"Takuro Spirit" (takurospirit)

"Takuro Spirit" (takurospirit)

04/06/2020 at 11:53 ē Filed to: trans amess, esprit, project car, parts car, trans am

4

4

19

19

"Takuro Spirit" (takurospirit)

"Takuro Spirit" (takurospirit)

04/06/2020 at 11:53 ē Filed to: trans amess, esprit, project car, parts car, trans am |  4 4

|  19 19 |

Like removing the Jeep from the garage and putting the Trans Am back into prime position to start doing the bodywork on it.

Because its nice out. And the Jeep has remote start. Not that we need to warm it up to take the kids to school anymore... Not that the Jeep even moves from the driveway every day.

Iíve been borrowing my delivery van from work since my wife works from home 2-3 days a week. Iíll do a review of it someday, its a 2008 with a 3.3 and 195k on it.

This is its GOOD SIDE:

Anywho, since I have the room in the garage to Do Work now, I started by pulling apart the rear end out of the Esprit parts car that Iíve had sitting all winter. I was in a rush to get rid of the smaller lighter parts before it got too cold out, and now all thatís left are the biggest and heaviest. The rear axle/springs have been in the garage so it came first. The engine/trans/front subframe have been outside all winter. Theyíre next. Which is also where the van comes into play. I need it to transport the rusty old junk to the scrap pile at work. And it needs to FIT in the van (

and be light enough to load)

so its gotta come apart.

The right rear wheel was stuck when I bought it, we never got it freed up, which made loading and unloading a bear. I wish we had tried harder.

But first I popped the cover off and for sitting in a field for 20 years with 133k on the car , the fluid was pretty good. It had obviously been changed.

Sadly being an Espirt, it had just an open diff with probably 2.43 gears or some silly high ratio highway gears. I wasnít able to read the stamping on the tube where Pontiac put them because rust . Not much value here, but Iím keeping the axles and carrier for parts JIC for my 3.23 Posi Trans Am rear .

The unstuck brake was mostly because someone had already dismantled it. No shoes to be found. I pulled this axle then went after the stuck side.

After some persuading with a couple pry bars on the backing plate, the drum came free of the shoes and the axle slid out . Like I said, we should have tried harder back in the day .

Axles out, I felt it was a good time to remove what was left of the leaf springs . Surprisingly , I didnít have to cut any hardware off. The U-bolts and retaining/shock plate nuts came off without drama. But the springs refused to move from the channels they fit into on the axle saddles.

Out came the air hammer and chisels.

It made quite the mess, but success was had. Along with ringing ears. And annoyed neighbors. And today a sore everything. Iím getting too old for this...

Pulling the carrier was next, also with the help of some pry bars and some light persuading.

By now my garage reeks of old gear lube and rust, and I get to load all this scrap in the van tonight and attack this hunk of junk next.

Not sure if I want to make a coffee table, or try to see if its at all salvageable. I mena, it DOES RUN.... but its a gutless 301 that no one makes performance parts for so thereís no real reason to keep it or try to sell it as is.

Right?

lone_liberal

> Takuro Spirit

lone_liberal

> Takuro Spirit

04/06/2020 at 12:05 |

|

O ld gear lube and rust. The smell of champions! They should sell it as a cologne so you sit out in the garage and drink beer and relax and still smell like you were doing shit.†

Future next gen S2000 owner

> Takuro Spirit

Future next gen S2000 owner

> Takuro Spirit

04/06/2020 at 12:08 |

|

You could make a pretty sweet boat anchor.

Highlander-Datsuns are Forever

> Takuro Spirit

Highlander-Datsuns are Forever

> Takuro Spirit

04/06/2020 at 12:10 |

|

I want an old gear lube and rust scented candle.†

TheRealBicycleBuck

> Takuro Spirit

TheRealBicycleBuck

> Takuro Spirit

04/06/2020 at 12:11 |

|

My first work-on-a-car moment that I remember came when I was six (?) and my uncle and I were put to work changing the brakes on my grandmaís car. We were working in the street in front of her house. The rear drums were rusted in place, so we had to smack them with a small sledge hammer to get them loose. It was the first time I was given permission to hit something with a big hammer, so I had playground bragging rights for at least a month. Iím sure I was in the way more than I was helpful, but I canít thank my uncle enough for giving me the chance to help.†

The Swedish Bandit

> Takuro Spirit

The Swedish Bandit

> Takuro Spirit

04/06/2020 at 12:13 |

|

Donít scrap the rear end housing. If itís the 8.5" it can be rebuilt to a pretty stout axle.

Detroit truetrac locker, 3.73 gears, 31 spine axles. Should be able to buy for under 10 grand. †

Takuro Spirit

> lone_liberal

Takuro Spirit

> lone_liberal

04/06/2020 at 12:14 |

|

Keeps most family members away too for maximum Me Time!

Takuro Spirit

> The Swedish Bandit

Takuro Spirit

> The Swedish Bandit

04/06/2020 at 12:16 |

|

Its just a 10 bolt with enough rust and scale to scare away any buyer... there are a million of these out there in various configurations, all better than this one.

The Swedish Bandit

> Takuro Spirit

The Swedish Bandit

> Takuro Spirit

04/06/2020 at 12:26 |

|

Ahh okay. Doesnít look horrible in the pictures but if you say so.

The 301 on the other hand; pull all the accessories, valve covers, bolts, etc. Then junk the block.

Stapleface-Now Hyphenated!

> Takuro Spirit

Stapleface-Now Hyphenated!

> Takuro Spirit

04/06/2020 at 12:37 |

|

Where the heck was that Esprit sitting when you got it?† I donít think Iíve ever seen a set of leaf springs rust through to the point of a hole like that.††

The Swedish Bandit

> Takuro Spirit

The Swedish Bandit

> Takuro Spirit

04/06/2020 at 13:13 |

|

Also 2 engine stands as a rotisserie?! Thatís actually really clever! Wish †I would have thought of that.

PyramidHat

> Takuro Spirit

PyramidHat

> Takuro Spirit

04/06/2020 at 13:20 |

|

Is the body on...engine stands? †Howíd you get it up there? †Jack it way the hell up and the drop everything underneath?

Takuro Spirit

> PyramidHat

Takuro Spirit

> PyramidHat

04/06/2020 at 13:23 |

|

Yes. Its my ghetto 3/4 rotisserie. I dropped everything from underneath and THEN jacked/lifted it onto the stands. The bare body is quite light, so long as one end is supported.

Takuro Spirit

> Stapleface-Now Hyphenated!

Takuro Spirit

> Stapleface-Now Hyphenated!

04/06/2020 at 13:25 |

|

In a field, I was told.

Everything had holes in it.

Takuro Spirit

> The Swedish Bandit

Takuro Spirit

> The Swedish Bandit

04/06/2020 at 13:27 |

|

I did some research on homemade rotisseries . I saw on that was two stands with the necks cut and extended to swing the car all the way around, but I just need to get it to near 90 degrees, which this does.

Then I can still use them as engine stands in the future, maybe for the 301 block as I turn it into a coffee table ;)

The Swedish Bandit

> Takuro Spirit

The Swedish Bandit

> Takuro Spirit

04/06/2020 at 13:38 |

|

Exactly! Cheap, simple, yet effective. Iím definitely doing the same for my next build as well.

Takuro Spirit

> The Swedish Bandit

Takuro Spirit

> The Swedish Bandit

04/06/2020 at 13:44 |

|

Plus if youíve never welded (like me) its a good way to learn. The hardest part was figuring out how to attach the car to the stands.

The Swedish Bandit

> Takuro Spirit

The Swedish Bandit

> Takuro Spirit

04/06/2020 at 13:53 |

|

Nice! Iím guessing finding the centre of gravity were it wouldnít fall over all the time must have been a bit tricky as well?

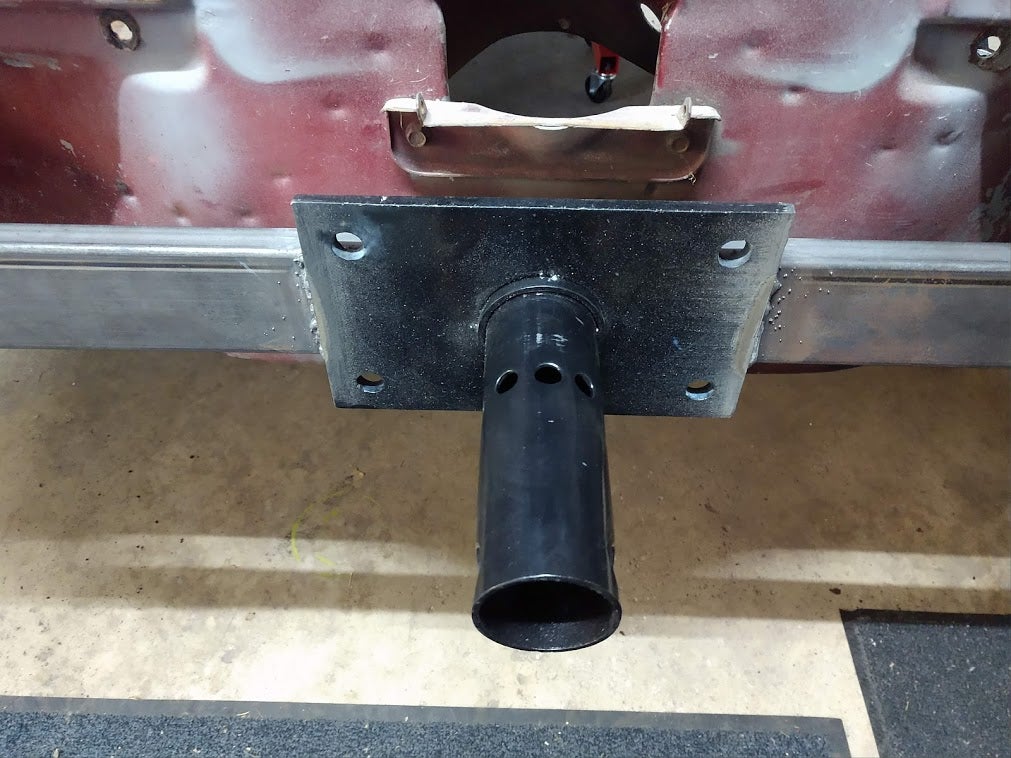

How is the beam connected to the standí s mounting surface, just clamped with a piece of thick metal and some bolts?

Takuro Spirit

> The Swedish Bandit

Takuro Spirit

> The Swedish Bandit

04/06/2020 at 14:41 |

|

I measured about a hundred times to find the exact center. In the back it was easy, measuring off the bumper mounts. The front where there the subframe/inner fenders mount was a bit more tricky. The stands are quite sturdy and any amount of me shoving the car sideways doesnít tip it at all. Even rotated its pretty sturdy, though it doesnít look like it.

The standís head is welded to some square tube stock

Front and back, strapped, and bolted, and welded some more

Its overkill, but I didnít want to be woken up in the middle of the night by the car falling off the stands.... or having it fall while I was working on it.

The Swedish Bandit

> Takuro Spirit

The Swedish Bandit

> Takuro Spirit

04/06/2020 at 15:33 |

|

Wow thatís awesome! Thanks for the detailed p ics.

I agree with your philosophy. Better do it overkill now than to be sorry later.