"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

04/23/2018 at 12:00 ē Filed to: Saab 900, project, wrenching

6

6

11

11

"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

04/23/2018 at 12:00 ē Filed to: Saab 900, project, wrenching |  6 6

|  11 11 |

But hereís a quick update.

The front brake calipers are finally rebuilt and painted (Iíll post up some more pics later). Weíre still hesitant to fully assemble the brakes though, as weíre not quite ready to unpack the new rotors and expose them to the atmosphere where they could start rusting. Those will have to wait until after the big purchase: tires.

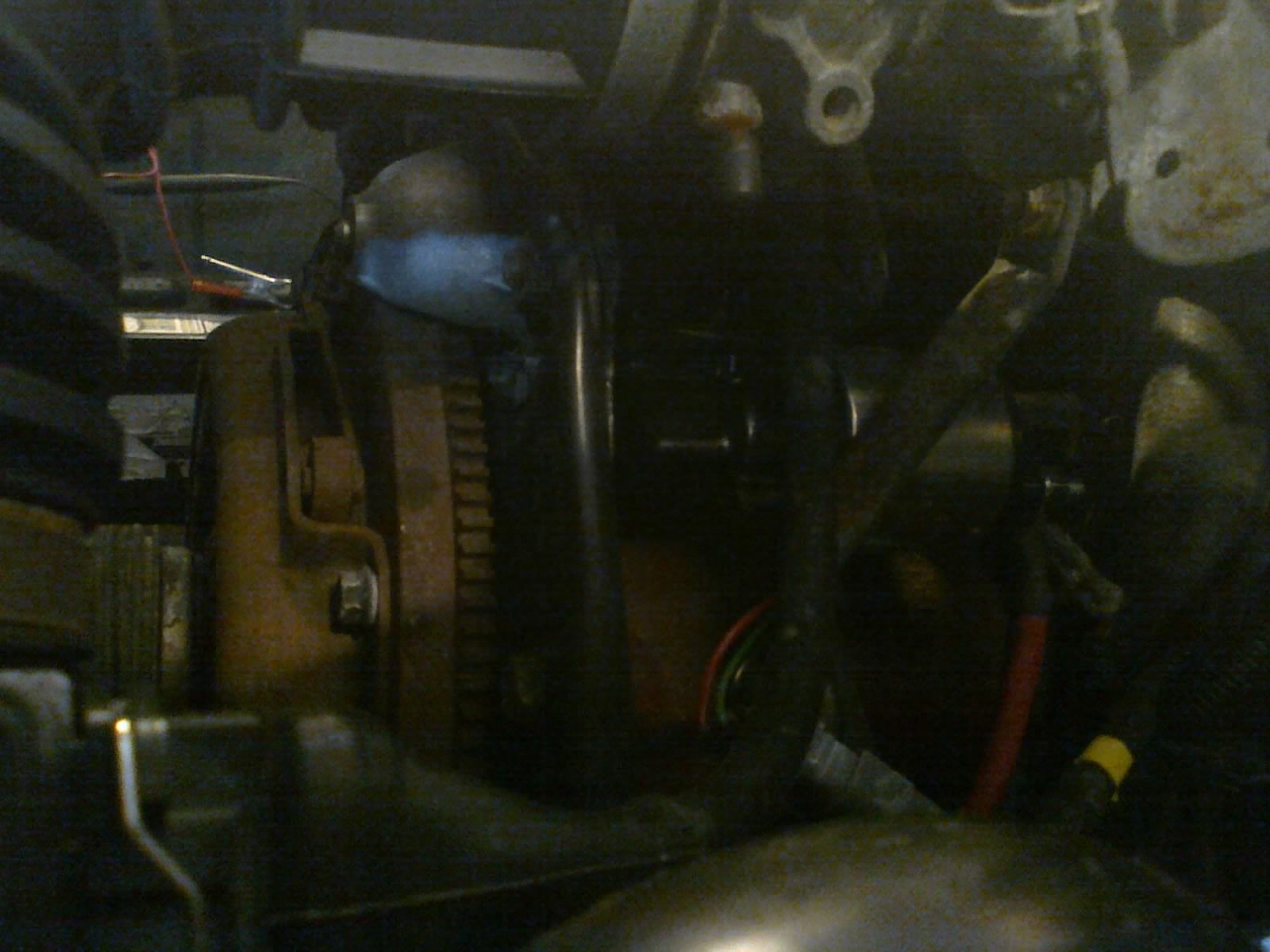

Fresh starter motor assembly w/new solenoid

We found a local rebuilder to freshen up the starter, which saved a few bucks compared to what it would have cost to ship a remanufactured one and ship the core back. Instead of just replacing the failed solenoid, this one now has a new lease on life thanks to a complete overhaul. We can finally run the engine again!

After bleeding the brakes, we decided to bleed the clutch as well. Fortunately, Iíve been in the habit of using Valvoline brake fluid on my cars, which came in very handy as this car takes DOT 4, (my cars have always had DOT 3 systems). The Valvoline stuff is compatible with both.

The brake bleeding went well, but not without a few hiccups, which Iíll go into more detail in a later post. The clutch, however, is a different story...

We began the process by loosening the bleeder, which was nowhere near as badly stuck as the ones in the brake calipers. I hooked up my Mityvac to start sucking the fluid out, as I didnít have a positive-pressure bleeder to push fluid from the reservoir. But only a dribble came out.

We played around with the clutch pedal, pushing it, pumping it, holding it, but nothing helped. The pedal had been successfully disengaging and re-engaging the clutch earlier (if it ainít broke, donít fix it?), but now that we had opened the bleeder, weíre past the point of no return. We have to finish what we started.

I happened to have a garden sprayer, so I searched around and managed to find a vitamin container that was a nearly perfect thread match for the brake fluid reservoir cap. I drilled a hole through it and cobbled up a fitting from the sprayer handle to attach the hose. Ta-da, instant pressure bleeder.

!!! UNKNOWN CONTENT TYPE !!!

I cut the bottom ring off of the cap to release the inner child safety mechanism so that I could glue it back together. The plastic was rather brittle and wanted to shatter instead of cutting cleanly, but I managed. Unfortunately, I didnít do a good enough job gluing the pieces together, and weíre back to having to firmly press down on the cap in order to unscrew it.

I got the new DIY positive pressure bleeder working, but alas, it wasnít helping push fluid out the bleeder. Something else is going on here.

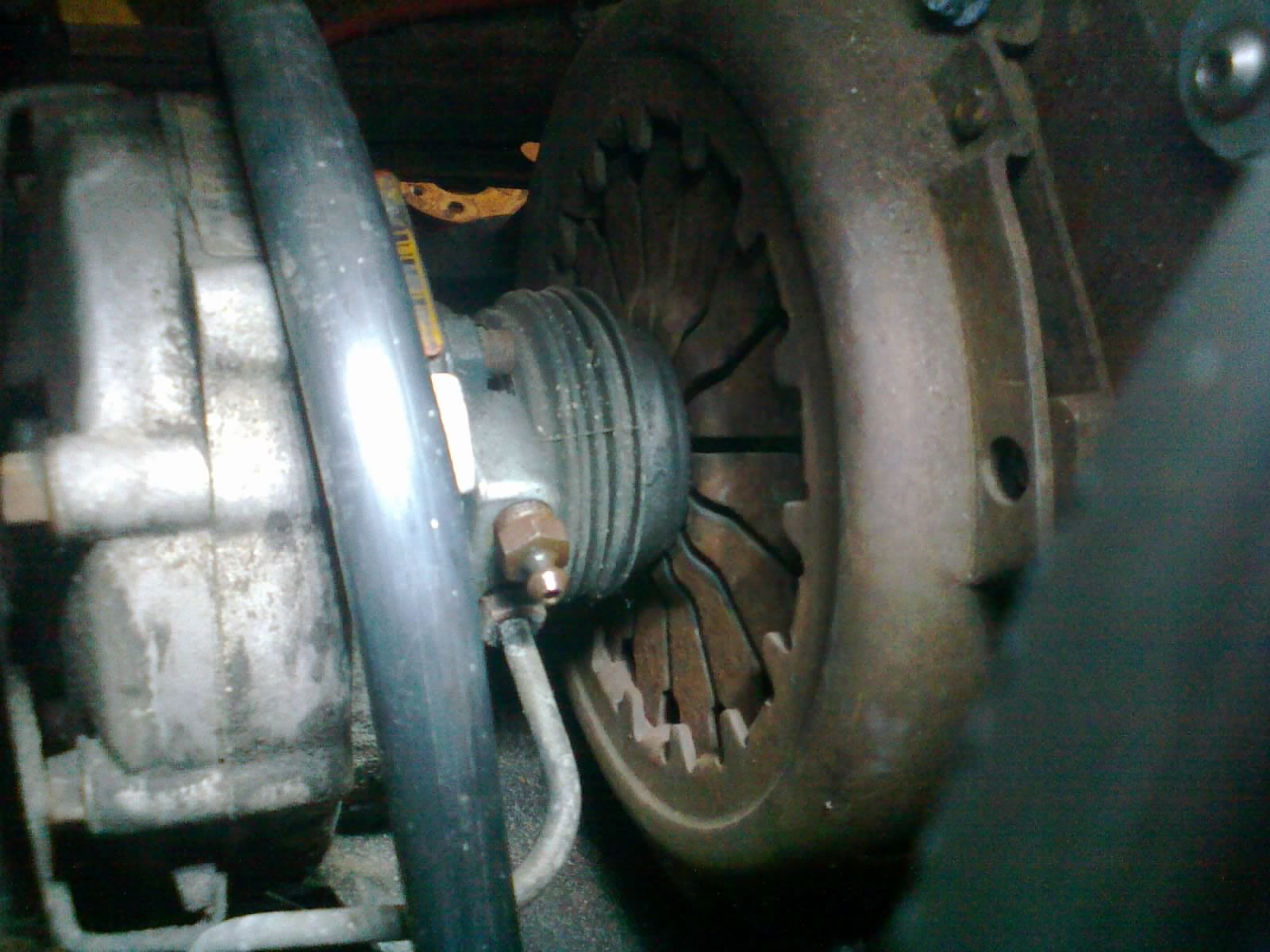

Clutch slave cylinder assembly

With the bleeder screw completely removed, we can hear fluid movement in the slave cylinder as the pedal is worked back and forth. But itís not pushing fluid out of the bleeder port, which suggests to me that the clutch master cylinder is not drawing more fluid from the reservoir to push forward. It must have had enough fluid downstream to disengage the clutch earlier, but now that we let some fluid dribble out, the MC is not replenishing the circuit with fresh supply from the reservoir.

If my guess is correct, then thereís either a problem with the MC, or the supply hose coming from the brake fluid reservoir (shared with the brake system).

Aside from that, weíve got other parts on the way, including a new exhaust from the cat rearward. And thereís a pinhole in the downpipe that my brotherís going to try to see about welding back up. In addition to all that, heís also decided to go with the wheel stud conversion kit. Yes indeedy, it turns out that heís already grown tired of

!!!error: Indecipherable SUB-paragraph formatting!!!

.

MM54

> Urambo Tauro

MM54

> Urambo Tauro

04/23/2018 at 18:18 |

|

My guess is the flex line for the clutch has closed off

Urambo Tauro

> MM54

Urambo Tauro

> MM54

04/23/2018 at 18:40 |

|

I was thinking about that too. Since weíre already stuck having to bleed it anyway, thereís no need to be shy about removing one or both ends of the fluid line to confirm.

We started to do just that, but thereís not a lot of room to swing a line wrench in there, and I donít like the way an open-end wrench feels on those line nuts either. I fear that we may have to commit to buying a new line, and cutting the old one right next to the line nuts so that we can put a six-point socket on them. My brotherís not a fan of that plan, but he hasnít come up with any better ideas yet.

MM54

> Urambo Tauro

MM54

> Urambo Tauro

04/23/2018 at 20:00 |

|

Itís probably due for replacement anyway, and bleeding it with a new line is the same as bleeding it with an old - are they weirdly expensive, or does he just not want to change it?

Urambo Tauro

> MM54

Urambo Tauro

> MM54

04/23/2018 at 20:23 |

|

Well, weíve still got quite a bit of work to do on the car before it goes on the road, and there are other things that heíd rather put that $40 towards.

MM54

> Urambo Tauro

MM54

> Urambo Tauro

04/23/2018 at 20:24 |

|

Okay yeah Iíd put that in the ďweirdly expensiveĒ category - $40 for a clutch flex line! I got a braided stainless flex line for the RX7 for $35

Urambo Tauro

> MM54

Urambo Tauro

> MM54

04/23/2018 at 20:37 |

|

To be fair, that price includes shipping, and this line is more than just a flex hose. (Thankfully the brake hoses for this thing were only like $10 a piece.)

MM54

> Urambo Tauro

MM54

> Urambo Tauro

04/23/2018 at 21:13 |

|

Ah, because of course the flex line is part of a crimped assembly, would be too easy to just put flare fitting on the end of the hose...

Akio Ohtori - RIP Oppo

> Urambo Tauro

Akio Ohtori - RIP Oppo

> Urambo Tauro

04/27/2018 at 17:32 |

|

Wait wait wait wait...

... did I always know your (brotherís) Saab was a sedan? I think I did and I forgot? Sedan love!

The clutch thing sounds weird. Probably wouldnít hurt to replace the hose. (Actually, yes it will but wounds heal.) Iíd also maybe double check there isnít something blocking the clutch fluid from leaving the reservoir. IIRC the clutch section is mildly quarantined from the rest of the reservoir?

Oddly when I did mine I used a jello shot syringe to inject fluid into the bleeder and reverse bleed the system. Time consuming, but effective.

Urambo Tauro

> Akio Ohtori - RIP Oppo

Urambo Tauro

> Akio Ohtori - RIP Oppo

04/27/2018 at 17:47 |

|

Yeah, itís a sedan alright! (I think you did say something about that earlier, something about we should be careful with the parcel shelf because theyíre unobtanium...)

I wish the clutch line didnít have such a weird texture to the rubber that makes it difficult to inspect for cracks. If it was smooth, it would be easier to gauge its condition. (Not that we even bothered inspecting the brake hoses; replacing those was always part of the plan..) But FWIW the clutch line doesnít see nearly as much hydraulic pressure as the brake lines do, so it might still have quite a bit of life left in it.

I thought about disconnecting it to check for flow from the master cylinder, but I donít think I can free the line nuts without cutting the line and slipping a 6-point socket over them.

Akio Ohtori - RIP Oppo

> Urambo Tauro

Akio Ohtori - RIP Oppo

> Urambo Tauro

04/27/2018 at 18:13 |

|

Hmm I remember the hard part being getting it in place. I did have to remove all the intake ducting, but after that it was pretty straight forward...

Urambo Tauro

> Akio Ohtori - RIP Oppo

Urambo Tauro

> Akio Ohtori - RIP Oppo

04/27/2018 at 19:22 |

|

The intake tube (oh thatís right, you probably have more of that to deal with on your turbo) is already out of the way, along with the clutch cover (for starter removal). The biggest hurdle to removing the clutch line now is releasing the line nuts.

I have a ď5-pointĒ line wrench, but thereís just not enough room to swing it far enough to engage the flats on the master cylinder line nut. The head of the wrench is also too bulky to fit onto the nut on the slave cylinder. I could shave it down but... thatíd be a waste of time if I canít use it on the master cylinder line nut anyway.

As stuck as these nuts are, I do NOT feel comfortable using a two-jaw open end wrench. I tried to budge one a little already with a 2-jaw and Iím pretty sure it wants to round off, so I stopped. I havenít tried locking pliers... but if I do and it just chews up the nut, then weíll never get a socket on there and weíll really be up shit creek.