"Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car" (pilot-and-car-guy)

"Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car" (pilot-and-car-guy)

02/25/2016 at 21:30 ē Filed to: None

6

6

10

10

"Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car" (pilot-and-car-guy)

"Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car" (pilot-and-car-guy)

02/25/2016 at 21:30 ē Filed to: None |  6 6

|  10 10 |

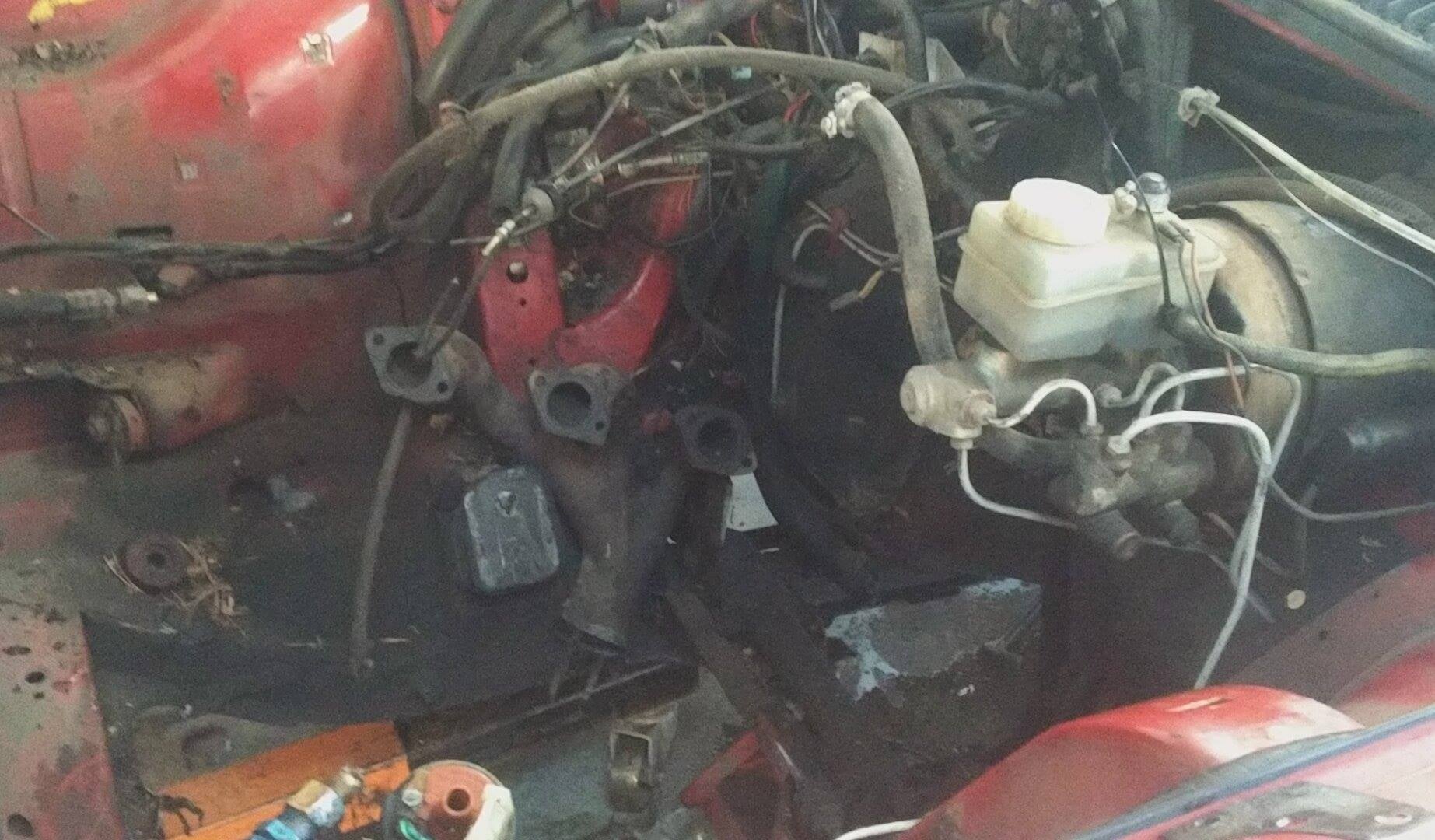

After a month and a half of no progress at all, yesterday and today I finally got some work done. Iím going to need a new drive shaft, because the one i have is really worn, but at least this happened.

Chargingstar - E92 M3 pilot

> Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

Chargingstar - E92 M3 pilot

> Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

02/25/2016 at 21:55 |

|

Did Loren have this Alfa stashed away at European auto?

Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

> Chargingstar - E92 M3 pilot

Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

> Chargingstar - E92 M3 pilot

02/25/2016 at 21:57 |

|

Nope.

Hereís part 1 for the full context, but it was a $400 POS.

http://oppositelock.kinja.com/the-alfa-from-Ö

Seat Safety Switch

> Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

Seat Safety Switch

> Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

02/25/2016 at 22:12 |

|

Is this one of the Alfas with a torque tube and rear-mounted transaxle instead of a driveshaft? If so, make sure to ask to get it balanced at high RPM.

Most shops only balance them up to 2000 rpm or so, because they assume itíll be like a normal driveshaftís usage.

Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

> Seat Safety Switch

Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

> Seat Safety Switch

02/25/2016 at 22:14 |

|

It is. And Iíll have to get it balanced for 6.500 rpm.

When I was taking it all apart the front just decided that it was done. I see why this car was let go so cheap.

Seat Safety Switch

> Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

Seat Safety Switch

> Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

02/26/2016 at 13:14 |

|

I am still jealous. All the GTVs here disappeared into a combination of thin air and iron-based vapour about a decade ago.

Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

> Seat Safety Switch

Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

> Seat Safety Switch

02/26/2016 at 13:16 |

|

Mines not far off. Next step is bodywork, lots of welding and bondo.

Seat Safety Switch

> Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

Seat Safety Switch

> Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

02/26/2016 at 13:20 |

|

When in doubt, thereís always structural adhesive and carbon fiber.

Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

> Seat Safety Switch

Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

> Seat Safety Switch

02/26/2016 at 13:43 |

|

Not quite in the budget.

As cheap as possible is the goal.

Seat Safety Switch

> Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

Seat Safety Switch

> Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

02/26/2016 at 13:56 |

|

Thatís like having a budget heroin addiction, and we both know it.

Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

> Seat Safety Switch

Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

> Seat Safety Switch

02/26/2016 at 14:18 |

|

I know there was a reason I liked you. Still, steel is much cheaper, and I can sorta weld, so itíll be fine.