"WiscoProud" (wiscoproud)

"WiscoProud" (wiscoproud)

10/08/2015 at 13:14 • Filed to: None

0

0

4

4

"WiscoProud" (wiscoproud)

"WiscoProud" (wiscoproud)

10/08/2015 at 13:14 • Filed to: None |  0 0

|  4 4 |

As part of my ownership of a 2004 Toyota Land Cruiser, I am doing my best to get it in top condition. In the past this has included replacing the heater Ts, new shocks, plugs, and a small lift. Next up was replacing the diff and transfer case fluids and greasing up the chassis.

Like many vehicles, I do not believe my diff and transfer case fluids had been ever changed. The manual calls for 75w-90 gear oil, and since I plan on changing it regularly I went with conventional, rather than synthetic. I won’t bother writing up the process as its pretty straight forward, but I will say that used gear oil is just as smelly as everyone says and a cheap harbor freight pump was needed to fill the transfer case and front diff. I also had to buy a set of allen sockets, as opposed to the transfer case and rear diff, the front diff used them. The only issue was my rear diff had more material on the plug than I would have liked to see, specifically, chunks that looks like pieces of bearing. Since its not making any noise I won’t worry about it unless the next change looks bad too. If it is bad, I have already thought about the logistics of putting a locking diff out of a 98-99 in it.

Next up was greasing the chassis. Once again, I have never done this before, so I picked up a cheap grease gun from HF and looked up the grease fittings in the service manual. There are only a few on the front and rear axles. After figuring out how to actually make grease come out of the gun (took way too long), I got them greased up. In hindsight, I probably used too much on the rear, as I crawled under the truck later and grease was on catalytic converter shields. Oh well.

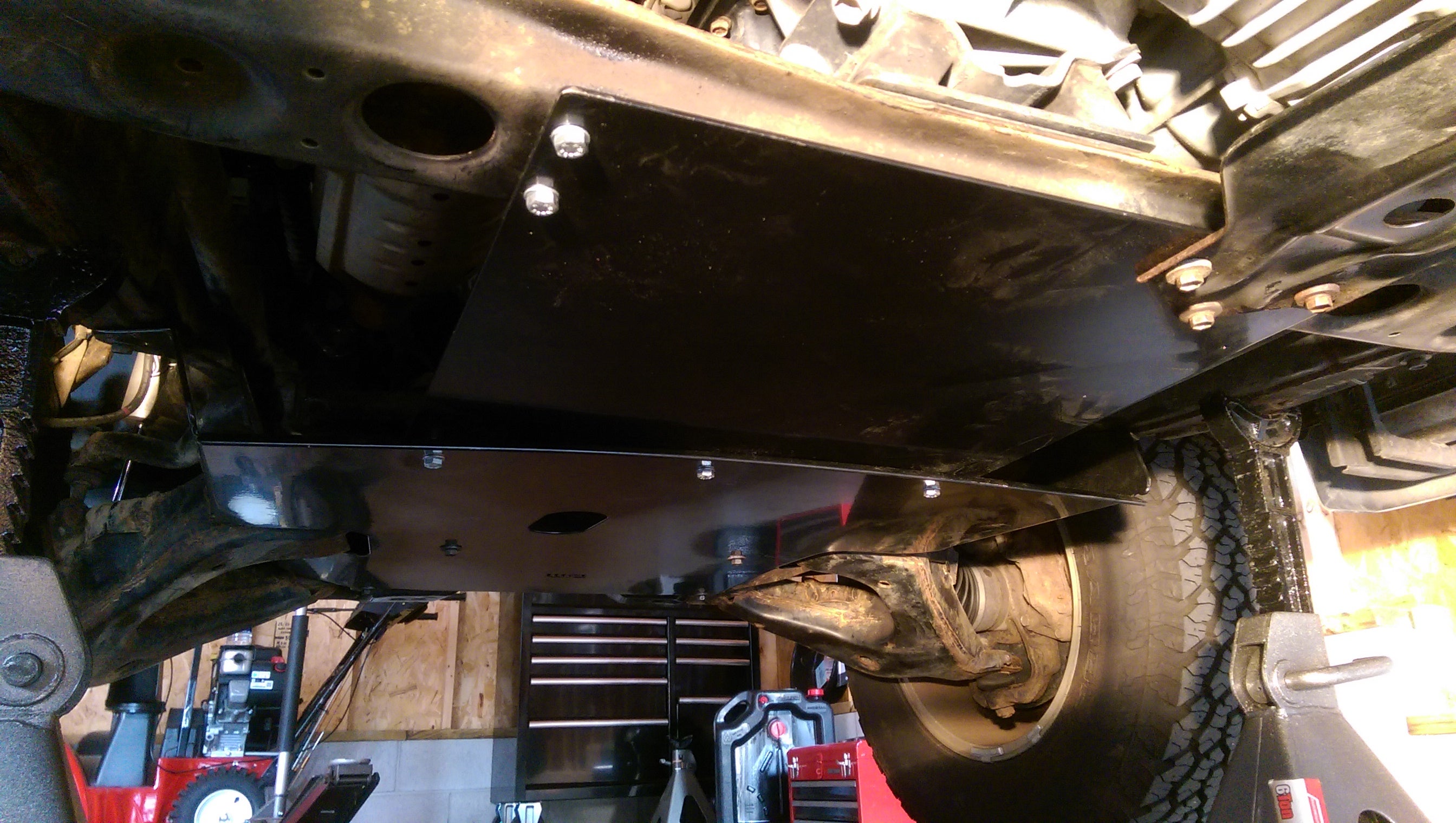

Now comes the fun part. Previously I had replaced the front skid plate (splash shield) as it had several decent rust holes. This time I replaced the intermediate shield which is inexplicably made of plastic rather than metal. To replace it, I purchase the TJM sump and transmission guards for a total cost with shipping of less than $300. Here is a picture of the new skids compared to the old.

The small plate on the lower right is the OEM transfer case guard, which is reused. I was hoping the TJM plate would cover it, but it ends at the transmission cross member. I saw a heavy duty version once on Mud, but apparently it wasn’t mass produced in favor of a version that replaced the entire cross member.

The new sump guard, while not as heavy duty as some options out there, is a lot stronger than factory. I’ve read accounts that it will support the entire weight of the truck in case of mishaps, but will be largely trashed. Although at a cost of $130, its well worth it to me.

Installation was a bit of a bitch. Turns out the same salt that destroyed my front skid and my gas tank skid (next project) also destroyed the bolts. I ended up having to drill out 9 bolts total. After getting them out I then busted out my impulse purchased tap and die set and cleaned out all the threads in the frame and the individual bolts. I also busted out my anti-seize to make sure I wouldn’t have this issue in the future. After that, the new sump skid popped right on.

The transmission guard was another matter altogether. Not only did I have to drill out two holes on the cross member, but three holes needed to be drilled joining the sump and transmission guards. I wish I knew why TJM felt the need to not provide bolt holes, but whatever. Its cheap. Edit: one item to note is that to install the two bolts on the driver side of the transmission crossmember, you either need to use an open ended wrench, or cut the bolts down 1/4”. If you dont you won’t have enough space to get the box wrench out when its tight.

The instructions say to just drill three 9mm holes for the bolts, but after reading on Mud about how much of a bitch this can be, I decided to put some adjustability into them. So I made three 3/8” by 20mm holes instead.

Thankfully my handy dremel cut off wheels were up to the task. After hitting all the new holes with black rustoleum, I buttoned everything back up.

All said and done, the skids are a fantastic value for the 100 series. However, the shipping from Australia cost a lot (1/3 of the total price) and took almost two months to get here. For my purposes, I think I would skip the transmission guard as everything is tucked nice and high above the frame rails anyways, and try to find a better transfer case guard.

BJ

> WiscoProud

BJ

> WiscoProud

10/08/2015 at 13:25 |

|

... I ended up having to drill out 9 bolts total.

Dear God. I had 4 break off when I put on my new skids, and one was behind the rear driveshaft. I did consider, very momentarily, trying to fix that myself but I gave up on that idea very quickly. It cost me over $300 with taxes to get the bolts drilled out at the shop.

I missed a club outing because of those rusted bolts. I still haz a sad...

WiscoProud

> BJ

WiscoProud

> BJ

10/08/2015 at 14:53 |

|

When I did my shocks I had one bolt on each sway bar hanger snap off. I didn't have time to fix it, so I paid a shop to do it. $160 down the drain. Thankfully I had the time and tools to do it this time. Not to mention since they were all bolts for skids, they were quite accessible, albeit upside down.

BJ

> WiscoProud

BJ

> WiscoProud

10/08/2015 at 19:37 |

|

The shop that drilled out my bolts also installed my new plates. They seem to have done a good job, except the two bolts that attach the transfer plate skid to the crossmember are upside down. Instead of having exposed heads, the excess length of the bolts is pointing down, ready to get broken off... It’s on my list to correct real soon.

WiscoProud

> BJ

WiscoProud

> BJ

10/08/2015 at 20:48 |

|

I forgot to write about that but that was a bitch. The problem is once you put a box wrench on it and get it tight, there isnt enough room to then get the wrench off the top. I ended up cutting about a quarter inch off of each bolt which worked perfect.