"sony1492" (sony1492)

"sony1492" (sony1492)

10/11/2020 at 11:41 • Filed to: locost

13

13

8

8

"sony1492" (sony1492)

"sony1492" (sony1492)

10/11/2020 at 11:41 • Filed to: locost |  13 13

|  8 8 |

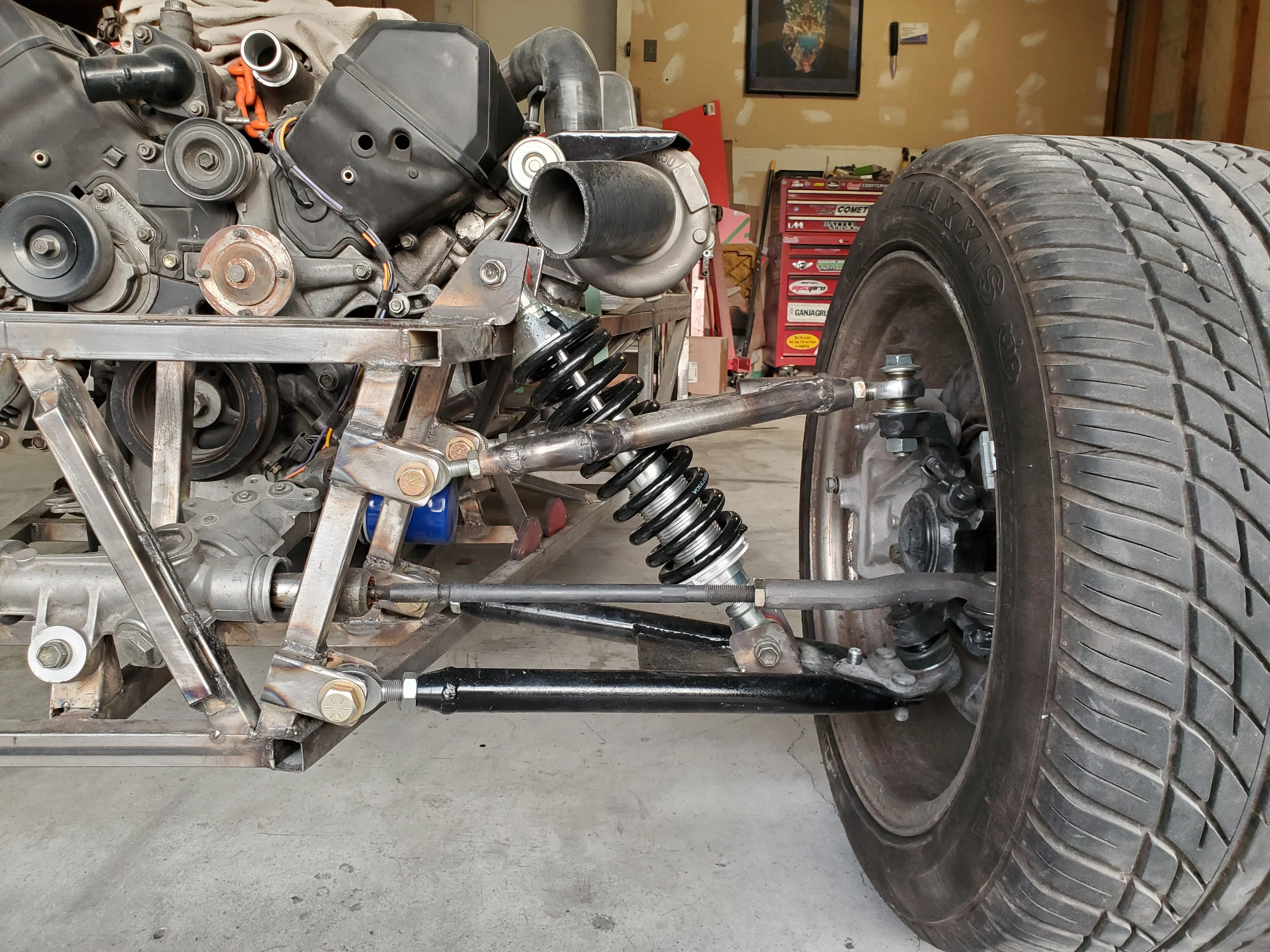

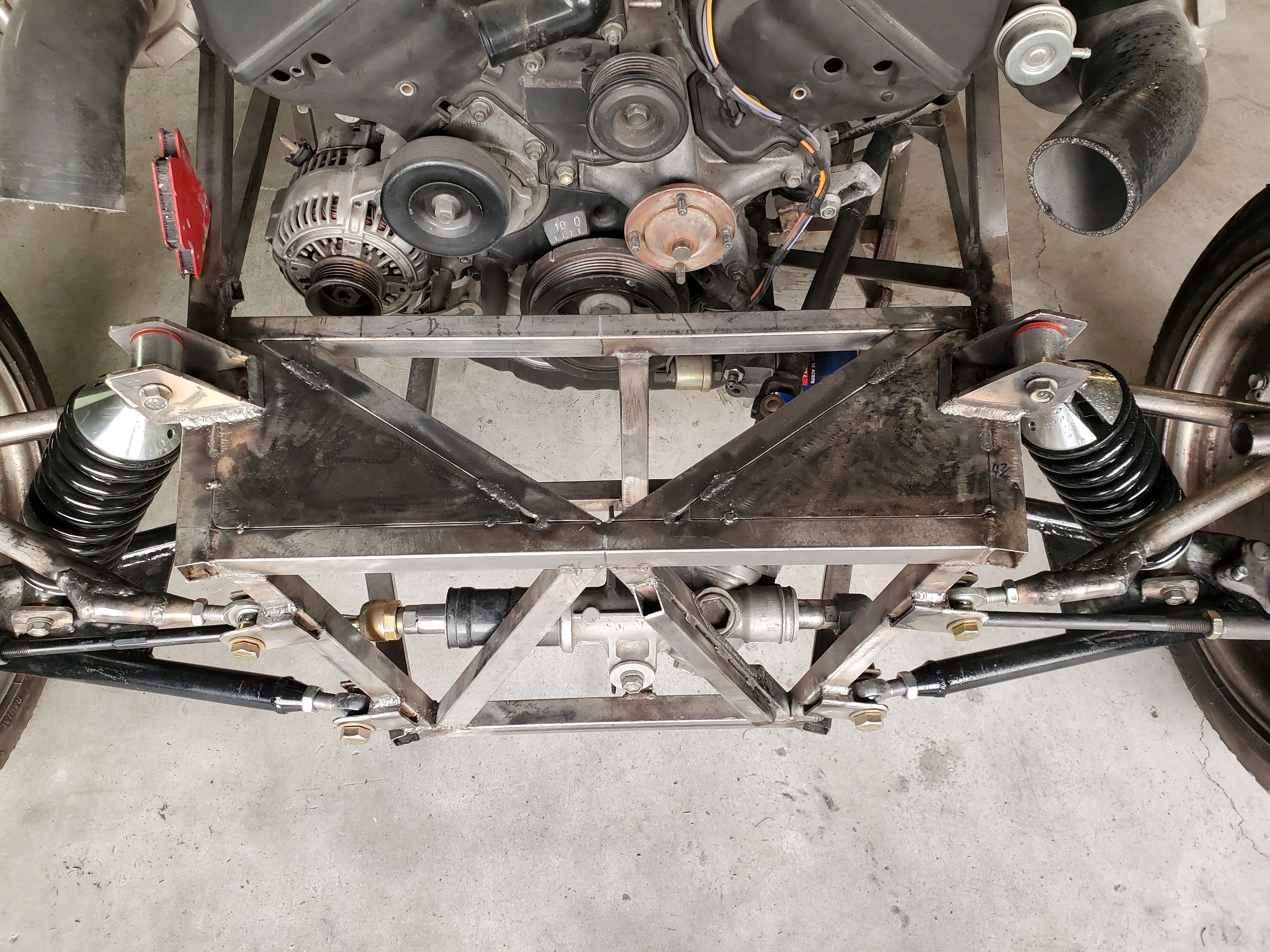

Photo dosent do justice how wide and low it looks, despite 7" of ride height(which should settle closer to 5.5" as it gets finished)

Made the shock mounts with 4.75mm steel plate, then on the chassis a 2.75mm plate was set down to act as a brace and to give the shock mount somthing to weld to.You can imagine the disaster that would be welding it to just the square tube with 1.3mm wall and no support from twist.

This is welded in enough to hold the weight, but not finished.

Finally the 3/4 of a car is suspended on its own!

Here is a more traditional setup for reference.

I like cars: Jim Spanfeller is one ugly motherfucker

> sony1492

I like cars: Jim Spanfeller is one ugly motherfucker

> sony1492

10/10/2020 at 22:38 |

|

Sick! What did you end up doing for the bracing about the engine?

Keep in mind too that those heim joints will get pretty noisy every few thousand miles. They’re not cheap either.

BaconSandwich is tasty.

> sony1492

BaconSandwich is tasty.

> sony1492

10/10/2020 at 22:41 |

|

The lower control arms - did you make those?

sony1492

> I like cars: Jim Spanfeller is one ugly motherfucker

sony1492

> I like cars: Jim Spanfeller is one ugly motherfucker

10/10/2020 at 22:44 |

|

A bolt in brace will get added down the line between the shocks and firewall with 1.5" round tube.(same as rollbar)

A few thousand miles without major repair sounds ambitious anyways

sony1492

> BaconSandwich is tasty.

sony1492

> BaconSandwich is tasty.

10/10/2020 at 22:46 |

|

Yes

I like cars: Jim Spanfeller is one ugly motherfucker

> sony1492

I like cars: Jim Spanfeller is one ugly motherfucker

> sony1492

10/11/2020 at 07:24 |

|

Very good point.

MM54

> sony1492

MM54

> sony1492

10/11/2020 at 11:44 |

|

(still) looking good! This is coming along pretty quickly.

Any progress on a rear axle?

sony1492

> MM54

sony1492

> MM54

10/11/2020 at 11:48 |

|

Trying to g et as much done in between jobs. The rear axle is still in purgatory, the nearest junkyard is now 4 hrs away.

jminer

> sony1492

jminer

> sony1492

10/11/2020 at 20:01 |

|

Man! This thing is looking great!