"PartyPooper2012" (PartyPooper2012)

"PartyPooper2012" (PartyPooper2012)

04/21/2020 at 12:15 ē Filed to: None

0

0

18

18

"PartyPooper2012" (PartyPooper2012)

"PartyPooper2012" (PartyPooper2012)

04/21/2020 at 12:15 ē Filed to: None |  0 0

|  18 18 |

Went to change oil yesterday. Got my oil drain pan out. The cap on it is trash. Any oil that builds up in the down portion of the spout, ends up dripping out. I was thinking - wouldnít it be great if the spout was pointing up a bit.

Am I reinventing the wheel here? Thoughts?

RamblinRover Luxury-Yacht

> PartyPooper2012

RamblinRover Luxury-Yacht

> PartyPooper2012

04/21/2020 at 12:27 |

|

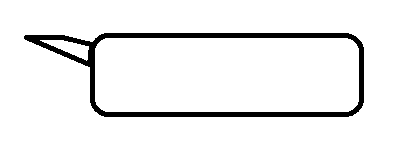

If the pan is mostly full, it needs to have a detachment edge so it drips free when you pour it, rather than running back down the spout. If the pan is open and unbaffled, you canít go all the way to a full tip with a spout type immediately.

So, with a partial tip like most people are doing , itís a tradeoff.

The best approach is probably a straight spout (tilted maybe a degree up

)

and a baffled pan.

PartyPooper2012

> RamblinRover Luxury-Yacht

PartyPooper2012

> RamblinRover Luxury-Yacht

04/21/2020 at 12:29 |

|

Know of any? my current pan is a closed top so if any oil were to leak out, it would be through the fill hole. I donít tip it aggressively so it shouldnít be an issue.

I just need any residual oil to flow back into the pan and not sit in the spout eating up the cap gasket.†

RamblinRover Luxury-Yacht

> PartyPooper2012

RamblinRover Luxury-Yacht

> PartyPooper2012

04/21/2020 at 12:36 |

|

I see a couple in existence that have a good baffle and a couple that have a short straight spout, but long straight spout + baffle... not seeing it. Thereís a FloTool one carried by WalMart and Advance that would be almost right if you cut off the outer part of the nozzle... but then youíd not have a working cap.

Might be possible to heat and bend, I dunno.

functionoverfashion

> PartyPooper2012

functionoverfashion

> PartyPooper2012

04/21/2020 at 12:39 |

|

I used to just use a kitty litter pan, and a funnel to pour it out into other containers. On my dirt driveway, I didnít mind if a few drops spilled, but if I did, that could have been mitigated also I am sure. I now have the same kind of pan, and yes, it drips out of that, itís annoying.†

PartyPooper2012

> RamblinRover Luxury-Yacht

PartyPooper2012

> RamblinRover Luxury-Yacht

04/21/2020 at 12:44 |

|

Yeah. looking at floTool people are happier with it, but the vent hole cap seems to break off. Not that it matters much

PartyPooper2012

> functionoverfashion

PartyPooper2012

> functionoverfashion

04/21/2020 at 12:46 |

|

I think they could have upped their game on the cap and would have been golden, but no.

Does anyone know if oil dissolves any of the 3D printer filament ? If there is one that does not get dissolved, maybe we can 3D print these caps in better quality?†

PartyPooper2012

> PartyPooper2012

PartyPooper2012

> PartyPooper2012

04/21/2020 at 12:55 |

|

Found this one - little bigger but it might still run into issues - this one does come with a rubber gasket on the fill cap, but the fill cap is sorta in the middle of the business area, not towards the top side. If this was stored vertically while full, it would probably leak out there.

functionoverfashion

> PartyPooper2012

functionoverfashion

> PartyPooper2012

04/21/2020 at 13:08 |

|

What about a flexible metal spout like those fancy gas cans? That seems like it would solve the problem.

like that, but on an oil pan.†

PartyPooper2012

> functionoverfashion

PartyPooper2012

> functionoverfashion

04/21/2020 at 13:12 |

|

This would require the car to be jacked up to the 10th floor. Too tall.

Flexible spout would work though. I donít see any available. FloTool seems like an ok solution. Maybe with an aftermarket gasket for the fill hole cap, it would work. Amazon has it for 22. Wallmart has it for 11.†

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> PartyPooper2012

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> PartyPooper2012

04/21/2020 at 13:30 |

|

PETG is relatively oil resistant, but will soften eventually, would probably be fine for prototyping/testing. You really need to go nylon, or acetyl homopolymer (aka POM, aka Delrin) to get long term oil resistance. I can tell you from experience that both are PITAs to print, and with POM you *MUST* have ventilation, and a heat enclosure is highly recommended. Nylon is doable without an enclosure as long as you can get good bed adhesion (lots and lots of Elmers PVA glue stick on glass has worked for me) and your bed temp can hold 110C+ for the whole print. The larger the area the more likelyhood of warping and loss of bed adhesion... but again, itís doable.

edit: some places say PLA has excellent resistance to oils and grease, but low tolerance to diesel and petrol. Polypropylene would be ideal, but bed adhesion is a super bitch and a half.

functionoverfashion

> PartyPooper2012

functionoverfashion

> PartyPooper2012

04/21/2020 at 13:35 |

|

lol I just mean the spout, not the whole can. Although I could probably get that can under my truck no problem.†

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> RamblinRover Luxury-Yacht

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> RamblinRover Luxury-Yacht

04/21/2020 at 13:49 |

|

found this one:

I may just buy two , I need to do a hydraulic flui d change on the Zetor, capacity is 12 gallons, and I donít have storage bigger than 5 gal anyway, so a 5 gall on pan makes sense...

PartyPooper2012

> functionoverfashion

PartyPooper2012

> functionoverfashion

04/21/2020 at 14:48 |

|

I would struggle kicking it under corvette...

PartyPooper2012

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

PartyPooper2012

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

04/21/2020 at 15:02 |

|

Polyoxymethylene (POM) filament is also known as Acetal or Polyacetal. The company DuPont uses the trade name Delrin for Acetal Resin. It is a commonly used thermoplastic to engineer specific parts. Acetal filament has high stiffness, low friction, and excellent wear resistance. It has good elastic resilience and great dimensional stability. The filament has good chemical and heat resistance. Because of itís low friction, POM is routinely used as gear wheels, ball bearings, etc. It has high impact resistance, which is one of the reasons the M16 rifleís stock is made out of POM.

The recommended print temperature is between 210įC - 220įC. POM can be printed on a heated bed plate 100įC - 130įC. Acetal does not adhere well to any of the typical 3D printer bed surfaces. Using wood or cellulose based platforms to print on is the best alternative. A cheap and quick alternative is to use a thick resume or sketch paper, roughly 80 pound weight. Glue down the paper with Elmerís glue stick on top of your printer bed which is typically metal or borosilicate glass. Some users print using blue tape covered with hairspray. Not all blue tape and hairspray are the same. If you have a heated chamber, then please remember to pre-heat your chamber to reduce warping. Printing in an enclosed chamber will help with delamination. Please keep Acetal away from moisture and always keep filament in an airtight container with a desiccant.

I think I can deal... who uses wood bed tho? Like plywood? Youíd have to recalibrate? Sorry. Just ordered my first 3d printer. Know nothing so far. Been watching youtube videos. How would a heated bed work with wood? Probably wouldnít. Also would probably be higher than normal bed.

Piece of plywood? wild

†

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> PartyPooper2012

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> PartyPooper2012

04/21/2020 at 15:41 |

|

POM is the warpiest material Iíve ever printed with. Bed adhesion is definitely the FIRST step, but it readily delaminates if not printed in a heated chamber... At least in my experience... It also outgases a lot and requires ventilation. I found Nylon, and even polycarbonate to be easier to print (though they both require much higher nozzle temps, near 300c - or even over- for PC!) make sure you have an "all metal" hot end that is rated for those high nozzle temps before trying to print Nylon or PC, if your PTFE nozzle throat melts it's both a very bad idea to breathe the fumes, and a complete shitshow to clean up.†

PartyPooper2012

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

PartyPooper2012

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

04/21/2020 at 15:53 |

|

Got you. I can probably print in garage on a hot summer day. Iíll have to shop for some different extruder nozzles. Lots to learn here.†

Urambo Tauro

> PartyPooper2012

Urambo Tauro

> PartyPooper2012

04/21/2020 at 19:02 |

|

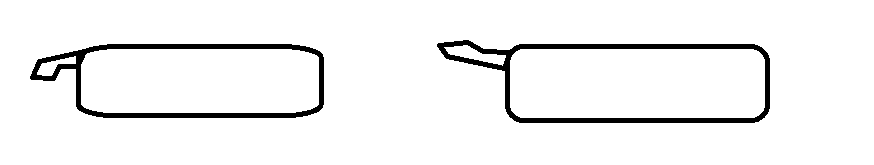

Sometimes I wonder if they ever bothered to perform any product testing. Hereís another one for ya- N ever ever buy one of these :

I made that mistake. T he curvatur e of the spout allows oil to pour out in a sheet roughly 3 inches wide. Useless for pouring back into a jug.

PartyPooper2012

> Urambo Tauro

PartyPooper2012

> Urambo Tauro

04/22/2020 at 08:16 |

|

How hard could it be to injection mold an oil drip pan with the right geometry?

God damn teapot has a spout. A good one does not leak from the nose when poured. A good one, does not leak from fill hole either.

Itís a simple friggin container and they fuck it up. WHY?

There. I designed it.