"coelacanthist" (coelacanthist)

"coelacanthist" (coelacanthist)

11/02/2015 at 14:34 • Filed to: None

1

1

17

17

"coelacanthist" (coelacanthist)

"coelacanthist" (coelacanthist)

11/02/2015 at 14:34 • Filed to: None |  1 1

|  17 17 |

I could really use your help.

So as part of my job, I have the pleasure of training our new hires. Part of their job is assisting customers in finding replacement parts for small engines, the kind used in outdoor power applications, you know, Briggs and the like.

They by no means are expected to be able to troubleshoot or diagnose problems, it’s mostly just assisting customers in correctly interpreting parts diagrams and schematics. I have found however, that a basic understanding of how small engines function makes the job much easier.

My goal is to give my students as much knowledge as possible without overwhelming them. Most of them have little to no experience coming in (apparently kids don’t grow up on mini bikes and go karts anymore, thanks Xbox) so I have to keep things fairly simple and easy to digest.

I’ve been doing this for a few years now, but there is always room for improvement. I have a lot of material I’ve generated on my own, and a few videos from various manufacturers, but I’m looking for any ideas you brilliant oppos might have. Good books, websites, animations, etc.

How did you first learn the basics? Did anyone ever offer a particularly clear and concise explanation of something related? Any help or tips would be greatly appreciated.

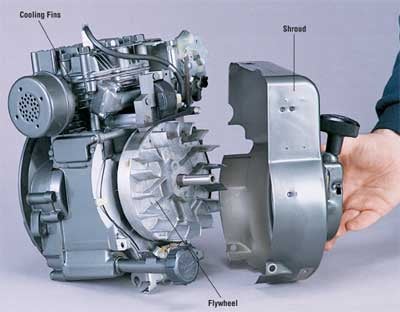

(Photo from howstuffworks)

Future next gen S2000 owner

> coelacanthist

Future next gen S2000 owner

> coelacanthist

11/02/2015 at 14:42 |

|

3-D parts would help you I think. Would be cheap and readily produced with a short time frame. People can grasp things better with it in their hands.

I learned by buying a book and telling myself it can’t be that hard to rebuild a motor.

Aaron M - MasoFiST

> coelacanthist

Aaron M - MasoFiST

> coelacanthist

11/02/2015 at 14:44 |

|

It might be too technical, but I figure it’d be a good supplement to the material you already have: MotoIQ has a series called “suck squish bang blow” which is targeted at people who want to modify cars but have no mechanical background.

http://www.motoiq.com/Tech/SuckSquis…

RamblinRover Luxury-Yacht

> coelacanthist

RamblinRover Luxury-Yacht

> coelacanthist

11/02/2015 at 14:45 |

|

Oh yes, classic Briggs 5HP.

ttyymmnn

> coelacanthist

ttyymmnn

> coelacanthist

11/02/2015 at 14:50 |

|

Have them spend a couple days with the mechanics. I didn’t know squat about small engines until I had to fix my lawnmower. I learned a lot in a hurry, mostly from YouTube.

Smallbear wants a modern Syclone, local Maple Leafs spammer

> coelacanthist

Smallbear wants a modern Syclone, local Maple Leafs spammer

> coelacanthist

11/02/2015 at 14:58 |

|

A Briggs&Scrapiron manual, + any of the following:

Taking apart our lawnmower engine when my dad wasn’t around to see why it sometimes didn’t work, amounted to looking at stuff and putting it back together

Taking apart my tractor motor in an attempt to see why it didn’t run

And so on. Basically, a bit of basic book knowledge and free reign to tinker.

coelacanthist

> Aaron M - MasoFiST

coelacanthist

> Aaron M - MasoFiST

11/02/2015 at 14:58 |

|

This is exactly what I'm talking about, thanks!

coelacanthist

> Future next gen S2000 owner

coelacanthist

> Future next gen S2000 owner

11/02/2015 at 14:59 |

|

I should say that I have tons of parts to look at and even some cutaways.

Berang

> coelacanthist

Berang

> coelacanthist

11/02/2015 at 15:00 |

|

I have or had some old power mechanics books that explained small engines very well (despite being printed in 70s, things haven’t changed that much in this area). You might find something like this on ebay or amazon pretty easily.

coelacanthist

> Smallbear wants a modern Syclone, local Maple Leafs spammer

coelacanthist

> Smallbear wants a modern Syclone, local Maple Leafs spammer

11/02/2015 at 15:01 |

|

I've been so tempted to just drop off a bunch of broken shit on Monday and tell them to have it fixed by Friday.

coelacanthist

> Berang

coelacanthist

> Berang

11/02/2015 at 15:01 |

|

To the used book store! Great idea.

jariten1781

> coelacanthist

jariten1781

> coelacanthist

11/02/2015 at 15:04 |

|

No real training. Shit would break on the farm and grandpa would send over a cousin with some experience and a cousin with no experience to figure it out. If we couldn’t we’d find an uncle (who’d be really irritated). If all of us couldn’t we’d go back to grandpa who could usually diagnose and fix it in about 20 seconds. That didn’t happen often because if you pulled him out of the field there was hell to pay...like suddenly just enough manure would need to be spread that very night that would last just until we needed to form up in the morning for the next days tasks.

So um...basically hands on with negative reinforcement...haha. I know that’s not in vogue anymore, but it does get you resourceful in a hurry.

Sweet Trav

> coelacanthist

Sweet Trav

> coelacanthist

11/02/2015 at 15:23 |

|

THIS.

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> coelacanthist

whiskeybusiness NOW A DANGER TO CROWDS NEAR YOU

> coelacanthist

11/02/2015 at 15:40 |

|

This plus find the cheapest one you can find and take it apart so they can see its working. I’ve found people selling 5 engines for 10 dollars at the local minibike swap meet. They don’t have to run to be a great visual aid.

gin-san - shitpost specialist

> Smallbear wants a modern Syclone, local Maple Leafs spammer

gin-san - shitpost specialist

> Smallbear wants a modern Syclone, local Maple Leafs spammer

11/02/2015 at 16:08 |

|

This is half joke, half serious - can you put forced induction on lawn mower engines (whether they're push mowers or ride mowers)? Are there any ones that come from the factory with forced induction?

Smallbear wants a modern Syclone, local Maple Leafs spammer

> gin-san - shitpost specialist

Smallbear wants a modern Syclone, local Maple Leafs spammer

> gin-san - shitpost specialist

11/02/2015 at 16:21 |

|

You can put forced induction on anything. I doubt if there are any from factory—what's the point? (from a manufacturers perspective I mean)

coelacanthist

> gin-san - shitpost specialist

coelacanthist

> gin-san - shitpost specialist

11/02/2015 at 16:41 |

|

B&S made a three cylinder turbo diesel. I have seen some people online putting turbos on singles but I suspect it’s more of a doing it just to do it thing.

Frank Grimes

> coelacanthist

Frank Grimes

> coelacanthist

11/02/2015 at 17:26 |

|

a dictionary

a tweed sport coat with elbow patches

one of these

and a test at the end of your lecture