"AestheticsInMotion" (aestheticsinmotion)

"AestheticsInMotion" (aestheticsinmotion)

09/11/2018 at 15:14 ē Filed to: None

1

1

20

20

"AestheticsInMotion" (aestheticsinmotion)

"AestheticsInMotion" (aestheticsinmotion)

09/11/2018 at 15:14 ē Filed to: None |  1 1

|  20 20 |

That hurts a lot.

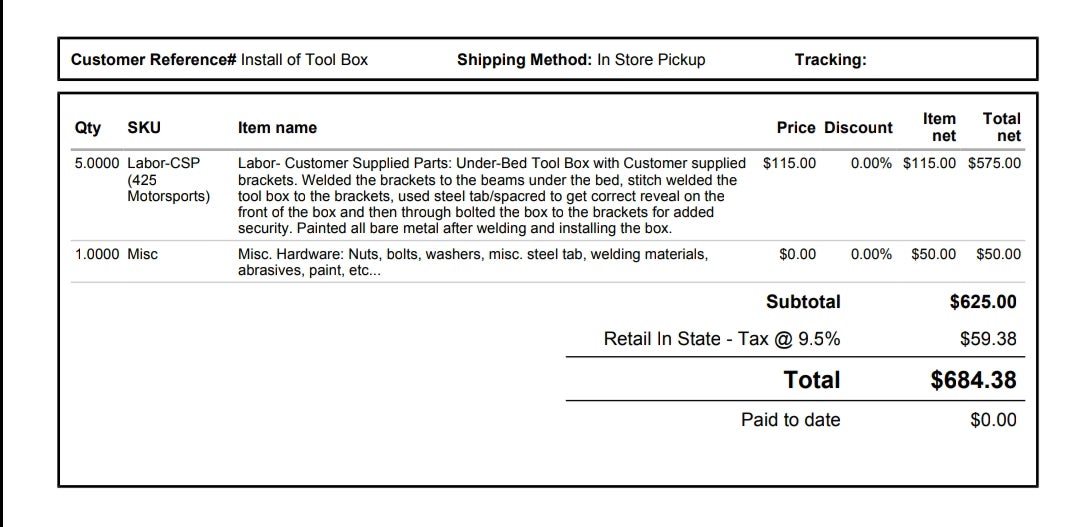

5 hours to attach an underbody box t hat already had mounting brackets ? Did you keep the clock running during a Lord of the Rings marathon? Sigh. I need to get a welder on the company p ayroll. How hard is it to learn, if you give zero fucks about appearances and just need to do things safely?†

PartyPooper2012

> AestheticsInMotion

PartyPooper2012

> AestheticsInMotion

09/11/2018 at 15:19 |

|

watch few youtube videos. Wear welding helmet, gloves and weld away from flamables.... you should be OK.

Mig welder, helmet and few other accessories could be had for less than what you paid up there.

RickSanchez:Fury Road Edition aka Junkrat

> AestheticsInMotion

RickSanchez:Fury Road Edition aka Junkrat

> AestheticsInMotion

09/11/2018 at 15:22 |

|

If you just want to stick stuff together I would go with a Lincoln stick welder aka ďThe TombstoneĒ. They are cheap and very easy to use, and if you perfect stick then TIG is not that far of a leap. I would stay away from the Flux Core MIG machines, they are junk for the most part. My dad taught me by having me lay beads on a thick piece of bar, getting used to the welder, before actually welding two pieces of metal together.

and 100 more

> AestheticsInMotion

and 100 more

> AestheticsInMotion

09/11/2018 at 15:24 |

|

AvE has a great primer on stick welding. No, really.

farscythe - makin da cawfee!

> AestheticsInMotion

farscythe - makin da cawfee!

> AestheticsInMotion

09/11/2018 at 15:28 |

|

give no shit about appearances?

couple practice runs on scrap metal and youtube should get you a long way... i mean.. youtube to tell you what to do... practice runs to actually do it

wont be pretty.... should do for a toolbox

NKato

> AestheticsInMotion

NKato

> AestheticsInMotion

09/11/2018 at 15:29 |

|

At Everett Community College AMTEC thereís a six month training program for welding. I highly recommend it. I plan to take weekend classes when I have the chance so Iím armed with the knowledge to work on the Queen.

Also, if youíre looking to hire a part time welder, connecting with local colleges is a good idea. Everett AMTEC has a career navigator that helps students get job leads.

AestheticsInMotion

> NKato

AestheticsInMotion

> NKato

09/11/2018 at 15:31 |

|

That's a great idea. Now I need to convince my boss to cover it...†

AestheticsInMotion

> and 100 more

AestheticsInMotion

> and 100 more

09/11/2018 at 15:43 |

|

Perfect. AvE is my favorite format for learning new things.

BrianGriffin thinks ďreliableĒ is just a state of mind

> AestheticsInMotion

BrianGriffin thinks ďreliableĒ is just a state of mind

> AestheticsInMotion

09/11/2018 at 15:44 |

|

If youíre brave, Iíve had very good success in getting Craigslist welders for a few automotive projects. One of these things where if theyíve invested in the tools, tends to mean that they kinda know what theyíre doing (unlike, say, painters).†

RamblinRover Luxury-Yacht

> AestheticsInMotion

RamblinRover Luxury-Yacht

> AestheticsInMotion

09/11/2018 at 15:47 |

|

I could see this taking about 2/3 that long, but itís the hourly rate that you get thoroughly owned on. That is absolutely buy-your-own welder money there, both in the sense of needing to buy one and in the sense of actually being able to buy one for what you paid.

Sovande

> AestheticsInMotion

Sovande

> AestheticsInMotion

09/11/2018 at 15:48 |

|

For a decent MIG welder and helmet you would be looking at something similar to the cost above. Learning how to do it is not overly difficult, just takes a bit of practice and a bit of knowledge on how to know if your welds are penetrating, heat, voltage etc.

My guess is if it took someone who knows what they are doing 5 hours, then it was a 5 hour job.

DipodomysDeserti

> AestheticsInMotion

DipodomysDeserti

> AestheticsInMotion

09/11/2018 at 15:57 |

|

AMGtech - now with more recalls!

> RickSanchez:Fury Road Edition aka Junkrat

AMGtech - now with more recalls!

> RickSanchez:Fury Road Edition aka Junkrat

09/11/2018 at 16:02 |

|

TIG is so much harder than stick. I think a closer analog to TIG would be oxy-acetylene. Figuring out the pedal is a bastard for most people.

AMGtech - now with more recalls!

> AestheticsInMotion

AMGtech - now with more recalls!

> AestheticsInMotion

09/11/2018 at 16:06 |

|

Half an hour on YouTube and a MIG with an auto setting will get you there if itís not a safety item. Half of day of YouTube and some practice will get you there without the auto setting. Neither of these will end up pretty, but should result in two pieces of metal stuck together.

At least this is my assumption based on the quality of welds most exhaust shops manage.

Lots of coaching and practice, like full time, over the course of at least a month and you might start approaching entry level welding job skill levels. Might. With some natural skill. And a good teacher.

Long_Voyager, Now With More Caravanny Goodness

> AestheticsInMotion

Long_Voyager, Now With More Caravanny Goodness

> AestheticsInMotion

09/11/2018 at 16:09 |

|

Welcome to the reason people sell vehicles that need basic repairs.

$20 in parts, $800 in labor.

gogmorgo - rowing gears in a Grand Cherokee

> AestheticsInMotion

gogmorgo - rowing gears in a Grand Cherokee

> AestheticsInMotion

09/11/2018 at 16:36 |

|

Welding is pretty simple once you know what you're doing. A good mig welder is only a little more advanced operation than a hot glue gun.†

NKato

> AestheticsInMotion

NKato

> AestheticsInMotion

09/11/2018 at 16:37 |

|

Itís a couple grand, and the classes take most of the day from Monday to Thursday; twelve hours per day on weekend classes. This is one of the most popular shift formats in the manufacturing industries, lets people rest for three days instead of two, and allows for more flexibility on overtime during crunch production.

Junkrat aka Rick Sanchez: Fury Road Edition

> AMGtech - now with more recalls!

Junkrat aka Rick Sanchez: Fury Road Edition

> AMGtech - now with more recalls!

09/11/2018 at 16:47 |

|

TIG is much harder, I agree. When I learned I relied on my stick technique more than MIG technique.†

ITA97, now with more Jag @ opposite-lock.com

> AestheticsInMotion

ITA97, now with more Jag @ opposite-lock.com

> AestheticsInMotion

09/11/2018 at 19:20 |

|

Learning to mig weld badly isnít hard. Learning to weld well is a serious skill, and there is both the art and skill of technique with welding itself, and also the whole body of experience of knowing how exactly to set up the equipment for each weld.

The problem is that a grinder and paint donít solve the real problem of an ugly weld. An ugly weld usually isnít a sound weld. If youíre doing something like welding supported sections of exhaust pipe together where there is nothing structural in play, you might get away with it. In anything that matters, even it works for awhile, crappy welds will come back to haunt you.

There is a lot of work involved in welding beyond the act of welding itself. Measuring and set up, sometimes needing to fabricate jigs or brackets just to hold things in place for welding, fabricating hardware when needed, prepping surfaces to get clean, bright and shiny metal mating to clean, bright and shiny metal. Itís kind of like painting. The act of painting itself, (a car, or even a wall) is a relatively small portion of the whole job.

Iím generally a bad welder myself, but Iíve worked with an known some folks who actually are very good (and in some cases great) welders in both the automotive restoration and racecar fabrication worlds, and in the industrial and equipment repair worlds. IF a good welder sets up the equipment for me, and the access is straight forward, right side up and easy, I can lay a not completely terrible bead that will probably work for non-critical applications that donít bear tremendous loads. If I have to set up the equipment myself, the odds of getting anything other than a really, really crappy weld are pretty slim.

That said, I completely understand how people become welders. Once you lower the helmet and pull the trigger, you are intensely focused on one thing (to the exclusion of the rest of the world) and you are rewarded (or punished) with immediate feedback on how well youíre doing it.† I find welding very relaxing.† In another life, learning to weld well and doing it for a living would be a pretty good way to spend my work day.

random001

> AestheticsInMotion

random001

> AestheticsInMotion

09/11/2018 at 20:06 |

|

Seriously, a few hundred buck for a Hobart, and youíre good to go. We

lding is easy. Not setting yourself on Fire is the hard part.

Bman76 (hates WS6 hoods, is on his phone and has 4 burners now)

> AestheticsInMotion

Bman76 (hates WS6 hoods, is on his phone and has 4 burners now)

> AestheticsInMotion

09/11/2018 at 23:30 |

|

If you can run a hot glue gun then you can run a MIG welder. I learned in about 2 weeks, immediately turned around and passed an AWS test and became a certified welder.