"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

12/11/2017 at 12:00 ē Filed to: saab 900, project, wrenching

2

2

6

6

"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

12/11/2017 at 12:00 ē Filed to: saab 900, project, wrenching |  2 2

|  6 6 |

Backside of harmonic balancer/crank pulley assembly, with oil seal and trigger plate attached

Delays, delays... maybe we should have seen this one coming, though.

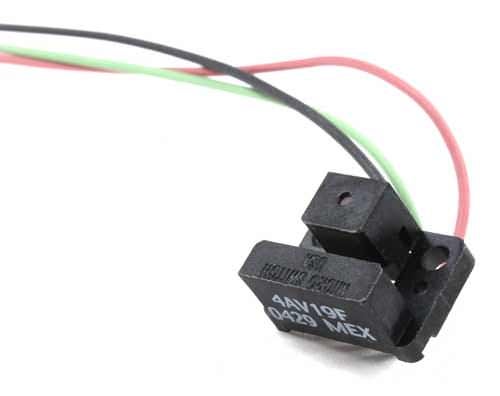

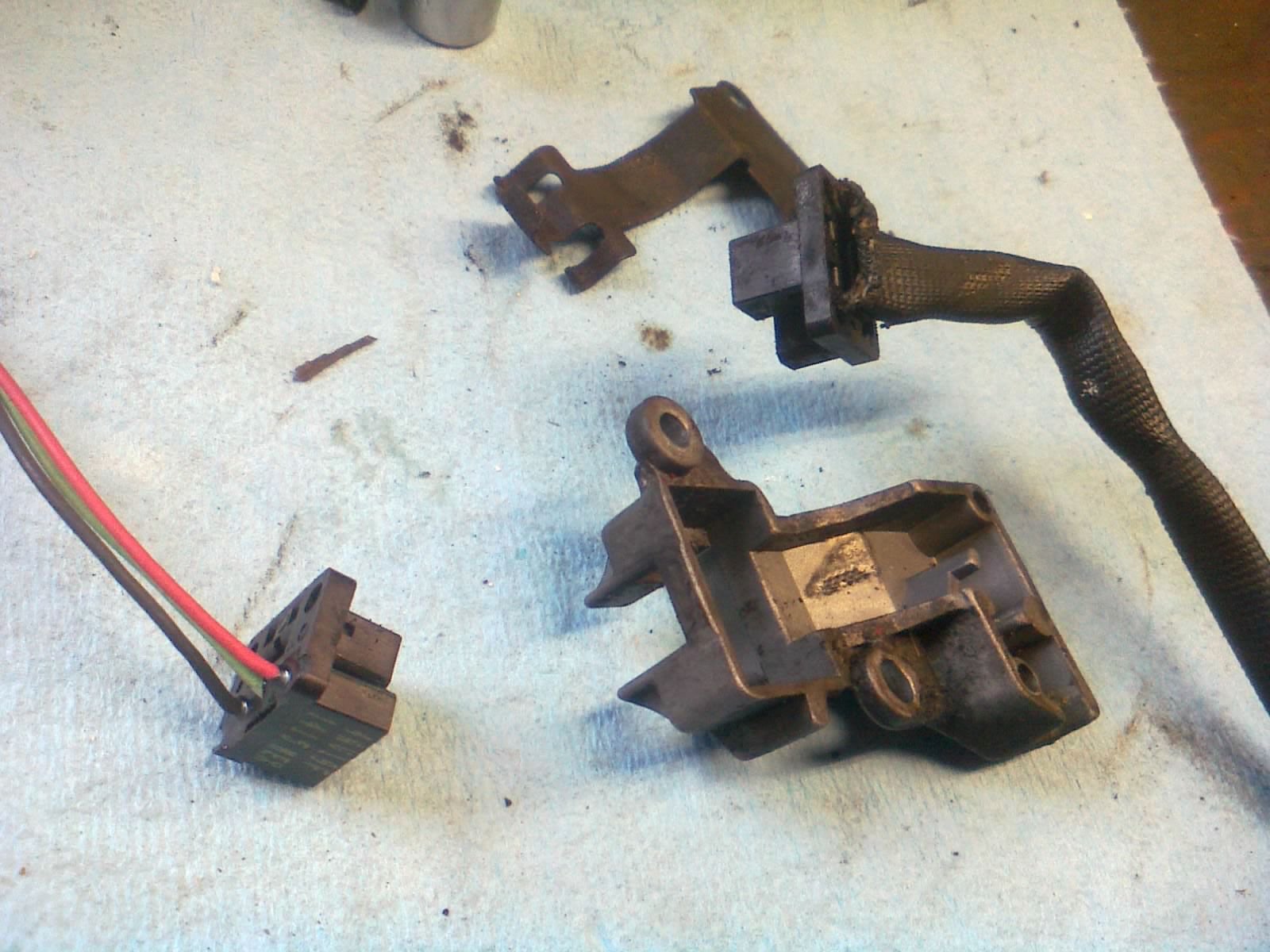

So it turns out that crank sensors for these cars are !!!error: Indecipherable SUB-paragraph formatting!!! . But !!!error: Indecipherable SUB-paragraph formatting!!! has a solution. They managed to track down the OE supplier and now offer the guts of the sensor assembly. No bracket, no connector, just the core pellet with some wires sticking out. Itíll need to be spliced in.

Old crank sensor disassembled, new one ready to swap in

But before ordering that sensor, my brother made sure to yank the belts off of the engine and confirm that yes, of course we should definitely replace them. He also found an idler pulley that rotates rather... crunchily. Good catch!

One of the old cracked belts vs new replacement

New idler pulley installed on its bracket

Well, here we are: the parts came in, and my brother managed to weasel the crank pulleys off. (Better his knuckles than mine haha. Saabís placing of the ďfrontĒ of the engine up against the firewall sure is a pain in the neck.) But thatís when we realized that maybe he should have ordered a harmonic balancer, too. The rubber insert is hardened and cracking, and we donít want to have to take this back apart again any time soon to deal with it.

Harmonic balancer/pulley assembly

So boom goes the parts cannon, again. Maybe weíll have the !!!error: Indecipherable SUB-paragraph formatting!!! again next weekend? Maybe?

Urambo Tauro

> Urambo Tauro

Urambo Tauro

> Urambo Tauro

12/11/2017 at 12:04 |

|

Anybody got any tips for splicing really small wires together?

diplodicus

> Urambo Tauro

diplodicus

> Urambo Tauro

12/11/2017 at 12:36 |

|

What are you using? Butt splices? or just soldering?

Urambo Tauro

> diplodicus

Urambo Tauro

> diplodicus

12/11/2017 at 12:40 |

|

Havenít decided yet. The wires are -I donít know- 22g or something like that.

diplodicus

> Urambo Tauro

diplodicus

> Urambo Tauro

12/11/2017 at 12:50 |

|

Solder is probably best long term as long as its not going to be getting bent. Just make sure you donít cut any strands when stripping the wire. Or you could go with something like this https://www.mouser.com/ProductDetail/TE-Connectivity-Buchanan/1776293-3/?qs=sGAEpiMZZMsntO7gZZwOWAKAhgHRm%2fluHZH0iui%252bf4E%3d If youíve got enough wire to make it from the sensor mount to somewhere you can mount that block.

Urambo Tauro

> diplodicus

Urambo Tauro

> diplodicus

12/11/2017 at 13:00 |

|

Nah, I donít want to use a block. The head of the sensor mounts near the crankshaft on the ďfrontĒ of the engine block, and the wires (inside a sleeve) are routed upward from there (behind the belts), underneath the intake, then out the side near the dipstick. Thereís nowhere to conveniently mount a terminal block, and I want to be able to seal the splices with heat-shrink.

Funny thing is, it almost doesnít need a splice. The wires come up just 2 inches short of the original. So close...

Noah - Now with more boost.

> Urambo Tauro

Noah - Now with more boost.

> Urambo Tauro

12/11/2017 at 13:35 |

|

Parts cannon delays are the worst. Iím currently waiting on a set of spacers that were out of stock in the 2 biggest retailers.