"BaconSandwich is tasty." (baconsandwich)

"BaconSandwich is tasty." (baconsandwich)

08/21/2015 at 10:39 ē Filed to: None

0

0

21

21

"BaconSandwich is tasty." (baconsandwich)

"BaconSandwich is tasty." (baconsandwich)

08/21/2015 at 10:39 ē Filed to: None |  0 0

|  21 21 |

This is something Iíve been thinking about lately: the current crop of electric cars seem to run out of steam, so to speak, when they approach their top speeds. Perhaps Iím mistaken in this, but I think this is happening because the electric motors they are using become less efficient at higher RPMs. I was thinking about how to get around this: why not use two different electric motors with different gearing?

(Torque curve of a three phase induction motor, from Google Images, for reference).

For example, letís suppose motor 1 has a gear ratio of 1:5, meaning it takes 5 turns of the motor to get the wheels to turn once. As motor 1 approaches its maximum RPM (or exceeds its breakover torque), it loses torque. Now if there was a second motor, with, say, a gearing ratio closer to 1:1, as motor 1 approaches its maximum RPM, motor 2 kicks in and matches its total output RPM to that of motor 1. Just making some numbers up, but if motor 1 is running at 2,500 RPM, the output speed would be 500 RPM. If motor 2 was attached so that it had a gear ratio of 1:1, it would be running at 500 RPM. As speeds get higher, motor 1 basically cuts out, and lets motor 2 take over. Because of its gearing and low-end torque, itís able to keep accelerating the vehicle faster than if it was using just a single motor.

I can imagine there is more inefficiency in such a setup: youíd have the extra weight of a second motor and controller, and the drag/friction/resistance of having one motor turn the other until they are both being powered. But I do wonder how well such a setup would work.

Is this idea nuts, or am I missing something?

Patrick Nichols

> BaconSandwich is tasty.

Patrick Nichols

> BaconSandwich is tasty.

08/21/2015 at 10:44 |

|

Iíd imagine a transmission and single engine could probably do the work of which you speak or even a CVT if programmed correctly, but I have no knowledge of electric motors.

jariten1781

> BaconSandwich is tasty.

jariten1781

> BaconSandwich is tasty.

08/21/2015 at 10:46 |

|

Why wouldnít you just use a gearbox on a single motor if that was the goal?

DrScientist

> BaconSandwich is tasty.

DrScientist

> BaconSandwich is tasty.

08/21/2015 at 10:51 |

|

Sounds something like Koenigsegg regera approach.

RamblinRover Luxury-Yacht

> BaconSandwich is tasty.

RamblinRover Luxury-Yacht

> BaconSandwich is tasty.

08/21/2015 at 10:53 |

|

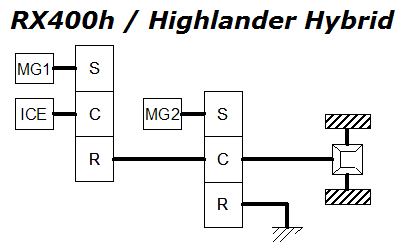

Youíre aware that the Prius/etc. ďHybrid Synergy DriveĒ uses two electric motors, right? The first one is in a planetary torque blender with the gas motor, and the second is in a torque blender with that output, going to the wheels. Itís somewhat for reasons like you describe - better match of ďidealĒ RPM to output, though thatís less important for electric motors than gas.

Nonster

> BaconSandwich is tasty.

Nonster

> BaconSandwich is tasty.

08/21/2015 at 10:54 |

|

A simple transmission can accomplish what youíre describing. As you mention, electric motors do have an effective power band, itís just usually over a broader rpm range than that of most combustion engines so many electric vehicles ditch the gearbox for weight and simplicity

BigBlock440

> BaconSandwich is tasty.

BigBlock440

> BaconSandwich is tasty.

08/21/2015 at 10:54 |

|

So imagine this: 2 engines, one geared to say 4:1 for when you need low down power, and one geared to 1:1 or even .8:1 for when you wanít speed. The first engine would be used for starting out, then when you get up to speed, you turn it off and use the higher geared one.

Or, alternatively, since you have a gearbox attached to the engine/motor anyway, you could devise a way to fit two gears in there and it could somehow use both gears selectively depending on speed.

At least thatís my take on it.

nermal

> BaconSandwich is tasty.

nermal

> BaconSandwich is tasty.

08/21/2015 at 10:56 |

|

Interesting idea. The problem that you described is the precise reason why multi-speed transmissions exist. However, the reason why they arenít commonplace on EVs is because the complexity they add outweighs the benefits.

In your example, the mechanical bits would be relatively simple, just have a motor at each end of the car with a different final drive. The software programming to get them to work together would be a bit complicated, but in the grand scheme of things nothing impossible. In this example, say the rear motor is the lower geared one, so that it gives a rear bias in launches and curves to help handling, but the front bias kicks in at highway speeds where itís less of an issue.

Thatís an example with AWD. As an alternative, you could just set it as RWD with a more conventional transmission, and may end up ahead. It wouldnít need to be a modern 8 spd, you could get away with as little as 3.

RamblinRover Luxury-Yacht

> jariten1781

RamblinRover Luxury-Yacht

> jariten1781

08/21/2015 at 10:56 |

|

Constant mesh and other limiting of the gearbox is one reason. If you torque-blend two motors at differing torque/speed ratios, then you donít actually have to have any kind of make/brake of power like a multispeed transmission. The required transmission setup is simple and bulletproof enough that you can get away with using a second motor without really paying for it in weight, efficiency loss, etc.

jariten1781

> RamblinRover Luxury-Yacht

jariten1781

> RamblinRover Luxury-Yacht

08/21/2015 at 11:02 |

|

I didnít read it as if he was talking torque blending; just a two step system with two motors.

BaconSandwich is tasty.

> jariten1781

BaconSandwich is tasty.

> jariten1781

08/21/2015 at 11:03 |

|

I think RamblinRover hit on it: part of the reason a lot of electric cars arenít using traditional transmissions is because they are difficult to get right for the amount of torque an electric motor can produce. I recall hearing that Tesla originally wanted to use a two-speed transmission in the Roadster, but it kept breaking. A setup like the one I mentioned would pretty much be two motors, a gear on each motor, and two gears on a common shaft - not much to break there.

BaconSandwich is tasty.

> nermal

BaconSandwich is tasty.

> nermal

08/21/2015 at 11:05 |

|

Thatís actually an interesting approach - I was thinking two motors, each geared so that they run onto a common shaft - but the benefit of having AWD would basically come for free. So thereís that!

EDIT: Also, as a programmer, the software side of things doesnít scare me. As long as you can get reasonably reliable RPM numbers from each motor and from the output shaft, it shouldnít be a problem.

BaconSandwich is tasty.

> RamblinRover Luxury-Yacht

BaconSandwich is tasty.

> RamblinRover Luxury-Yacht

08/21/2015 at 11:07 |

|

Actually, I wasnít aware of that. I thought the Synergy drive system used a single electric motor, a gas engine, and a series of three differentials.

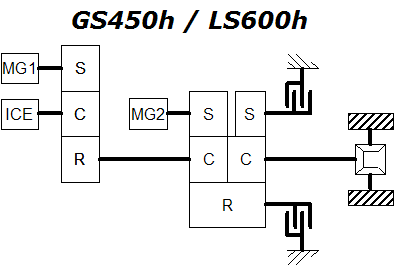

The new Volt has a rather interesting setup as well - it too, uses two motors, but one of them can act on one of the planetary gears, essentially turning their setup into a CVT. Really quite a smart design.

RamblinRover Luxury-Yacht

> jariten1781

RamblinRover Luxury-Yacht

> jariten1781

08/21/2015 at 11:08 |

|

Right - but a torque blender like Toyota uses is the version of what heís talking about that actually works. Having one engine turning the other over is too gooney for primetime.

BaconSandwich is tasty.

> DrScientist

BaconSandwich is tasty.

> DrScientist

08/21/2015 at 11:08 |

|

Exactly. I love what theyíve done. I thought they were just using a single motor (or set of motors), and when they run beyond a certain RPM, it clutches in a direct input from the engine to the rear wheels.

DrScientist

> BaconSandwich is tasty.

DrScientist

> BaconSandwich is tasty.

08/21/2015 at 11:11 |

|

right... kind of... its electric motors (3 of them)

and when the car gets to a certain speed (not engine speed) the clutch engages.

BaconSandwich is tasty.

> Nonster

BaconSandwich is tasty.

> Nonster

08/21/2015 at 11:11 |

|

From what I understand, thereís been issues with getting a lot of larger electric motors working through traditional transmissions for various reasons. E.g.: https://en.wikipedia.org/wiki/Tesla_RoaÖ Torque being one of the problems.

BaconSandwich is tasty.

> DrScientist

BaconSandwich is tasty.

> DrScientist

08/21/2015 at 11:13 |

|

Interesting. I wasnít aware they were using three different motors. I really should do more reading about their setup.

jariten1781

> RamblinRover Luxury-Yacht

jariten1781

> RamblinRover Luxury-Yacht

08/21/2015 at 11:13 |

|

Hrmm...youíre almost making me want to look up Toyotaís system. Almost.

RamblinRover Luxury-Yacht

> BaconSandwich is tasty.

RamblinRover Luxury-Yacht

> BaconSandwich is tasty.

08/21/2015 at 11:18 |

|

The first gen system has the second motor/generator on the shaft and no second planetary. This version does. As does this:

This system uses two clutches (or brakes) to switch the second motorís gear ratio to the wheels between a ratio of 3.9 and 1.9, for low and high speed driving regimes respectively. This decreases the power flowing from MG1 to MG2 (or vice versa) during higher speeds. The electrical path is only about 70% efficient, thus decreasing its power flow while increasing the overall performance of the transmission.

RamblinRover Luxury-Yacht

> jariten1781

RamblinRover Luxury-Yacht

> jariten1781

08/21/2015 at 11:18 |

|

Boiled down slightly:

http://oppositelock.kinja.com/the-first-gen-Ö

DrJohannVegas

> BaconSandwich is tasty.

DrJohannVegas

> BaconSandwich is tasty.

08/21/2015 at 11:24 |

|

Bacon, itís also important to note that the graph you posted assumes a single frequency on the supply current. Modern AC motors are controlled with variable frequency controllers (hello, IGBT), so you are looking for a three-dimensional graph, where the supply frequency is the third axis.

That said, spinning any motor at really high RPM is going to create friction. No amount of electrical wizardry is going to fix that. So, yea, gearboxes are probably a good idea, but the tradeoffs that others have mentioned still remain.

Rover mentioned the Priusí system below, and I wanted to share a video which did a great job explaining how the thing works. Itís pretty neat.