"Twingo Tamer - About to descend into project car hell." (oppisitelock)

"Twingo Tamer - About to descend into project car hell." (oppisitelock)

02/05/2018 at 11:54 ē Filed to: None

1

1

8

8

"Twingo Tamer - About to descend into project car hell." (oppisitelock)

"Twingo Tamer - About to descend into project car hell." (oppisitelock)

02/05/2018 at 11:54 ē Filed to: None |  1 1

|  8 8 |

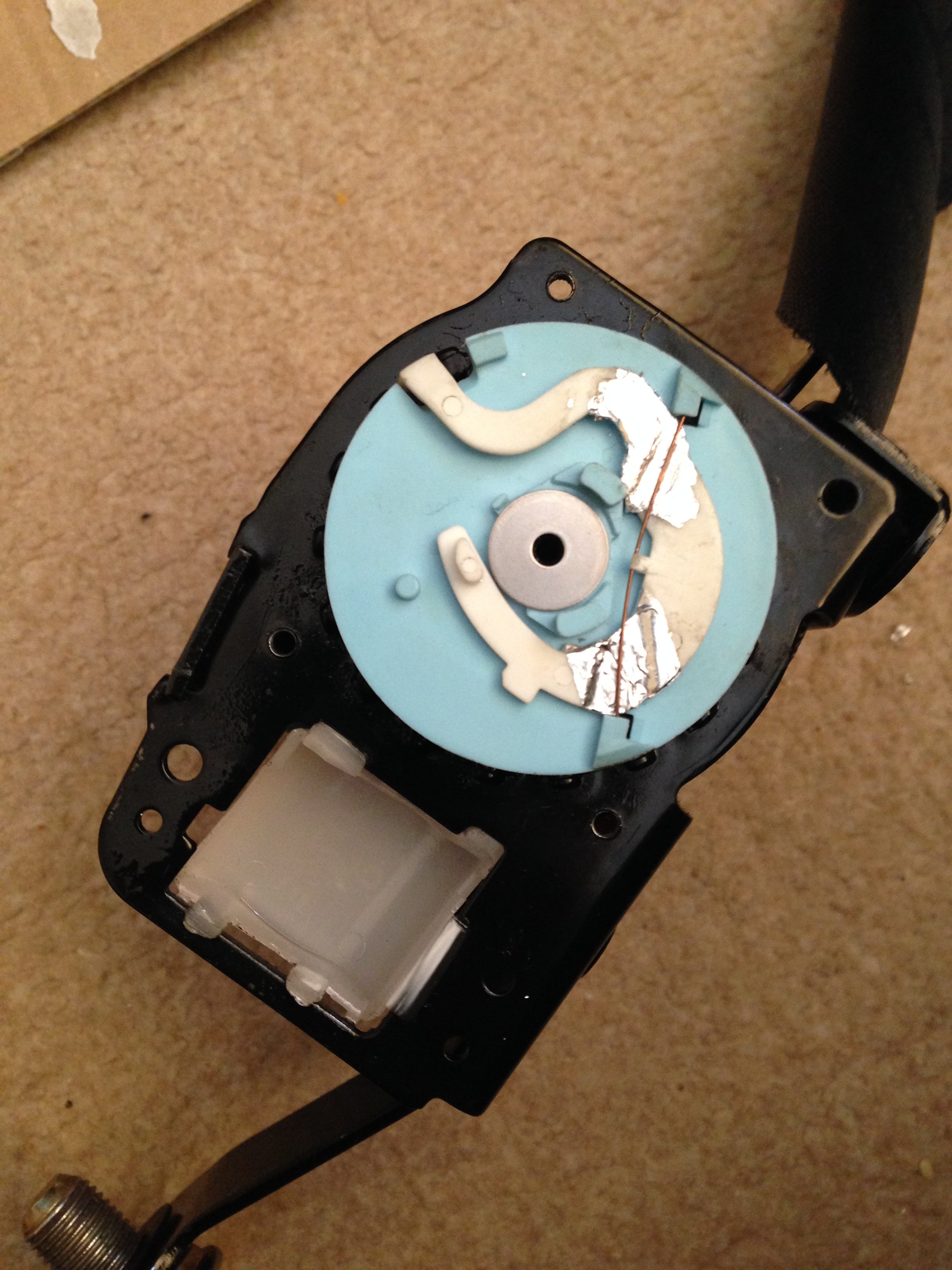

The seatbelt for the Daihatsu kept jamming to the point where it was sometimes impossible to use. So i fixed it with tinfoil.

A piece of the mechanism had snapped and got stuck. Now itís flimsy thin plastic so just trying to superglue it together wouldnt work, but what if I reinforced it? I pasted glue on small sheets of tinfoil and wrapped the breaks, building up several layers. The seatbelt now works as it should.

If/ when my bodge fix fails, the seatbelt mechanism will just lock. So thankfully I have no worries about it breaking in a crash and releasing me through the windscreen.

Eric @ opposite-lock.com

> Twingo Tamer - About to descend into project car hell.

Eric @ opposite-lock.com

> Twingo Tamer - About to descend into project car hell.

02/05/2018 at 12:16 |

|

This looks like a case where a 3D printed part would be a great solution...

Twingo Tamer - About to descend into project car hell.

> Eric @ opposite-lock.com

Twingo Tamer - About to descend into project car hell.

> Eric @ opposite-lock.com

02/05/2018 at 12:23 |

|

I actually thought just that, but this repair is fairly strong at the moment so Iíll see how it goes. If it breaks again Iíll fire up AutoCAD and sort out a new part.

TheRealBicycleBuck

> Twingo Tamer - About to descend into project car hell.

TheRealBicycleBuck

> Twingo Tamer - About to descend into project car hell.

02/05/2018 at 12:28 |

|

You could also pick up some thin carbon fiber rod or sheet material at your local hobby shop. You could even get a bit of fiberglass cloth at Walmart. Any of these †would be stronger than foil.

Twingo Tamer - About to descend into project car hell.

> TheRealBicycleBuck

Twingo Tamer - About to descend into project car hell.

> TheRealBicycleBuck

02/05/2018 at 12:31 |

|

It had to be super thin or itd foul on the rest of the mechanism. I only had a millimetre or two to work with.

TheRealBicycleBuck

> Twingo Tamer - About to descend into project car hell.

TheRealBicycleBuck

> Twingo Tamer - About to descend into project car hell.

02/05/2018 at 12:44 |

|

Iíve used CF rod to make a similar repair by cutting a groove perpendicular to the crack into the two halves, inserting the rod, then epoxying the whole shebang together.

Twingo Tamer - About to descend into project car hell.

> TheRealBicycleBuck

Twingo Tamer - About to descend into project car hell.

> TheRealBicycleBuck

02/05/2018 at 13:11 |

|

The white plastic piece is only 2-3mm thick so that probably wouldnt work in this instance.

TheRealBicycleBuck

> Twingo Tamer - About to descend into project car hell.

TheRealBicycleBuck

> Twingo Tamer - About to descend into project car hell.

02/05/2018 at 14:30 |

|

Maybe not. They sell CF rod down to 1.8mm diameter. The stuff is pretty cheap. Might be worth a try if your other plans donít work out.

Twingo Tamer - About to descend into project car hell.

> TheRealBicycleBuck

Twingo Tamer - About to descend into project car hell.

> TheRealBicycleBuck

02/05/2018 at 15:54 |

|

Iíll keep it in mind for any future bodges at least haha.