"TheBloody, Oppositelock lives on in our shitposts." (thebloody)

"TheBloody, Oppositelock lives on in our shitposts." (thebloody)

01/05/2017 at 11:23 ē Filed to: FML.

5

5

32

32

"TheBloody, Oppositelock lives on in our shitposts." (thebloody)

"TheBloody, Oppositelock lives on in our shitposts." (thebloody)

01/05/2017 at 11:23 ē Filed to: FML. |  5 5

|  32 32 |

It needs to be recalibrated every once and a while.

crowmolly

> TheBloody, Oppositelock lives on in our shitposts.

crowmolly

> TheBloody, Oppositelock lives on in our shitposts.

01/05/2017 at 11:25 |

|

How far out was the wrench? Not just a torque sequence problem?

RamblinRover Luxury-Yacht

> TheBloody, Oppositelock lives on in our shitposts.

RamblinRover Luxury-Yacht

> TheBloody, Oppositelock lives on in our shitposts.

01/05/2017 at 11:26 |

|

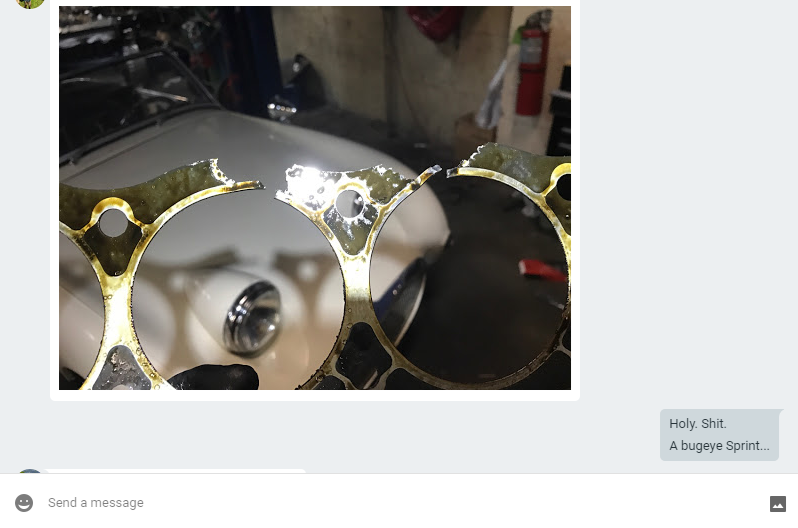

I want more info on how you got roped into a head gasket job on a Mk1 Sprite. This could be the stuff of legend.

Nibby

> RamblinRover Luxury-Yacht

Nibby

> RamblinRover Luxury-Yacht

01/05/2017 at 11:26 |

|

also remember if you have a CRT use it every now and then

TheBloody, Oppositelock lives on in our shitposts.

> crowmolly

TheBloody, Oppositelock lives on in our shitposts.

> crowmolly

01/05/2017 at 11:29 |

|

Not a sequence problem, there are a multiple bolts that are undertorqued. Iím having the heads rebuilt now... FML.

Tripper

> TheBloody, Oppositelock lives on in our shitposts.

Tripper

> TheBloody, Oppositelock lives on in our shitposts.

01/05/2017 at 11:30 |

|

Good point. Is there a calibration tool, or what?

Smallbear wants a modern Syclone, local Maple Leafs spammer

> TheBloody, Oppositelock lives on in our shitposts.

Smallbear wants a modern Syclone, local Maple Leafs spammer

> TheBloody, Oppositelock lives on in our shitposts.

01/05/2017 at 11:31 |

|

AKA always unwind your torque wrench when you finish with it.

TheBloody, Oppositelock lives on in our shitposts.

> RamblinRover Luxury-Yacht

TheBloody, Oppositelock lives on in our shitposts.

> RamblinRover Luxury-Yacht

01/05/2017 at 11:34 |

|

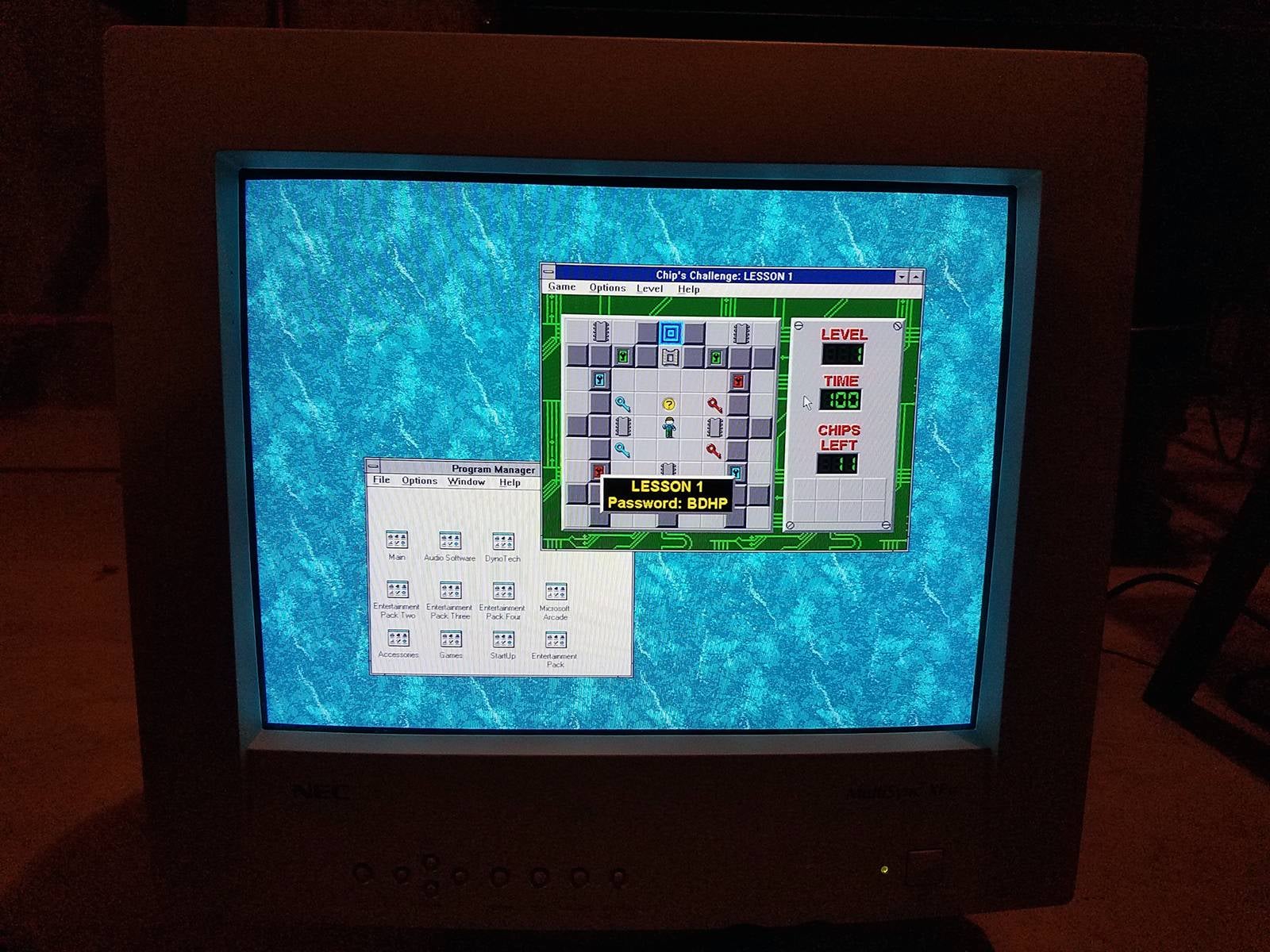

Lol, if only.

My Disco blew a head gasket so having just done the gasket job myself and it being the 4.6, I thought it was a liner so I took it to a place near me that specializes in British vehicles. The is the same place that had the 2b in itís yard for a while, he also has a few E-Types in the yard. I could spend hours walking around it and itís not even big.

Heís rebuilding the heads for me so Iím just having him do the gaskets at the same time. Sigh.

TheBloody, Oppositelock lives on in our shitposts.

> Smallbear wants a modern Syclone, local Maple Leafs spammer

TheBloody, Oppositelock lives on in our shitposts.

> Smallbear wants a modern Syclone, local Maple Leafs spammer

01/05/2017 at 11:38 |

|

Borrowed it from my dad as Iím still building my tool set and it never crossed my mind to double check it. Live and learn I guess.

RamblinRover Luxury-Yacht

> TheBloody, Oppositelock lives on in our shitposts.

RamblinRover Luxury-Yacht

> TheBloody, Oppositelock lives on in our shitposts.

01/05/2017 at 11:39 |

|

Please say youíre doing ARP studs and hacking the running temp.

DarrenMR

> TheBloody, Oppositelock lives on in our shitposts.

DarrenMR

> TheBloody, Oppositelock lives on in our shitposts.

01/05/2017 at 11:40 |

|

I bought a cheap ass one like 10 years ago. It wouldnt fit in my toolbox so I had it cranked down all the way as short as it would get and it sat there for years. Needless to say I dont use it as a torque wrench any longer.

TheBloody, Oppositelock lives on in our shitposts.

> RamblinRover Luxury-Yacht

TheBloody, Oppositelock lives on in our shitposts.

> RamblinRover Luxury-Yacht

01/05/2017 at 11:47 |

|

Thatís the worst part, I did use ARP studs and I have the soft spring thermostat already in there. Truck idles around 180F, if I had just bothered to check the torque wrench was properly calibrated I would have been free and clear!

†

RamblinRover Luxury-Yacht

> TheBloody, Oppositelock lives on in our shitposts.

RamblinRover Luxury-Yacht

> TheBloody, Oppositelock lives on in our shitposts.

01/05/2017 at 11:56 |

|

According to the book I have, RV8s actually reach peak efficiency at around 165F coolant temps. No, really.

Combine the absolutely garbage cooling system design with heat/shrink set liners and minimal cooling passages in the heads, and the ďhurr hurr crank up temps because emashunsĒ guy ought to be shot. The tin gaskets and 14 bolts on the heads are old design and an honest mistake respectively, but that?

TheBloody, Oppositelock lives on in our shitposts.

> RamblinRover Luxury-Yacht

TheBloody, Oppositelock lives on in our shitposts.

> RamblinRover Luxury-Yacht

01/05/2017 at 12:01 |

|

Jesus, well seeing as it was originally idling around 210 (no seriously I thought the thermostat was broken when I saw that the first time) I felt it was a marked improvement. I agree the emashuns guy needs to be drawn and quartered... slowly.†

It seems when I get the truck back Iíll need to do a few more tweeks to get the heat down further.

RamblinRover Luxury-Yacht

> TheBloody, Oppositelock lives on in our shitposts.

RamblinRover Luxury-Yacht

> TheBloody, Oppositelock lives on in our shitposts.

01/05/2017 at 12:05 |

|

180F seems like it would be fine, as long as the whizzmatically arcane cooling system isnít leaking. Hurr hurr plumb heater lines into lower hose hurr hurr radiator hose with a dip in it hurr. Since the cooling passages are so small, and the heads mostly rely on direct thermal transfer to the block, any leak is bad, bad, bad.

Urambo Tauro

> Tripper

Urambo Tauro

> Tripper

01/05/2017 at 12:06 |

|

I donít know about re-calibration, but you can test what you have against a beam-style wrench. Theyíre cheap and never lose calibration, as long as you donít abuse them.

TheBloody, Oppositelock lives on in our shitposts.

> RamblinRover Luxury-Yacht

TheBloody, Oppositelock lives on in our shitposts.

> RamblinRover Luxury-Yacht

01/05/2017 at 12:30 |

|

Tell me about it, heat are these engines worst enemy and itís compounded by the nearly useless temp gauge in the cluster. ďHurrdurr Iím not gonna move until itís too lateĒ

PotbellyJoe and 42 others

> RamblinRover Luxury-Yacht

PotbellyJoe and 42 others

> RamblinRover Luxury-Yacht

01/05/2017 at 12:31 |

|

The exact conversation I had with him when Bloody texted me the image. Of course, my phone didnít like the Swype of Sprite, but whatever.

punkgoose17

> Smallbear wants a modern Syclone, local Maple Leafs spammer

punkgoose17

> Smallbear wants a modern Syclone, local Maple Leafs spammer

01/05/2017 at 12:32 |

|

Oh crap... there is one more thing to do next summer.

Smallbear wants a modern Syclone, local Maple Leafs spammer

> punkgoose17

Smallbear wants a modern Syclone, local Maple Leafs spammer

> punkgoose17

01/05/2017 at 12:32 |

|

DAMMIT WHAT DID YOU DO

RallyWrench

> TheBloody, Oppositelock lives on in our shitposts.

RallyWrench

> TheBloody, Oppositelock lives on in our shitposts.

01/05/2017 at 13:00 |

|

Oh come on, it only takes like 7 minutes to get the head off an A-series, this is parking lot stuff. You think Churchill used a torque wrench whilst fastening the cylinder heads on Merlins while taking fire in midair? I dare say not, old boy.

*reminded that my 3 wrenches have not been calíd in 3 years, and have been used by others who donít back them off...

adamftw

> TheBloody, Oppositelock lives on in our shitposts.

adamftw

> TheBloody, Oppositelock lives on in our shitposts.

01/05/2017 at 13:24 |

|

Yup, this is why Iím not fixing mine. I know when I get in there more shit is gonna need replacing and when itís all done I bet itíll just leak again.

TheBloody, Oppositelock lives on in our shitposts.

> adamftw

TheBloody, Oppositelock lives on in our shitposts.

> adamftw

01/05/2017 at 13:30 |

|

If itís done correctly it wonít. Had I torqued down the nuts with the correct torque settings I wouldnít have to have the heads rebuilt. So annoyed with myself.

adamftw

> TheBloody, Oppositelock lives on in our shitposts.

adamftw

> TheBloody, Oppositelock lives on in our shitposts.

01/05/2017 at 13:52 |

|

I also have an old spring torque wrench so I probably would have had the same problem.

Frank Grimes

> TheBloody, Oppositelock lives on in our shitposts.

Frank Grimes

> TheBloody, Oppositelock lives on in our shitposts.

01/05/2017 at 15:15 |

|

nah just tighten until it creaks or cracks and back off a 1/4 turn.

AMGtech - now with more recalls!

> RallyWrench

AMGtech - now with more recalls!

> RallyWrench

01/05/2017 at 16:27 |

|

Digital ftw

AMGtech - now with more recalls!

> TheBloody, Oppositelock lives on in our shitposts.

AMGtech - now with more recalls!

> TheBloody, Oppositelock lives on in our shitposts.

01/05/2017 at 16:28 |

|

DISCO, NO!!!!

Replace with cometic gaskets? Those composite ones are junk

RallyWrench

> AMGtech - now with more recalls!

RallyWrench

> AMGtech - now with more recalls!

01/05/2017 at 16:36 |

|

Yep, theyíre damn nice. I just never got around to dropping the cash on one before I came into the office going on 4 years ago. Bad decision, that was.

TheBloody, Oppositelock lives on in our shitposts.

> AMGtech - now with more recalls!

TheBloody, Oppositelock lives on in our shitposts.

> AMGtech - now with more recalls!

01/05/2017 at 16:40 |

|

Iíll have to check and see what gaskets he uses, he said it will be better than factory when heís done so itís possible?

AMGtech - now with more recalls!

> TheBloody, Oppositelock lives on in our shitposts.

AMGtech - now with more recalls!

> TheBloody, Oppositelock lives on in our shitposts.

01/05/2017 at 22:03 |

|

Itís unlikely. Theyíre a special order item and cost about $150 each IIRC, but totally worth it

razorbeamteam

> TheBloody, Oppositelock lives on in our shitposts.

razorbeamteam

> TheBloody, Oppositelock lives on in our shitposts.

01/06/2017 at 12:08 |

|

I just wrapped up the head gasket job on my 92 RRC with the 3.9. I think if I found out it failed I would cry. That job kicked my ass. I didnít burp the coolant properly and had the therm shut and the freeze plug blow out on the highway. 2 new freeze plugs later and weíre back in business.

ARP studs have torque specs of 100ftlbs! I thought for sure I was gonna crack a head just installing them.

TheBloody, Oppositelock lives on in our shitposts.

> razorbeamteam

TheBloody, Oppositelock lives on in our shitposts.

> razorbeamteam

01/06/2017 at 12:10 |

|

I also used ARP studs in my head gasket job, I have to tell you Iím still very annoyed with myself today.

atfsgeoff

> TheBloody, Oppositelock lives on in our shitposts.

atfsgeoff

> TheBloody, Oppositelock lives on in our shitposts.

01/20/2017 at 01:51 |

|

On stuff like head bolts where thereís usually lots of room and visibility, no reason not to use a beam style wrench (no recalibration necessary).