"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

04/05/2017 at 18:00 • Filed to: 41TE, Automatic Transmission, Rebuild, Blog

6

6

0

0

"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

04/05/2017 at 18:00 • Filed to: 41TE, Automatic Transmission, Rebuild, Blog |  6 6

|  0 0 |

Stack ’em up!

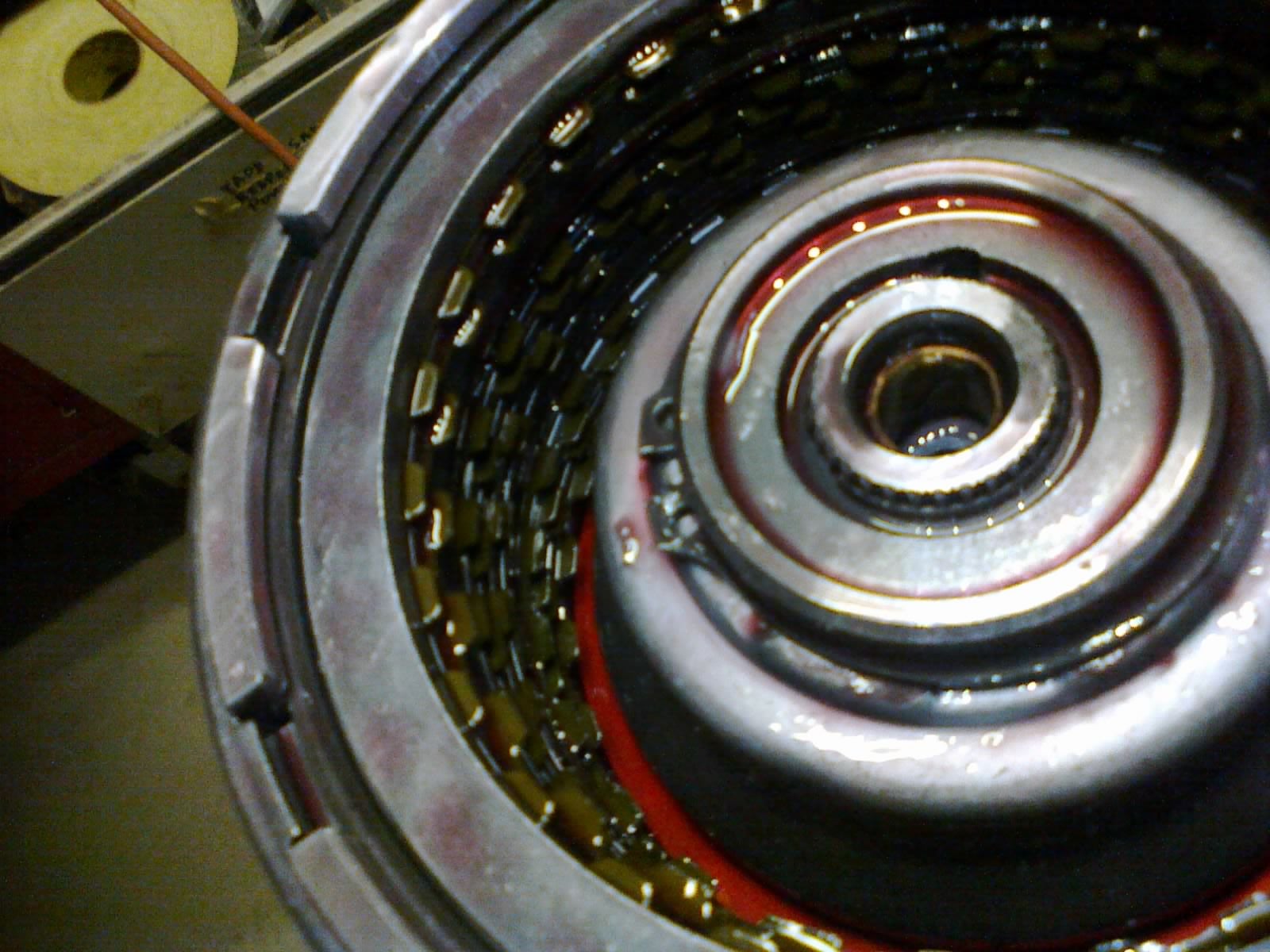

Underdrive clutch (pictured with old frictions) prior to cleaning

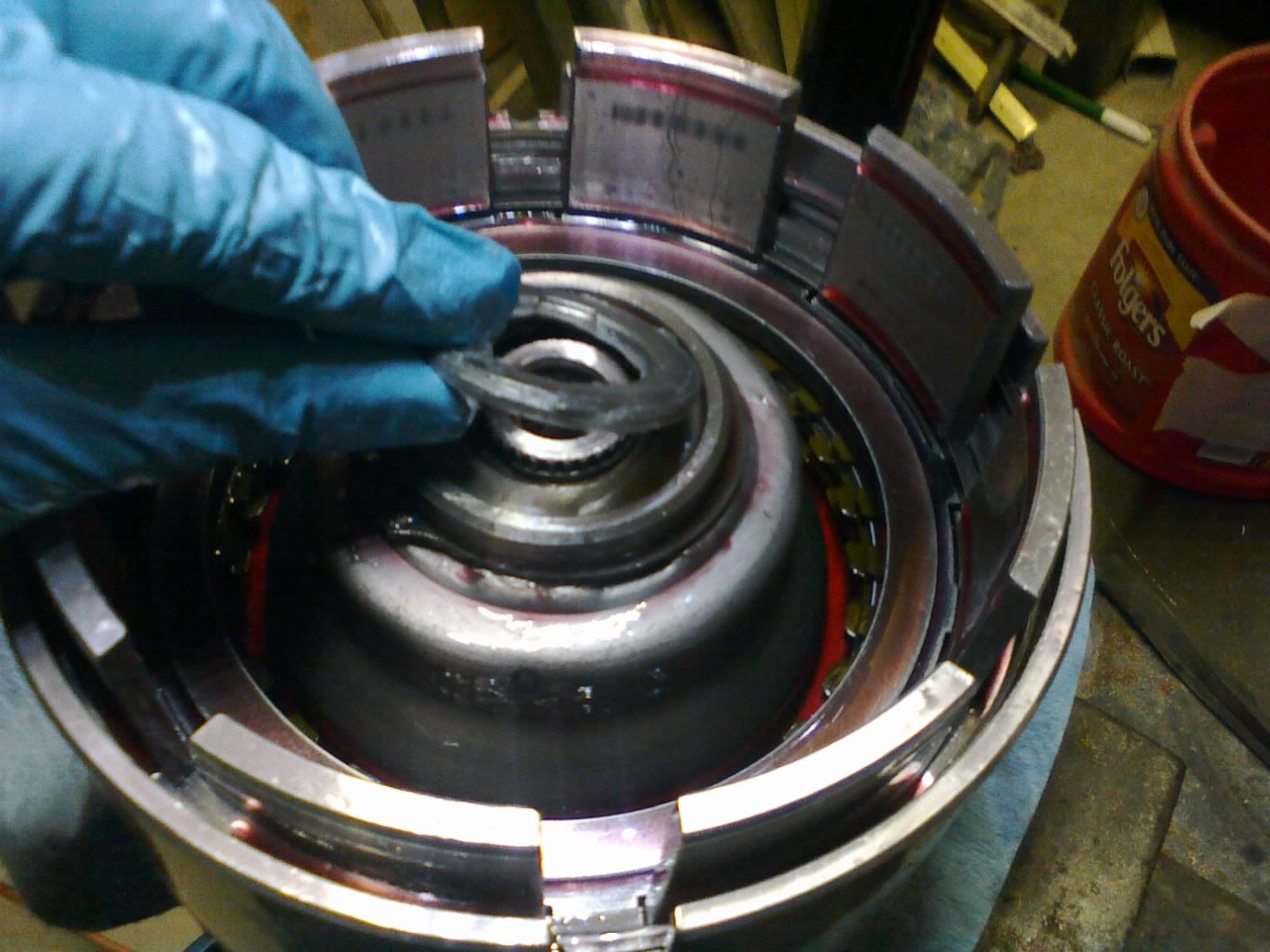

UD pack stacked with new parts and fresh fluid

UD clutch in the drum, snap-ring ready to go in

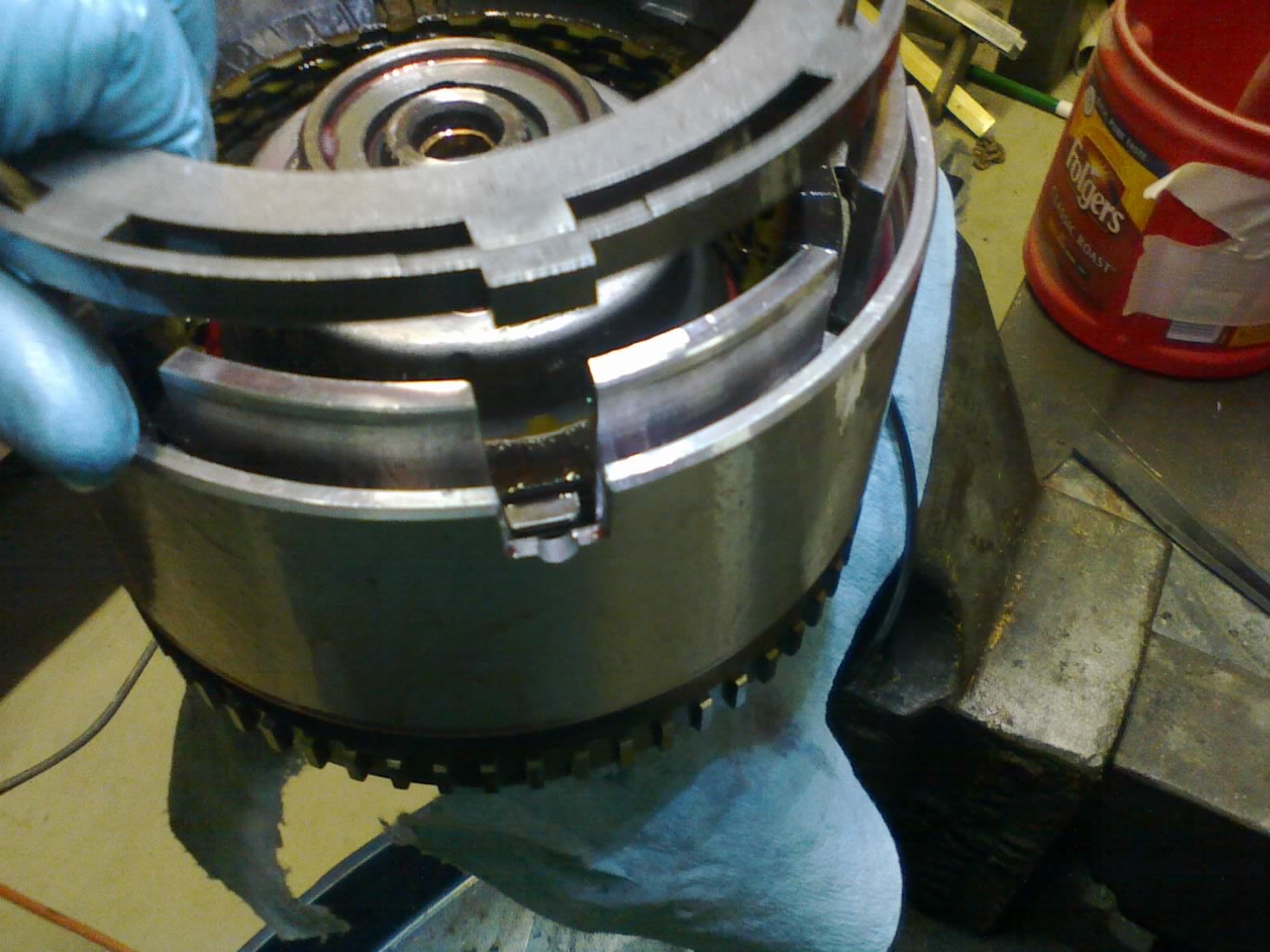

Then another UD friction, and this thick “reaction”/pressure plate, which gets held down by another snap-ring

(If you’ve done a 41TE before, you may have already noticed that the notches of the input clutch drum and OD/R piston are not aligned in the above pics (nor in the previous post). I made the rookie mistake of continuing assembly, and got all the way up to the reverse clutches before I realized that the reverse pressure plate wouldn’t go in. Backtracking sucks.)

Now we gather and clean these parts

A flat roller bearing, packed with assembly jelly, goes here

This thrust washer gets stuck onto the underdrive shaft hub with some jelly

This thrust plate get stuck underneath the OVERdrive shaft hub with more jelly

The OD hub slide over the UD shaft, then this thrust plate goes on top of the OD hub

Now that stack of hubs and shafts go into the input drum. The UD hub (underneath the visible OD hub) gets worked down in with the UD clutch frictions.

OD clutch parts (old frictions pictured). The OD frictions showed more wear than the others, but still had clearly defined grooves.

Friction, steel, friction, steel... you know the drill. And this wavy snap-ring goes on the outside of the input clutch drum, just inside the OD/R piston. (OD&UD hubs removed for clarity) (Note: this is one of the early pics I took, before the notches were aligned. You’ll see why this is important in the next pic.)

The thick overdrive pressure plate slides over the clutch drum, and nestles in the notches of the OD/R piston (OD&UD hubs removed)

(W OD&UD hubs in place) OD pressure plate is now held in by a snap-ring

Reverse clutch parts (old frictions pictured). Yup, just two frictions here.

Reverse clutch in, topped with the reverse pressure plate, and held in with another snap-ring (OD&UD hubs removed)

(W OD&UD hubs in place)

Input drum is now assembled!

Input drum goes into the case, and another flat roller bearing slides in

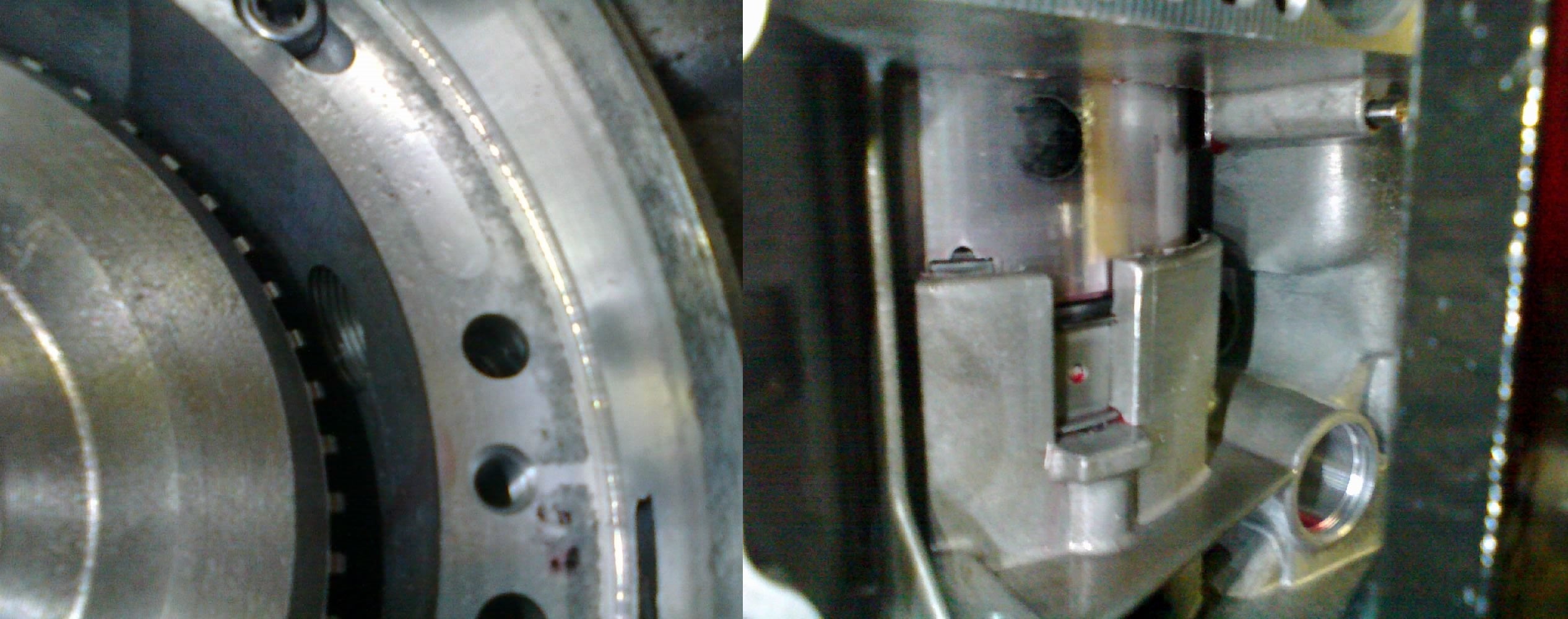

LEFT: The input hub’s tone ring should now line up with the input sensor hole. RIGHT: The whole drum assembly should slide this far into the case (view from valve body area). If it does, we’ll have room for...

Next: the pump !!!error: Indecipherable SUB-paragraph formatting!!!