"thejustache" (thejustache)

"thejustache" (thejustache)

11/02/2020 at 15:55 ē Filed to: None

7

7

14

14

"thejustache" (thejustache)

"thejustache" (thejustache)

11/02/2020 at 15:55 ē Filed to: None |  7 7

|  14 14 |

A month or so ago I asked on here for advice about buying a welder. The prevailing recommendation was almost overwhelmingly Ďbuy a Hobart 140'. Iím here to say that I ignored that advice in spectacular fashion and ended up buying something even I wasnít sure about: !!!error: Indecipherable SUB-paragraph formatting!!!

Iím also happy to say that while Iíve barely used the thing yet, I think I made the right choice for me. Let me explain.

Minus the post vise, this was what I was sold to re-up my home shop

A number of years ago as a nerdy homeschooled teenager I got into blacksmithing. I never got super good, but I became obsessed with learning to forge weld. I burnt a lot of steel trying to smack two white-hot pieces coated in borax into one. While I was sometimes successful , I probably should have realized there was a better way for me and moved on.

Fast forward 15 years or so, and the equipment I had was moving from storage to storage with no place to set it up. My brother-in-law gave me an old stick welder, but my workspace is in the basement rather than a garage. This made it almost impossible to lug the machine around when it was time to use it.

Cleaning up the shed this fall gave me an idea - what if I sold the blacksmithing stuff and bought a welder I could actually move around? I ended up giving the post vise away to a friend that does Ferrier work, and then sold the rest as a bundle for $550.

While that could have landed me the aforementioned Hobart handler 140, I had 2 issues with that plan. First, while the Hobart is no doubt much more portable than the old Forney stick welder I had, itís still transformer based and therefore a bit of a clunker these days. True, it would probably last forever, but having used an inverter welder before I decided I wanted something even smaller and lighter. Lastly, I kind of like stick welding and decided it would be handy to have a machine that could do that in a pinch too.

So I started looking at inverter MIG/Stick welders, but then something else happened : I developed a need for an air compressor. Not wanting to waste much of the welder budget but wanting something big enough for light shop duty, I ended up using a coupon and picked up this guy - the HF McGraw 20 gallon.

So basically that left me with 2 choices: hold off on buying a welder for a while and save, or get something stupid cheap. So naturally, I did the latter.

Oddly, Sungoldpower (looks like they originally started selling solar panels and power inverters, hence the name) sells 2 very similar welders with about a $140 price difference. They are both dual voltage MIG/Stick welders, one 190 amp and the other 200 amp. Other than the 10 amps and the color, the only functional difference I could see was the more expensive machine had a 4 pin mig gun, which could support a spool gun for aluminum.

I decided that wasnít worth it and bought the cheaper unit, under $300 with a 4 year warranty. As it turns out, the machine I was sent actually has a 4 pin gun (unlike the photos on Amazon). Score! Other than that, itís about as Iíd expect. Quality on the welder itself seems decent, but the leads are laughably short and cheap. At least thatís an easy upgrade!

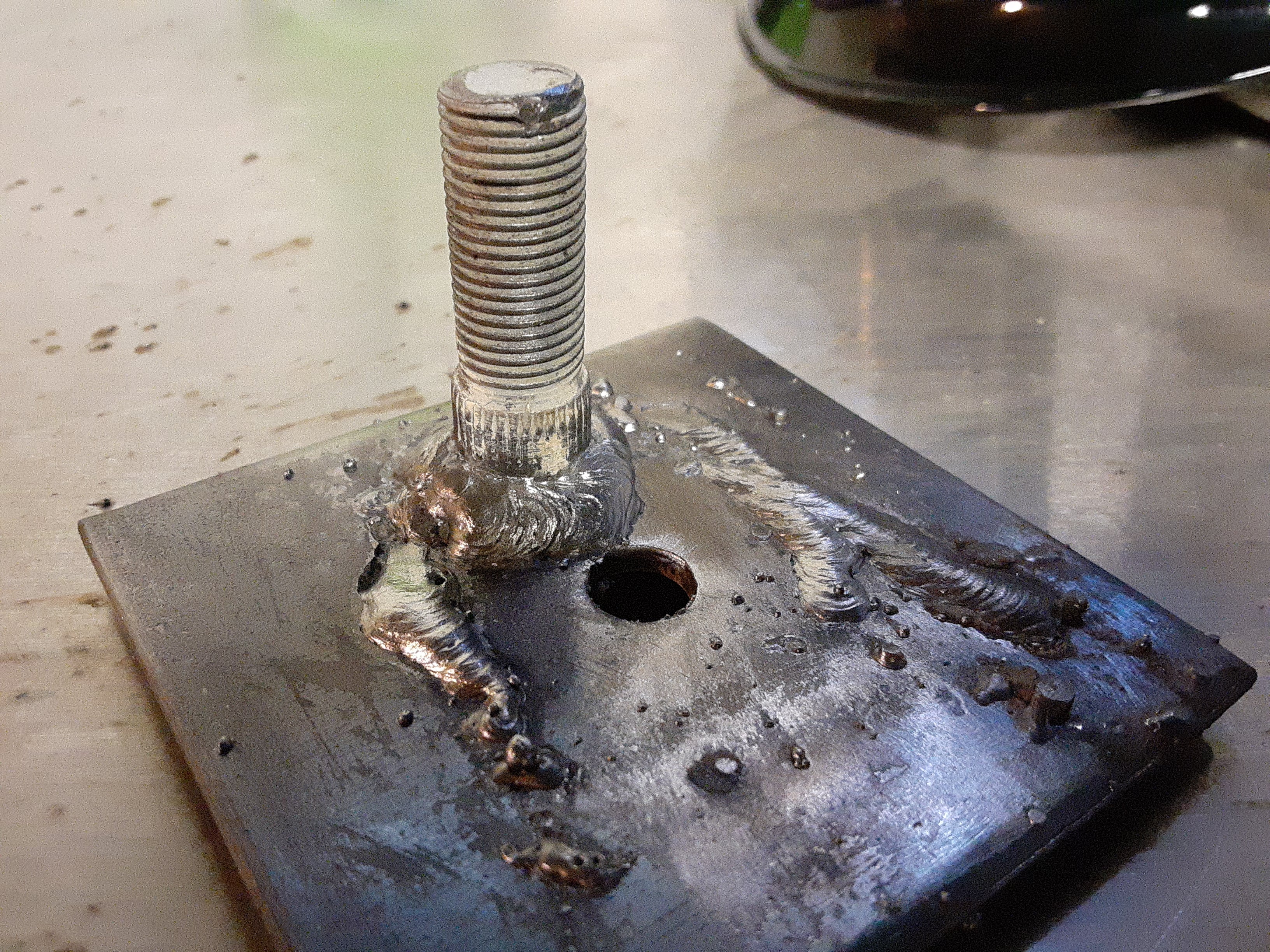

Ugly, but that bolt is not going anywhere

So does it weld? So far Iíve only run a few test beads, and Iíll need to save up for a gas tank and regulator so itís flux only. At my level of welding, which is Ďglue metal to metalí it seems great so far. The arc is smooth and steady and itís much easier to use than stick. Iíve got a lot of learning to do, but as long as it keeps running Iím pretty sure this machine will be able to keep up with whatever hobby or automotive projects I throw at it.

So for under $300 I have a capable flux/stick machine. Add a bottle of mixed gas and solid wire, and I can MIG . Add a bottle of Argon and a spool gun, and I should be able to do aluminum. At that point I could probably get a tig torch with a gas valve and try some basic scratch start tig. If it can last me 4 years (or I can buy another with the warranty) and lets me try all that, Iíll consider it a win.

In order to celebrate the underdog , I decided to give its blue exterior a hand cut Miller spoof decal. ladies and gentleman, I give you the Mill-eh. May it live forever (or at least the next 4 years).

Stainless steel darkroom sink? Or makeshift welding table? You decide

Finally, after 2 years of thinking about it I finally pulled the motor out of my KZ750 twin and hauled it into the basement for a winter top end rebuild. I donít think Iíll need the welder at all for this project, but Iím glad to finally be getting to it. First things first though - I think I need to build an engine stand.

Sad motor is sad

VincentMalamute-Kim

> thejustache

VincentMalamute-Kim

> thejustache

11/02/2020 at 16:24 |

|

You got me with the photo. Didnít look at it closely and was discombobulated when I read ďOne of the cheapest dual voltage MIG welders on AmazonĒ.

Iím also surprised at how good the weld looks for cheap-ass

welder, flux-core, beginner.

thejustache

> VincentMalamute-Kim

thejustache

> VincentMalamute-Kim

11/02/2020 at 16:30 |

|

I figure that blue color HAD to have been intentional, right? Why not lean into it...

Iím impressed so far. Time will tell how it holds up

BaconSandwich is tasty.

> thejustache

BaconSandwich is tasty.

> thejustache

11/02/2020 at 16:34 |

|

That actually looks not that bad for the price. Welcome to the club!

thejustache

> BaconSandwich is tasty.

thejustache

> BaconSandwich is tasty.

11/02/2020 at 16:45 |

|

Thanks!

AdverseMartyr

> thejustache

AdverseMartyr

> thejustache

11/03/2020 at 05:52 |

|

a skateboard with cardboard is a better engine stand than many I have seen/used.

SBA Thanks You For All The Fish

> thejustache

SBA Thanks You For All The Fish

> thejustache

11/03/2020 at 06:31 |

|

I love the element of wildly ignoring the OPPOhive advice. Itís called ďoppoĒ for a reason...

Looks like a great buy and a smart move.† Keep us posted!

Sovande

> thejustache

Sovande

> thejustache

11/03/2020 at 08:30 |

|

I bet replacing the leads would cost half the price of the machine but i t seems like its small enough to easily move to the work, so thatís cool. I wouldnít trust that bolt weld with my life - it looks like the weld is just sitting on top of the base metal, like maybe it needed more heat. Whatís the max stated material thickness you can weld with that machine ? These little boxes seem like they would be great since they are so small and portable. Let us know how it holds up!

Sovande

> thejustache

Sovande

> thejustache

11/03/2020 at 08:33 |

|

It also looks like they have a unit that will allow you to run gas for MIG welding. And itís cheap!

Michael

> thejustache

Michael

> thejustache

11/03/2020 at 09:21 |

|

Looks like a ďMill-ehĒ

Thatís gotta be on purpose, too

thejustache

> Sovande

thejustache

> Sovande

11/03/2020 at 09:46 |

|

The one I have takes gas as well, I just need to get a regulator and a bottle

thejustache

> Sovande

thejustache

> Sovande

11/03/2020 at 09:54 |

|

Youíre not too far off - I can get 20' of #2 wire for around $40, so with a better stinger and ground clamp that might be $100 to make a better set of 10' leads. Still might consider it worth it in the long run if it lasts.

Iím sure youíre right about that weld. I will say, the rim around the bolt was quite thick and it ate into it quite a bit. Perhaps all the penetration got directed into the bolt rather than ty ing it into the base? Or it was just too cold. That was the first 2 pieces of metal I tried to stick together and the settings were a total guess. Voltage and wire speed were both about half way.

Iíll let you know how it holds up!

thejustache

> Michael

thejustache

> Michael

11/03/2020 at 09:55 |

|

Well yes, intentional by me

Michael

> thejustache

Michael

> thejustache

11/03/2020 at 10:07 |

|

Ah, I missed that part. Excellent pun-craft!

Sovande

> thejustache

Sovande

> thejustache

11/03/2020 at 10:14 |

|

Oh damn, thatís nice!