"traderQAMobileTestAutomationMobileBoostOn" (el-peasant)

"traderQAMobileTestAutomationMobileBoostOn" (el-peasant)

08/21/2016 at 17:38 ē Filed to: None

2

2

7

7

"traderQAMobileTestAutomationMobileBoostOn" (el-peasant)

"traderQAMobileTestAutomationMobileBoostOn" (el-peasant)

08/21/2016 at 17:38 ē Filed to: None |  2 2

|  7 7 |

As a self-proposed future mechanical engineer, I have this pastime of designing my very own V12. One with high power, a 7000 RPM redline, and a pancake-flat torque curve. About that curve...

How will each area of the engine affect the power at low end (700-2800), midrange (2800-5000), and high end (5000-7000)?

Cam profile (including duration, lift, LSA)

Displacement (bore/stroke)

Valve area

Intake length & size

Header length & size

I understand that every part must be balanced for that flat torque band. I canít hop in a long-stroke, mild-cam V12 and rightfully complain about lack of high-end power.

S65

> traderQAMobileTestAutomationMobileBoostOn

S65

> traderQAMobileTestAutomationMobileBoostOn

08/21/2016 at 17:43 |

|

Go buy Automation already

traderQAMobileTestAutomationMobileBoostOn

> S65

traderQAMobileTestAutomationMobileBoostOn

> S65

08/21/2016 at 17:46 |

|

Pfft now I feel stupid. $30 isnt bad for this.

jimz

> traderQAMobileTestAutomationMobileBoostOn

jimz

> traderQAMobileTestAutomationMobileBoostOn

08/21/2016 at 18:20 |

|

Cam profile (including duration, lift, LSA)

low lift/short duration improves low end by promoting higher velocities through the intake port/valve, which promotes more thorough mixing of the fuel and air. it becomes a problem at high RPM due to pumping losses; the engine wastes a ton of power just from the pistons trying to pump air. This is one thing VTEC tries to help; at low engine speed the intake valves are opened by a shorter duration, lower lift cam lobe, then above a certain RPM it switches over to a longer duration, higher lift lobe.

Displacement

(splitting these two out) Displacement will tell you a ďball-parkĒ figure for your peak torque. if you know the maximum feasible brake mean effective pressure (BMEP) you can predict the maximum torque the engine may be able to produce. for example, with a normally aspirated 5.0 liter engine (cylinder config not important here) a typical BMEP of 9 bar means itís effectively capped at about 400 lb-ft. And interestingly enough, the 5.0 Coyote engine demonstrates that. Itís made anywhere from 360 hp in the F-150, to 444 in the Mustang, but they all have about 390-400 lb-ft.

forced induction changes everything.

(bore/stroke)

this doesnít tell you much about torque/horsepower, but it plays into the engineís redline. A long-stroke engine (or more correctly, one with a lower connecting-rod to crank-radius ratio) will have higher peak piston velocities for a given RPM. If you push the piston speeds too high, wear is greatly accelerated.

Valve area

larger valves flow better, of course. but make them too big, and you hurt low-RPM performance. make them too small, and you hurt higher-RPM performance.

Intake length & size

size is obvious, a duct with a larger cross-sectional area will flow better. But as important as the port size is the port shape. a port with sharp bends will flow much worse than ones with relatively gentle curves. This is why the 5.0 Mustang makes over 100 more horsepower than the 4.6 despite only being 400 cc larger. The 4.6 3-valve heads have good intake ports, but terrible exhaust ports. The exhaust gases exit through the valve then immediately have to go around a ďbendĒ to get to the header.

Header length & size

entire books have been written about exhaust tuning, and itís above my pay grade.

in short, your dream of a V-12 with both a 7,000 RPM redline and a ruler-flat torque curve is going to be very difficult to realize.

traderQAMobileTestAutomationMobileBoostOn

> jimz

traderQAMobileTestAutomationMobileBoostOn

> jimz

08/21/2016 at 18:23 |

|

Thanks for the info...but Automation is about to make this a whole lot easier. WHERE HAS IT BEEN ALL MY LIFE?!

Stephenson Valve Gear

> traderQAMobileTestAutomationMobileBoostOn

Stephenson Valve Gear

> traderQAMobileTestAutomationMobileBoostOn

08/21/2016 at 19:19 |

|

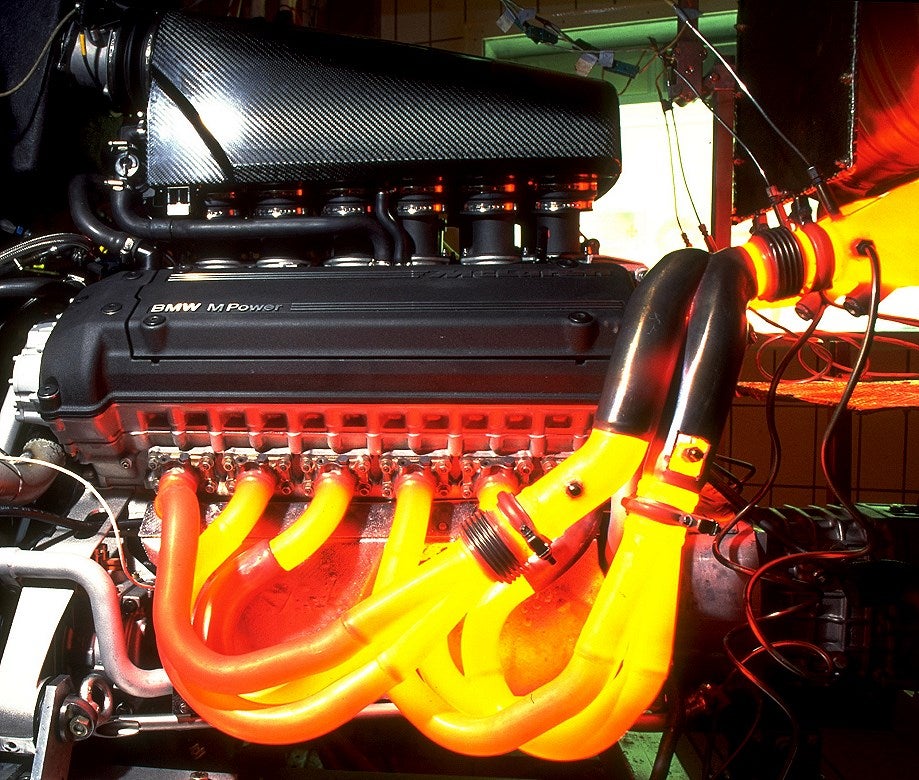

You have received some good responses to your questions, so I wonít muddy the waters with any more input. However, I do wish to congratulate you on your fine choice of picture that accompanies your post... is there any more glorious image of an engine running than one going full-out on a dyno with glowing headers? I think not. Well done sir. Well done indeed.

ChooChooMotherFudger

> traderQAMobileTestAutomationMobileBoostOn

ChooChooMotherFudger

> traderQAMobileTestAutomationMobileBoostOn

08/21/2016 at 19:33 |

|

It isnít a overly simple way to brake it down as between each thing.

Take a look at this stuff, if you want to go into mech eng then it might be helpful. We have used it a bit for fsae (which you should do if you go into Engineering).

briannutter1

> traderQAMobileTestAutomationMobileBoostOn

briannutter1

> traderQAMobileTestAutomationMobileBoostOn

08/21/2016 at 23:15 |

|

Absorb the following and we will have another conversation about what is required to hit your goals. Throw stroke measurement out of the window as far as torque. Same for rod ratio which is primarily a packaging concern these days. Speaking of which, packaging is more important these days to allow for lower cg and longer control arm lengths for a given track

Torque is almost entirely a function of displacement. Horsepower is almost entirely independent and based on piston speed and intake valve and runner length assuming good valve train stability. Piston speed vs valve area is what matters assuming all the rest are corrected. Take a sbc with a huge range of common displacement figures. Given the same top end and induction, horsepower peak will match piston speed across different displacements. Valve area x cylinders = horsepower potential. Down from there, Displacement determines rpm at which HP and torque peak (piston speed before mentioned). Correct intake runner length maximizes avg horsepower through a given gear ratio. Correct cam timing means opening the intake for desired idle quality and closing it to match intake runner length. Exh timing wide open on opening point but closing point is a big more critical with emissions and intake opening(overlap) Exh runner length normally thrown out the window due to space constraints and the fact most cars run full length exhaust but must be compensated for in cam timing.