"TheRealBicycleBuck" (therealbicyclebuck)

"TheRealBicycleBuck" (therealbicyclebuck)

05/14/2020 at 09:15 ē Filed to: None

1

1

45

45

"TheRealBicycleBuck" (therealbicyclebuck)

"TheRealBicycleBuck" (therealbicyclebuck)

05/14/2020 at 09:15 ē Filed to: None |  1 1

|  45 45 |

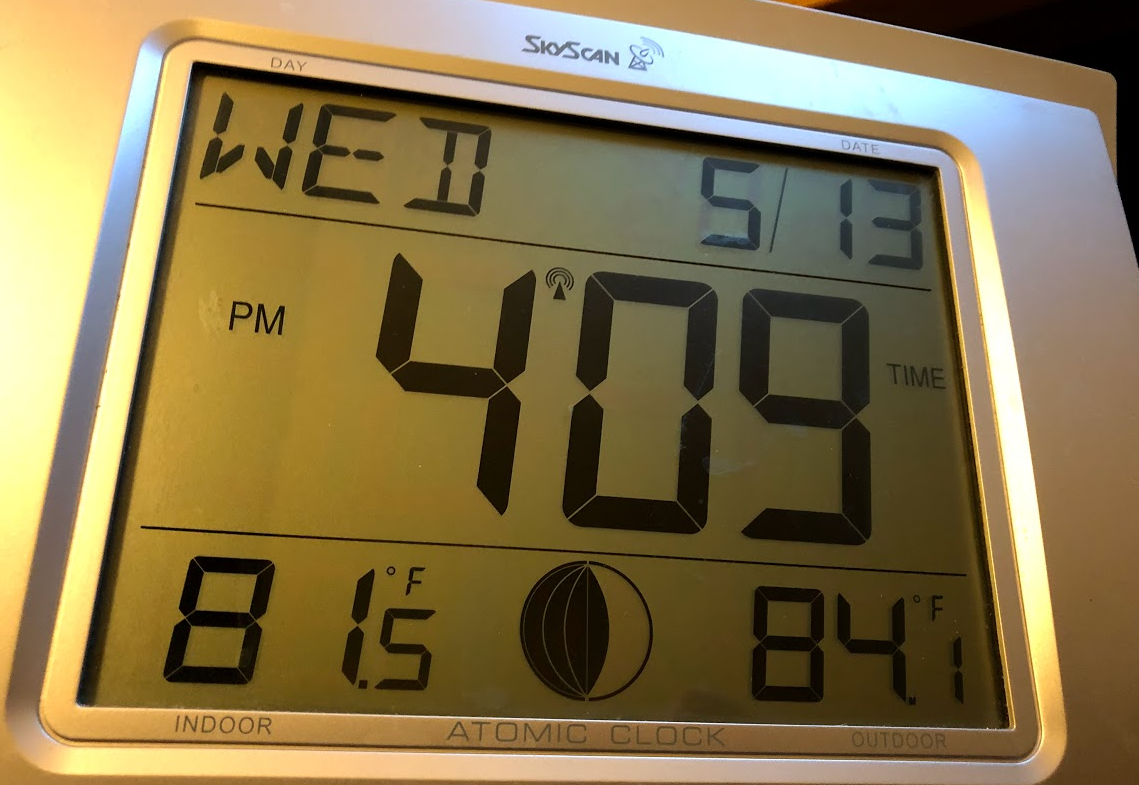

The temperature inside my office climbed even higher today. I stepped into the living room and discovered that it was a lot warmer than usual . Uh, oh. Sure enough, the a/c was freezing up.

So, we called in the experts. You have to understand that my BS detector

goes on high alert when any kind of ďprofessionalĒ comes into my home. Of course, t

he fellow the a/c company sent did the usual up-

sell routine. ď

Well, sir, considering the age of the unit, we should probably go ahead and replace the whole thing and not waste any time or money on repairing something that might fail next week.Ē

Yeah, right. First, letís get it de-iced and get your gauges connected to see where things stand.

First, he kicked on the heat to help speed up the deicing. We have a gas furnace located before the evaporator coils, so this was a quick way to remove some of the ice. Once it was done, the news was dire. ďSir, thereís oil all over the coils and that means that itís leaking everywhere. Iíd be surprised if there were any refrigerant left in the system.Ē

Well, he was surprised. His gauges told him that the system had slightly more refrigerant than it was supposed to. He said he ďrecoveredĒ some of the refrigerant to get the pressure down. I didnít see a tank and I did see him release refrigerant as he disconnected his gauges, so I doubt he recovered anything.

Funny thing, though. The last time refrigerant was added was at least three years ago when the prior technician found that the schrader valve used to recharge the system had a slow leak. That tells me that what he said about the evaporator coil being covered in oil indicating a leak is a bunch of BS. How would the system remain charged for at least three years with any kind of leak that would cover the coil with oil?

So, whatís going on with the system? The tech thinks the thermal expansion valve, the part that regulates the flow of refrigerant through the system, was stuck and he did what he could to get it open and flowing again. We know the system is getting old and will need to be replaced soon. My wife is already redesigning the system to be more space efficient and maximize performance. Right now, the air return is on the opposite side of the house from the a/c unit, so the return air has to flow through a 30' return duct which is probably a bit undersized for the unit.

Why did it ice up in the first place? Iím pretty sure someone didnít replace the filter when I asked and the dirty filter stopped the air flow. I should have climbed into the attic to check for icing myself. Thatís an easy fix if the problem was a lack of air flow. B ut my wife wanted a ďrealĒ technician to come check it out just in case.

Now our renovation plans include a new a/c unit sooner rather than later.

SilentButNotReallyDeadly...killed by G/O Media

> TheRealBicycleBuck

SilentButNotReallyDeadly...killed by G/O Media

> TheRealBicycleBuck

05/14/2020 at 09:22 |

|

Ahhh....air conditioning. Now that we live in a mud brick and earthen floored house with appropriate solar access and insulation...I don't miss it.

Exage03040 @ opposite-lock.com

> TheRealBicycleBuck

Exage03040 @ opposite-lock.com

> TheRealBicycleBuck

05/14/2020 at 09:39 |

|

What kind of idiot HVAC-R Tech finds a frozen AC

evaporator and suspects the charge might be low? You got a good

chuckle out of me this morning

.

TheRealBicycleBuck

> SilentButNotReallyDeadly...killed by G/O Media

TheRealBicycleBuck

> SilentButNotReallyDeadly...killed by G/O Media

05/14/2020 at 09:44 |

|

If we ever build a house, itís going to be a lot more energy efficient than this one. Although †this one hasnít been too bad, it could be a lot better.

SilentButNotReallyDeadly...killed by G/O Media

> TheRealBicycleBuck

SilentButNotReallyDeadly...killed by G/O Media

> TheRealBicycleBuck

05/14/2020 at 09:47 |

|

This is the second one we've rebuilt!

TheRealBicycleBuck

> Exage03040 @ opposite-lock.com

TheRealBicycleBuck

> Exage03040 @ opposite-lock.com

05/14/2020 at 09:49 |

|

Well, he wasnít wrong about that. If the level of refrigerant drops too low, then the temperature at the coils drops below freezing and ice forms. Low air flow, either due to a clogged filter (in my case) or a blower fan not working properly can also cause freezing because not enough air is moving across the coils. Without air movement to warm them up, the whole system gets colder and colder until ice forms.

Immediately assuming †that low refrigerant was the cause without any testing was his mistake.

HoustonRunner

> TheRealBicycleBuck

HoustonRunner

> TheRealBicycleBuck

05/14/2020 at 09:51 |

|

Iím lucky to have found a company my family has used now for about 10 years. It definitely took use two or three tries to find a good one, but they have been solid for us. †The units in my old house (which is now my rent house) are almost 20 years old, but they are still moving along with only minor issues the past few years.

HoustonRunner

> SilentButNotReallyDeadly...killed by G/O Media

HoustonRunner

> SilentButNotReallyDeadly...killed by G/O Media

05/14/2020 at 09:55 |

|

With the humidity in Houston I donít think that would work for us. Not to mention my house is 6 feet off the ground since Iím in a flood plain.

My house is only 3 years old so it is pretty well insulated, though each summer so far I try to find one or two ways I can improve just a little. †This summer it may be insulation on the garage door. †It faces west and gets pretty much full sun until late in the evening since the lot next to us is empty (and will be until 2099 or Harris County goes bankrupt).

TheRealBicycleBuck

> SilentButNotReallyDeadly...killed by G/O Media

TheRealBicycleBuck

> SilentButNotReallyDeadly...killed by G/O Media

05/14/2020 at 09:57 |

|

I was surprised to find that mud brick reinforced with spanish moss has been used in southern Louisiana. It looks like itís being used as a filler with wood strips throughout for bracing. A bit different technique, but mud brick, nonetheless!

https://prcno.org/bousillage-relearning-uniquely-louisiana-building-technique/

http://fitchfoundation.org/wp-content/uploads/2017/05/FITCH_Blokker-Knight_final_web.pdf

TheRealBicycleBuck

> HoustonRunner

TheRealBicycleBuck

> HoustonRunner

05/14/2020 at 09:59 |

|

If we werenít doing renovations and the current layout wasnít so inefficient, I would push to make repairs instead of buying a whole new system. Buying a new one will let us reconfigure it to something more appropriate for this house.

Exage03040 @ opposite-lock.com

> TheRealBicycleBuck

Exage03040 @ opposite-lock.com

> TheRealBicycleBuck

05/14/2020 at 10:01 |

|

If you have little to no

refrigeration

charge either by leak or improper amount

, ice wonít

ever

form on the evaporator

.

The unit

will have severely

reduced cooling capacity

if any

and

you just have a big expensive semi blocked

fan.

TheRealBicycleBuck

> Exage03040 @ opposite-lock.com

TheRealBicycleBuck

> Exage03040 @ opposite-lock.com

05/14/2020 at 10:04 |

|

True. He was, of course, speaking in hyperbole. Itís part of upselling the customer and itís BS.

Cash Rewards

> HoustonRunner

Cash Rewards

> HoustonRunner

05/14/2020 at 10:13 |

|

I just recently lost faith in our guys, and itís unnerving. Theyíve expended from just HVAC to include plumbing and electrical, and their prices have soared since they did that. So, time to find new guys , which sucks.

Jay, the practical enthusiast

> TheRealBicycleBuck

Jay, the practical enthusiast

> TheRealBicycleBuck

05/14/2020 at 10:23 |

|

Years ago when my mom bought her first house she had someone from a big company come over and check over the ac. Of course they said she needed an all new system. 6 months later the ac stopped blowing cold air so she called a different company. They found one of the lines looked like it had been intentionally loosened. They tightened it and charged it back up. The ac worked fine for another 15 years.

When we bought our house 7 years ago we had our ac checked by one of the big companies as part of the home inspection. They said we needed a new ac. Weíve spent about $300 repairing it ourselves but thatís still cheaper than buying a new unit like these companies always suggest.†

Exage03040 @ opposite-lock.com

> TheRealBicycleBuck

Exage03040 @ opposite-lock.com

> TheRealBicycleBuck

05/14/2020 at 10:24 |

|

I suppose, but itís a bit like calling an electrician for a flickering florescent light (ballast issue) and he tells you he suspects thereís no little to electricity to it. The light very

obviously has full

power to it

, this issue is current

regulation

...

I

f someone tried to pull that on me Iíd probably

send them

packing.

TheRealBicycleBuck

> Jay, the practical enthusiast

TheRealBicycleBuck

> Jay, the practical enthusiast

05/14/2020 at 10:48 |

|

I rented a room at my auntís house for a while. My room was really hot, so my aunt called in the a/c guys and they ď fixedĒ it. The room was hot again just a week later. She insisted it couldnít be because it was just repaired. She finally relented and called them again.

The refrigerant was low. They claimed they had a problem with kids following the trucks around and stealing the refrigerant from houses they just serviced so they could huff it. While that really was happening frequently enough to make the local news, I doubted it. Kids would have had to jump the privacy fence to get to the a/c unit. Iím sure itís possible, but I get the feeling that there may have been another cause.

Highlander-Datsuns are Forever

> TheRealBicycleBuck

Highlander-Datsuns are Forever

> TheRealBicycleBuck

05/14/2020 at 10:48 |

|

I hate slimy contractors like that. I have been fortunate to only encounter issues like this very rarely.

When our central heat went out on our house in January I found a good local small business and they had the thing diagnosed very quickly. Turned out the heat exchanger cracked and was pumping exhaust into our house which explains the head aches and general crankiness for a few days. Turns out they could get a replacement exchanger but it was like 6 weeks out. We found a program with our local utility for a low interest loan and bought a new system for about $10,000 and my god it was so much better than the old one. Our gas bill went down and the AC unit was so much better in the summer.

TheRealBicycleBuck

> Highlander-Datsuns are Forever

TheRealBicycleBuck

> Highlander-Datsuns are Forever

05/14/2020 at 10:57 |

|

Ours has some strange quirks. The return is on the opposite side of the house from the unit. It takes 30 feet of 16" flex duct to get the return air to the unit. Itís like sucking air through a very long straw. The flex duct is suspended from the rafters, so at best, the insulation is being compressed, at worst, the internal duct is kinked. I think they did this to limit the length of the gas and electrical connections since both the breaker box and gas meter are on the side of the house where the air handler is located. Weíre going to move things around to limit the use of flex duct under negative pressure and add balancing dampers so we can better balance the system.

Highlander-Datsuns are Forever

> TheRealBicycleBuck

Highlander-Datsuns are Forever

> TheRealBicycleBuck

05/14/2020 at 11:02 |

|

Our unit was initially installed and designed well, the return sat right under the unit. They did install new ducting as the old ducting was 30 years old and deteriorated. About 1/4 of the heat or chilled air was discharging into out attic.

I canít see a long return like that working very well, all that NPSH to overcome to get the air back and then push it again back into the house. Shortening up the return should help the fan efficiency greatly.†

RacinBob

> TheRealBicycleBuck

RacinBob

> TheRealBicycleBuck

05/14/2020 at 11:25 |

|

Say, I work in HVAC and I donít think the explanation on why low charge represented here causes icing is very satisfying.

The size of the coil, expansion device, and compressor are matched. The expansion device provides enough liquid refrigerant such that when boiled it matches the capacity of the compressor. The coil is sized to boil enough liquid refrigerant to match the compressor. When every thing works right, the refrigerant is flowing and boiling such that the temperature of the boil is about 40 degrees or less. And the amount of refrigerant boiling is such that by the time you get to the end of the coil its gone and all you have is cold vapor which is good because our freind the compressor hates compressing liquid.

Now the compressor does not modulate, it is 100% all the time. So what does the compresso r do if there is not enough refrigerant to boil or not enough heat to boil it. It pulls the same and the pressure in the system drops. As the pressure drops, the boiling temperature drops and if you get below 32 degrees boiling you start forming ice. That is why systems with low charge ice- Too much compressor for the amount of boiling refrigerant causes the refrigerant to boil too cold.

Ice formation is diabolical in that where there is ice, there is no heat transfer. So the liquid in the tube canít boil and moves until it finds tubes that arenít iced. Guess what, the refrigerant then boils and it ices there too and the process continues until you have a nice snowball. I am not a technician but I know of no way for an overcharged system to cause Icing. And if he did take charge out, he is not doing you any favors.

I am going to assume your system had enough charge to work properly. So why did it ice? First is you were probably correct to assume low airflow was the cause. We need heat in air to boil the refrigerant, if the filter or the coil is dirty you would not have enough heat input and it will boil at a lower temperature and ice. My bet is that was your problem.

It could be your expansion device, (this could be a valve or for most small systems it is probably a fixed orifice). If you get a chunk of something in the expansion device to restrict refrigerant flow, the coil will ice. Orifices are reliable so if it ever worked, I expect it to keep working. Valves do have problems, weíve changed my mother in lawís in florida. The plugging was because of some sort of wax deposit that plugs them. Either way, the tech should be able to diagnose a plugged exppansion device.

It could be just a warm but very low humidity day. About 75% if the cooling that the coil does is dehumidification. And a wet coil transmits lots of heat. So if it was a low humidity day but you ran the compressor for hours because say you set the thermostat setpoint to 65 f. You could end up frosting a coil. You have lots of capacity but not a lot of heat to boil the refrigerant.

My civic Si frosts its coil on march/april days when I have lots of sunlight load so I want AC but the outside air temp is not much over 70 and the air is dry. On a three hour trip I would find the AC would go quiet and hardly any air was coming out of the vents. If I turned off the compressor, it would blow cold about 10 minutes until all the ice melted and then I would be good for another 1/2 hour. This may be a factor for you too.

Though it is good for my business for you to buy a new unit, Your old one is fine as long as it holds charge, there are fins on the heat exchangers, the fans work and the compressor and expansion device works. I would run it and keep an eye on the coil to check for frosting. Assuming its clean and has correct airflow but it coninues to frost, I would have someone first check to make sure that there is enough charge. If that doesnít fix it, take a hard look at the expansion device. This aint rocket science, coils frost because there is something wrong, fix it and they work like they are supposed to.

It worked before, it will work again. Donít replace it till you have a reason such as a dead compressor or it needs a fix that is 60% the cost of new. My first home system lasted 30 years and we only replaced it because we needed the capcity for a new addition.

DipodomysDeserti

> TheRealBicycleBuck

DipodomysDeserti

> TheRealBicycleBuck

05/14/2020 at 11:25 |

|

I feel very fortunate to have a guy in my family circle that owns an AC company. I asked him about replacing my handler motor a few years ago. He told me if I could swap a transmission in my driveway I could swap a handler motor, and told me where to buy the motor.

Captain of the Enterprise

> TheRealBicycleBuck

Captain of the Enterprise

> TheRealBicycleBuck

05/14/2020 at 11:49 |

|

At our old house the filter would get clogged pretty quickly and then it would freeze over. We had two dogs at the time that sheíd a lot and never got our vents cleaned.†

TheRealBicycleBuck

> Highlander-Datsuns are Forever

TheRealBicycleBuck

> Highlander-Datsuns are Forever

05/14/2020 at 12:39 |

|

Thatís our thought too. Flex ducts should perform better under positive pressure.†

TheRealBicycleBuck

> RacinBob

TheRealBicycleBuck

> RacinBob

05/14/2020 at 12:49 |

|

Thank you for the detailed explanation. I had the concepts, but failed in putting them into words.

Ours has a variable expansion valve. When the system was checked last year, the pressures kept fluctuating. We were told that was an indication that the expansion valve was sticking and there may be some debris in the system. This tech said he thinks the valve is bent and should be replaced. He said that replacement would cost us close to $2k. I see that the valves are fairly cheap, so Iím questioning a labor charge of $1.9k. We will have another tech from a different company give us a quote before we make any repairs.

The long-term plan is to put in a new unit so we can reconfigure the ductwork and get a more efficient unit.†

Highlander-Datsuns are Forever

> TheRealBicycleBuck

Highlander-Datsuns are Forever

> TheRealBicycleBuck

05/14/2020 at 12:57 |

|

Return duct work should be sheet metal, flex ducting is a terrible choice.†

RacinBob

> TheRealBicycleBuck

RacinBob

> TheRealBicycleBuck

05/14/2020 at 13:04 |

|

You need a small one man shop HVAC tech. The work is probably a 4 hour job.

1. Arrive and evacuate the unit. (2 Hr)

2. Sweat in the new valve. (1 Hr)

3. Charge the system (1 Hr)

I would think a tech would be happy with $400 to $500 range. Ask around and see who people recommend. I suggest talking to people in the construction trade or mechanics. Somebody has a buddy who is in the HVAC trade who wouldnít mind trading an eveningís work for a five spot.....

Whatever the problem is, it is something major. HVAC is pretty simple and does not have to be perfect to work. Whatever the problem is, I am confident that for example flow or charge are not 10% off, they are more like 50% off. When you identify the problem, you will know it.....

By the way, what size, type and manufacturer is your system?

RacinBob

> TheRealBicycleBuck

RacinBob

> TheRealBicycleBuck

05/14/2020 at 13:10 |

|

By the way, every five years† or so lube the condenser fan bearings, and if they cannot be lubricated give the fan a spin and see if the bearings are still free. I swear condenser fans are the number one wear items and most easily repaired/maintained items.†

TheRealBicycleBuck

> RacinBob

TheRealBicycleBuck

> RacinBob

05/14/2020 at 13:26 |

|

After my mom passed, it was several months before I could get back to her place and start clearing it out. The first thing I heard when I pulled up was the loud hum of a motor that wasnít running. Sure enough, the condenser motor was locked up tight. I had a hell of a time finding a replacement motor on a S aturday morning , but I found one and replaced the fan and motor that afternoon.

I did that same job at my own house about five years ago, so Iíll take your advice and check the motor this weekend.

TheRealBicycleBuck

> RacinBob

TheRealBicycleBuck

> RacinBob

05/14/2020 at 13:47 |

|

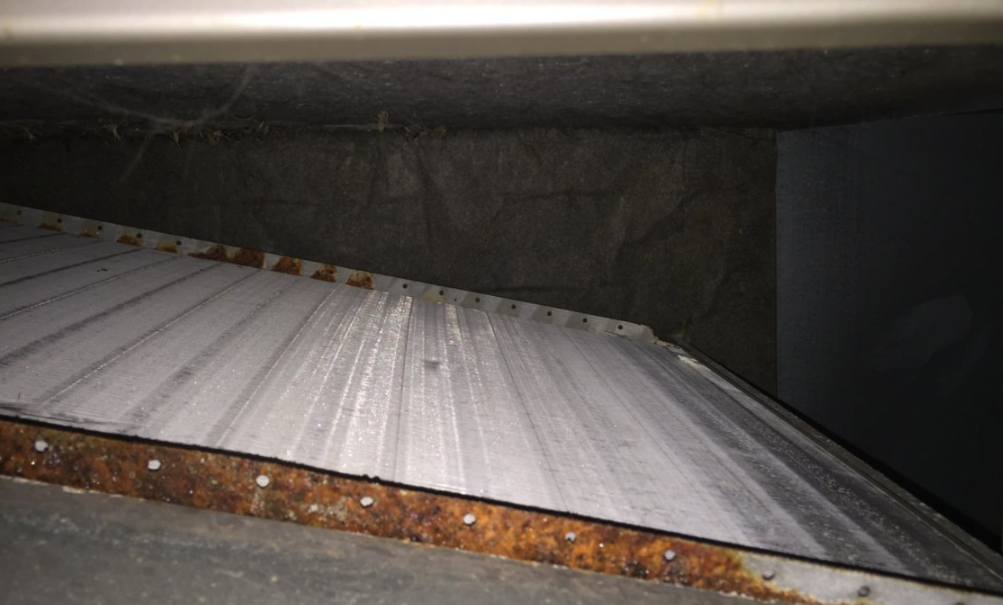

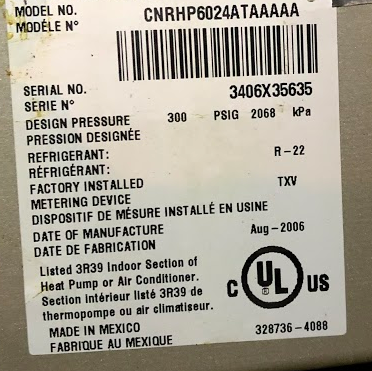

Without climbing into the attic, I know itís a Carrier and I think itís a 5-ton system. Type? Iím not sure how to answer that one. Hereís a pic I took when I was in the attic four years ago.

I donít know why builders in Louisiana hang them sideways from the rafters, but there you go. The cover has always had issues because the installer didnít run the gas line (yellow) through a punch-out and didnít make a cut-out in the door to accommodate the line. I popped the cover to the evaporator coil to see if it was frozen (it was). I took the se pictures after the ice melted. Other than rust, it looked pretty clean to me. Airflow is from left to right in both pictures.

RacinBob

> TheRealBicycleBuck

RacinBob

> TheRealBicycleBuck

05/14/2020 at 15:02 |

|

Looks like a cooling only system with a duct furnace upstream. Iíd guess 10 years old. The coil looks fine, the case has some rust but that is not a concern, Being in louisiana, I doubt you have to worry about too low of humidity. I would have expected suction pressure to be steady, so if it is not, Iíd think a plugged expansion valve to be a logical conclusion.

My mother in lawís 4 year old Trane system had one fail d

own in Florida my a couple of years ago. The mechanic said it was doe to some sort of contaminent in the oil/lines that was causing them to plug up. Not sure whoís fault it was, the oil in the Trane compressor, something coating the lines, or what. We replaced the valve and it has been fine ever since.

How an expansion valve stem could be bent is beyond my understanding. I donít think he knows either. Were it mine, I would consider taking a hair dryer and heating the bottom of the expansion valve to maybe 15 0 degrees down at the valve body (not the head) and then run it to see if anything changes. Maybe it would clear the goo . (BTW, this is assuming your attic is not 150 f every sunny day, if it is, donít bother.)

My biggest thing though would be to make sure the charge is not low as that would be the easiest and most obvious cause.

I hate it when mechanics assume their readings are correct and start changing charge because it easy . My bet is the charge was right or maybe even low and now is lower . ( Thanks buddy).

Itís just like I never let shops touch my alignment unless I know there is a problem. I swear for every three alignment jobs, one is where the alignment was good and the tech just made it worse by ďfixing itĒ . My philosophy is donít correct something that is hard to measure such as refrigerant charge unless you are sure it is way out of adjustment and known to be caus ing a problem.

TheRealBicycleBuck

> RacinBob

TheRealBicycleBuck

> RacinBob

05/14/2020 at 15:12 |

|

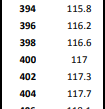

He said w hen he hooked up his gauges, the high side read nearly 400 psi. After the ice was cleared, he ran the system and he said the pressure was still a bit too high, so he ďrecoveredĒ some refrigerant (I went out there to check on him and didnít see a recovery tank).

I appreciate the feedback. We are going to get quotes to replace the valve and weíll see what they have to say.

RacinBob

> TheRealBicycleBuck

RacinBob

> TheRealBicycleBuck

05/14/2020 at 16:03 |

|

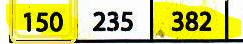

Yep, Iíll assume since it is Carrier that the system is R410a or Puron. A t 400 psi, that would be about 117 F saturated discharge temperature. https://www.bpa.gov/EE/Sectors/Residential/Documents/R-410A_Pressure_Temperature_Chart.pdf

That temp erature is a bit high though not crazy.

This looks like a site that shows some good diagnostic hints for high head pressure . https://inspectapedia.com/aircond/High_Head_Pressure_Diagnosis.php

This article talks about why coils frost. https://inspectapedia.com/aircond/Cooling_Coil_Frost_Ice.php

A common thread to both is charge amount expansion valve problems or plugged liquid line filter (though if it was a plugged filter the whole line would be frosted downstream of the filter) .

Here are some interesting reads from google search fluxuating suction pressure.

Debris in line and changing TXV https://hvac-talk.com/vbb/showthread.php?601822-Fluctuating-Suction-Pressure

This one discusses need to get charge correct. https://hvac-talk.com/vbb/showthread.php?1971991-Cause-of-pressure-fluctuation

another talking about TXV problems,

https://hvac-talk.com/vbb/showthread.php?149045-Unstable-suction-pressure

Back to the point. The problem to be solved is coil frosting. I would find a mechanic who could properly set the charge and confirm that charge is not a problem. That is not as easy as it sounds as the charge amount is different for each installation and it takes a while to figure these systems out.

It may very well be that the charge was low and that is why it was frosting. Then the TXV closes and that is why the head pressure is high. And the tech did further harm by taking even more charge out.

So first do everything you can to get the refrigerant charge correct and then and only then if you canít rule out the expansion valve being bad, c hange it and see if things improve.

My bet is frosting, high head pressure and fluctuating suction pressure are symptoms of a charge problem. If that is true, fix the charge and they will go away. Though we have to ask where did the charge go away?

Not being a technician, i

f you confirm charge is right, then it is a TXV. My gut says it is a plugged TXV, but donít jump to conclusions as a low charge would do most everything you are seeing too.

RacinBob

> RacinBob

RacinBob

> RacinBob

05/14/2020 at 16:05 |

|

PS, these are really basic problems. The difficulty is they are hard to diagnose. It would be a lot easier if the system was made of glass so you could see what the problem was...

TheRealBicycleBuck

> RacinBob

TheRealBicycleBuck

> RacinBob

05/14/2020 at 16:21 |

|

T he system is 13 years old and is charged with R-22. Iíll read through all the links this evening. Thank you very much for putting these together.

RacinBob

> TheRealBicycleBuck

RacinBob

> TheRealBicycleBuck

05/14/2020 at 17:14 |

|

Discharge temp is avout 12 to 15 f higher than outside ambient. So its maybe 100f. My chart which says at 382 psi R-22 is 150 f. If the tech thought it was R-22, he would have shut it down instantly. This is because at 150 f discharge plus and your compressor would be very shortly dead.

My AC was 2004 and it was one of the last R-22 Trane units sold. Carrier was an early adopter and I doubt they were selling any R-22 units by 2007. R-22 was phased out in 2010.

Now it leads to an interesting question which is did somebody put R-22 in the system? I think if they did, it would result in reduced pressure and capacity. When is the last time somebody put charge in the unit?†

TheRealBicycleBuck

> RacinBob

TheRealBicycleBuck

> RacinBob

05/14/2020 at 17:44 |

|

Now those are some interesting facts. Interesting enough to prompt me to climb into the attic. This is the tag on the unit:

Built in 2006 and filled with R-22. The house was completed in 2007.

It was last charged in 2016 or 2017. Thatís why I doubt the techís claim that itís ď

leaking everywhereĒ as can be seen by the ďoil all over the evaporator coil.Ē Yeah, buddy. Iím not seeing any oil on the coils.

SilentButNotReallyDeadly...killed by G/O Media

> HoustonRunner

SilentButNotReallyDeadly...killed by G/O Media

> HoustonRunner

05/14/2020 at 18:12 |

|

Yeah, mud brick is very much a building material whose practical use is governed by regional conditions.

I contend though that anyone currently designing, building or even renovating a house should challenge themselves during the design process to see if they can design out the need for artificial cooling and heating. Even if they are not successful in this...they will produce a house that will require much less heating and cooling. And that can only be a good thing.

RacinBob

> TheRealBicycleBuck

RacinBob

> TheRealBicycleBuck

05/14/2020 at 20:27 |

|

What does the sticker on the outside unit say? Itís the compressor that cares.

RacinBob

> TheRealBicycleBuck

RacinBob

> TheRealBicycleBuck

05/14/2020 at 20:30 |

|

Or whomever installed it used the wrong coil set. If he did, this might explain some stuff. https://hvac-talk.com/vbb/showthread.php?821122-R410a-TXV-vs-R22-TXV

TheRealBicycleBuck

> RacinBob

TheRealBicycleBuck

> RacinBob

05/14/2020 at 21:23 |

|

Itís raining and dark right now. Iíll check in the morning.

TheRealBicycleBuck

> RacinBob

TheRealBicycleBuck

> RacinBob

05/15/2020 at 09:25 |

|

I went out this morning to see if I could get a picture, but thereís no label on the outside of the unit. I can see a label on the compressor, but Iíll have to break out the tools tomorrow so I can get to it.

RacinBob

> TheRealBicycleBuck

RacinBob

> TheRealBicycleBuck

05/15/2020 at 10:57 |

|

Yep that is kind of odd not finding a nameplate as the condensing unit. The nameplate is required by code and UL, I cannot think of a reason why it would not be there. The nameplate would not be on the compressor, maybe it is under an access cover. One way to check what the refrigerant type is, is to just read the pressure and compare it to a pressure temperature chart for the various types.

I contemplated what would happen if you tried to run a 410a system with a R-22 valve and I think it matches up with what you are seeing.

In a charged running system, there should be enough refrigerant to fill the liquid line to the coil and mostly fill the cooling coil tubes while running. You donít want liquid refrigerant leaving the coil as it breaks the compressor. The TXV is there to prevent that. You also donít want refrigerant backed up into the condenser coil as it takes away condensing surface. That is why a high head pressure diagnosis usually leads to finding the system was overcharged.

You might want to watch this video on the TXV.

Now the trick here is that the refrigerant in the TXV bulb I have been told is the same refrigerant type as used in the application. I believe the reason they do this is so that the can have reasonable spring ranges in the valve.

So the problem is, ďwhat happens if you have at R-22 in the bulb at (69 PSI) and R-410A (118 PSI) in the system when running at a 40 degree operating temperature?Ē Answer; the pressure pushing the diaphhram closed is 49 pounds higher than the pressure on the top of the diaphram. As a result the TXV closes to its minimum position. This has a couple of outcomes.

1. The TXV is starving the coil of refrigerant, resulting in lower than expected expansion temperature which results in frosting.

2. The liquid refrigerant that should be in the coil is mostly not there, Instead it backs up into the condenser, resulting in higher than normal condensing pressure.

As I mentioned before, systems can be really screwed up and still work. My guess is that when you turn the system on, the valve is shut because the pressure differential. Then with all the refrigerant in the condenser, the condensing pressure rises and that pressure overcomes the TXV spring pressure and forces the valve open. So you get a gush of refrigerant that hits the coil and you get some cooling probably at a temp below freezing. However as soon as this happens, head pressure drops and the valve slams shut, and then the cycle repeats.

This would explain the frosting, it also explains the pressure cycling, and it explains why when he lowered the charge, the head pressure somewhat dropped. My bet is you will find that you have a R-410a condensing unit with what what is marked as a R-22 coil and TXV.

If I am right, I am thinking if you put the correct R-410a expansion valve on it, it will work correctly, have a lot more capacity, dehumidify better and may be more efficient.

One last thought is the question of ďshould I be worried that I am running a 300 PSI R-22 coil on 410aĒ. The answer is I donít know but I donít think so. http://www.jackappliancerepair.com/AC_PTChart.htm

R-410a hits 300 psi at 95 degrees so if your unit is idle the pressure at 95+ outdoors can get more than 300 PSI at the cooling coil. But the coils are proof tested at 1.5 working pressure and they are design tested at 3 times working pressure so there seems like plenty of margin. Also, my impression is that these designs are good for about 600 PSI or higher and that companies didnít really change anything in the tubing when they went from R-22 to 410a. Since it has lasted for 13 years my guess is it will not be a problem. And were it to fail, I believe the tube will split and that will be that. Were it mine, I would not replace the coil but that decision is up to you. Note that the tubes are a bit too large for a optimal 410a design but I donít think that makes much of a differance.

This leads to a really important point though. Any service company worried about their liability will refuse to service a 300 pound rated R-22 coil used on a 410a system. Itís ok for you to take the risk but they will not want any part of it. This is another reason to find a free lancer who isnít worried about liability. But if you do get caught, I would go to the guy that originally installed it and make him change the coil for as they are the ones that screwed up. Or in the alternative give you a new system at his cost.

If you want to confirm what you have, I believe you will find a part number on the TXV. Search the make and part number and you will know what you refrigerant it was designed for.

TheRealBicycleBuck

> RacinBob

TheRealBicycleBuck

> RacinBob

05/15/2020 at 11:14 |

|

Thanks for all the insight. Iím looking forward to finding the label on the condenser unit this weekend so we can solve this mystery.

RacinBob

> TheRealBicycleBuck

RacinBob

> TheRealBicycleBuck

05/15/2020 at 11:20 |

|

Yep, I am on furlough this week from my day job. I work with much larger AC systems mostly on controls. Questions like yours let me step back and think about how these things work. Its been interesting.

Today is l ast day of vacation, back to work Monday.

RacinBob

> TheRealBicycleBuck

RacinBob

> TheRealBicycleBuck

06/07/2020 at 19:00 |

|

Whatever did you find regarding your expansion valve ?

TheRealBicycleBuck

> RacinBob

TheRealBicycleBuck

> RacinBob

06/07/2020 at 20:12 |

|

I didnít have a chance to open up the condenser unit and get the information off it, but everything has been running fine, even if it isnít running optimally. I appreciate you asking and Iíll be sure to respond here once I get the info.