"BeaterGT" (beatergt)

"BeaterGT" (beatergt)

10/20/2018 at 18:10 ē Filed to: None

0

0

33

33

"BeaterGT" (beatergt)

"BeaterGT" (beatergt)

10/20/2018 at 18:10 ē Filed to: None |  0 0

|  33 33 |

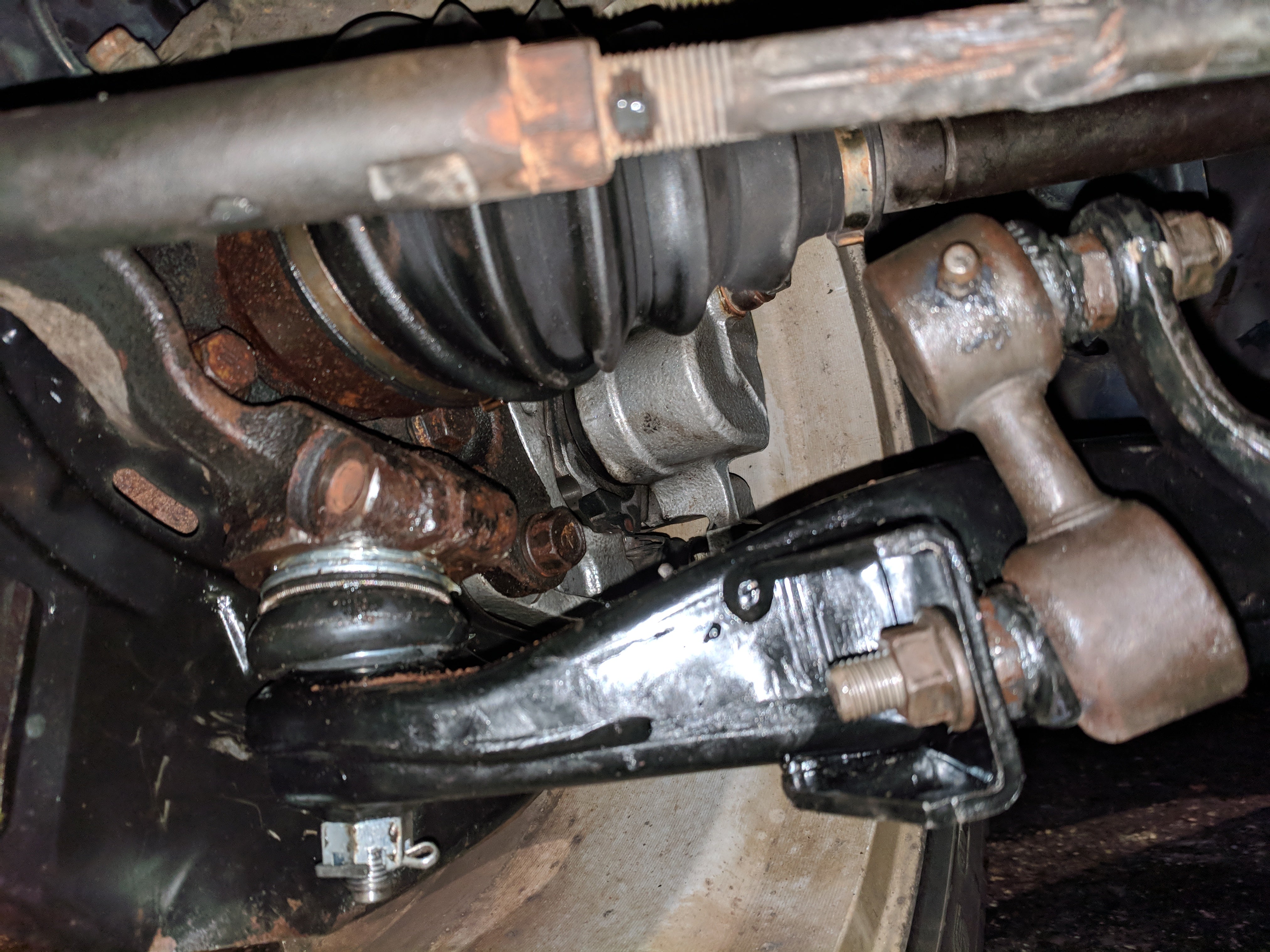

Trying to replace ball joints on my Legacy GT. Getting the old one out was hard enough but now the new ball joint wonít seat all the way inside the knuckle. Tried putting the jack underneath the ball joint and jacking it up into the knuckle but no luck, it was raising the car off the stands. Any suggestions, Oppo?

Now with picture!

My X-type is too a real Jaguar

> BeaterGT

My X-type is too a real Jaguar

> BeaterGT

10/20/2018 at 18:15 |

|

You are braver than I, ball joints are one thing I wonít DIY

sony1492

> BeaterGT

sony1492

> BeaterGT

10/20/2018 at 18:20 |

|

If your pressing in a ball joint you need a press or a special c clamp.

MoCamino

> sony1492

MoCamino

> sony1492

10/20/2018 at 18:41 |

|

This, very much. †I have always had to use the clamp/press tool. †It just wonít seat right otherwise. †Fortunately you can get them as a full refund rental at the parts store. †

Sovande

> BeaterGT

Sovande

> BeaterGT

10/20/2018 at 18:43 |

|

Is it just the tapered bolt part that wonít seat? If so, put the taper in the hole and let the car down in it. Then hit the adjacent flat part of the (Iím assuming) control arm with a hammer and it should slide in.

sony1492

> MoCamino

sony1492

> MoCamino

10/20/2018 at 18:44 |

|

Id be more afraid if it didn't require the clamp

BeaterGT

> sony1492

BeaterGT

> sony1492

10/20/2018 at 19:04 |

|

Hereís a pic. Got a C clamp but it isnít too special. We did rent a press kit from Advanced but ran out of light.†

BeaterGT

> Sovande

BeaterGT

> Sovande

10/20/2018 at 19:22 |

|

Added a pic. It doesn't seem like the ball joint is fully seated to put the pinch bolt back in.†

sony1492

> BeaterGT

sony1492

> BeaterGT

10/20/2018 at 19:38 |

|

Youíll need to rerent the press to finish this

Wild

> BeaterGT

Wild

> BeaterGT

10/20/2018 at 19:40 |

|

Pu t the ball joint in a freezer for a couple hours. Next time put the internal part in the freezer as soon as ya get it and leave it there until immediately before installation.

BeaterGT

> sony1492

BeaterGT

> sony1492

10/20/2018 at 19:40 |

|

I still have it. Will give it a shot in the morning.†

Sovande

> BeaterGT

Sovande

> BeaterGT

10/20/2018 at 19:42 |

|

I'm not sure what I'm looking at, but c an you just tighten the nut until it sucks it in tight? Any chance you have an impact wrench?†

BeaterGT

> Wild

BeaterGT

> Wild

10/20/2018 at 19:42 |

|

Definitely wish I had done this but I'm actually replacing the entire control arm so I didn't have to press in or out anything, so the ball joint was already in the control arm. Watched a bunch of people just hammer the new ball joint in but that is not working here.†

BeaterGT

> My X-type is too a real Jaguar

BeaterGT

> My X-type is too a real Jaguar

10/20/2018 at 19:44 |

|

Iím just happy I didnít break the old pinch bolt in the knuckle. Didnít expect installation to give me this much trouble.

Boxer_4

> BeaterGT

Boxer_4

> BeaterGT

10/20/2018 at 19:46 |

|

Whatís the surface look like in the cup? If the old ball joint had corrosion on it, Iím guessing the mating surface doesnít look to great.

Not any help, but I hate those ball joints. I couldnít even get it out. I ended up paying a local shop $160 all in for the replacement. Totally worth it in my opinion.

BeaterGT

> Sovande

BeaterGT

> Sovande

10/20/2018 at 19:48 |

|

The castle nut is fully fastened, which draws the ball joint in to the control arm . The exposed top of the ball joint should be in up to the shoulder but itís not quite there. No way to pound the knuckle down into it either.†

BeaterGT

> Boxer_4

BeaterGT

> Boxer_4

10/20/2018 at 19:58 |

|

It wasnít great but we cleaned it up real well and greased it too . And I know what you mean, we had to use some real interesting, yet effective, techniques to get the old ball joint out of the knuckle. $160 is a great price!†

Sovande

> BeaterGT

Sovande

> BeaterGT

10/20/2018 at 20:00 |

|

Ah gotcha. I was thinking of the wrong end. I gots nothing.†

BeaterGT

> Sovande

BeaterGT

> Sovande

10/20/2018 at 20:00 |

|

Thanks for your help anyway, I know the setup youíre talking about.

Urambo Tauro

> BeaterGT

Urambo Tauro

> BeaterGT

10/20/2018 at 21:07 |

|

Is the ball-joint retained by a pinch bolt? Kinda looks like it from here. Canít say Iíve come across a setup like that before. If that i s the case, you should be able to open up the ears with a chisel.

BeaterGT

> Urambo Tauro

BeaterGT

> Urambo Tauro

10/20/2018 at 21:10 |

|

Yep! Thought about that too but would hate to break an ear. Hoping tomorrow brings more luck.†

ItalianJobR53 - now with added 'MERICA and unreliability

> BeaterGT

ItalianJobR53 - now with added 'MERICA and unreliability

> BeaterGT

10/20/2018 at 21:24 |

|

I dont have any suggestions, but best luck for tomorrow!

Also, wish me luck since iíll be doing the outer ball joints on the Mini on Wednesday.

BeaterGT

> ItalianJobR53 - now with added 'MERICA and unreliability

BeaterGT

> ItalianJobR53 - now with added 'MERICA and unreliability

10/20/2018 at 21:37 |

|

Haha, thanks. Good luck and don't forget to pre soak with some PB!

brianbrannon

> BeaterGT

brianbrannon

> BeaterGT

10/20/2018 at 22:57 |

|

I use a man height pry bar to pop those out. Just hit the arm with a big hammer to seat the new one.

May be difficult to get a good swing† from your angle. Did you try bouncing the car while jacking the arm up slightly?

BeaterGT

> brianbrannon

BeaterGT

> brianbrannon

10/20/2018 at 23:03 |

|

Sure did, and yeah there is almost no room to swing up but surely the jack should have worked . We used a socket trick to unseat the old ball joint. Thereís also a possibility RockAuto sent me the wrong parts so going to try a different ball joint tomorrow and go from there.†

ItalianJobR53 - now with added 'MERICA and unreliability

> BeaterGT

ItalianJobR53 - now with added 'MERICA and unreliability

> BeaterGT

10/20/2018 at 23:39 |

|

Thanks!

ITA97, now with more Jag @ opposite-lock.com

> BeaterGT

ITA97, now with more Jag @ opposite-lock.com

> BeaterGT

10/21/2018 at 01:16 |

|

The ďrightĒ answer is a ball joint press. In the alternative, you can probably spread the ears a bit on arm. Thereís also the old school trick of freezing the ball joint overnight to shrink it a bit.

Khalbali

> BeaterGT

Khalbali

> BeaterGT

10/21/2018 at 10:30 |

|

Thatís the way Iíd do it, never had an ear brake and there was a huge recall on cx9 ball joints while I was a Mazda tech, did 1-5 sets a day for close to a year.

BeaterGT

> Khalbali

BeaterGT

> Khalbali

10/21/2018 at 10:35 |

|

Looks like I might have been sent the wrong control arm so Iíll have to wait and see what the solution is.

MoCamino

> sony1492

MoCamino

> sony1492

10/21/2018 at 15:15 |

|

Excellent point. †No clamp = way too loose = death trap. †

BeaterGT

> Khalbali

BeaterGT

> Khalbali

10/26/2018 at 08:19 |

|

You use a hammer and chisel to spread the ears?†

Khalbali

> BeaterGT

Khalbali

> BeaterGT

10/26/2018 at 23:13 |

|

Yep, spread them out a bit, hammer the old arm out, line up bolts on the new one and then hammer new one in, just donít hammer directly on the ball joint, hit the arm itself close by.

BeaterGT

> Khalbali

BeaterGT

> Khalbali

10/27/2018 at 01:27 |

|

Had to unbolt the strut assembly but got the new one in. Unfortunately the pinch threads came out with the old bolt so now I have to get a bolt and nut in there.†

Khalbali

> BeaterGT

Khalbali

> BeaterGT

10/27/2018 at 07:58 |

|

Weird I've never seen that threaded, mazdas have a bolt anyways. Just be careful tightening it (maybe get a couple lol) I couldn't tell you how many I've stripped. When you've got it together do a tight figure 8 in a parking lot and listen for chunks as you load up each corner, we had a lot of apprentices at my old shop so we had a lot of comebacks on them and it was almost always that bolt being overtightened and stripping.