"Nick Has an Exocet" (nickallain)

"Nick Has an Exocet" (nickallain)

04/14/2017 at 13:14 ē Filed to: None

0

0

9

9

"Nick Has an Exocet" (nickallain)

"Nick Has an Exocet" (nickallain)

04/14/2017 at 13:14 ē Filed to: None |  0 0

|  9 9 |

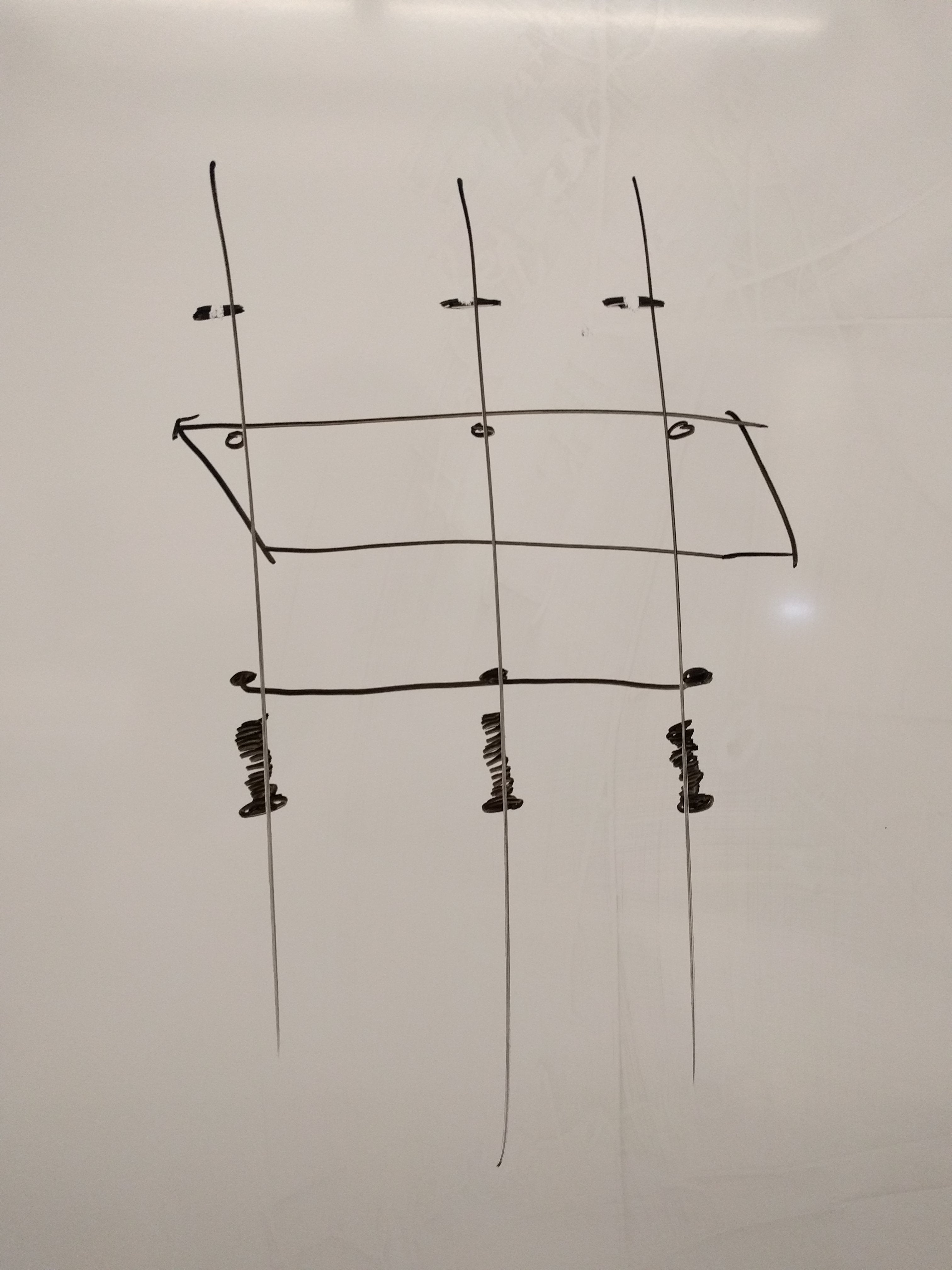

Warning: my drawing is crap but it probably an accurate depiction for why all the threads are busted.

I have an aluminum undertray for the ralliart. It bolts up between a chassis brace and the frame. Unfortunately, all 3 bolts that hold the brace/tray seem to have stripped their threads. They all turn wonderfully freely and never release. This is blocking me from servicing the transmission and transfer case. Anyone have any sweet tips on getting these things unstuck using my driveway and charisma? Happy to drive to harbor freight and pick up an extra tool or two if it will help.

Iíd like to avoid drilling them out if possible because itís a really awkward position under the car.

The Crazy Kanuck; RIP Oppositelock

> Nick Has an Exocet

The Crazy Kanuck; RIP Oppositelock

> Nick Has an Exocet

04/14/2017 at 13:19 |

|

Sell it & buy a Juke.

SidewaysOnDirt still misses Bowie

> Nick Has an Exocet

SidewaysOnDirt still misses Bowie

> Nick Has an Exocet

04/14/2017 at 13:20 |

|

If theyíre free spinning, the drill might not even work. From what Iíve seen of things like this, thereís usually a nut tack-welded inside, so if free spinning Iíd think those welds broke. When I ran into this with the rear sway-bar on my car, I had to cut into the frame rails and weld a new nut down. :(

TahoeSTi

> Nick Has an Exocet

TahoeSTi

> Nick Has an Exocet

04/14/2017 at 13:29 |

|

JB weld a nut on the other side...or to the front if you canít get to the back.....or get a helicoil kit.

Rust and Dust - Oppositelock Forever

> Nick Has an Exocet

Rust and Dust - Oppositelock Forever

> Nick Has an Exocet

04/14/2017 at 13:37 |

|

Iím guessing thereís a tack welded nut, or a cage-nut that the screw goes into thatís spinning. You may be able to get something between the undertray and the body to pry down, putting a force on the screw to hopefully pin the nut in place and allow the screw to unthread itself. (I do this alot with screws that thread into plastic grommets, the plastic will strip and the screw will spin in place).

Or just take a grinder and grind the head off of the fastener, and replace.

Nick Has an Exocet

> SidewaysOnDirt still misses Bowie

Nick Has an Exocet

> SidewaysOnDirt still misses Bowie

04/14/2017 at 14:00 |

|

Ack, that sounds awful.

Nick Has an Exocet

> The Crazy Kanuck; RIP Oppositelock

Nick Has an Exocet

> The Crazy Kanuck; RIP Oppositelock

04/14/2017 at 14:00 |

|

This post was just waiting for that reply.

bobbe17

> Rust and Dust - Oppositelock Forever

bobbe17

> Rust and Dust - Oppositelock Forever

04/14/2017 at 14:20 |

|

These were the two options I was thinking too. Get a screwdriver or pry bar to pull down on the bolt while unscrewing. If there isnít room to get something under, you could get a vice grips on the head to pull down while turning it.

When all else fails, just cut that shit out.

Rust and Dust - Oppositelock Forever

> bobbe17

Rust and Dust - Oppositelock Forever

> bobbe17

04/14/2017 at 14:31 |

|

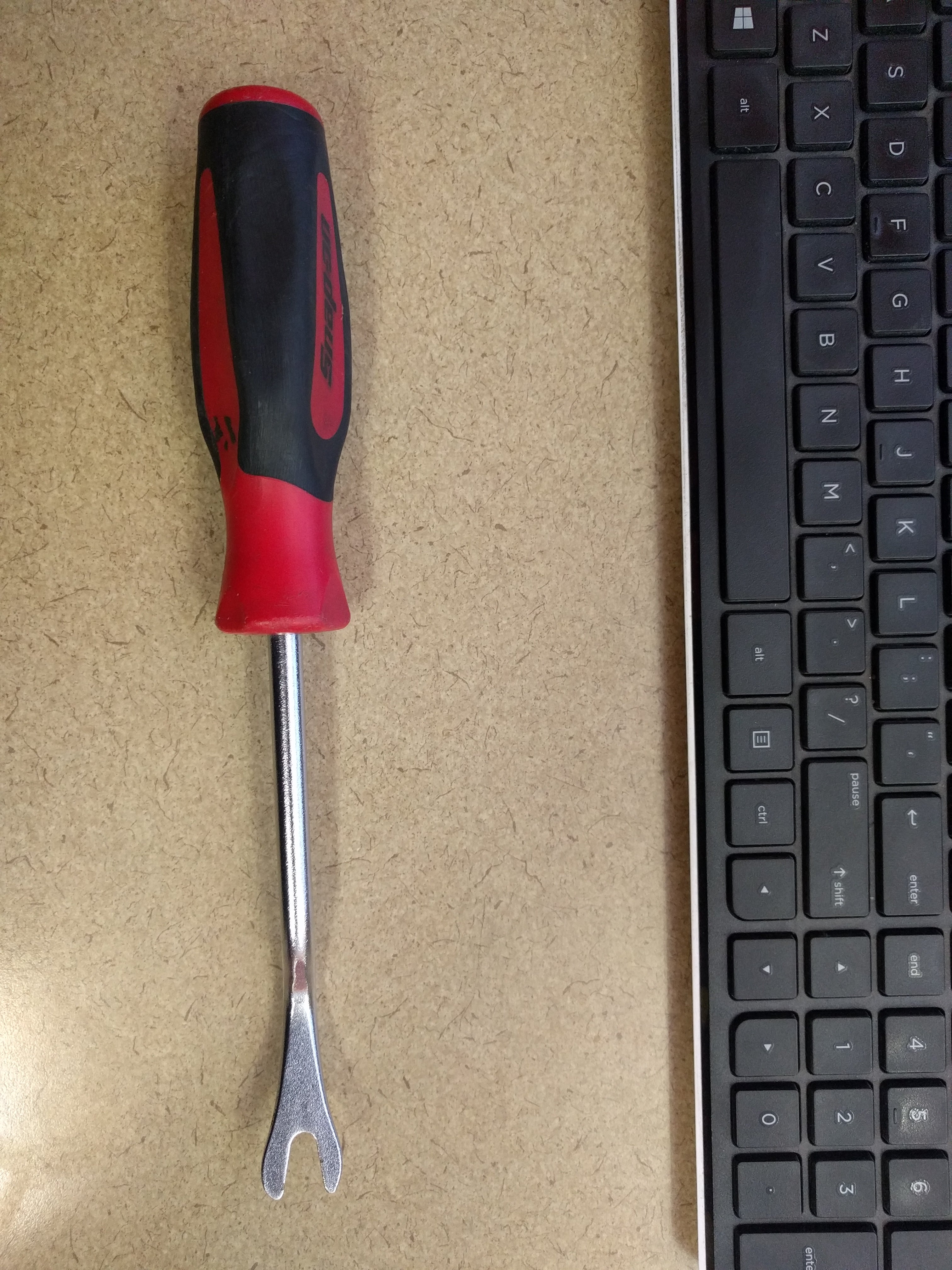

Clip tools work really well, too. Theyíll fork around the bolt/screw, and focus or isolate the pressure.

PS: You know itís a slow day at work when youíre taking photos of clip tools.

StudyStudyStudy

> Nick Has an Exocet

StudyStudyStudy

> Nick Has an Exocet

04/14/2017 at 19:46 |

|

I am guessing stripped is the wrong word sounds more like the tacks have broken off allowing the nut to spin freely. If so you can pry down on the head of the bolt and use an impact or what not to try and get the nut to jam against the remnants of the weld/friction to get it to spin out.

Alternatively just cut the heads off the bolt and push the remnants up into the under tray. Then replace the stuff after with a longer/better bead.