"sony1492" (sony1492)

"sony1492" (sony1492)

05/05/2019 at 23:55 ē Filed to: SC400

1

1

16

16

"sony1492" (sony1492)

"sony1492" (sony1492)

05/05/2019 at 23:55 ē Filed to: SC400 |  1 1

|  16 16 |

Thats all vaguely burned oil at idle, now picture a thick smoke screen reminicent of a forest fire and you have 3000rpm. The new turbos did the exact thing I bought them to fix.

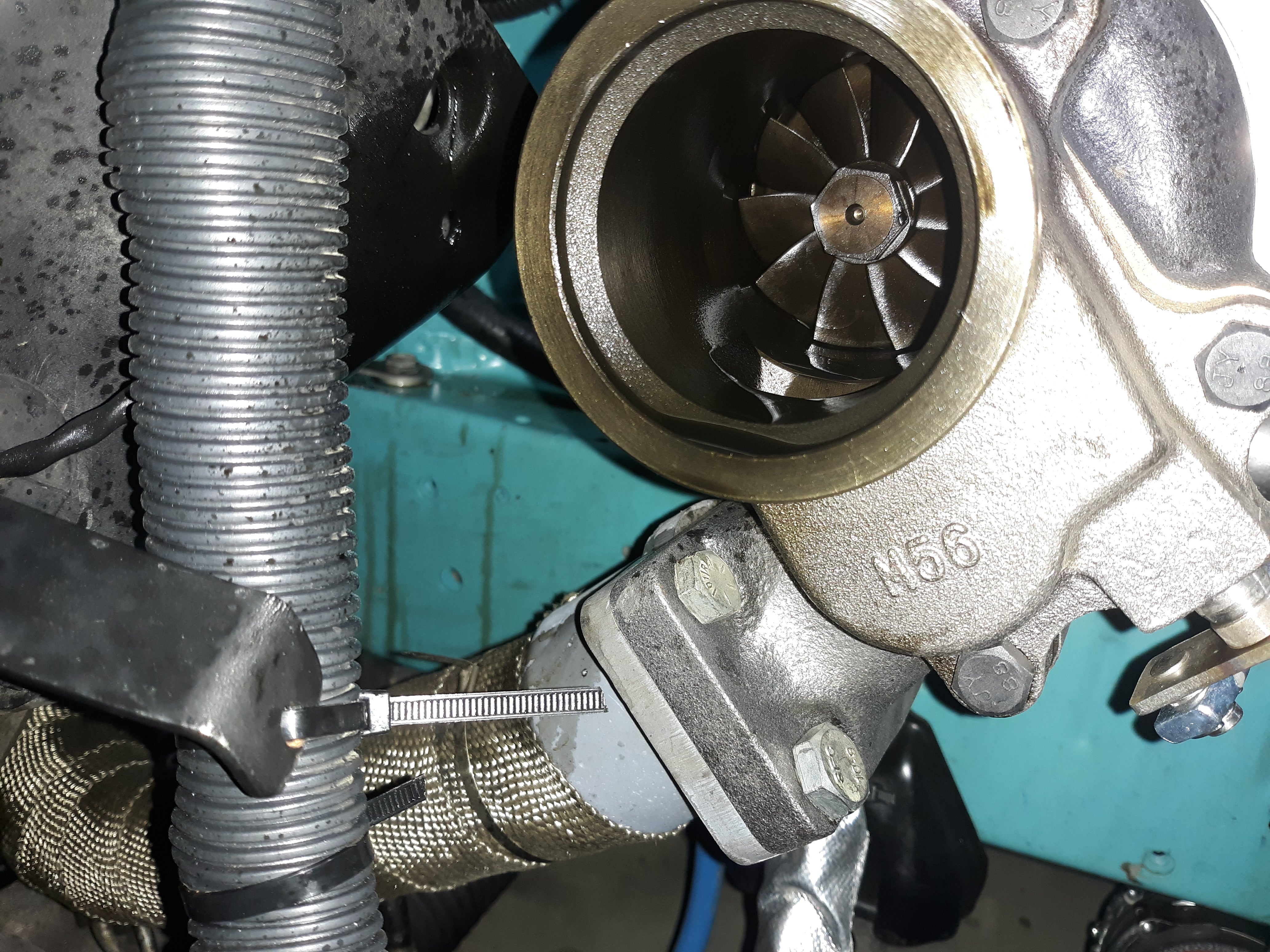

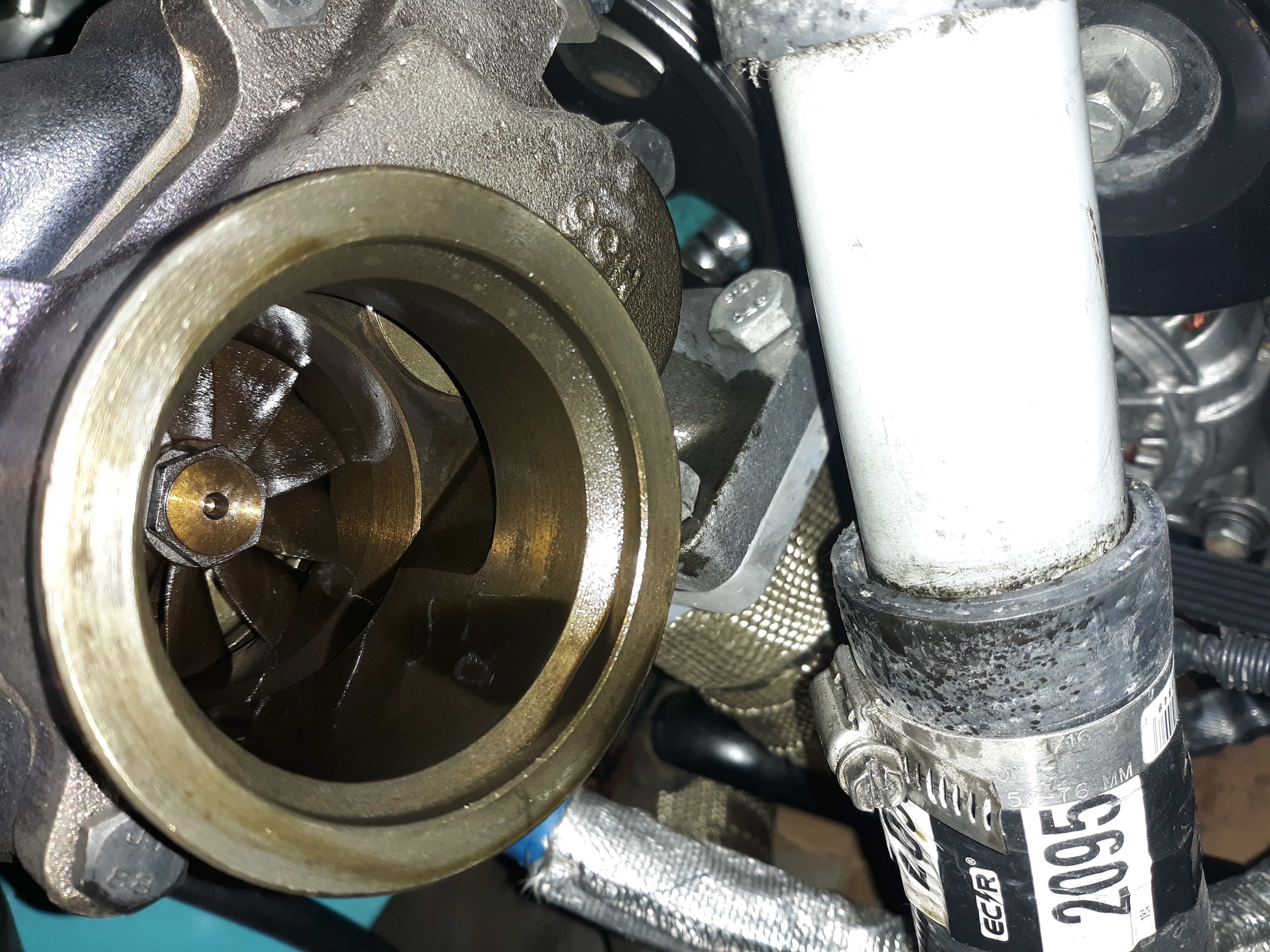

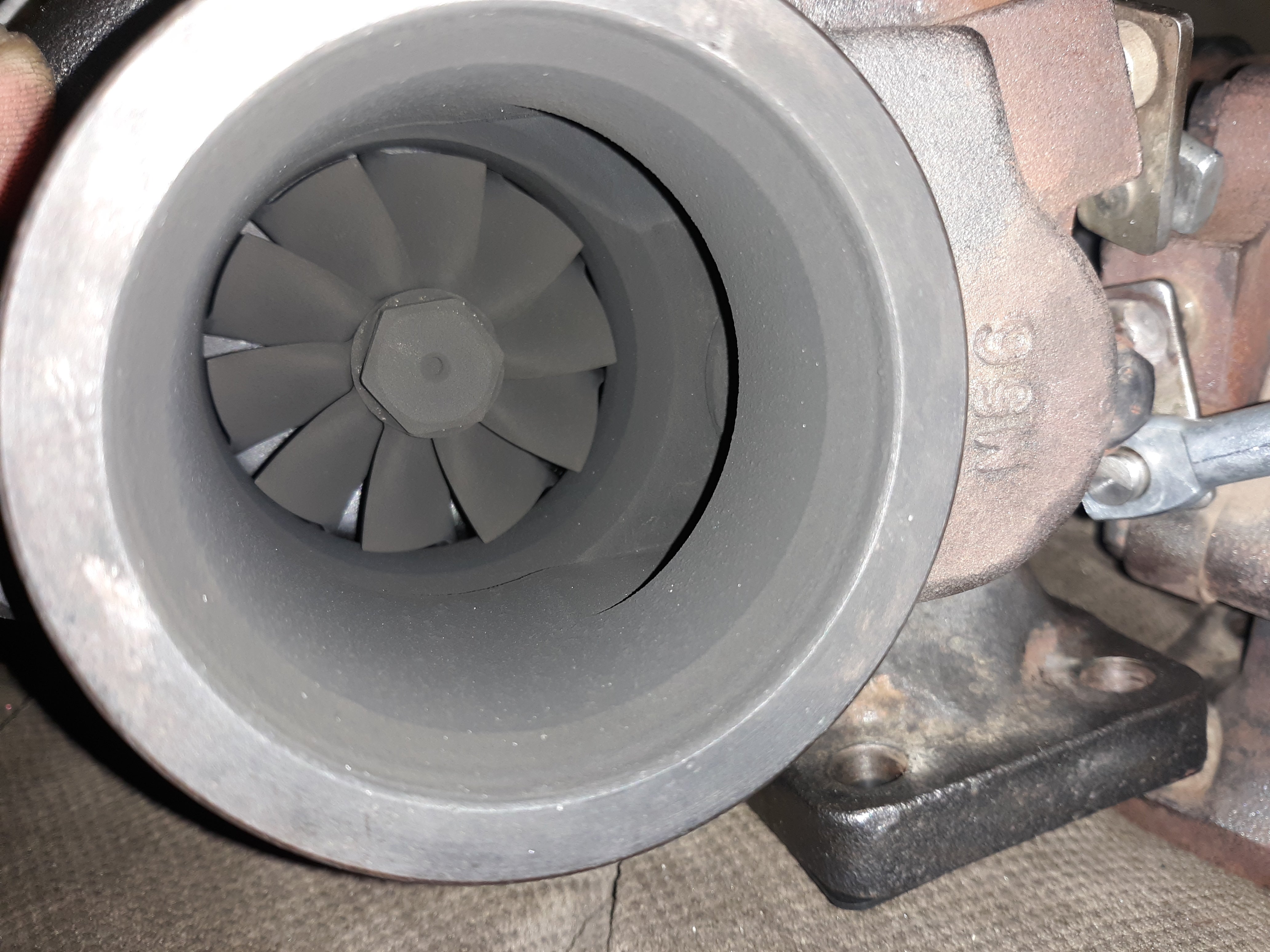

The question is now, whatís causing exhaust seals to leak? These are cheapo turbos but they have worked on other vehicles before. I did notice during the rebuild of the older ebay turbos that the design of a particular part was different and although they still smoked, the exhaust housing was looks much less oily:

Iíve contacted the seller to see about getting a partial refund on these new turbos to purchase a couple more rebuild kits. Theres not much else to be done on this front besides moving to a larger drain diameter, currently its 10an.

wafflesnfalafel

> sony1492

wafflesnfalafel

> sony1492

05/06/2019 at 00:04 |

|

sony1492

> wafflesnfalafel

sony1492

> wafflesnfalafel

05/06/2019 at 00:13 |

|

That's where my patience was 2 months ago

Junkrat aka Rick Sanchez: Fury Road Edition

> sony1492

Junkrat aka Rick Sanchez: Fury Road Edition

> sony1492

05/06/2019 at 01:10 |

|

Are you running a restrictor on the oil inlet? Turbos donít like a lot of PSI.

sony1492

> Junkrat aka Rick Sanchez: Fury Road Edition

sony1492

> Junkrat aka Rick Sanchez: Fury Road Edition

05/06/2019 at 01:23 |

|

Ive tried with and without to the same effect , currently it has them, not sure what the oriface diameter is but about as much as a 2hb pencil lead.

It may have to do with the 1uz, it will †idle at 70-80 psi warm and make in excess of 100psi at rpm. Cold is worse with 100psi at idle.(not my readings)

Is using a restrictor on a journal bearing turbo okay though?

†

StudyStudyStudy

> sony1492

StudyStudyStudy

> sony1492

05/06/2019 at 02:15 |

|

With that much oil pressure you definitely need one. I was shown that nominally it should be almost just a drop or so, and the drain needs to be fully clear. Do you have a link to a previous post of your setup?

kanadanmajava1

> sony1492

kanadanmajava1

> sony1492

05/06/2019 at 03:21 |

|

Do you have scavenge pump for the turbos? If I remember correctly they

are in the trunk and the return lines might be

very long.

sony1492

> kanadanmajava1

sony1492

> kanadanmajava1

05/06/2019 at 09:45 |

|

The old setup rearmount ran 1 scavange into a reservoir and 1 pressure into the turbos, it never worked properly and had the same issue of blowing shaft seals(and oil pressure loss on occasion). Moved to front mounts after that chassis caught fire.

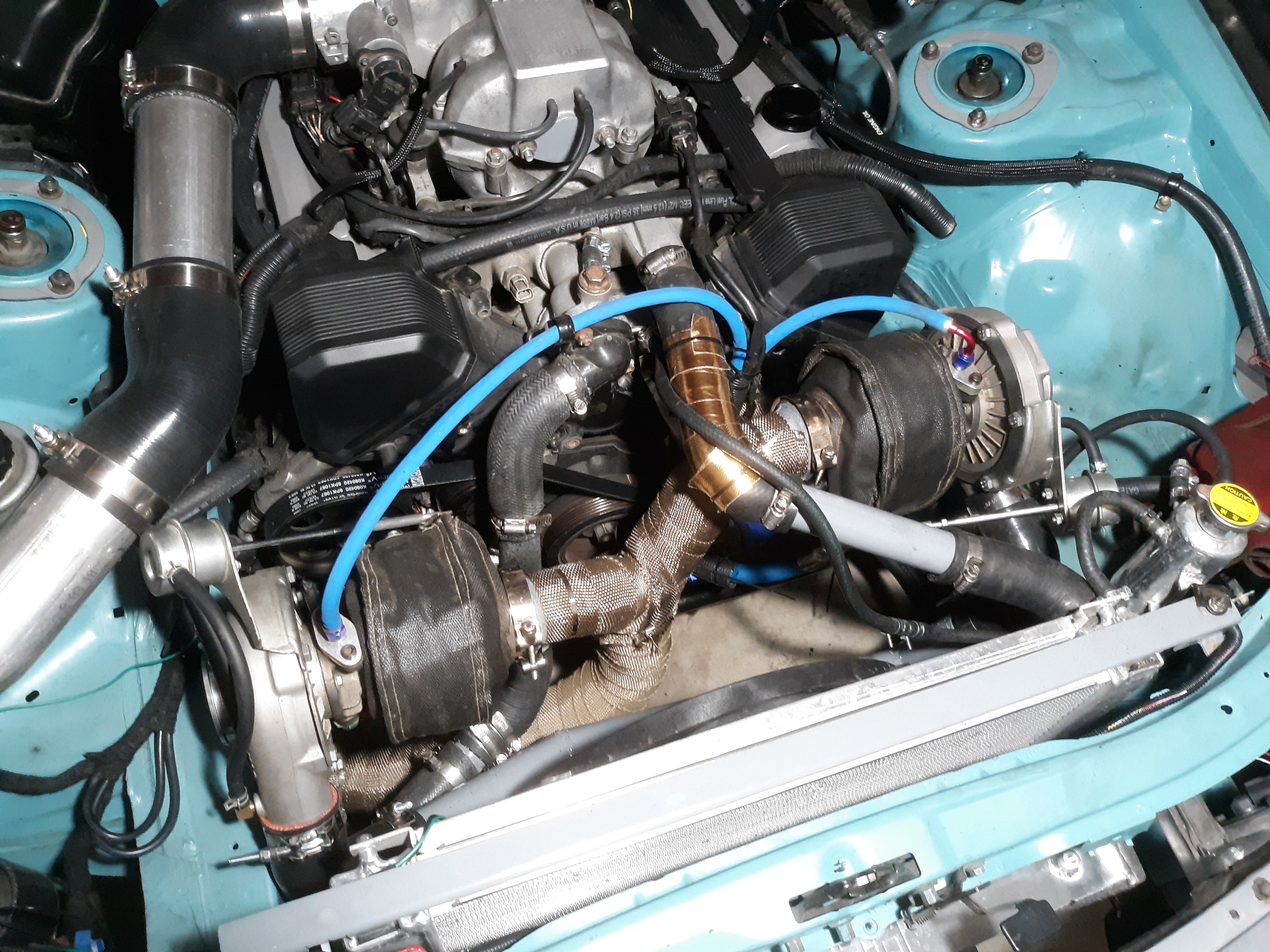

This is the current setup:

GoodIdeaAtTheTime

> sony1492

GoodIdeaAtTheTime

> sony1492

05/06/2019 at 11:01 |

|

Journal bearing I highly recommend a 1.5mm.

sony1492

> StudyStudyStudy

sony1492

> StudyStudyStudy

05/06/2019 at 14:37 |

|

https://oppositelock.kinja.com/tt-sc400-6-speed-setup-rundown-1834558871

The drain does go flat as it enters the sump, not sure how to get around that. Maybe run a restrictor move to a 3/4 drain hose with associated fittings an upgraded exhaust side shaft seal?

StudyStudyStudy

> sony1492

StudyStudyStudy

> sony1492

05/06/2019 at 22:24 |

|

That really helps.

Unrelated, but the turbos will get blisteringly hot. Iím not sure what the pushlock lines are rated to, but it gets hot enough to bake annodized fittings, which usually undergo color change at 500*F.

That is a long way for the return, but it doesnít seem like you should be filling the drain or anything. Does your oil level sit above where you tapped into the sump? Ideally you want it to drop into the pan, on the 7m and such they drain into almost the side of the block above the oil sump. In the JZ they have a return fitting for the oil level sender switch.

Do you have a vacuum source for the crank case? If you are on a stock block that has miles you may be experiencing blowby the rings and pressurizing your crank case, if you have positive pressure there you will have positive pressure on the drain lines so it wonít drain until it sees more than the boost PSI from the feed. Which may not occur readily with the restrictor. Combined with low quality seals on the ebay turbos.

Iíd say to check the drain line, if it sits above the oil level, take it off and see how fast it is filling, it should be barely a dribble. Iíd really look at routing a vacuum sourced catch can (on my JZ the only vents for the crank case are through the valve covers on the head, so I have a pre turbo line in big 1/2 inch size going to each one and to a catch can)† and maybe look at getting some quality rebuild kits from garrett as you were thinking to round it out. And highly suggest replacing the feed lines or at least wrapping them, granted I worry about the direct transmission heat more than radiation.

sony1492

> StudyStudyStudy

sony1492

> StudyStudyStudy

05/06/2019 at 23:52 |

|

The return lines sit above oil level, getting them into the pan isnít possible with the rear sump . Getting to the oil level port was the initial goal but theres alot of exhaust and steering shaft in the way.

Oil inlet lines are rated to 300įF so sounds like that might become an issue, over time pretty much all of the lines will be covered in heat sleeves but like you said direct heat transfer is the larger fear . What are the options for inlet lines that will handle the temp and pressure?

W hats pressing to me is the 4an T fitting off of the oil filter housing, Iím worried that it will fatigue over time due to vibration and weight leading to failure. I imagine my other option is a singl e 4an 90į with the T fitting moved further up and not hard mounted to the engine?

Both valve covers have seperate 1/2 PVC lines going into a small catchcan thatís venting to atmosphere. It doesnít seem to catch oil so much as blow it out of its third(ďvacuumĒ) port, having just explained that I now realize how wonky that is. I need to get a bigger catchcan and attempt driving the car with the catchcan removed and let the valve covers vent individually. Engine has 200k so there is more then a little crank pressure.

Plans for the turbos were the generic t3/t4 rebuild kits and a staggered gap shaft seal.

Thank you for taking your time to help with this.

Junkrat aka Rick Sanchez: Fury Road Edition

> sony1492

Junkrat aka Rick Sanchez: Fury Road Edition

> sony1492

05/07/2019 at 01:03 |

|

Yeah thatís pretty high. Is your crankcase venting properply? That can cause return issues and cause the seals to fail.†

StudyStudyStudy

> sony1492

StudyStudyStudy

> sony1492

05/07/2019 at 01:38 |

|

Oh dude, that is probably a major source of your problem. You have to vent the valve covers to a vacuum source if you arenít running them through the factory PCV which wouldnít work anyway since it would be seeing boost.

Big problem on the JZís people would actually blow the front or rear main seals out by venting to atmosphere, not big enough to vent the positive pressure just by leaving the two of them open. You have to have a source actively pulling the air to keep the crank case from building pressure. I bet if you put gauge on it, you would see quite a bit of positive pressure right now which basically negates the effect of the gravity drain. The added pressure blows up the drain line and keeps them from draining freely.

The only place for constant vacuum on a turbo engine is on the turbo inlet, so post filter, but pre-turbo.

The same test would work, if the seals arenít already ďblownĒ in that they havenít changed shape to accomodate the constant pressurized oil, take the return lines off the turbo and I bet when you run the car it wonít smoke nearly as bad.

For an oil feed line

, I think I went with treadstone or vibrant

and bought a specificly named

turbo oil

feed line as that is not something I wanted to try and save a few dollars on.

That and brake lines I tend to spend what people ask instead of trying to cheap out.†

P

retty thankful I did as the fittings on both my car and my friendís have toasted to a nice brown color on the feed side

. I would say any line indicated for a turbo feed from the big manufacturers I would tend to trust, or at least you can blame someone if something goes wrong.

StudyStudyStudy

> sony1492

StudyStudyStudy

> sony1492

05/07/2019 at 01:55 |

|

No worries, I enjoy this stuff.

I just want to reiterate, do not refer to other engines that run atmosphere venting. They most likely have massive crank case vent hoses/tubes. I did a quick look and it seems the 1UZ is very similar to the JZ in that it vents via the oil drain holes in the head instead of a dedicated crank case vent. So imagine you are putting boost, on top of whatever worn rings are letting by in exhaust gases from two turbos into the crank case all of which have to go up some relatively tiny holes that are reduced in diameter from the oil coming down and up through the valve cover through little 1/2 inch lines that I presume collect in a single catch can that vent out of a single outlet. Before it comes out it is going to make sure to pressurize every seal, hose and whatnot.

If you want to know how much pressure it sees, in my car I routinely blow off the 1/2 inch lines that should be under constant vacuum during boost . There is so much pressure, that even with a vacuum source on two lines going to two vacuum ports on the pre turbo intake, during boost the lines see pressure and can† pop off. That reminds me Iím going to have to add a bigger filter, maybe a longer tube and some real clamps.

sony1492

> StudyStudyStudy

sony1492

> StudyStudyStudy

05/07/2019 at 07:51 |

|

Wasnt making an attempt to save money with the aeroquip line, itís not exactly cheap. D idnt know what lengths I actually needed and didnt want to risk blowing out hand made hose connections. But with heat being a concern Iíll replace them with precrimped lines now that I know my lengths.

Funny you should mention blowing crank seals, I just replaced a cam seal that started dumping oil at an alarming rate. Not to mention oil seeping out of basically everywhere.

C atchcan to turbo inlets was the plan all along but for now Iíll ditch the catchcan and just plumb the lines into the turbo inlet (will make a catchcan later)

StudyStudyStudy

> sony1492

StudyStudyStudy

> sony1492

05/07/2019 at 14:40 |

|

Ah, did not know they were the real deal Aeroquip, I just bought long and routed it the long way, but Iím with you there, not sure I would trust any hand made lines that are under that much pressure. Still a little concerned with the turbo drain line that I made and that isnít under pressure at all.

Hey, looks like we may have found the culprit here. That is a tell tale sign. As long as the seals havenít blown out from the crank being pressurized ala FMS, RMS, oil pan gasket etc you should find less oil.