"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

12/08/2015 at 09:13 ē Filed to: None

0

0

30

30

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

12/08/2015 at 09:13 ē Filed to: None |  0 0

|  30 30 |

a

Does anyone know what thickness of metal you really need inbetween the bores for safe use without poking a hole through your cylinder wall. Would be a cast-iron block if that makes a difference...

crowmolly

> BiTurbo228 - Dr Frankenstein of Spitfires

crowmolly

> BiTurbo228 - Dr Frankenstein of Spitfires

12/08/2015 at 09:16 |

|

There are a lot of variables in play. Are you trying to build an engine with a big overbore?

iSureWilll

> BiTurbo228 - Dr Frankenstein of Spitfires

iSureWilll

> BiTurbo228 - Dr Frankenstein of Spitfires

12/08/2015 at 09:18 |

|

I donít know the distance but... I would know that block anywhere. Its an M20! I think the largest bore you can go is roughly 88mm (+4 over stock). You should be able to go up to 86mm (+2) while still using the stock head gasket though.

BiTurbo228 - Dr Frankenstein of Spitfires

> crowmolly

BiTurbo228 - Dr Frankenstein of Spitfires

> crowmolly

12/08/2015 at 09:22 |

|

Relatively yeah. Itís a Rover 2600 engine from an SD1 and itís very difficult to find parts for. However, one of the things BL were actually rather good at is using standardised measurements for components in an effort to improve parts compatability and economies of scale. Didnít work quite to plan, but thereís a possibility that a number of Triumph OHC pistons would be the right height for my engine.

If I use Saab 99 1.7l pistons I get 2.8l (2.5mm wider), if I use Dolomite 1850 pistons I get 3.0l (6mm wider) and if I use TR7 pistons I get 3.2l (9.3mm wider).

Each one is slightly easier to find than the one before...

BiTurbo228 - Dr Frankenstein of Spitfires

> iSureWilll

BiTurbo228 - Dr Frankenstein of Spitfires

> iSureWilll

12/08/2015 at 09:28 |

|

It is! But itís not the engine that Iíll be doing it on. Iíll be using a Rover 2.6l out of an SD1 which has enough similarities to an M20 to make the two fairly comparable if only BL had developed the Rover one.

Both small-displacement alloy-head 12v belt-driven OHC inline 6s with 42mm inlet valves. Only real difference is that the Rover only has 5 main bearings, but has a forged steel crank from stock so that evens things out...

Nibby

> BiTurbo228 - Dr Frankenstein of Spitfires

Nibby

> BiTurbo228 - Dr Frankenstein of Spitfires

12/08/2015 at 09:28 |

|

The solution is just to add more cylinders.

BiTurbo228 - Dr Frankenstein of Spitfires

> Nibby

BiTurbo228 - Dr Frankenstein of Spitfires

> Nibby

12/08/2015 at 09:29 |

|

V12 it is then!

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

12/08/2015 at 09:33 |

|

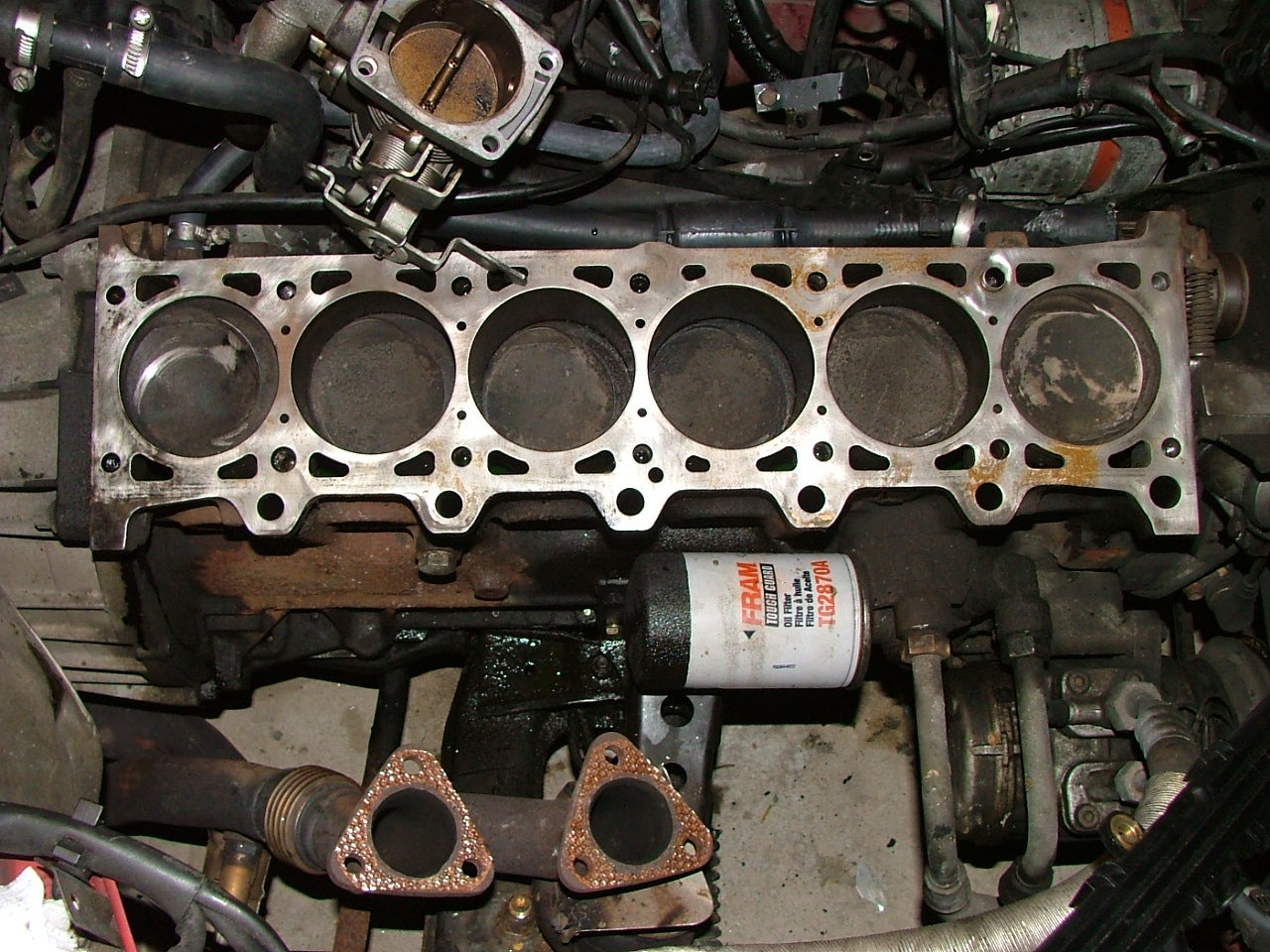

As you can see from this image of a Chevy 400 small-block, there exist engines which from the factory have a stupidly tiny spacing:

Bores are 4.125, which means the space between is around .27Ē when original, and they can apparently be bored out in some cases as much as .060, which makes for a notional .155 or so between bores when done. Insane.

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

12/08/2015 at 09:36 |

|

Further: you see that your block has two small holes between each pair of cylinders. Those are ďsteam holesĒ, also employed on most Chevy 400s. There isnít in all likelihood any separation between the inner castings for your cylinders - all one lump, so there actually probably isnít any air space at all between your bores. None.

BiTurbo228 - Dr Frankenstein of Spitfires

> crowmolly

BiTurbo228 - Dr Frankenstein of Spitfires

> crowmolly

12/08/2015 at 09:38 |

|

Oh, what are the variables? I might know them.

Max rpm will be around 6000-6500. Looking for ~230bhp. Mean piston speed should be between 16.8m/s and 18.2m/s depending on what rpm the limit is so shouldn't be too high wear. Compression fairly low at 9.5:1?

Ash78, voting early and often

> BiTurbo228 - Dr Frankenstein of Spitfires

Ash78, voting early and often

> BiTurbo228 - Dr Frankenstein of Spitfires

12/08/2015 at 09:40 |

|

Just make sure all 6 are on the compression cycle at the same time. The cylinder pressures will counteract each other! You might get some pulsating and vibration, but thatís just part of the charm.

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

12/08/2015 at 09:42 |

|

That is nuts! Shall see if I can do some measurements on my Rover block to see whatís left. Thatís heartening though.

The picture isn't actually the engine I'll be using. Couldn't find a pic of mine :S

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

12/08/2015 at 09:45 |

|

I donít know why the one picture I posted of a Chevy 400 doesnít have the steam holes, but most do. The ďrecommendedĒ overbore limit on one is about .030, which still makes for a less than quarter inch spacing. ĎTwould be a good way to find out just how porous the BL casting process was. :X

BiTurbo228 - Dr Frankenstein of Spitfires

> Ash78, voting early and often

BiTurbo228 - Dr Frankenstein of Spitfires

> Ash78, voting early and often

12/08/2015 at 09:46 |

|

Ď Some pulsating and vibrationí.

You sound like my local MOT inspection garage. Because they know me and they know I'll fix things if I point them out, they tend to pass cars that have no right to be on the road. When a wishbone is probably 20 miles from falling off they say 'slight play in O/S balljoint...'

Ash78, voting early and often

> BiTurbo228 - Dr Frankenstein of Spitfires

Ash78, voting early and often

> BiTurbo228 - Dr Frankenstein of Spitfires

12/08/2015 at 09:51 |

|

You need to come to some of the smaller states in the US. When a car is registered, a clerical person checks the odometer, turn indicators, and brake lights. Then that car can travel on the roads with no further inspection or repair indefinitely!

Itís weird, because itís one of the only policies that both political parties agree on ó itís small government AND not burdening the poor with undue ďhidden taxes.Ē Never mind that these offices are so wasteful, it negates almost all arguments there.

And both sides are idiots.

Nibby

> BiTurbo228 - Dr Frankenstein of Spitfires

Nibby

> BiTurbo228 - Dr Frankenstein of Spitfires

12/08/2015 at 09:52 |

|

yessssss

crowmolly

> BiTurbo228 - Dr Frankenstein of Spitfires

crowmolly

> BiTurbo228 - Dr Frankenstein of Spitfires

12/08/2015 at 09:55 |

|

Wasnít sure if it was a siamesed block already, what your power level was going to be, etc.

You could probably get it sonic tested to figure out what the maximum safe bore size would be. Best to talk to a machine shop and see what they can do.

crowmolly

> RamblinRover Luxury-Yacht

crowmolly

> RamblinRover Luxury-Yacht

12/08/2015 at 09:57 |

|

Yeah, the 400 SBC is an odd duck. Most places wonít go over 0.030 overbore, in contrast to the 454 blocks that can sometimes go 0.100-0.125 over.

RamblinRover Luxury-Yacht

> crowmolly

RamblinRover Luxury-Yacht

> crowmolly

12/08/2015 at 09:58 |

|

Judging by the steam holes and small spacing, Iíve been assuming his block is siamesed - youíre quite right that a sonic check is the only way to be sure how big he can go, though.

RamblinRover Luxury-Yacht

> crowmolly

RamblinRover Luxury-Yacht

> crowmolly

12/08/2015 at 10:00 |

|

Boring a whole eighth out of *anything* is sheer comedy.

BiTurbo228 - Dr Frankenstein of Spitfires

> crowmolly

BiTurbo228 - Dr Frankenstein of Spitfires

> crowmolly

12/08/2015 at 10:05 |

|

Gotcha. I donít think itís a siamesed block but so far having difficulty finding a pic of the block. So far this is the best I can find:

Message received on the sonic testing though...

StndIbnz, Drives a MSRT8

> BiTurbo228 - Dr Frankenstein of Spitfires

StndIbnz, Drives a MSRT8

> BiTurbo228 - Dr Frankenstein of Spitfires

12/08/2015 at 10:13 |

|

Take it the block is siamese then right? Also, are there cross drillings for coolant that you would run into if you went to overbore? As crowmolly said, lots of variables. I know some of our engines are only a few mmís between bores. Cast iron would be easier than Al with a liner.

crowmolly

> RamblinRover Luxury-Yacht

crowmolly

> RamblinRover Luxury-Yacht

12/08/2015 at 10:14 |

|

#YOLO comes in a bucket for your .125 over needs

RamblinRover Luxury-Yacht

> crowmolly

RamblinRover Luxury-Yacht

> crowmolly

12/08/2015 at 10:28 |

|

Porosity, meet not-give-a-fuckosity!

BiTurbo228 - Dr Frankenstein of Spitfires

> StndIbnz, Drives a MSRT8

BiTurbo228 - Dr Frankenstein of Spitfires

> StndIbnz, Drives a MSRT8

12/08/2015 at 10:34 |

|

Gotcha. As far as I can tell it's not siamesed (couldn't find a pic of the engine block I'm using so picked an M20 block). I'll see if I can find info about cross-drillings but afaik the cooling system in the block is fairly basic.

Snuze: Needs another Swede

> BiTurbo228 - Dr Frankenstein of Spitfires

Snuze: Needs another Swede

> BiTurbo228 - Dr Frankenstein of Spitfires

12/08/2015 at 13:44 |

|

In theory you can go pretty thin - in the Chevy V8 world you can take some blocks out as much 4.185Ē bore on 4.400Ē bore spacing, leaving only .215Ē between cylinders. This is considered the absolute max though, and only works on blocks with siamesed bores.

The other issue with going big bore is you thin out your water jackets. Eventually this can cause the water jackets to rupture which will ruin the engine (ask me how I know). As others have suggested, youíd do best to talk to a machine shop and have them inspect and sonic check the block.

sdwarf36

> BiTurbo228 - Dr Frankenstein of Spitfires

sdwarf36

> BiTurbo228 - Dr Frankenstein of Spitfires

12/08/2015 at 23:23 |

|

.090 is min. safe thickness Iíve heard if youíre not boosting.

Are you completely stupid?

> sdwarf36

Are you completely stupid?

> sdwarf36

12/10/2015 at 21:17 |

|

No. No, no, no, no, no, no nononononononononononononononoooooooooooooo.

sdwarf36

> Are you completely stupid?

sdwarf36

> Are you completely stupid?

12/10/2015 at 21:56 |

|

Correction-I just re-read to see why the opposition. I meant the min wall thickness PER CYLINDER. So .180 between.

CCtahoe

> Snuze: Needs another Swede

CCtahoe

> Snuze: Needs another Swede

12/12/2015 at 15:06 |

|

How do you know?

Snuze: Needs another Swede

> CCtahoe

Snuze: Needs another Swede

> CCtahoe

12/13/2015 at 23:32 |

|

In FSAE we competed with a Honda CRF450R engine, and they have extremely thin cylinder walls with spray in bore liners (nikasil or alusil). Itís very thin.

Anyways, I think we were over taxing that engine from the get go - it was made for a 200lb dirt bike driving one tire on loose surface, not a race car that weighed 600lbs plus aero load and tons of grip. During a competition a bolt on our jackshaft broke and bounced up into the left rear wheel where it lodged itself between the brake caliper and wheel shell. All the extra load, plus the added vibration now coming from the jackshaft was just too much for it to take, and the cylinder wall split right into a water jacket. This momentary widening of the cylinder allowed the piston (which had a very short skirt to begin with) to literally flip sideways in the boor. And that was the end of our competition season.