"Rock Bottom" (rockbottom81)

"Rock Bottom" (rockbottom81)

10/07/2016 at 15:30 ē Filed to: None

15

15

23

23

"Rock Bottom" (rockbottom81)

"Rock Bottom" (rockbottom81)

10/07/2016 at 15:30 ē Filed to: None |  15 15

|  23 23 |

I am an automotive aerodynamicist and this is what I do.

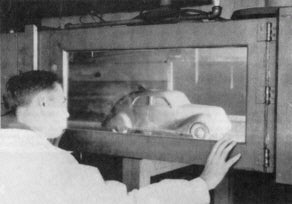

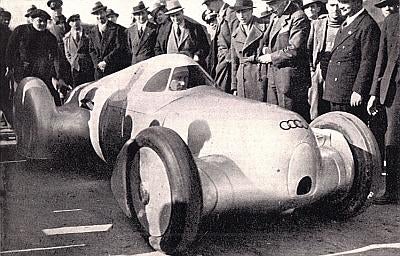

Modern automotive aerodynamics really began in the 1920s when Chrysler built a small scale wind tunnel and hired Orville Wright to help conduct a comprehensive study of something like 50 test articles. Oh sure, there were earlier efforts to improve the aerodynamic performance of production cars, but the Chrysler effort was among the first scientific pushes by an automaker to reduce the amount of horsepower lost to the air. The resulting car, the Chrysler Airflow, was a sales flop. Despite being a colossal disappointment, it signaled the birth of my craft and Iím grateful for it.

Early automotive wind tunnel experiment

Today, we use many tools to aerodynamically improve cars. The wind tunnel is still very much in use, though now it comes in many flavors (full-scale and sub-scale, static ground and moving ground, and some other stuff). We also use several types of Computational Fluid Dynamics software (CFD) in an attempt to predict the way air will flow around and through a car. Itís worth mentioning here that thermal engineers also use a ton of thermally coupled CFD to design, locate, and size things like heat shields and radiators. That is a whole different topic that, while related to general aerodynamics, is worth itís own write-up.

†

The Balance

As with any type of engineering, there are compromises to be

made when it comes to aerodynamics. If

nothing else mattered, it would be easy to make cars with super low drag. We would optimize to one shape, and then Iíd

be out of a job because physics never change. In the real world, aero performance has to compete for attention with

thermal performance, vehicle weight, crash safety, pedestrian safety, and, most

importantly, the design studio.

To keep the car from melting down or catching on fire or just plain overheating, itís important that cooling air flows through the car. Most cars get this cooling air from the grill, or under-car openings (look under a C5 Corvette for an example). The only problem with this is that air going through the car is going to have a net momentum loss, which translates to drag and lift. Both are bad for aero.

How about safety? How does this impact aero? Look at a Mercedes C Class front end from the mid 90s, and compare it with the nose on a brand new one. Notice how tall and blunt the new one is? Thatís government safety requirements driving the shape of cars. You can see it on Corvettes, Mustangs, and Accords. There are similar safety regulations regarding tire coverage (when seen from dead-ahead or directly above). Every additional mandated shape change constrains us a little more and makes our job just a little more challenging. To be sure, Iím not saying safety is ruining aero, itís just pushing us to get a little more creative than we otherwise would have been. I like being creative.

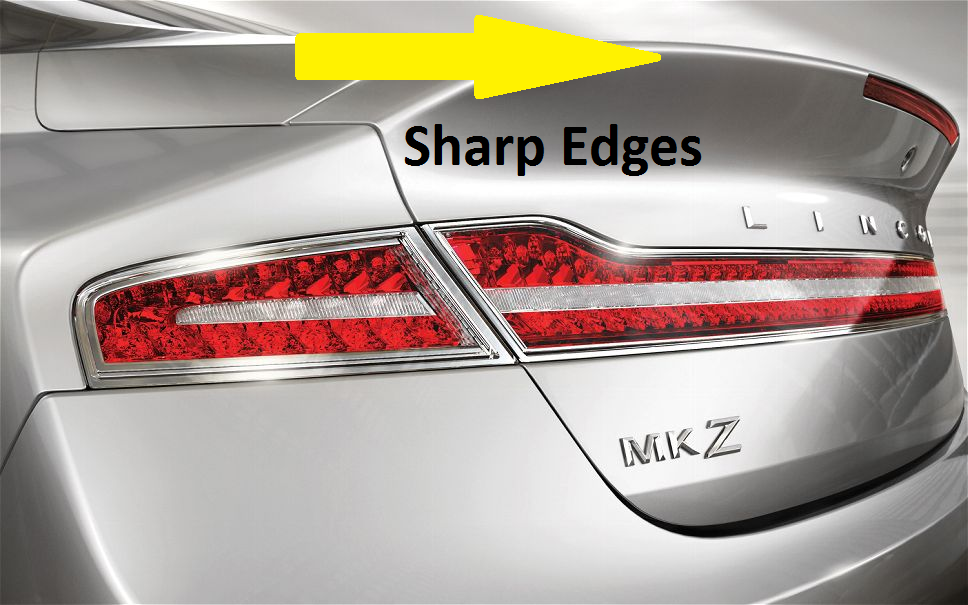

In general, the biggest battle that an aerodynamicist will fight is going to be with the design studio. The people that make cars look so good often donít believe aerodynamic features are attractive. This means that in order to keep the car looking like something people want to buy, I need to find creative aero tricks that arenít visible, or the designers need to find creative ways to hide my features. Youíll see examples of the former in places like little air dams in front of the tires, and the latter in little ďkicksĒ built into the tail lights. Both are mostly out of sight but can help aero performance way more than youíd expect.

†

Aerodynamic Forces

We often hear car companies bragging about the coefficient of drag (Cd) of their cars. Cd is a non-dimensional way of describing how slippery that car is, but it only tells part of the story. In reality, when calculating the drag on a car, you must also consider the frontal area (Af), or cross sectional area. If two cars both have a Cd of .32, but one has an Af of 2 square meters and the other is 3 square meters, the bigger car will incur a bigger aero penalty. This seems obvious, but when everyone is trying to blind us with Cd numbers, itís easy to forget that equally critical Af term. So the next time you hear some auto engineer brag that they dropped the Cd on their new car by 10%, ask them if the Af changed. Thereís a good chance it went up, potentially negating that Cd improvement. One important note here: bigger Af generally get you a roomier interior, so itís not like theyíre adding size just to be jerks. I just like to pick on Af because it makes my job harder!

Drag isnít the only force we care about. Lift is also important. I will point out that 90% of the cars that we mortals own do not produce downforce. They almost all produce lift, and itís important to keep in mind that thatís not necessarily a bad thing. In general, a car with low drag will have more lift than a car with higher drag. Reducing lift (or adding downforce) will almost always add drag because of how the physics shake out. So the deal here is that we spend a fair amount of time getting the balance between front and rear lift correct without adding unnecessary drag. If the lift values are out of whack, they can make a car act funny during things like emergency lane changes (see: Moose Test).

†

Tips and Tricks

So how do you get the aero performance to meet your targets? Well, in a perfect world the aerodynamicist can work with the studio designers, packagers, safety engineers, and a host of other people to get the basic shape the way we want it. For example, try keeping the front end kind of round while keeping the trailing edges nice and sharp is a good place to start. The current Lincoln MKZ and the Prius are good examples of drag-optimized cars.

What about when you want the car to look rad while still behaving well? If you look closely, you may notice some little tricks that can make a big difference. Look at the tail lights on a BMW 5 Series and you will see some small ridges that help kick the air off the car at the optimal point to reduce drag. In fact, youíll see these ridges in a lot of tail lights if look closely.

BMW 5 Series with little aero features ďhiddenĒ in the tail lights

Another trick is little air dams in front of the tires. These help keep air from getting into the wheel wells and impacting the spinning tires, which is generally bad for drag. In fact, you want the air to stay out from under a car as much as possible. Thatís why you will see deep valences under the bumpers of most new full-size pickups. If the air does manage to sneak under, you want to get it out as quickly and efficiently as possible, so you may try to install flat shields that cover all the bumpy bits under a car. These smooth shields will generally also make a car quieter, which is good. Any time you can make something serve two purposes, youíre winning. The downside to underbody shields is that they can trap heat where you donít want it, and they can add weight. This all has to be balanced to make sure your aero gain isnít completely offset by a weight penalty, therefore netting zero MPG gain while costing money that could better be spent elsewhere.

Front tire air dam, sometimes called a tire spoiler

Another trick that is becoming more common on SUVs is a feature that blends a roof-top spoiler to the sides of the car. This serves a similar purpose as those tail light kicks in that is kicks the air off the car, preventing it from ďstickingĒ to a rounded rear shape. If air ďsticksĒ to the rear of a car, itís making drag. You want to do whatever you can to kick it off and never bother you again!

Lexus SUV with funny side kick features

†

Testing

After an aerodynamicist spends all that time working with all the other people who influence the shape of a car, after all the CFD work is done and all the predictions have been made, you build a car and put it in a wind tunnel to see how you did. Sometimes you will start with a clay mock-up, sometimes you just build a running, driving prototype. While testing in the tunnel, you almost always learn that things arenít exactly what you think theyíd be. Sometimes drag is low, sometimes itís high. Sometimes your lift numbers are all wrong. If things are good, you can sign the dotted line and certify that your design works as promised and the car can go to production. More often, you find out in the test that you need to make small changes to things like underbody shields or tail light ridges. Iteration with CFD will be the name of the game until you get the aero performance you targeted.

The last bit, testing a full-sized car!

†

Lessons Learned

I have had three jobs since I graduated college with my aeronautical engineering degree. I worked as an aerodynamicist at a company that built business jets, then I worked as a wind tunnel test director at NASA, mostly doing rotorcraft research, and now Iím an aerodynamicist at a major auto maker. What Iíve learned from all this is that jets are easy, cars would be easy if they didnít have to look good or be safe in a crash, and helicopters operate on miracles. Theyíre seriously the most aerodynamically and structurally challenging machines humans make.

†

Aaaaaand Iím spent.

HammerheadFistpunch

> Rock Bottom

HammerheadFistpunch

> Rock Bottom

10/07/2016 at 15:34 |

|

See this...this would be a great story to share to the front page. But it wonít be, and thats a shame. Great stuff.

Milky

> Rock Bottom

Milky

> Rock Bottom

10/07/2016 at 15:36 |

|

I am an automotive aerodynamicist

Owns Wrangler

I did not see that career choice coming.

RallyWrench

> Rock Bottom

RallyWrench

> Rock Bottom

10/07/2016 at 15:37 |

|

Thanks for writing this, I donít have time to read it all at the moment so Iíll finish later, but from what I have read itís highly informative. Definitely a front-page worthy piece.

Rock Bottom

> HammerheadFistpunch

Rock Bottom

> HammerheadFistpunch

10/07/2016 at 15:39 |

|

Yeah, I wrote it in a few spurts over the day so it might be a little disjointed! I donít expect it to make it to the front either. Itís 100% click-bait free, contains no partisan political jabs, and doesnít assume that most of America is Manhattan. Iím glad you liked it though!

Rock Bottom

> RallyWrench

Rock Bottom

> RallyWrench

10/07/2016 at 15:42 |

|

I appreciate the feedback! I wrote it in a few spurts, so it might be a bit disjointed. Sorry in advance!

RallyWrench

> Rock Bottom

RallyWrench

> Rock Bottom

10/07/2016 at 15:43 |

|

No apologies necessary. This is great stuff, thoughtfully written.

Rock Bottom

> Milky

Rock Bottom

> Milky

10/07/2016 at 15:44 |

|

I call my Jeeps rebellions against the gods I serve. Theyíre my own way of ďtaking a kneeĒ during the national anthem!

Clemsie McKenzie

> Rock Bottom

Clemsie McKenzie

> Rock Bottom

10/07/2016 at 15:58 |

|

That was great! Iíd love to hear more about it. Fascinating!

random001

> Rock Bottom

random001

> Rock Bottom

10/07/2016 at 17:09 |

|

I tried to do your job once. Designed hypersonic craft for a bit. Talk about fun! I want your job.

Steve is equipped with Electronic Fool Injection

> Rock Bottom

Steve is equipped with Electronic Fool Injection

> Rock Bottom

10/07/2016 at 17:12 |

|

The Cd and Af stuff reminds me of an article I read when the 2005 mustang came out. An engineer wth one of the major SCCA organizations lamented how the new retro mustang was ďjust a brickĒ compared to the outgoing models even though it had lower Cd. This made it less competitive on high-speed tracks.

Rock Bottom

> Steve is equipped with Electronic Fool Injection

Rock Bottom

> Steve is equipped with Electronic Fool Injection

10/07/2016 at 22:03 |

|

Yeah, the S197 sure looks a lot bigger than the SN95! Now Iím curious what the actual difference is... hmm...

Rock Bottom

> random001

Rock Bottom

> random001

10/07/2016 at 22:08 |

|

Itís not very glamorous! Lots of meetings to negotiate for little features and bits. One tries hard not to throw a punch at the wind noise guys for hosing up your nice clean A-pillar, or Ďhuck a chair at the artist †designer that just called your perfectly functional rear spoiler ďclumsy lookingĒ. And then some manager informs you that your nice underbody shield costs $0.20 more than budgeted and that you need to figure out some magic physics violation to meet target without it.

Hypersonics sounds interesting! Military stuff?

Rock Bottom

> Clemsie McKenzie

Rock Bottom

> Clemsie McKenzie

10/07/2016 at 22:10 |

|

Thanks, but this is pretty much everything I know! Ha ha

briannutter1

> Rock Bottom

briannutter1

> Rock Bottom

10/08/2016 at 09:16 |

|

Great article! I love your job and the most amazing day I ever had was testing spoiler , air dam, and side sill configurations at the a2 tunnel in NC. I have a 2002 c5z that I run the Optima street car events, hpde, auto x and have the Wilmington Ohio Mile.

I have some questions for you or Milky if you donít mind dispensing advice. Iím looking at venting the hood to reduce front lift but interestingly people are seeing some pretty serious reductions in top speed....more than would be expected from muddying the flow in front of the windshield. Could it be that packing the engine bay is acting as a aero tray allowing incoming air to pass by easier rather than flowing up and out through vents?

For speed events Iím considering a pro stock drag style spoiler in the back to extend the wake back further.

Also considering Adding some plexiglass side sills to the windshield for the handling events to use the windshield high pressure zone for additional downforce at the expense of drag. Havenít seen anyone else do that though.

Would also like to move the radiator to the trunk area for weight distribution and thinking of using the low pressure area behind the glass as a good ducting location. Maybe feeding that area air might even reduce drag?

torque

> Rock Bottom

torque

> Rock Bottom

10/08/2016 at 13:01 |

|

Great write up! Very interesting career indeed!

About the start of history of aero research w.r.t. Automotive sector, itís hard, (for me at least), to not think of Tatra at the mention the the Chrysler Airflow and Jaray suing Chrysler for ďborrowed/influencedĒ design and (aero) ideas, of course they settled out of court.

+ influence of aeronautical industry and top speed racers like the Mercedes and Auto Union Arrow cars of the early 30s...

random001

> Rock Bottom

random001

> Rock Bottom

10/08/2016 at 13:20 |

|

Yep. Scramjet carrier with a piggyback slug, Mach 6+ travel. You want a hard aerodynamics problem, well there you go.

Rock Bottom

> random001

Rock Bottom

> random001

10/09/2016 at 20:39 |

|

Dat CFD+chemistry modeling tho!

Rock Bottom

> torque

Rock Bottom

> torque

10/09/2016 at 20:44 |

|

Thanks! Interestingly, the Germans claim to be the first to do full-scale automotive wind tunnel tests, though Iím pretty sure Ford beat them to the punch ( http://oppositelock.kinja.com/what-did-automotive-wind-tunnel-testing-look-like-in-th-1782688562 ). That being said, I feel like the Chrysler guys really got the ball rolling on† production car aero for the people. Racing aero is just crazy!

Rock Bottom

> briannutter1

Rock Bottom

> briannutter1

10/09/2016 at 21:04 |

|

If it were my program, I would start by obtaining a base C5 hatch for testing. The C5Z rear upper shape just looks like itís leaving drag on the table. As for venting the hood, itís entirely possible that itís adding drag by adding downforce. Momentum changes in the longitudinal direction are always bad for drag. Itís worth noting that hood vents are almost never added for aero purposes, but generally only for cooling. Must be a reason for that! Maybe try better utilizing those big vents in front of the doors on the sides? Theyíre already there, and at least on my stock C5 they looked to be there to look pretty. I didnít get the feeling that they did anything functional.

Next time youíre in the tunnel or on track, try sharpening the rear edges, kinda like the MKZ picture above, or like those flaps you see on the backs of semi trucks (pic below). The C5 already has a pretty clean aero shape, so youíre going to have to work to get more out of it without adding a lot of weight. Something else to consider is closing out the sides between the axles. Bruce Cambern did a pretty good job of it on his Optima Challenge GT (pic also below). Getting the front down will help in both drag and lift, though the C5 is a little more complicated since itís a bottom breather.

Mostly, Iíd focus on underbody on a clean car like a C5. Filling in voids whre you can, or just plain keeping the air from getting under there in the first place. Thereís so much left on the table under there, itís almost criminal. If you ever get a chance, lay under a Panamera and look at the underbody shielding. Itís pretty much the gold standard when it comes to managing underbody air on a regular car. The current Ford Fusion is pretty good, too.

random001

> Rock Bottom

random001

> Rock Bottom

10/09/2016 at 21:06 |

|

The only saving grace was I didnít have to model the transition from sub to super to hyper. I did have to model hypersonic impacts, though. Vaporize all the things!

Rock Bottom

> random001

Rock Bottom

> random001

10/09/2016 at 21:09 |

|

I know this is soooo not hypersonic, but this is where my mind went when I read that:

briannutter1

> Rock Bottom

briannutter1

> Rock Bottom

10/09/2016 at 23:07 |

|

Kinda just ate my first reply. I was running against Bruce at that ousci event in 2011. Badass car. There is a good paper written on c5z aero and the side vents donít do anything...it may be possible to put a wicker in the front of the vent to create a low pressure zone to extract air. I can work under the back....just a lot of exhaust control arms and transaxle in the way currently.

Mike Reichens evo2 at a2 was where we tested the cowcatcher front, side sills, and rear factory wing location. The sills initially trapped air from the rear wake until we moved the wing backwards on its mounts to push the wake back. Then the side sills produced a net decrease in lift. Amazing learning day. Also Thanks for writing back!

Rock Bottom

> briannutter1

Rock Bottom

> briannutter1

10/10/2016 at 14:21 |

|

Yeah, I feel like Iím a little out of my element on the race stuff since lift balance is so critical. With production cars, our lift tolerance is usually pretty loose. We will generally do what we can to reduce drag (without making the studio mad) and take whatever lift we get unless itís way out of the box.

Back when I worked on planes, we would call a lip in front of an outlet a ďscupperĒ, and they were generally known to be an indicator that the aero guys messed something up! I had more than a few scuppers on my planes :) That being said, Iím certain there is higher static pressure at the cooling pack inlet under the nose than there is at that front fender vent. If thereís a flow path, then there should be decent flow. Now that I think about it, I wonder what venting the front wheel wells out through that vent would do...