"ttyymmnn" (ttyymmnn)

"ttyymmnn" (ttyymmnn)

03/09/2015 at 12:06 • Filed to: None

0

0

25

25

"ttyymmnn" (ttyymmnn)

"ttyymmnn" (ttyymmnn)

03/09/2015 at 12:06 • Filed to: None |  0 0

|  25 25 |

Does anybody in Oppoland have any experience repairing electric dryers? I replaced the heating element in mine a little more than two years ago, but the dryer is not heating again. I'm not convinced it's the element.

RamblinRover Luxury-Yacht

> ttyymmnn

RamblinRover Luxury-Yacht

> ttyymmnn

03/09/2015 at 12:13 |

|

If it has an overtemp safety (I think most do, now), it's possible that has failed, or that the drier is having breathing problems (lint collection in an invisible place). OTOH, if the element tests open for continuity with a multimeter, it's dead.

jariten1781

> ttyymmnn

jariten1781

> ttyymmnn

03/09/2015 at 12:16 |

|

I do. Have anymore info?

Most common cause of non-heating, especially on newer driers is poor flow through the vent causing it to hit thermal overload. You can try unplugging the exhaust and just running it in your utility room and see if that fixes it. If it does you'll just need to clean out the run of lint. There's brushes for short runs or you can duct tape a leaf blower to the exhaust run and just blast it out. If you've scrubbed every bit out, or it's not heating even venting without an exhaust run, and you have good flow (measured at drier out and the exhaust out) your overload switch could be jammed and need to be refurbed or replaced. If you can't get good enough flow you may need to redo the ducting. Newer driers are way more sensitive than those from 10-20 years ago.

ttyymmnn

> RamblinRover Luxury-Yacht

ttyymmnn

> RamblinRover Luxury-Yacht

03/09/2015 at 12:17 |

|

I don't have a multimeter, and I'm waiting to hear from my neighbor if I can borrow his. I used it last time to suss out that the coil was dead. But I would think that the coil would last longer than two years; the last one lasted ten. Once I got inside the dryer, I took the opportunity to clean out all the lint that collects inside. I was a little concerned to find some charred lint on top of the box that surrounds the element. So I guess it's conceivable that the overtemp safety isn't working. I need to check the element and all the other thermostats to be sure.

ttyymmnn

> jariten1781

ttyymmnn

> jariten1781

03/09/2015 at 12:19 |

|

This dryer is ~13 yo. What has me concerned is that when I cleaned out the case, I found charred lint on top of the box surrounding the heating element.

RamblinRover Luxury-Yacht

> ttyymmnn

RamblinRover Luxury-Yacht

> ttyymmnn

03/09/2015 at 12:23 |

|

The overtemp safety is *probably* just a simple cutoff - will test continuous if cool, discontinuous if hot. A discontinuous test cold would mean it's toast, probably. It's not outside the realm of possibility for the coil to have failed, though, particularly if there's a contributor to the first failure still present. Something like a blower only operating at 50% original rate due to aged armature/etc. or clogs. It's also very possible to have a heating element with flaws that cause failure in a tenth the time of an original - potting issues, uneven heating, issues with grain in the metal...

ttyymmnn

> RamblinRover Luxury-Yacht

ttyymmnn

> RamblinRover Luxury-Yacht

03/09/2015 at 12:26 |

|

Thanks. Once I get my hands on a multimeter I'll know a lot more. In the interim, I'm going to pull the unit away from the wall and check the vent. I did not clean it last time I worked on the dryer. And then I may just go out and buy a multimeter. I don't need one often, but when you need one you need one. I'm also learning a lot about resistance and continuity, so there's that.

RamblinRover Luxury-Yacht

> ttyymmnn

RamblinRover Luxury-Yacht

> ttyymmnn

03/09/2015 at 12:28 |

|

I was going to remark on that. Even a terrible multimeter is better than none, and very useful to have.

jariten1781

> ttyymmnn

jariten1781

> ttyymmnn

03/09/2015 at 12:30 |

|

Lint by the heating element can be a sign of the drum seal failing. If it's failing your belt, idler pully, and rollers are probably at EOL as well.

That's probably separate from your heating issue though.

E92M3

> ttyymmnn

E92M3

> ttyymmnn

03/09/2015 at 12:31 |

|

I had to replace ours after 2 years. Wasn't in warranty anymore because it sat for 3 years while the house was a model home. I could see a burnt place on the element so I knew that's what it was. Have you looked at it yet?

Sn210

> ttyymmnn

Sn210

> ttyymmnn

03/09/2015 at 12:32 |

|

have you tried feeding it more socks?

Mine has been doing the same thing, it doesn't dry in one run anymore. I bought it second hand when I first got my house and I've already replaced the switch. Time for a new one I guess

ttyymmnn

> E92M3

ttyymmnn

> E92M3

03/09/2015 at 12:43 |

|

I have not looked at it yet. I wanted to test it in situ before I hauled it out. Working on cleaning out the vent hose right now. It's dirty, but not clogged. Still needs a good cleaning, though, and I'll probably go buy a new connector hose.

ttyymmnn

> jariten1781

ttyymmnn

> jariten1781

03/09/2015 at 12:44 |

|

All those parts are OEM. There's lots of lint inside the box, but no more than what was there the first time I opened it up after 10 years.

jariten1781

> ttyymmnn

jariten1781

> ttyymmnn

03/09/2015 at 13:03 |

|

That description would make me believe the seal has failed. Am I reading you right that you had the same build up in 2 years as you did in 10 prior?

Generic felt seals are 20-50 bucks with adhesive. Some driers have plastic or teflon ones but I've never had a chance to play with those so I'm not really sure what that entails. Replacing it requires pulling the drum so it's a good time to do the belt and rollers (and idler if you have one). There's usually refurb kits for <30 bucks with all those piece parts. I'd work out the heating issue first though before deciding whether or not to tackle this; no point refurbing the moving parts if there's a terminal electric problem.

ttyymmnn

> jariten1781

ttyymmnn

> jariten1781

03/09/2015 at 13:14 |

|

That description would make me believe the seal has failed. Am I reading you right that you had the same build up in 2 years as you did in 10 prior?

I was having that exact same thought as I was typing that. I'm going to replace the vent hose and buy a multimeter (after I take my wet clothes to the laundromat). Here's another question: The dryer was installed with a 90 degree joint on the vent at the back of the dryer. Then they snaked about 5 feet of aluminum hose and joined it to the hole in the wall. Is there any reason why I couldn't get another 90 degree joint to put on the house side, then just have one U-shaped loop of vent hose? That way I could get the dryer closer to the wall without kinking it.

jariten1781

> ttyymmnn

jariten1781

> ttyymmnn

03/09/2015 at 13:34 |

|

Yeah you could do that. I don't think you have a routing problem though if you had 10 trouble free years.

Flow restriction general rule of thumb: smooth hard ducting (plastic or metal) >>>>> flexible hoses, shorter >>> longer, straight runs > corners, smooth corners > hard transitions.

If you can jig up a route using non-flexible ducting that would probably be worth a change. If it's still going to have a flexible hose portion then it's kind of meh. A smooth U is better than a kink but probably only trivially. Anything you do to shorten the exhaust path is beneficial...sometimes the installers just throw on a standard length of hose rather than stretching and trimming it due to laziness.

ttyymmnn

> RamblinRover Luxury-Yacht

ttyymmnn

> RamblinRover Luxury-Yacht

03/12/2015 at 12:06 |

|

Finally getting back to the dryer today. I pulled the drum out and tested the sensors on the lint exhaust and the housing around the heating element. One sensor on each place tested negative on continuity. The heating element tested positive, so it's still good. I'm going to see if I can find some replacement parts and plug and chug.

Do you know if there's any reason why I can't run the dryer in its disassembled state? I'd like to know if it's heating before I put the damn thing back together.

RamblinRover Luxury-Yacht

> ttyymmnn

RamblinRover Luxury-Yacht

> ttyymmnn

03/12/2015 at 12:09 |

|

Other than making your fingers warm, as long as all the mechanical parts are buckled down in their places the setup should run. The check of the sensors as continuous in normal operation, discontinuous otherwise isn't surefire, but anyone who designs a system the other way (e.g. fail ON) should legitimately be shot, and it's rare.

ttyymmnn

> RamblinRover Luxury-Yacht

ttyymmnn

> RamblinRover Luxury-Yacht

03/12/2015 at 12:12 |

|

Well, the only moving part is the drum motor, and the drum is completely removed (I'm not looking forward to getting the belt back on the tensioner). I find it interesting, though, that two sensors that presumably monitor overheat both failed. The one on the heater box may regulate heater temp. Maybe I should find a schematic.....

RamblinRover Luxury-Yacht

> ttyymmnn

RamblinRover Luxury-Yacht

> ttyymmnn

03/12/2015 at 12:15 |

|

Yeah, one of them very possibly, in that it would serve as an "up-to-temp" sensor to flick off the heater, with the other sensor functioning as the WTF?! ALARM sensor that shuts things down. Safety sensors need to err to system fail off, but other sensors are allowed to be otherwise.

ttyymmnn

> RamblinRover Luxury-Yacht

ttyymmnn

> RamblinRover Luxury-Yacht

03/12/2015 at 12:17 |

|

The check of the sensors as continuous in normal operation, discontinuous otherwise isn't surefire

Can you explain this a bit more? How else could you check it unless the part is disconnected from the power supply, short of trial and error replacement?

RamblinRover Luxury-Yacht

> ttyymmnn

RamblinRover Luxury-Yacht

> ttyymmnn

03/12/2015 at 12:23 |

|

A safety sensor will break connection to indicate a fault. Something you know is a safety sensor (where diagrams are helpful) would in most cases test as dead just that easily. Something that is a control sensor *can* in some cases operate the other way, and the only thing I can think of to make sure a control sensor isn't that way (other than replacing it) would be to stick one end on the stove, heat it up gradually, and check continuity as it heats up.

ttyymmnn

> RamblinRover Luxury-Yacht

ttyymmnn

> RamblinRover Luxury-Yacht

03/12/2015 at 12:32 |

|

Okay, I think I got it.

These are the two units on the heat element box. The one on the left tested no continuity, the other tested good continuity. The two of them together list as a "thermostat fuse kit". Which makes me wonder if I should go ahead and replace both while I'm in there. The one on the right is as old as the machine, ~13 years.

The other part that is testing bad is a thermoresistor that sits on the vent pipe. I don't really know how all these parts work together, but it would make sense that the failure of one could lead to the failure of another.

RamblinRover Luxury-Yacht

> ttyymmnn

RamblinRover Luxury-Yacht

> ttyymmnn

03/12/2015 at 12:44 |

|

What you've got there, I think, is basically a thermal switch and a timer element/breaker. In other words, I think one trips out the other when you're overheating, and then the other forces the system to wait. I could be wrong on all of this, but that seems at least possible. If I had to guess an element for direct failure, it would be the vent pipe sensor, but depending on how it's set up, it's a gamble. Wouldn't hurt to replace both items - the "fuse kit" and the vent pipe one. If you're feeling miserly, test the switch thingy on the left in the picture - based on the setup, it may very possibly trip on with heat - i.e. "short" the other one as a breaker to make it trip, which then makes the system wait.

Anyway, without seeing the wiring, I'm somewhat limited, but "general thermal protection circuit" + last-ditch clogged drier kill sensor would make sense as a setup, if that's what you have. Also, take this as a Saab plane engineer building a car sort of approach - it's what I, as an automotive and conditioning system guy would design if I were building a dryer vs. what a Dryer Engineer would.

ttyymmnn

> RamblinRover Luxury-Yacht

ttyymmnn

> RamblinRover Luxury-Yacht

03/12/2015 at 12:49 |

|

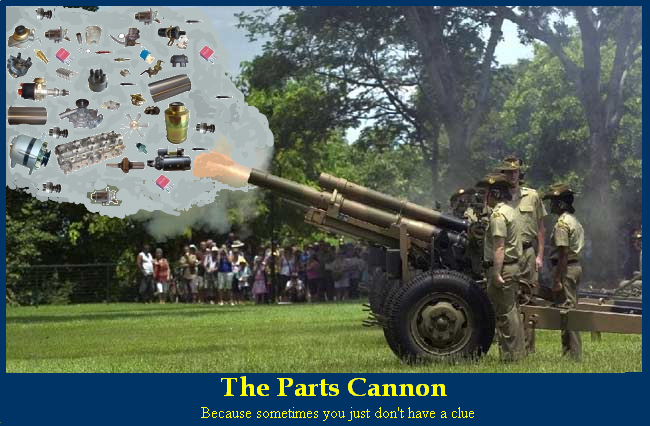

Thanks again for all your help with this. I am not an engineer in any sort of the word. I'm a musician who's trying to save money and learn a few things along the way. I imagine a Sears repair guy would simply replace everything, broken or not, charge me double the price for the parts and $250 in labor. It's a pretty simple machine, really, and ought to be pretty easy to fix. We shall see. Off to the hardware store after lunch to buy some parts. Will smoke a cigar on the way for my trouble.

Cheers!

RamblinRover Luxury-Yacht

> ttyymmnn

RamblinRover Luxury-Yacht

> ttyymmnn

03/12/2015 at 12:56 |

|

The cost of parts being what it is on this sort of thing, wholesale part swapping isn't a bad choice for the home repair enthusiast. What gets to be a real bastard is on full-scale electronics like stereos, which have gone so far beyond operating with simple sub-component networks like this it's ridiculous. With those, you swap a whole control board as often as not - if they even still make one.