"E90M3" (e90m3)

"E90M3" (e90m3)

12/13/2018 at 08:55 ē Filed to: None

5

5

8

8

"E90M3" (e90m3)

"E90M3" (e90m3)

12/13/2018 at 08:55 ē Filed to: None |  5 5

|  8 8 |

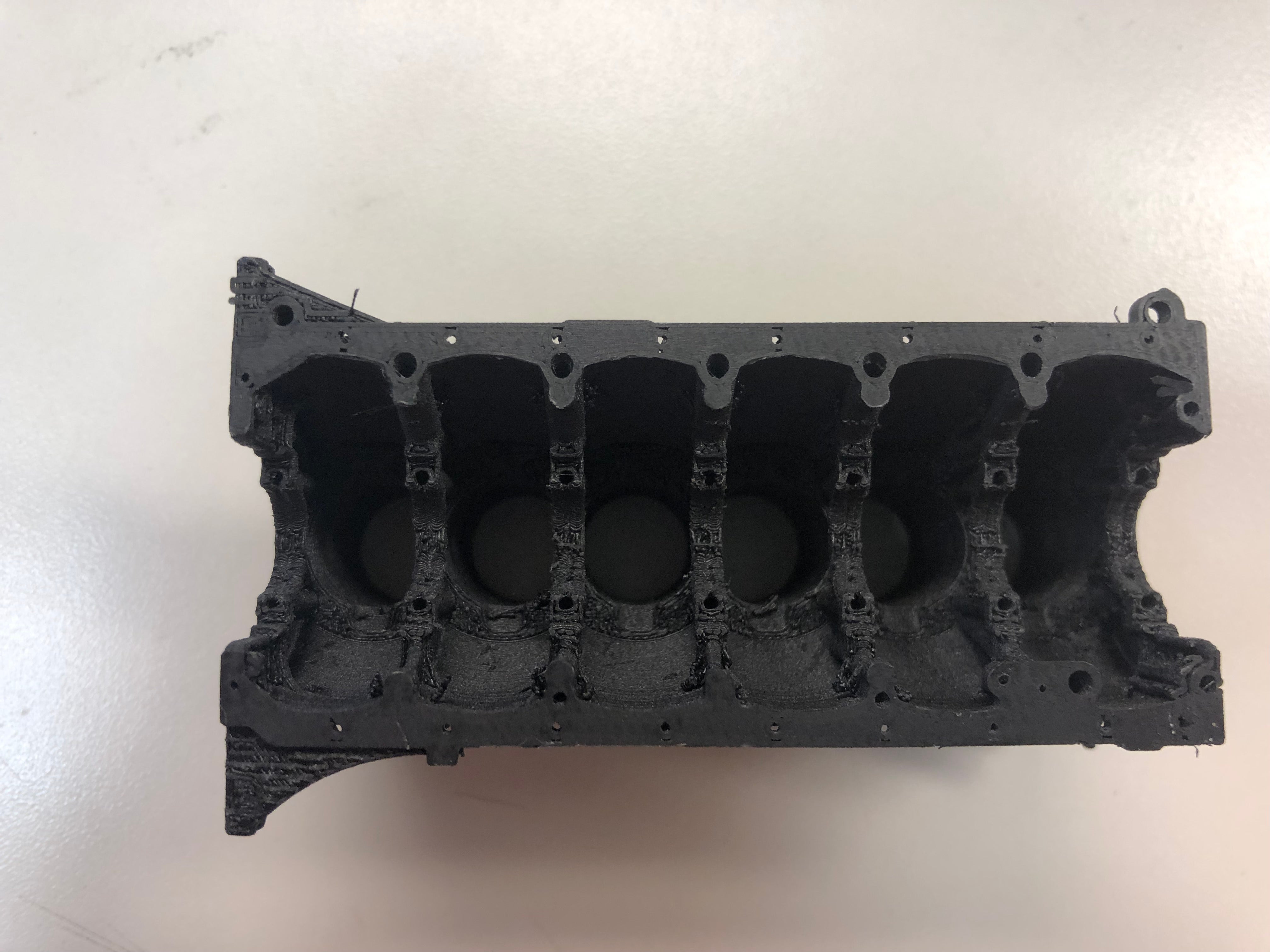

Itís a little rough, but the nylon with chopped carbon fiber in it is certainly strong. Makes a cool little desk piece. !!!error: Indecipherable SUB-paragraph formatting!!!

cletus44 aka Clayton Seams

> E90M3

cletus44 aka Clayton Seams

> E90M3

12/13/2018 at 08:56 |

|

Wow cool how big is it? If you could make other engine blocks, Iíd happily buy one from you.†

TheRealBicycleBuck

> E90M3

TheRealBicycleBuck

> E90M3

12/13/2018 at 09:21 |

|

I read an article about chopped CF. They were saying that it wasnít as strong as the same part CF fabric, but itís supposed to be a lot more versatile and easier/cheaper to work with. They suggested that it would replace the normal layup process, making CF composites more common and a lot less expensive.

Whatís your take on it?

user314

> E90M3

user314

> E90M3

12/13/2018 at 09:31 |

|

E90M3

> cletus44 aka Clayton Seams

E90M3

> cletus44 aka Clayton Seams

12/13/2018 at 10:17 |

|

Itís 15% of the size, would love to do that, but since Iím pretty sure my company wouldnít be too happy about it, wonít be able to.

E90M3

> TheRealBicycleBuck

E90M3

> TheRealBicycleBuck

12/13/2018 at 10:18 |

|

Seems to be pretty strong. The MEs pressed a piece they †made with 37% infill and it stood up to 2500 PSI before it failed. It also seems somewhat flexible, which can be a good thing.†

tromoly

> TheRealBicycleBuck

tromoly

> TheRealBicycleBuck

12/13/2018 at 10:48 |

|

It canít strengthen layer bonding because thatís not how FDM works, youíre still relying on adhesion of plastic between layers for strength. Itíll strengthen each individual continuous layer though, youíll get much better strength in two directions and youíll need to take your object printing orientation into account more than usual to really see a benefit from the filament.

Downside is it can wear out nozzles quicker due to forcing a harder substance through the openings, some people are experimenting with Ruby tipped nozzles and other harder materials to try making more wear-resistant nozzles.

TheRealBicycleBuck

> tromoly

TheRealBicycleBuck

> tromoly

12/13/2018 at 11:02 |

|

Neat. I was wondering about adhesion between layers. I figured that the CF wouldnít extend between the layers, making that the weakest part. I thought that the primary advantage of CF weave is the strength in tension, so I wasnít sure how chopped CF would be a big advantage unless the entire part was injection molded. Really, I was surprised that they are using it in 3D printing at all.

nerd_racing

> E90M3

nerd_racing

> E90M3

12/13/2018 at 11:14 |

|

Iím toying with the idea of getting a Creality CR10 to do big prints.† Might have to do an engine if I ever get one.†