"sony1492" (sony1492)

"sony1492" (sony1492)

10/02/2019 at 19:50 • Filed to: None

1

1

26

26

"sony1492" (sony1492)

"sony1492" (sony1492)

10/02/2019 at 19:50 • Filed to: None |  1 1

|  26 26 |

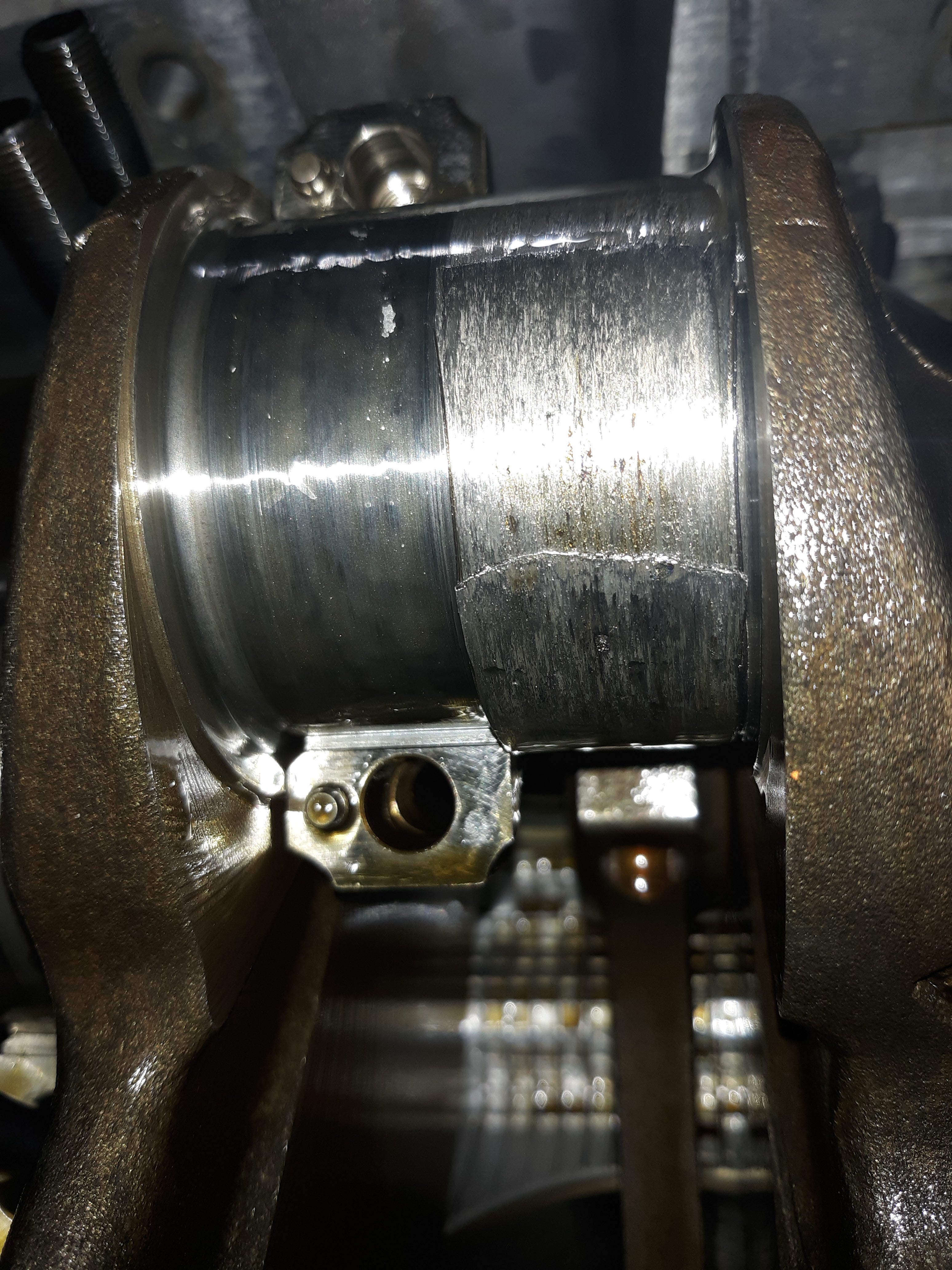

It was cylinder #1, apparently the bearing half made it’s way under the other side leading to a knocking noise as the crank smacked the connecting rod with essentially no bearing. I’m not sure how to prevent this next time, the bearing fit snug with a centering slot to the rods.

This was using Ki ng trimetal bearings

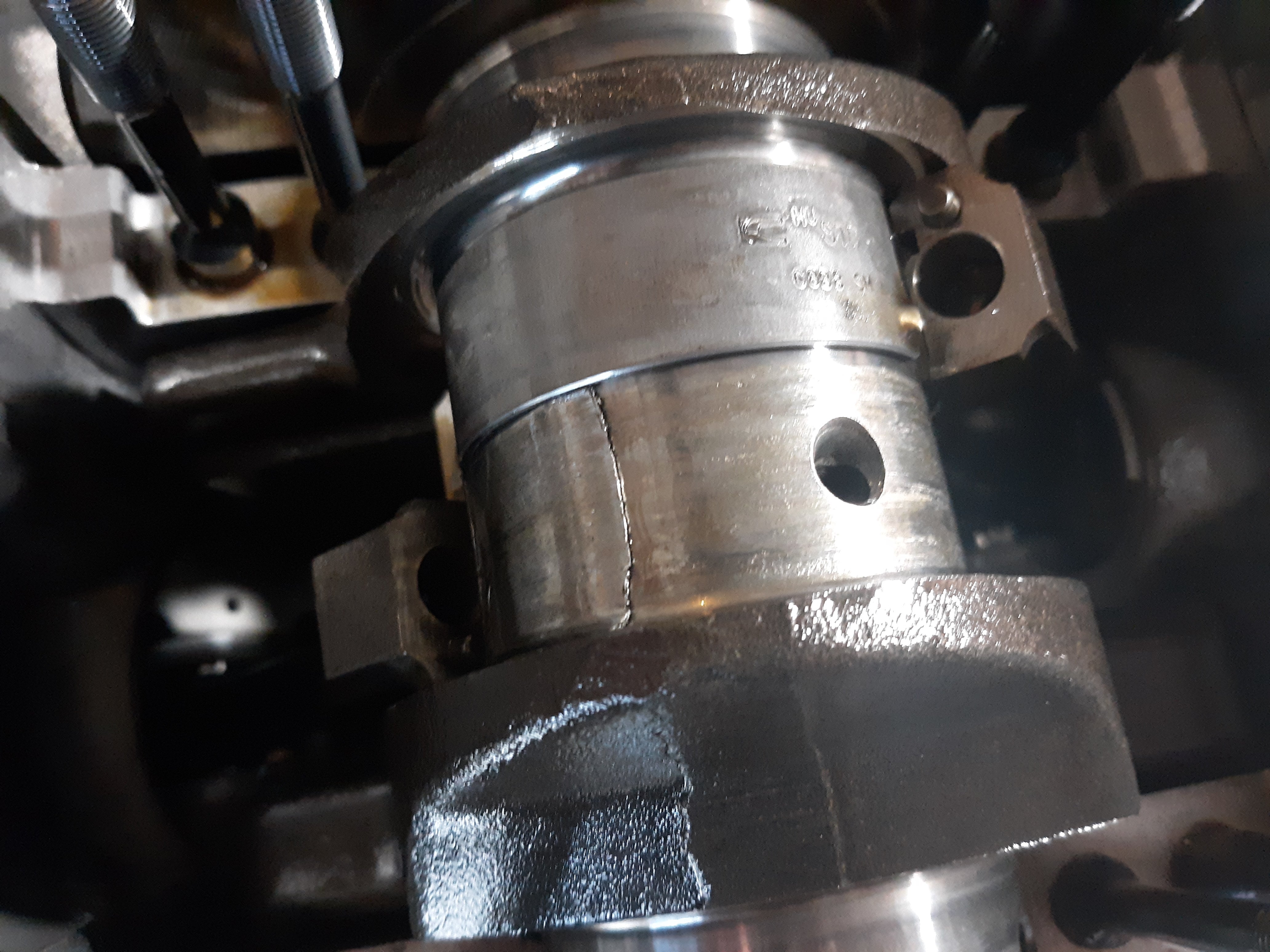

This is the bearing after uncoupling the two halves that were smearing together.

RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

> sony1492

RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

> sony1492

10/02/2019 at 20:08 |

|

Wow, those bearings do not seem like they were good quality if they did that to you...

Were you driving the car really hard?

sony1492

> RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

sony1492

> RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

10/02/2019 at 20:13 |

|

Not for any extended period of time, the clutch would slipped before full pwr.

It may have spun because I lubricated the backside of the bearing surface during the install, apparently that oil film can allow the bearing to move.

Other then that I cant think of why it went out like this.

RutRut

> sony1492

RutRut

> sony1492

10/02/2019 at 20:21 |

|

knock?

sony1492

> RutRut

sony1492

> RutRut

10/02/2019 at 20:29 |

|

It’s possible, the dyno tuning was extrapolated after 5 psi but the car saw as high as 15 with a regular 9psi. But with a bad tune the rest of the bearings should show wear right?

RutRut

> sony1492

RutRut

> sony1492

10/02/2019 at 20:44 |

|

It’s a toss up, build variation could do it, one bad plug or injector, regulated return vs. dead heading a fuel rail, different thermal patterns per cylinder, location of the knock sensor could miss it in tuning.

sony1492

> RutRut

sony1492

> RutRut

10/02/2019 at 20:49 |

|

M ostly interested to not have this happen on the next rebuild

glemon

> sony1492

glemon

> sony1492

10/02/2019 at 21:07 |

|

The bearings should have little tabs or tangs that fit in the cap and block, these should keep the bearing from spinning or sliding out. Suspect this would not have happened if something else wasn’t wrong, bearing caps should go back on exactly as they came off, same journal same orientation, if they aren’t you will likely not get a good fit, I am guessing you had a fit problem with either the cap or the bearing size which led to friction which led to the bearing somehow sliding off.

I don’t know any history here, and you may know all this stuff already. The engine communicates with you as you put it back together. I always spin the crank by hand as I put each bearing cap on. Should spin easy with lube on mains, you will get pretty good resistance with rod journals and the Piston/ring friction, but ant issues with something clearly wrong will be self evident.

66P1800inpieces

> sony1492

66P1800inpieces

> sony1492

10/02/2019 at 21:11 |

|

Working on my Volvo B20 rebuild now and cleaned the back side with brake cleaner before installing. Although, even when installed properly I have to imagine oil can seep in behind the shells . I don’t know much about this type of engine but would a higher oil pressure helped reduce metal to metal contact?

66P1800inpieces

> glemon

66P1800inpieces

> glemon

10/02/2019 at 21:15 |

|

The tang is for locating during a ssembly but are not really there to retain them axially during operation (although I imagine it helps some) . Some newer engines assembled by robots don’t even have the tangs as the robots are precise enough to not need them and I guess it saves the manufacturer from machining the slots . Reading what I just wrote makes me thing they will be taking over soon.

RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

> sony1492

RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

> sony1492

10/02/2019 at 21:23 |

|

Was it new? Guessing they were aftermarket? King would never have some kind of warranty for stuff like this that kills people’s engines, would they?

sony1492

> glemon

sony1492

> glemon

10/02/2019 at 21:28 |

|

This is the first engine rebuild so feel free to explain everything.

The crank spun freely with by hand and was measured, I didn’t m easure the rods since the crank was polished and using standard sizes. (so if anything I figured gaps would be a tad large, probably a big mistake).

With the rods installed it still spun smoothly , minus the resistance of 8 pistons. The caps may have gotten mixed up with the rods they went with but the orientation of everything was double checked. Everything felt good going back together, I felt that if anything the mains would be a problem since they didnt have a centering tab like the oem ones

sony1492

> RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

sony1492

> RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

10/02/2019 at 21:31 |

|

They were new, but I doubt anything can be warrantied since user instal error cannot be ruled out. Even if it was, I’d be getting a black a grand total of $90 for the rod bearings.

I doubt it had anything to do with the manufacturer.

RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

> sony1492

RallyDarkstrike - Fan of 2-cyl FIATs, Eastern Bloc & Kei cars

> sony1492

10/02/2019 at 21:50 |

|

:(

RacinBob

> sony1492

RacinBob

> sony1492

10/02/2019 at 21:53 |

|

Something doesn’t look right. As was mentioned that the bearings have tabs that fit into the rods. I think the caps were mismatched or something else....

Also, what is with the metal on the back of the other bearing?

RacinBob

> RacinBob

RacinBob

> RacinBob

10/02/2019 at 21:54 |

|

PS, how do the other bearings look?...

sony1492

> RacinBob

sony1492

> RacinBob

10/02/2019 at 22:06 |

|

The intact bearing fell out after the cap got removed, the lower side slid under the crank in that photo. The tabs are offset on the cap and rod.

Heres a close up, its writing

sony1492

> RacinBob

sony1492

> RacinBob

10/02/2019 at 22:11 |

|

Keep in mind the oilpump was circulating this at 100psi:

sony1492

> 66P1800inpieces

sony1492

> 66P1800inpieces

10/02/2019 at 22:13 |

|

It operates around 100psi or more, 70 at the lowest. It seems odd, during disassembly the rod bearings are falling out of the journals like they shrank.

RacinBob

> sony1492

RacinBob

> sony1492

10/02/2019 at 23:11 |

|

100 psi seems like a formula for thin oil due to the heat needed to pump it to that pressure.

Also I’ve replaced Honda B18C5 bearings after 50 hours of racing with 8200 rpm at each shift, that haven’t looked anything like as bad the deposits on your good bearing.

I’ve found that b earings are mostly forgiving. And t hey basically work as long as they are wet with pressure. I think there is more going on than lube on the bearing backside .....

sony1492

> RacinBob

sony1492

> RacinBob

10/03/2019 at 06:09 |

|

Well the good bearings look bad thanks to all the metal that was in the oil, up close you can see flake embedded. With the oil pressure I ran the recommended weight, since that's the pressure all 1uz's run

Michael

> sony1492

Michael

> sony1492

10/03/2019 at 07:52 |

|

Gotta keep the caps in order, they are line honed at the factory and machined in place with the block.

Larger gaps are also not so good for bearings. Load holding capacity on a fluid film lay er decreases with a larger gap

Michael

> sony1492

Michael

> sony1492

10/03/2019 at 09:37 |

|

Sorry, thought it was a main not a rod cap. It is still crucial to either:

1. put the cap back on the same rod it came off of or

2. Re-machine the rod and cap combo as it will be used

They are machined assembled, and if you use cap 2 on rod 1, the mating surfaces may not line up perfectly and you’ll have a step or ledge in the circle. That would certainly cause a bearing to spin, even with the locating tang. Forces in an engine are huge.

My engine builder has never let me re-use an old rod without machining to the next oversized size, due to the risk of spinning the bearings.

sony1492

> Michael

sony1492

> Michael

10/03/2019 at 10:10 |

|

This is probably what happened then, thank you.

Bylan - Hoarder of LS400's

> sony1492

Bylan - Hoarder of LS400's

> sony1492

10/03/2019 at 13:50 |

|

Not giving up on the Turbo 1UZ's? :D

66P1800inpieces

> sony1492

66P1800inpieces

> sony1492

10/03/2019 at 19:15 |

|

That sounds stout!

sony1492

> Bylan - Hoarder of LS400's

sony1492

> Bylan - Hoarder of LS400's

10/03/2019 at 20:37 |

|

Im pretty well spent(pun), sold the manual swap, not getting much interest in anything else though(chassis, turbo system), but I’d like to sell everything and move on. I dont make enough money to build this platform. (Its trans was on the way out[$1300], needed a stronger clutch[$1300], and the 2nd motor rebuild in 3 months each to the tune of [$ 1500] in parts and machining.

If I have to keep the chassis I’d like to throw it together as cheaply as possible, since I now have 2 1uzs needing a rebuild I’ll make 1 working one with as little money as possible, oem style bearings, new rings, reuse the mls head gaskets.

Then slap an oem ecu and wiring harness back on with the stock automatic/ open diff and call it good.