"JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t" (jawzx2)

"JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t" (jawzx2)

10/20/2019 at 19:55 ē Filed to: None

8

8

21

21

"JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t" (jawzx2)

"JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t" (jawzx2)

10/20/2019 at 19:55 ē Filed to: None |  8 8

|  21 21 |

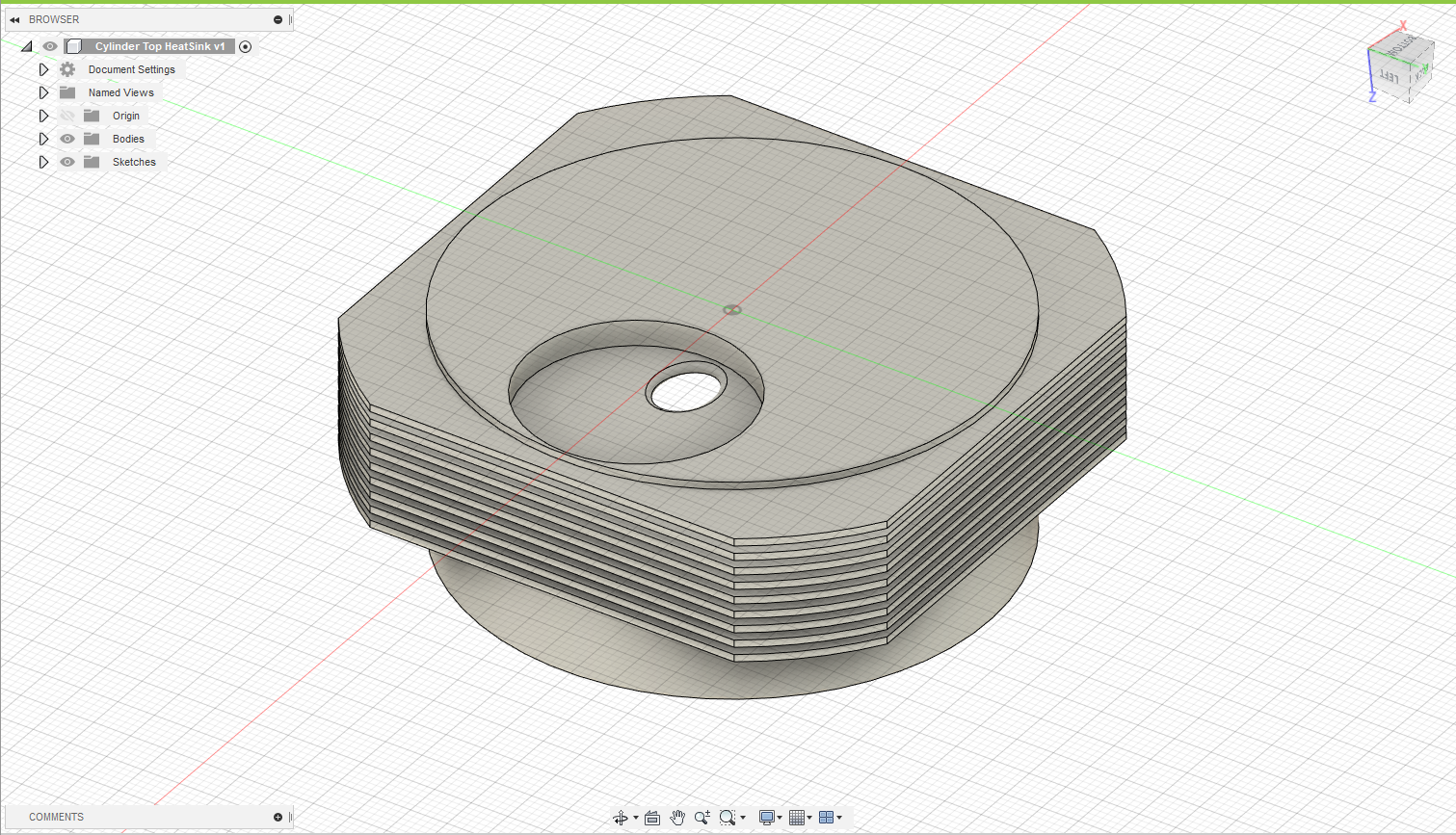

1) Make a stirling engine.

artistís conception

itís a start....

Bored out to the diameter of a Red Stripe bottle, which will be my displacer cylinder wall ;)

I knew i should have measured the offset instead of just eyeballing it... Iím not concerned, this is a seat of the pants build... Just disappointed that I missed. Probably did order of operations wrong too...

Still to do:

Bore transfer port

Power cylinder sleeve

Power piston

Crankshaft

Con rods

Displacer cylinder sleeve

Decide on displacer material

Lots of other stuff

really pleased with the fit of the Red Stripe bottle to the displacer and the top

!!!CAPTION ERROR: MAY BE MULTI-LINE OR CONTAIN LINK!!!

!!!CAPTION ERROR: MAY BE MULTI-LINE OR CONTAIN LINK!!!

MrDakka

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

MrDakka

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

10/18/2019 at 19:53 |

|

You require more vespene gas I mean fins

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> MrDakka

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> MrDakka

10/18/2019 at 19:55 |

|

I only have an 1/8" groove tool, OK?

BaconSandwich is tasty.

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

BaconSandwich is tasty.

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

10/18/2019 at 19:55 |

|

Ooooh. Pretty.

Some day Iíd like to learn to use a metal lathe.

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> BaconSandwich is tasty.

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> BaconSandwich is tasty.

10/18/2019 at 19:58 |

|

Itís fun. Y ou should do it.

NKato

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

NKato

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

10/18/2019 at 20:07 |

|

Until you forget to remove the chuck key from the lathe before starting it. Then everybody loses their minds.†

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> NKato

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> NKato

10/18/2019 at 20:15 |

|

well, donít do that then!

TorqueToYield

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

TorqueToYield

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

10/18/2019 at 20:19 |

|

What CAD program is that?

Rainbow

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

Rainbow

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

10/18/2019 at 20:20 |

|

That doesn't look like sterling silver to me.

Rainbow

> BaconSandwich is tasty.

Rainbow

> BaconSandwich is tasty.

10/18/2019 at 20:22 |

|

T heyíre fun until you find metal shavings in your clothes for three weeks after just glancing in the direction of one.

sn4cktimes

> NKato

sn4cktimes

> NKato

10/18/2019 at 20:35 |

|

Minds... foreheads... a limb...

I had to relearn to use a lathe for my first year of Millwright training. I forgot how much I liked it. Iíve m ade a few things at work since. One guy in my class was constantly leaving his key in the chuck. Never did start it with it in there as the teacher was ON IT. But considering the machine layout I would have been first in the ďline of fireĒ.

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> Rainbow

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> Rainbow

10/18/2019 at 20:59 |

|

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> Rainbow

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> Rainbow

10/18/2019 at 21:00 |

|

itís true. I wore a hoodie with a po uch pocket when I turned this... Iíll be finding aluminum chips in that bitch for the next six months.

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> TorqueToYield

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> TorqueToYield

10/18/2019 at 21:01 |

|

Fusion 360.

Shoop

> BaconSandwich is tasty.

Shoop

> BaconSandwich is tasty.

10/19/2019 at 21:04 |

|

It's really not too hard.†

sn4cktimes

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

sn4cktimes

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

10/19/2019 at 22:11 |

|

Anytime I work on the equipment in our machine shop I have to switch out my coveralls right after . Those chips get everywhere. Our multi- sp indle drill presses are bad, but the lathes are still the worst. One of the harder† stainless steels that they occasionally work with makes these savage little barbs when they face a part . Theyíre like porcupine quills, they just keep digging deeper.

Echo51

> sn4cktimes

Echo51

> sn4cktimes

10/20/2019 at 03:30 |

|

I find the die/air grinders with the little carbide burrs to be way worse at leaving sharp shavings youíll prick yourself on/step into your foot. The lathe stuff is big enough to spot easily/stay mostly clear off. Then again, i also only turned Stainless, which doesnít do small chips really?

sn4cktimes

> Echo51

sn4cktimes

> Echo51

10/20/2019 at 19:49 |

|

N ormally most of stainless varieties they do are fine and have the standard curly chips. Itís just the one really hard variety they do that makes the tiny barbs, they only ever use carbides on it, never the HSS tooling. And really rip coolant across it. Itís messy. I had to get one of them to stop while I worked on a neighbouring machineís coolant pump. I was getting showered.

And yeah, die grinder burrs on aluminum are particularly awful. 12+ years ago when I worked on trucks I used to get them embedded in my skin all the time.

Future Heap Owner

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

Future Heap Owner

> JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

10/20/2019 at 21:41 |

|

This is incredibly cool!! Keep updating!

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> Future Heap Owner

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> Future Heap Owner

10/20/2019 at 22:03 |

|

T hanks! I will keep updating... Hopefully itíll end with a run video ;)

Echo51

> sn4cktimes

Echo51

> sn4cktimes

10/21/2019 at 03:00 |

|

Die grinder burrs on *steel* i find worse. Luckily i rarely do that, i mostly deal with sanding the cast aluminium parts, which rarely if ever makes whiskers or such, itís mostly just little round balls of AL or dust, depending on the sanding.

I can imagine harder stuff being awful-er for chip formation ye

BaconSandwich is tasty.

> Rainbow

BaconSandwich is tasty.

> Rainbow

10/24/2019 at 20:44 |

|

Eh, Iím already half way there. The last week or so Iíve come back into the house (from being in the garage) either smelling like ground metal, grinding disks, welding, or spray paint.