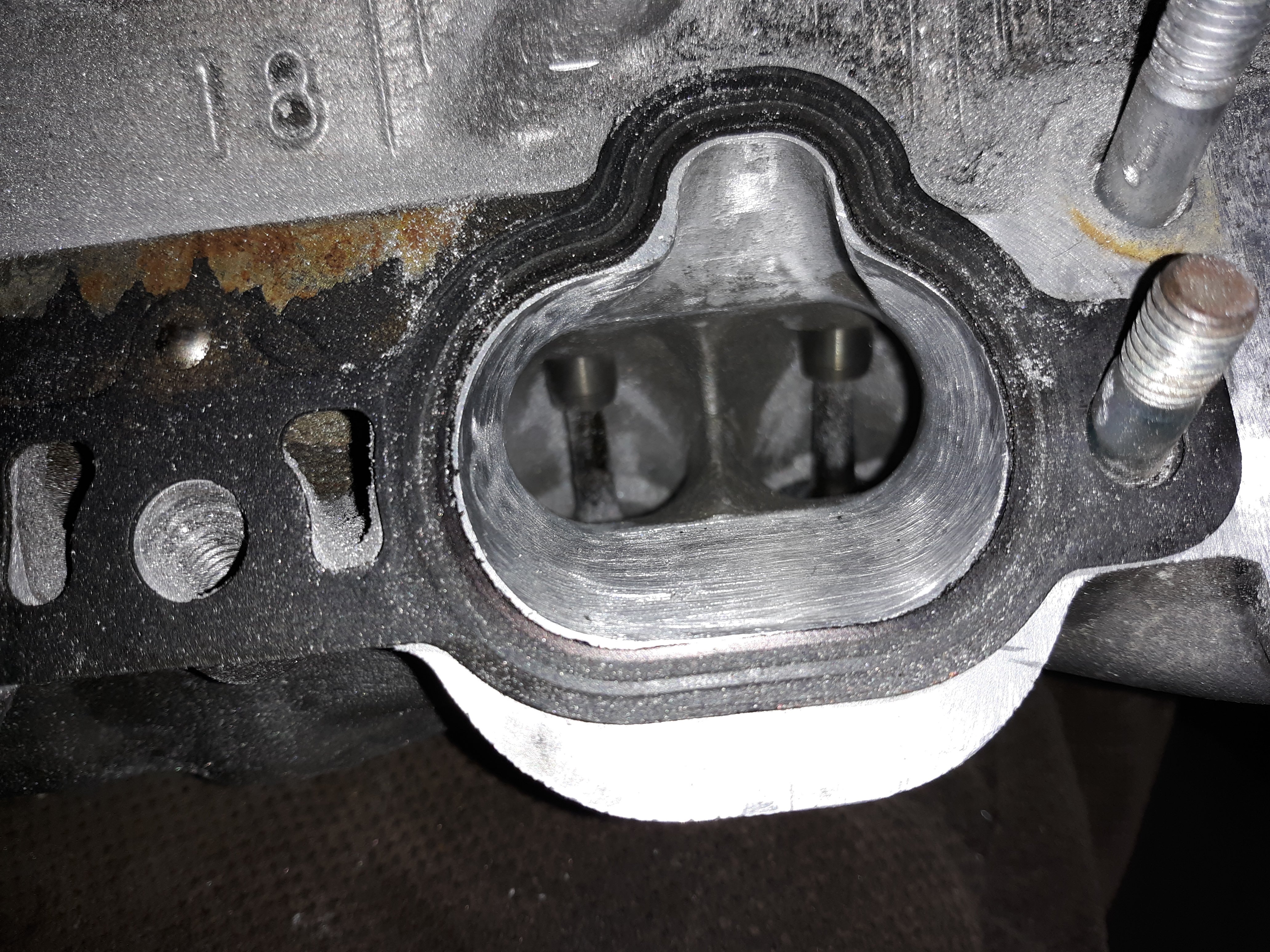

Iíve always wanted to learn how to port cylinder heads. The idea that you can get some free horsepower out of your engine with a little work and patience is pretty cool. I picked up this set of heads off a Discovery II in the junkyard for $100. My longer-term plan is eventually build up an entire engine for the Range Rover, but for now this is as much as Iíve committed. I got started disassembling the heads over the weekend and making a plan.

Iím not looking to do anything major, just some gasket

matching and smoothing of curves. If I donít completely botch that part, I may

opt for some larger valves and bulleted guides.

Guess where the leak was

†

I donít really know what Iím doing, but I figured this is the best way to learn. Iíve read two books on the subject and watched at least five YouTube videos, so what could go wrong?

Anyone else have experience doing something like this?

GoodIdeaAtTheTime

> razorbeamteam

GoodIdeaAtTheTime

> razorbeamteam

09/28/2020 at 17:42 |

|

Aluminium heads. Get the proper tools, the non- ferrous materials will clog most grinding tools very quickly. Rover heads are rather thin c ompared to cast iron heads , so be careful. Go slow, and maybe even slower than that.

Iíd recommend having bronze valve guides installed too, not common, but Iíve seen enough worn guides on them to justify the expense.

And find someone that can really tune the ecu. Extra air means you can add extra fuel which means extra power!

sony1492

> razorbeamteam

sony1492

> razorbeamteam

09/28/2020 at 17:43 |

|

Went at some 1uz heads with a Dreme l a while back. Used the gasket as a template for laying in sharpie on the head, then used a huge pack of 80grit sanding drums. In these heads it necked down pretty severely right before t he valves.

Cant comment on the performance difference because it went to FI with a lower compression ratio, and spun a bearing before getting more then a thousand miles

Manwich - now Keto-Friendly

> razorbeamteam

Manwich - now Keto-Friendly

> razorbeamteam

09/28/2020 at 17:43 |

|

From what I understand, you take a bottle of port:

Put some if it in your head through your mouth:

.

.

.

.

.

.

.

.

And now your head has been ported.

glemon

> razorbeamteam

glemon

> razorbeamteam

09/28/2020 at 17:43 |

|

I got a cheap head and have ported it for my TR250. There were obvious constrict ion points I bunged out as evenly as I could, and I also smoothed out the edges in the combustion chamber that may cause pre-ignition. But that is as far as I have gotten. It was always a long term project, and I got busy with a move, work, family, etc. and took the next step, getting it milled and valve job at a machine shop hasnít happened. I probably need to do a little more polish with my port. An extension thingy for the dremel makes the job much more doable.

Not offering much, pretty much started the same place you did, not a lot of knowledge, but some good books and online tools.

3point8isgreat

> razorbeamteam

3point8isgreat

> razorbeamteam

09/28/2020 at 17:45 |

|

Im very interested in how this turns out for you. Its a project that sounds fun, but id be afraid of making things uneven between ports.

Future next gen S2000 owner

> razorbeamteam

Future next gen S2000 owner

> razorbeamteam

09/28/2020 at 18:02 |

|

.... watched at least five YouTube videos, so what could go wrong?

Modern driveway mechanics at its finest.

NYankee1927

> razorbeamteam

NYankee1927

> razorbeamteam

09/28/2020 at 18:48 |

|

ď ....watched at least five YouTube videos, so what could go wrong?Ē

But how many mom FaceBook groups have you consulted?

Highlander-Datsuns are Forever

> razorbeamteam

Highlander-Datsuns are Forever

> razorbeamteam

09/28/2020 at 19:11 |

|

Generally cleaning up the intake and exhaust ports helps a bit, donít touch the combustion chamber unless you want to become an internet meme. Bigger valves is a machine shop job . New valve guides and seats †is always a good idea if the motor has a lot of miles on it.

Also I see the head gasket let go...

razorbeamteam

> Manwich - now Keto-Friendly

razorbeamteam

> Manwich - now Keto-Friendly

09/28/2020 at 19:34 |

|

That sounds waaaay easier TBH

razorbeamteam

> sony1492

razorbeamteam

> sony1492

09/28/2020 at 19:35 |

|

That looks good! Canít believe you just used a Dremel. Iím trying to decide if I can get by with a Dremel or if I should upgrade to a die grinder.

Shame the motor went kaput after all that work.†

razorbeamteam

> glemon

razorbeamteam

> glemon

09/28/2020 at 19:37 |

|

Yeah, I feel like Iíve gotten as far as I can with reading/learning. I need to bite the bullet and just† get started grinding. I figure if it comes out decently, I can spend money on machine work.†

razorbeamteam

> Highlander-Datsuns are Forever

razorbeamteam

> Highlander-Datsuns are Forever

09/28/2020 at 19:39 |

|

Yep, the reason it was in the junkyard I believe. Thatís cylinder #2, blew right into the water passage.†

razorbeamteam

> 3point8isgreat

razorbeamteam

> 3point8isgreat

09/28/2020 at 19:40 |

|

Thatís why I think less is more here. Iím going to focus on smoothing rough edges and curves more than removing material, that way I can make sure the port shape stays the same across cylinders.†

razorbeamteam

> GoodIdeaAtTheTime

razorbeamteam

> GoodIdeaAtTheTime

09/28/2020 at 19:42 |

|

My goal is to have the engine run off of a Speeduino. I bought an assembled board earlier this year and have been looking into wiring up a V8 harness for it. Iíll leave the tuning to a professional.

razorbeamteam

> Highlander-Datsuns are Forever

razorbeamteam

> Highlander-Datsuns are Forever

09/28/2020 at 19:45 |

|

Is there an internet meme about porting the combustion chamber ?

Highlander-Datsuns are Forever

> razorbeamteam

Highlander-Datsuns are Forever

> razorbeamteam

09/28/2020 at 19:48 |

|

Iím willing to make one. I doubt many people will understand tho...

sony1492

> razorbeamteam

sony1492

> razorbeamteam

09/28/2020 at 19:53 |

|

For got to mention I did use metal cutting blades too.

Using the dremel did take forever but youíve got good control over the amount that gets cut out.

The heads are still around for another project even if the crank and rods are no longer with us

66P1800inpieces

> razorbeamteam

66P1800inpieces

> razorbeamteam

09/28/2020 at 20:09 |

|

I did the heads on my Volvo 1800's cast iron heads and it was relatively straightforward. I bought a quality FOREDOM H.44T handpiece and connected it to the Harbor Freight flex shaft tool as the one the HF tool comes with is not up to the task. The HF tool was $49 - the 20% coupon) and the Foredom piece was another $49 new from ebay (it is a perfect fit, old one pops off, this one pops right on). It is a better handpiece than the HF one and the better construction and bearings stay cooler if you are running it for a while. It also has different collets including one for a standard 1/4 shaft bit. This setup is supposedly much easier to control for beginners than a die grinder. Note for the flexshaft on the HF tool, be sure to pull it out and coat it with a good moly grease (or something for flexshafts).

I bought a couple different carbide bits but found 95% of the time I used a 3/8 diameter flame burr. If they are Aluminum heads make sure to get the carbide bit with the correct flutes as the ones for steel will get clogged. I also put down a layer or two of thick duct tape over the entire head and cut out the chambers incase I missed a little. I then had the head cut down so it would not have been an issue but just incase.

Try to find an enthusiast page where someone has really dialed in the correct cuts for your combustion chamber as some things are not intuitive and what you think would work has an opposite effect. Also, every bit you grind off increases the chamber volume and decreases compression so you might need to skim the heads after to maintain the compression ratio.

Damn the handpiece are up to $62.

razorbeamteam

> 66P1800inpieces

razorbeamteam

> 66P1800inpieces

09/28/2020 at 20:29 |

|

Thanks for the throough reply. I was actually looking at that HF rotary tool, but hadnít figured out how to use the 1/4" shafts in it. Appreciate the insight.

I donít think Iím even gonna touch the combustion chambers. The rover forums are iffy on if it makes a difference. If I do anything, it will likely just some simple smoothing of the relief edge. The heads will need to be skimmed anyway.

old-busted-hotness-still-cant-comment

> razorbeamteam

old-busted-hotness-still-cant-comment

> razorbeamteam

09/28/2020 at 22:04 |

|

I did a BMC 1275 head many years ago. 5-port head, so the passages were convoluted and tricky. I took out maybe 2 cups of shavings, using a diagram made by someone who knew what he was about. With some more compression and a lot more cam, that little booger would scream. Didnít have much to say below 4,000 rpm, but from there to 8,000 it was good fun.

Snuze: Needs another Swede

> razorbeamteam

Snuze: Needs another Swede

> razorbeamteam

09/28/2020 at 22:13 |

|

I ported a Honda CRF450 head for the Formula SAE car back in college. I had no idea what I was doing but I made a dyno verified 2 HP, which was a 5% gain on a mostly stock engine pulling through a 25mm restrictor that normally made 40 HP. We were also at choked flow with the restrictor, so all gains were likely an effect of reducing pumping losses. With no restrictor the engine should have made about 50 HP with our light mods (mainly exhaust and tuning) and I suspect the porting would have been worth closer to 10%.

Bike intakes and exhaust connect up a little differently than car parts typically, so no gasket matching. It was also a 4v head instead of 2. I also didnít know how thick it was so I didnít want to go too aggressive. But basically what I did was remove all the casting flashing, smooth out the dividers between the pairs of ports on both intake and exhaust. Then I attacked the short radii - the area in the valve that connect to the bottom of the ports. In particular the exhaust side on the 450 was bad, it was like a 90 degree sharp angle, so I rounded that off, smoothed, and blended it. Our Formula advisor was a hot rod guy who had built some wicked Olds 455 drag motors, including hand porting, and he gave me a lot of advice on this little sub-project. I listened and it paid off and didnít break anything. He told me on his Olds motors that short side radius, particularly on the exhaust side was where he picked up most of the power when porting, so focus your efforts there.

Beyond that, listen to everyones advice here on tools, there are some great suggestions. I did it with an air grinder with a 3/8 carbide bit and also some l ight D remel sanding in places. One word of advice, do not polish it. Leave about a 60 grit finish on it, it actually flows better than a mirror polish (its for the same reason golf balls have dimples).

Speed

> razorbeamteam

Speed

> razorbeamteam

09/29/2020 at 08:53 |

|

I havenít tried my hands at porting heads, but Iíve used a giant Milwaukee to clearance iron blocks for stroker cranks, modify the oil passages and port the inlet for the oil pump pick up. Cast iron is super forgiving because of the time and deliberate effort it takes to make ground, but aluminum will cut quickly and gum up. My brother has ported a few aluminums. Iíll see if he can send me some input to share.

I was using a big Milwaukee 11 amp like this †but I wonder if something like a 4 amp would work well for aluminum.†

Speed

> razorbeamteam

Speed

> razorbeamteam

09/29/2020 at 09:21 |

|

Donít hesitate to scour something like Facebook Marketplace to see if someone has some good used tools theyíll let go of for cheap. I wouldnít hesitate to pick up a Milwaukee like this if it was in good condition. A new one is roughly in the $300 neighborhood.

AMGtech - now with more recalls!

> razorbeamteam

AMGtech - now with more recalls!

> razorbeamteam

09/29/2020 at 10:04 |

|

Donít worry about specifically matching the gaskets as much as matching manifold openings to the heads and maintaining a smooth transition. If thereís a sudden spot in the airflow where the runner opens up extra wide, then necks right back down, you wonít be doing yourself any favors.

If you donít have non-ferrous carbides, find an unscented candle and run your carbides against it ever minute or so while grinding. The wax will keep the carbide from getting loaded up with aluminum.

IIRC, you can fit small block chevy valves in these. Go for nice ones with cut-down stems. Pair your port work and valves with a cam, and you might be up 30-50hp by the time itís all said and done.

Ooh, and cometic makes a multi layer steel gasket that works on these, available is custom thicknesses.

razorbeamteam

> AMGtech - now with more recalls!

razorbeamteam

> AMGtech - now with more recalls!

09/29/2020 at 10:46 |

|

I read something about having essentially a bubble of airspace by widening the ports to the gasket, results in less velocity as the air hits the wider portion.

Thanks for the tip on the gasket and valves. If you can use SBC valves then that gives me a lot more options to consider in terms of sizes.†