"ttyymmnn" (ttyymmnn)

"ttyymmnn" (ttyymmnn)

05/08/2018 at 09:28 • Filed to: planelopnik

4

4

29

29

"ttyymmnn" (ttyymmnn)

"ttyymmnn" (ttyymmnn)

05/08/2018 at 09:28 • Filed to: planelopnik |  4 4

|  29 29 |

jimz

> ttyymmnn

jimz

> ttyymmnn

05/08/2018 at 09:45 |

|

classic sign of progressive fatigue cracking. I wonder how quickly that progressed.

Ash78, voting early and often

> jimz

Ash78, voting early and often

> jimz

05/08/2018 at 09:48 |

|

Maybe the blade read too many Peak Oil and gay marriage blog posts and just said “THATS IT I’M OUT!”

user314

> ttyymmnn

user314

> ttyymmnn

05/08/2018 at 09:52 |

|

Welp, there’s your problem:

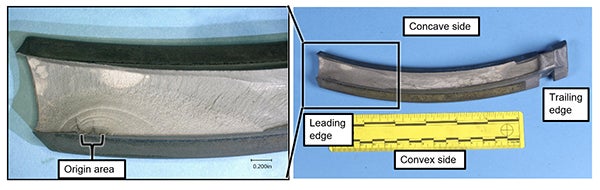

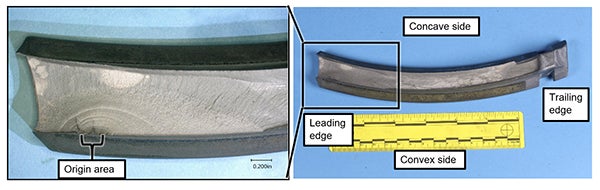

The No.13 fan blade had separated at the root; the dovetail remained installed in the fan disk. Examination of the No. 13 fan blade dovetail exhibited features consistent with metal fatigue initiating at the convex side near the leading edge. Two pieces of fan blade No. 13 were recovered within the engine between the fan blades and the outlet guide vanes. One piece was part of the blade airfoil root that mated with the dovetail that remained in the fan disk; it was about 12 inches spanwise and full width and weighed about 6.825 pounds. The other piece, identified as another part of the airfoil, measured about 2 inches spanwise, appeared to be full width, was twisted, and weighed about 0.650 pound. All the remaining fan blades exhibited a combination of trailing edge airfoil hard body impact damage, trailing edge tears, and missing material. Some also exhibited airfoil leading edge tip curl or distortion. After the general in-situ engine inspection was completed, the remaining fan blades were removed from the fan disk and an ultrasonic inspection was performed consistent with CFM International Service Bulletin 72-1033. No cracks were identified on the remaining blades.

The No. 13 fan blade was examined further at the NTSB Materials Laboratory; Figure 2 shows a portion of the blade in detail. Fatigue fracture features emanated from multiple origins at the convex side and were centered about 0.568 inch aft of the leading edge face of the dovetail and were located 0.610 inch outboard of the root end face. The origin area was located outboard of the dovetail contact face coating, and the visual condition of the coating appeared uniform with no evidence of spalls or disbonding. The fatigue region extended up to 0.483 inch deep through the thickness of the dovetail and was 2.232 inches long at the convex surface. Six crack arrest lines (not including the fatigue boundary) were observed within the fatigue region. The fracture surface was further examined using a scanning electron microscope, and striations consistent with low-cycle fatigue crack growth were observed.

According to maintenance records, the fan blades from the accident engine were last overhauled 10,712 engine cycles before the accident. At the time of the last blade overhaul (November 2012), blades were inspected using visual and fluorescent penetrant inspections.

That bolded part worries me. Assuming it was done correctly, either that blade fatigued very quickly, or the fluorescent test missed it. Neither of those possibilities is good for the flying public.

Ash78, voting early and often

> ttyymmnn

Ash78, voting early and often

> ttyymmnn

05/08/2018 at 09:54 |

|

I’m still amazed so much of the engine was still intact. It wasn’t long ago this was referred to as “rotor burst” because one blade would take all of them out with shrapnel flying in every direction. When that happens, you get fuel leaks, hydraulic failures, and a lot more fuselage (and human) damage.

I’m always reluctant to say “well it could have been much worse” but yes.

ttyymmnn

> user314

ttyymmnn

> user314

05/08/2018 at 09:56 |

|

Yeah, fatigue does look a bit premature. But I also read that SWA was doing everything by the book, and that subsequent inspections have turned up no other issues. But, as you suggest, if the cracks are not getting caught, that’s a problem. The question is, though, are they being missed by the inspection gear or the operator?

ttyymmnn

> Ash78, voting early and often

ttyymmnn

> Ash78, voting early and often

05/08/2018 at 09:57 |

|

Yes, it says a lot about engine design and construction that this wasn’t significantly more catastrophic, though it was for one passenger, sadly. But even that was a pretty freak occurrence.

RamblinRover Luxury-Yacht

> Ash78, voting early and often

RamblinRover Luxury-Yacht

> Ash78, voting early and often

05/08/2018 at 10:00 |

|

If I remember correctly, the original jet-engined Green Monster of Art Arfons was put together with a J57 or something like that had experienced bird strike and rotor damage. Totaled, so he bought it out of a junkyard and painstakingly cut off blades to rebalance it... figuring out how to set it up to operate because the operating manual was technically still classified.

WilliamsSW

> ttyymmnn

WilliamsSW

> ttyymmnn

05/08/2018 at 10:03 |

|

The question is, though, are they being missed by the inspection gear or the operator?

Yes - I’m sure this will get a lot of scrutiny in the coming days. Interesting that the origin *appears* to be at the surface, so you would think SWA maintenance could have caught it, but there may be other mitigating factors that prevented that (location, speed of propagation, etc etc).

Another area of investigation will be why the failure was uncontained, as well.

That’s the great thing about the NTSB, they’ll leave no stone unturned and will likely make multiple recommendations to reduce/eliminate this issue in the future.

Spanfeller is a twat

> ttyymmnn

Spanfeller is a twat

> ttyymmnn

05/08/2018 at 10:06 |

|

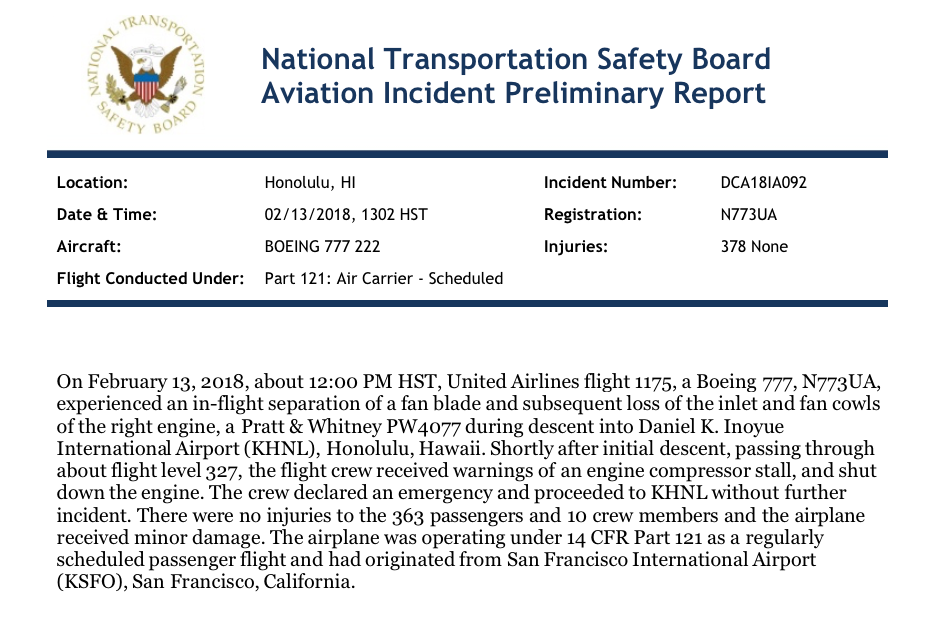

Didn’t something similar just happen to a UA 777 in Hawaii?

ttyymmnn

> WilliamsSW

ttyymmnn

> WilliamsSW

05/08/2018 at 10:14 |

|

That’s the great thing about the NTSB, they’ll leave no stone unturned and will likely make multiple recommendations to reduce/eliminate this issue in the future.

But it’s the FAA that has to make the rules, and they are tasked with both policing and promoting the airline industry. I think that sometimes those two tasks are at odds with each other.

WilliamsSW

> ttyymmnn

WilliamsSW

> ttyymmnn

05/08/2018 at 10:18 |

|

Yep - the weak link in that quote is the word “recommendations”. The NTSB isn’t afraid to call out the FAA when their recommendations are ignored, for certain.

ttyymmnn

> Spanfeller is a twat

ttyymmnn

> Spanfeller is a twat

05/08/2018 at 10:20 |

|

Yes it did. I had forgotten about this. Different engine manufacturer, though.

https://www.scribd.com/document/373245092/20180307-WEB-NTSBprelim3-6-18

BigBlock440

> user314

BigBlock440

> user314

05/08/2018 at 10:27 |

|

To me, that reads like it was last inspected in 2012. I’d expect 6 years of use to require some re-inspection, no?

Spanfeller is a twat

> ttyymmnn

Spanfeller is a twat

> ttyymmnn

05/08/2018 at 10:28 |

|

GE vs engine alliance or Rolls Royce?

The link is broken btw..

gmctavish needs more space

> RamblinRover Luxury-Yacht

gmctavish needs more space

> RamblinRover Luxury-Yacht

05/08/2018 at 10:29 |

|

!!! UNKNOWN CONTENT TYPE !!!

Jesus

Takuro Spirit

> user314

Takuro Spirit

> user314

05/08/2018 at 10:31 |

|

13... of COURSE it was number 13....

RamblinRover Luxury-Yacht

> gmctavish needs more space

RamblinRover Luxury-Yacht

> gmctavish needs more space

05/08/2018 at 10:37 |

|

Yes. I’m pretty sure “sawing blades off a classified junkyard jet engine, then testing it like a podracer engine by tying it to trees, before building a car around it” is the platonic ideal of engineering YOLO.

ttyymmnn

> Spanfeller is a twat

ttyymmnn

> Spanfeller is a twat

05/08/2018 at 10:41 |

|

Works for me. Here’s a screen shot.

Spanfeller is a twat

> ttyymmnn

Spanfeller is a twat

> ttyymmnn

05/08/2018 at 10:42 |

|

#GeoDenied.

Spanfeller is a twat

> ttyymmnn

Spanfeller is a twat

> ttyymmnn

05/08/2018 at 10:43 |

|

That sucker runs on PW engines? It is truly an old 777!

ttyymmnn

> Spanfeller is a twat

ttyymmnn

> Spanfeller is a twat

05/08/2018 at 10:59 |

|

One of the oldest on the fleet, I think.

user314

> BigBlock440

user314

> BigBlock440

05/08/2018 at 11:04 |

|

It’s not the years, it’s the flight cycles. I can’t find the standard service schedule from CFM, but if I’m reading the AD from last year correctly, the NTSB wants CFM56-7Bs inspected by eddy-current within the first 25,000 flight cycles, then every 3,000 afterwards.

user314

> ttyymmnn

user314

> ttyymmnn

05/08/2018 at 11:39 |

|

Just for reference, here’s the How It’s Made segment on how GE Canada fabricates jet turbine compressor blades (though I’m sure CFM’s method differs).

ttyymmnn

> user314

ttyymmnn

> user314

05/08/2018 at 11:44 |

|

I wonder how old this is (haven’t watched it yet). Blades have gotten so much more advanced over the years, with more efficient shapes, materials, etc.

user314

> ttyymmnn

user314

> ttyymmnn

05/08/2018 at 12:02 |

|

That was Season 9 , so somewhere in 2006 to ‘07. I guess I should have said “fabricat ed ”.

ttyymmnn

> user314

ttyymmnn

> user314

05/08/2018 at 12:07 |

|

It’s still worth watching. I love that show as it is. Although it should really be called “How it’s assembled” in most cases.

beautimouse

> gmctavish needs more space

beautimouse

> gmctavish needs more space

05/08/2018 at 12:58 |

|

His card at the time just said:

Art Arfons.

Back Yard Bad Ass.

For Sweden

> ttyymmnn

For Sweden

> ttyymmnn

05/08/2018 at 13:48 |

|

NTSB certainly has a graphic design language

For Sweden

> user314

For Sweden

> user314

05/08/2018 at 13:48 |

|

That may be the most textbook example of fatigue that I’ve seen outside of a laboratory