"No, I don't thank you for the fish at all" (notindetroit)

"No, I don't thank you for the fish at all" (notindetroit)

08/02/2014 at 10:12 • Filed to: airliners, planelopnik, tensile strength

55

55

64

64

"No, I don't thank you for the fish at all" (notindetroit)

"No, I don't thank you for the fish at all" (notindetroit)

08/02/2014 at 10:12 • Filed to: airliners, planelopnik, tensile strength |  55 55

|  64 64 |

In many aviation online communities I see many of the same fundamental question: why did this one type of airliner outlast newer ones? Why did they get rid of this one type? When are they finally going to retire this plane? And so on. The reasons why some planes get sent sooner than others depend on the airline itself, why it got that type in the first place and whether or not that justification or reasoning still exists. Regardless of why or when, all airliners share the same fate: sooner or later, they'll get to the Boneyard eventually.

Topshot by Dale Coleman via Wikipedia, used under GNU Free Document License

To demonstrate why, here's a fun little experiment you can do:

1. Get yourself a good pair of !!!error: Indecipherable SUB-paragraph formatting!!! .

2. Get an empty aluminum beer or soda can and use a pair of metalworking shears to cut a nice long strip from the can. Or if you don't feel like getting the aforementioned gloves, just play with the can's tab.

3. Use a can opener to remove the lid from a tuna can or a similar metal package (as long as it's a steel container).

4. Bend the aluminum strip repeatedly until it fails and make note of how long it took to fail.

5. Bend the tuna can lid until it fails and make note of how long it took to fail (hint: this is going to take a while)

Aluminum has a certain "shelf life" (or fatigue life, to use the technically correct term) where it can take a theoretically fixed amount of abuse before it fails, and depending on the nature of that use that can occur quickly. The number one reason why military aircraft get retired to !!!error: Indecipherable SUB-paragraph formatting!!! is because they reach a state of being "surplus to requirements" either due to technical or performance obsolescence or budget cuts, but many F/A-18C "Legacy" Hornets are being sent there because the heavy toll of the wars in Afghanistan and Iraq have used up the "safe" hours available on their airframes. For most tactical fighters like the F/A-18, this is typically in the 5,000 to 7,000 flight hour range. If that seems low, that's because it is. Fortunately, fighter planes aren't flown as frequently as jetliners, so they can stretch those 5,000 hours out over years and even decades. Plus, upgrade and remanufacture programs (often in the form of a "Mid-Life Upgrade" or MLU) can add life back into the airframe, sometimes even doubling it, by completely tearing the aircraft down and replacing critical "timed-out" components like wing spars with brand new ones.

!!! UNKNOWN CONTENT TYPE !!!

The general rule of thumb is that airliners (especially large and particularly sturdy ones like the 747) can last up to 100,000 flight hours or 100,000 cycles. What's the difference? Flight hours is exactly what it sounds like - the total amount of time the aircraft is in the air (well, not quite, but for our purposes we'll stick to this simplistic definition). A cycle represents one trip of the aircraft from Airport A to Airport B, or more specifically for our purposes, the time the pressurization system is activated on the ground to the time it's de-activated on the ground at the destination airport. Flying puts a lot of stress on an aluminum tube - turbulence for one, but also the simple act of moving through the air. Wings bend - actually, they bend a lot as part of how the aircraft defeats turbulence for the sake of passenger comfort and achieve high fuel efficiency. Things bend and move imperceptibly as flight attendants move about the aircraft, systems function within their normal parameters, and in just experiencing the act of existing as a component of a large moving machine. These are small, tiny forces, but after 20 years of flying across the Pacific Ocean for half a day each flight, they add up.

Image by Timothy Smith via Wikipedia, used under Creative Commons License

But wait! you ask. There are so many really old aircraft that have been flying around for decades! Like this Kenn Borek DC-3! What's so special about them? And don't give me any "They don't build them like they used to!" BS!

Well...the thing is, they really do ...er, don't build them like they used to.

First of all, aircraft like the DC-3 actually do require complete tear-downs and rebuilds every so often, !!!error: Indecipherable SUB-paragraph formatting!!! , which tends to be inevitable if an airplane flies long enough (not necessarily to the degree of having fatalities, but the aeronautical equivalent of a fender-bender). The Kenn Borek DC-3s (actually Basler BT-67s) in particular have been heavily remanufactured into new aircraft including new wing and fuselage plugs.

!!! UNKNOWN CONTENT TYPE !!!

Secondly, what really does damage to the airplane is its pressurization system. Remember the secondary definition I gave for what a "cycle" is? The time the pressurization system is activated on the ground to the time it's de-activated on the ground at the destination airport. That's an important distinction because the pressurization system tends to literally inflate the aircraft's fuselage like a balloon - it's not enough for the average passenger to notice, but the aluminum structure does indeed get stretched to the same effect as if you were blowing up a balloon, and the cycle of pressurization from the inside when the aircraft starts boarding passengers against when it's facing pressure again from the outside atmosphere at rest on the ground results in major structural movements. Imagine taking a soda can and crumpling it just slightly, then stretching the ends to try to smooth those crinkles out, then compressing it again to create new crinkles. See how many times you can do that before the can completely fails. A major reason why the DC-3 can last so long is that it simply doesn't have a pressurization system, so the fuselage structure experiences comparatively stable forces. Tube-and-fabric aircraft like, say, a Piper Super Cub tend to have their frames constructed from mild steel which is closer related to that tuna can lid than the soda can, so they can keep on flying for as long as the owner keeps care of it (but have the downside of constant maintenance to their fabric covering).

It's not the only reason why airliners get sent to the boneyard, but it is a major one, and the reason why all airliners will inevitably be sent to the boneyard. With "plastic" planes like the Boeing 787 becoming popular, and Airbus sending its A350 into service, airliners might stick around longer, but if nothing else economic factors will take them out of service. Technology outpaces all aircraft and sooner or later said aircraft simply can't keep up with new frames. Even these carbon aircraft will reach a point of structural compromise eventually - right now, we're just not sure after what time and under what circumstances, but pretty sure the aircraft will simply become economically unviable before that. Financing structures also play a role, which is why Northwest Airlines and Delta Air Lines !!!error: Indecipherable SUB-paragraph formatting!!! than some of the far newer and fancier Airbus and Boeing aircraft it leased.

!!! UNKNOWN CONTENT TYPE !!!

As for refurbishing airliners, that tends to be out of the question - well, not entirely. In industry parlance there's a thing called a "Heavy D Check" - the last of a sequence of maintenance procedures starting from A. The paint comes off, the old engines get swapped out for new ones and stripped of what can be reused, and even whole skin panels are removed and replaced. Basically, what needs to be replaced does get replaced - as long as it's economic to do so. Theoretically you can replace a timed-out wing spar on a 747 and keep it flying forever - but the process to do that is so complicated and expensive, all you've accomplished is to completely disassemble an airplane and !!!error: Indecipherable SUB-paragraph formatting!!! using a mixture of old and new parts.

Image credit Julian Herzog via Wikipedia, used under Creative Commons License

Airlines are obsessed with fuel savings in order to stay relevant in today's economy, and they're willing to put down money for new planes in the name of less use of the gas pump. An old jetliner can't compete with a new one even with massive upgrades - a 737 "Next Generation" (600 through 900 models) for example has fewer holes cut into it because a combination of engineers and bean-counters decided those holes weren't needed after all (or rather, they decided it was preferable to sacrifice the cabin-air feed they provided for passenger comfort in order to make the fuselage more aerodynamic and instead continuously recycle the air already in the plane). An NG might have engines that belong in the same CFM-56 family as what hangs on a 737 "Classic" but said engines have undergone a decade's worth of evolution in the meantime. Some parts that used to be aluminum are now composite. The NG even has an entirely different wing design compared to the older model, and the new MAX models will have a further redesigned wing. Factoring all the major design changes, the hours that have accumulated on the old airframe, and other refurbishment costs, and that old bird is going to be sent to the boneyard.

Image from the official !!!error: Indecipherable SUB-paragraph formatting!!!

!!! UNKNOWN CONTENT TYPE !!!

And yet in the general aviation world there are quite a few total refurbishment programs available, such as from !!!error: Indecipherable SUB-paragraph formatting!!! specializing in a complete tear-down so extensive they're allowed to call the airplane something different than what it was called when it left the original production line and call themselves the original manufacturer.

!!! UNKNOWN CONTENT TYPE !!!

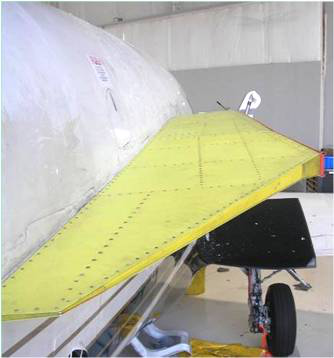

A brand new engine pylon is manufactured and placed on this ex-Beechcraft 400 after the removal of the old one at Nextant Aerospace's remanufacturing facility as part of the "400XT" conversion process. The pylon incorporates structural and aerodynamic improvements for better efficiency and to accommodate the Williams FJ44 turbofans in place of the original Pratt & Whitney JT15D turbofan engines. The FJ44s incorporate new fabrication and software control technologies to leap ahead in efficiency, and are highly popular on the latest small bizjet designs. Image taken from the official Nextant Aerospace website.

The difference is the scale - in this case, smaller is better. Used Beech/Hawker 400s and King Air 90s are fairly plentiful, span decades of production and depreciation means they can be picked up on the cheap. Cheap enough such that they can have their engines replaced, their internal guts ripped out and new wingtips put on and still be sold cheaper than newer jets while offering the same performance and technological advantages. The flight hours/cycles aren't as much of an issue because of the infrequency of business jet use. Even after decades of use they still have thousands of hours available on the clock, and at the scale of these small planes even wing spars can be replaced with relative ease to create a "zero-time" aircraft. Remanufacturing isn't limited to former Beechcraft products - the !!!error: Indecipherable SUB-paragraph formatting!!! series of aircraft have had a few similar programs offered as well including the !!!error: Indecipherable SUB-paragraph formatting!!! and Dash-10.

Image from !!!error: Indecipherable SUB-paragraph formatting!!! !!!error: Indecipherable SUB-paragraph formatting!!! !!!error: Indecipherable SUB-paragraph formatting!!!

Airliners live a hard life, but it's possible to stretch a general aviation aircraft's life span for generations of use. A large remanufacturing and support base helps create highly skilled technical jobs in the aerospace industry, offer more affordable flight and transportation options for every price point, and keep many classic out-of-production designs flying. Remanufacturing can help the 172 Skyhawk pilot as much as it helps the corporate executive who loves NetJets. With engineers, technical advisers and number crunchers passionate about general aviation, expanding the GA remanufacturing base tremendously helps preserve aviation as an active flying art and useful means of rapid conveyance.

505Turbeaux

> No, I don't thank you for the fish at all

505Turbeaux

> No, I don't thank you for the fish at all

08/02/2014 at 10:23 |

|

great post, thanks!

Grindintosecond

> No, I don't thank you for the fish at all

Grindintosecond

> No, I don't thank you for the fish at all

08/02/2014 at 10:35 |

|

A regular airliner has a pressurization differential from 6:1 up to 8:1 or slightly more. That higher number usually isn't seen until it travels near or in to the 40,000+ ft. area. At that point, the cabin is at 8,000 feet altitude. The new Dreamliner has a lower cabin elevation, somewhere in the 5,000's but that points to a larger differential as consequence, so the more cycles of that, the more fuselage stress as pointed to in the article. I'm just showing how much differential there is.

DoYouEvenShift

> No, I don't thank you for the fish at all

DoYouEvenShift

> No, I don't thank you for the fish at all

08/02/2014 at 10:43 |

|

That was awesome. Thanks for that.

heliochrome85

> No, I don't thank you for the fish at all

heliochrome85

> No, I don't thank you for the fish at all

08/02/2014 at 11:18 |

|

Excellent post. You are a great writer man and this hits all of my interests!

NotUnlessRoundIsFunny

> No, I don't thank you for the fish at all

NotUnlessRoundIsFunny

> No, I don't thank you for the fish at all

08/02/2014 at 11:57 |

|

Wow, that was terrific. Great information and very well written. Thanks for posting!

Viggen

> No, I don't thank you for the fish at all

Viggen

> No, I don't thank you for the fish at all

08/02/2014 at 12:23 |

|

Good that you specifically mentioned F/A-18Cs. While the F/A-18s fly to the boneyard or undergo center barrel replacement the squadrons that flew them are using F/A-18A++s.

jariten1781

> No, I don't thank you for the fish at all

jariten1781

> No, I don't thank you for the fish at all

08/02/2014 at 12:41 |

|

Thanks for the write up.

Unsurprisingly we have the same concerns in the submarine world on hull life.

Manuél Ferrari

> No, I don't thank you for the fish at all

Manuél Ferrari

> No, I don't thank you for the fish at all

08/02/2014 at 14:43 |

|

This post was awesome. I always wondered about the answers to many of these questions. Thanks for the good work!

ScreenShot

> No, I don't thank you for the fish at all

ScreenShot

> No, I don't thank you for the fish at all

08/02/2014 at 14:53 |

|

Boneyards are great - we once worked a whole afternoon in one, cramming bits of broken aluminum into the back of a pickup - then we drove 100 miles back to civilization to find a scrap dealer where we received the glorious sum of $42 for our efforts. Might have worked out to $2.50 an hour after expenses...

Galant Enthusiast

> No, I don't thank you for the fish at all

Galant Enthusiast

> No, I don't thank you for the fish at all

08/02/2014 at 14:57 |

|

Its fatigue life not shelf life.

rUDy Flyer 41

> No, I don't thank you for the fish at all

rUDy Flyer 41

> No, I don't thank you for the fish at all

08/02/2014 at 15:28 |

|

Excellent write up! I love me some aerospace articles, and this is no exception.

SoManyBlueCars

> No, I don't thank you for the fish at all

SoManyBlueCars

> No, I don't thank you for the fish at all

08/02/2014 at 15:31 |

|

Another good example from a military perspective is the entire F-15 fleet being grounded from airframe stress after one crashed. Navy jets have it the worst, which go through all the rigors of an Air Force jet, but must also land on a carrier and deal with a harsh salt water environment.

Enginerrrrrrrrr

> No, I don't thank you for the fish at all

Enginerrrrrrrrr

> No, I don't thank you for the fish at all

08/02/2014 at 15:42 |

|

Nice article. One of the biggest differences between steel and aluminum is that steel can have a potentially infinite fatigue life, whereas aluminum won't. With the small factors of safety in aircraft, though, even the steel has a limited fatigue life. Yay engineering! (also determining a composite's fatigue life is not easy...)

dannocaz

> No, I don't thank you for the fish at all

dannocaz

> No, I don't thank you for the fish at all

08/02/2014 at 16:15 |

|

Good article. Also, due to financial reasons, I know of at least one airline that has mothballed brand new aircraft right off the Boeing line while waiting for more favorable yields on certain routes or better fuel prices. It's not always just because of cycles or hours.

kniga

> No, I don't thank you for the fish at all

kniga

> No, I don't thank you for the fish at all

08/02/2014 at 16:39 |

|

I wish we could still see the MD-10/MD-11 in regular service. I guess all good things come to an end.

LeftHook

> No, I don't thank you for the fish at all

LeftHook

> No, I don't thank you for the fish at all

08/02/2014 at 16:40 |

|

Funny, my Dad flies this Commander for LonAire.

special_k_side

> No, I don't thank you for the fish at all

special_k_side

> No, I don't thank you for the fish at all

08/02/2014 at 16:55 |

|

Great write up. But show me a Beaver, please! :) Talk about longevity, and abuse! :) You can pound them into the ground all day, or get them sopping wet, over load them, but remember, they need to be treated with respect, and dignity. Some occasional maintenance is needed. Shite, I just described my wife.

Enginerd

> No, I don't thank you for the fish at all

Enginerd

> No, I don't thank you for the fish at all

08/02/2014 at 16:57 |

|

I actually used to work for the contractor that produced the fatigue reports for NAVAIR. Not a bad job as long as you don't mind pouring through lines and lines of flight data and debugging Fortran code.

f86sabre

> No, I don't thank you for the fish at all

f86sabre

> No, I don't thank you for the fish at all

08/02/2014 at 17:03 |

|

Another factor is obsolescence and scarcity of components and engine parts as aircraft programs age. One thing that finally ended the DC-9s service was the difficulty in finding life limited engine parts. Avionics and systems issues also increase while it gets harder to find spares. At some point your dispatch reliability drops below an exceptable level and then the plane goes from asset to liability.

Jimmy Joe Meeker

> No, I don't thank you for the fish at all

Jimmy Joe Meeker

> No, I don't thank you for the fish at all

08/02/2014 at 17:30 |

|

Steel has what is known as a fatigue limit. If the stress is less than the fatigue limit the steel structure lasts an infinite number of loading cycles. Aluminum does not have a fatigue limit. No matter what the stress level is eventually it will fail. Of course the lower the stress the more cycles until failure.

If I recall correctly steel is unique in having a fatigue limit, but I got my learning in material science before a fair number of modern materials were created so that may no longer be true.

OneRotor

> No, I don't thank you for the fish at all

OneRotor

> No, I don't thank you for the fish at all

08/02/2014 at 18:05 |

|

Great article. The one nit I need to pick is this: your explanation of material fatigue. Steel and aluminum (your two examples, which correspond to what has historically been used in aircraft construction) have vastly different fatigue curves. Steel has a finite fatigue life, that is well documented for each alloy. Aluminum does not. There is not the sharp transition between usefulness and catastrophic failure that is well defined with steel.

Because of this unknown, aluminum structures are given a "safe" fatigue life. To the casual observer these parts are completely fine, but the risks are too much for the engineers to recommend using the parts past a certain number of cycles. Steel OTOH has a well defined fatigue curve, and so the parts can get far closer to the fatigue limit than aluminum parts can.

auzzya

> No, I don't thank you for the fish at all

auzzya

> No, I don't thank you for the fish at all

08/02/2014 at 18:08 |

|

This question has always been at the back of my mind whenever I read an article about aircraft bone yards. Why are aircraft sent away to sit on a piece of land, and not be recycled down?? I just don't understand, but if someone who does could chime in, I would really appreciate it!

UserNotFound

> No, I don't thank you for the fish at all

UserNotFound

> No, I don't thank you for the fish at all

08/02/2014 at 18:13 |

|

Dude this is awesome.

Viggen

> auzzya

Viggen

> auzzya

08/02/2014 at 18:25 |

|

There's a couple reasons for it. Some aircraft sit in bone yards awaiting a new operator.

Others are recycled. It's just done in a different way called reclamation. Take for instance the few B-1B Lancers sitting in AMARG, the US military's bone yard. Their being parted out, piece by piece ever so slowly to allow the rest of the B-1B fleet to continue flying. Nearly ever aircraft in a bone yard undergoes the same process. Eventually, the parted out hulks will be disassembled and shredded. It's possible you shaved with an F-14 this morning.

Viggen

> SoManyBlueCars

Viggen

> SoManyBlueCars

08/02/2014 at 18:31 |

|

Carrier based aircraft are built to sustain that. Beefier landing gear and tail hooks and anti-corrosive paints. They're built to be able to perform hundreds if not thousands of traps. For F/A-18s, running out of traps doesn't mean their rigorous flying is over. These trapped out aircraft are the ones that end up being flown by the Blue Angels and NSAWC as aggressors.

listlast

> No, I don't thank you for the fish at all

listlast

> No, I don't thank you for the fish at all

08/02/2014 at 19:03 |

|

While the parameters of replacement are interesting, who is capable of, and responsible for tallying the usage?

For example, when "first world" planes are sold to "third world" airlines, do "authorities" comprehensively monitor those planes through their use? That seems like a tough thing to monitor over time given the disparate capacities.

Craig Lloyd

> No, I don't thank you for the fish at all

Craig Lloyd

> No, I don't thank you for the fish at all

08/02/2014 at 19:30 |

|

For the love of god just please retire all MD-80s. Please.

500hpford

> No, I don't thank you for the fish at all

500hpford

> No, I don't thank you for the fish at all

08/02/2014 at 19:47 |

|

Damn you're good

Mister_Moon

> kniga

Mister_Moon

> kniga

08/02/2014 at 19:59 |

|

I see lots of MD-11s out there. But they are all in Fedex livery.

FWIW, 11s used to be called 'Deathstars' by some wags (L-1011 pilots mostly) . They were supposedly hard to land owing to the small rudder. I used to fly ATL-PDX a lot back when Delta served that route with one MD11 flight daily. It was pretty nice in the Biz Elite cabin.

emjayay

> No, I don't thank you for the fish at all

emjayay

> No, I don't thank you for the fish at all

08/02/2014 at 21:46 |

|

Interesting post. The first commercial passenger jet, the very cool British deHaviland Comet, had cracking issues, (resulting in blowing up or falling out of the sky and killing everyone issues) that were all or mostly having to do with pressurization. Even though they did a lot of testing in water etc. they didn't understand enough about pressurization plus new alloys. Also more recently a while back a 727 or something like that blew off its tail because a pressure bulkhead at the back of the plane blew out. I think it killed everyone also. It turns out the tapered end of the plane isn't pressurized because it is much better to put a sort of hemispherical bulkhead near the back behind the passenger compartment before the plane gets too pointy.

GOU_NoMoreMrNiceGuy_v2

> No, I don't thank you for the fish at all

GOU_NoMoreMrNiceGuy_v2

> No, I don't thank you for the fish at all

08/02/2014 at 22:30 |

|

it would be impractical and dangerous but interesting to see just how long you could fly planes until they literally fall apart.

everyone's familiar with the notion of "over-engineering" so that systems can be stretched past specs...

but there also seems to be another factor at play where things kind of hit a plateau where they just don't get much worse if they survive a "critical period". everyone knows cars that have been around for 40+ years and they're still going even without total tear downs.

i'm reminded of a william gibson line where a character is asked why he keeps shaving with the same razor. his answer is, "after awhile, it just doesn't get any duller."

pfftballer

> No, I don't thank you for the fish at all

pfftballer

> No, I don't thank you for the fish at all

08/02/2014 at 22:44 |

|

How many fighter planes have crashed due to actual metal fatigue? Zero? That's what I thought. The military industrial complex needs it's money so shit "needs" replaced.

fukuuuu

> No, I don't thank you for the fish at all

fukuuuu

> No, I don't thank you for the fish at all

08/03/2014 at 00:16 |

|

Get your LIMITED EDITION "Fuck You" Shirts here!

http://teespring.com/fuckyou2014

sklooner

> No, I don't thank you for the fish at all

sklooner

> No, I don't thank you for the fish at all

08/03/2014 at 00:31 |

|

not an airliner but o read somewhere recently that most beech starships are not flying due to lack of parts and are waiting in boneyards

Vracktal

> emjayay

Vracktal

> emjayay

08/03/2014 at 04:32 |

|

I think the plane you're referring to that blew it's tail off was Japan Airways flight 123, which suffered a tailstrike that was badly repaired afterwards. The repair fatigued until it fractured and the entire rear bulkhead and most of the tail came off, as well as all the hydraulic lines. The pilots flew the plane for over half an hour using engines alone to try and steer but in the end crashed into the mountain range in Osaka.

Vracktal

> No, I don't thank you for the fish at all

Vracktal

> No, I don't thank you for the fish at all

08/03/2014 at 04:34 |

|

Metal fatigue is serious shit.

Newsboy

> No, I don't thank you for the fish at all

Newsboy

> No, I don't thank you for the fish at all

08/03/2014 at 05:11 |

|

Also keep in mind that variable costs (primarily fuel) far outweigh the initial purchase price of an airliner.

Case in point: a Boeing 747-8 costs $367M to buy, but about $3B to operate (at current fuel prices, over the lifetime of the aircraft this number will increase dramatically.) A small increase in fuel economy could pay for itself over the life of the aircraft, and justify scrapping an existing airliner.

Sources:

Aircraft Operating Costs:

https://www.conklindd.com/CDALibrary/ACC…

Boeing Jet Prices:

http://www.boeing.com/boeing/commerc…

Newsboy

> No, I don't thank you for the fish at all

Newsboy

> No, I don't thank you for the fish at all

08/03/2014 at 05:25 |

|

On the subject of carbon composite airliners:

Carbon composite doesn't have the type of structure that metal alloys do, and therefore has no fatigue limit. Failures are typically caused by compression or physical damage resulting in fractures that manifest over time and cause catastrophic failure.

I remember a university test that was published in Bicycling magazine about 20 years ago that compared steel, aluminum, titanium, and carbon fiber handlebars in fatigue failure. IIRC, the aluminum bar lasted about 50k cycles, steel 100k, titanium 300k, and they shut the machine off after the carbon bar went over 1M cycles. It was as good as new.

Not only that, it was by far the lightest at just 90g.

I agree with the author's assessment that "Even these carbon aircraft will reach a point of structural compromise eventually...but pretty sure the aircraft will simply become economically unviable before that."

We will run out of oil before composite aircraft fail due to fatigue.

Newsboy

> Newsboy

Newsboy

> Newsboy

08/03/2014 at 05:26 |

|

Here's what the experts say:

Question: "

What is a reasonable fatigue life for a carbon mountain bike bar and stem?"

Sean Coffey of Ritchey:

"Any well-made carbon component should be removed and inspected periodically for damage (especially after crashes, shipping or any trauma) but barring any damage, carbon does not have a fatigue life like alloy components and does not fatigue over time. So in theory an undamaged carbon component should hold up indefinitely under normal riding and racing circumstance. However crashes and damage from over-clamping can dramatically reduce durability."

Chuck Teixeira, Director of Bike Advanced Concepts Group at Easton:

"Carbon bars are so good in fatigue that we almost think it's a waste of time to test them because they always pass. Carbon's fatigue life is nearly unlimited because carbon has a very different type of structure than metals. What fails carbon bars is compression from clamping levers, stems, constant re-adjusting and clamping or big hits/crashes. Our lab testing has documented that carbon bars fatigue is easily five times better than aluminum. Impact strength is also better on carbon and will withstand much higher energies before breaking. Aluminum bars start to bend at comparably low energy and do give you an idea that something is changing and that maybe its time to replace them. Any metal bar can fail unexpectedly under the correct conditions so they cannot be expected to last forever. If you're a big hucker who never crashes or never moves anything you could easily get five years out of a carbon DH bar. If you're a skinny, cross-country rider who travels, tweaks his position, changes parts or takes frequent little diggers you might only two years out of your bars. Sorry, nothing is black and white."

http://velonews.competitor.com/2011/10/bikes-…

frances_ity

> No, I don't thank you for the fish at all

frances_ity

> No, I don't thank you for the fish at all

08/03/2014 at 07:42 |

|

last pay check was $9500 working 12 hours a week online. My neighbour's sister has been averaging 15k for months now and she works about 20 hours a week. I can't believe how easy it was once I tried it out.

This is what I do,,,,,,,,,,

Arrrgh-Type

> frances_ity

Arrrgh-Type

> frances_ity

08/03/2014 at 08:13 |

|

Speaking of fatigue...

frances_ity

> No, I don't thank you for the fish at all

frances_ity

> No, I don't thank you for the fish at all

08/03/2014 at 08:55 |

|

last pay check was $9500 working 12 hours a week online. My neighbour's sister has been averaging 15k for months now and she works about 20 hours a week. I can't believe how easy it was once I tried it out.

This is what I do,,,,,,,,,,

frances_ity

> No, I don't thank you for the fish at all

frances_ity

> No, I don't thank you for the fish at all

08/03/2014 at 09:50 |

|

last pay check was $9500 working 12 hours a week online. My neighbour's sister has been averaging 15k for months now and she works about 20 hours a week. I can't believe how easy it was once I tried it out.

This is what I do,,,,,,,,,,

robmclaughjr001

> No, I don't thank you for the fish at all

robmclaughjr001

> No, I don't thank you for the fish at all

08/03/2014 at 10:09 |

|

but why the "boneyard" and not recycled aluminum?

elev8r

> No, I don't thank you for the fish at all

elev8r

> No, I don't thank you for the fish at all

08/03/2014 at 11:14 |

|

I wonder if the aluminum chassis automobiles that are becoming more popular will have a shorter shelf life than a steel chassis car. Or if other factors (like rust) will still be the biggest factor

Porkins

> No, I don't thank you for the fish at all

Porkins

> No, I don't thank you for the fish at all

08/03/2014 at 11:51 |

|

the real question is, why do boneyards even exist? Soooo much metal and various other materials to be recycled...

none8239487234

> No, I don't thank you for the fish at all

none8239487234

> No, I don't thank you for the fish at all

08/03/2014 at 12:05 |

|

Difference between a passenger airliner and a DC-3? Cabin pressurization. Airliners get regularly pressurized so they can fly over 10,000 feet. Metal fatigue certainly affects both aircraft but it's slightly more of an issue in a pressurized aircraft because the entire skin has to be able to maintain the forces of being pressurized.

Commercial airlines are a lot more conservative when it comes to service life because of the economics involved. At the end of the day they are flying to turn a profit. Vintage aircraft have a different following with many people flying them for fun. Regular inspection and maintenance can keep them going forever if you are willing to pay the price.

Many of the aircraft that the USA based airlines don't want to operate anymore end up in the 3rd world. That's why they keep them around rather than scrapping them other than just the parts supply. Supply and demand is in play here though which is why they end up in the desert. The less than deep pocketbooks of 3rd world countries makes flying not as common as it is here.

RUFFORD

> Grindintosecond

RUFFORD

> Grindintosecond

08/03/2014 at 14:00 |

|

Cabin differentials are in psi, not a ratio. You'll see differentials around 10psi in business jets, but 6-8 is fairly typical (the A320 can do 8.6) for airliners. Running your max differential is more stress on the airframe, so the realistic point is that most 787 operators will still run their typical cabin altitude (6-8,oooft) with less stress on the airframe.

Clevis Pinn

> No, I don't thank you for the fish at all

Clevis Pinn

> No, I don't thank you for the fish at all

08/03/2014 at 14:26 |

|

It's been my understanding that airliners are (usually) pressurized to 8,000 feet. This means that the pressure inside the fuselage pretty much matches external atmospheric pressure up to that 8,000-foot mark, at which point the aircraft maintains that pressure for the duration of the flight. At the destination, the pressurization system deactivates as the aircraft descends through 8,000 feet and the cabin is at ambient outside air pressure for the remainder of the flight. Ergo, the cabin is not pressurized from takeoff to landing.

Is that incorrect?

El_Royo

> Newsboy

El_Royo

> Newsboy

08/03/2014 at 18:35 |

|

ooh thats an interesting way of looking at it. the airframe will last so long that only its obsolence will kill it

El_Royo

> RUFFORD

El_Royo

> RUFFORD

08/03/2014 at 18:38 |

|

i like my air thick and chunky loke a bowl of CHOWDA!!!

HellPhish89

> No, I don't thank you for the fish at all

HellPhish89

> No, I don't thank you for the fish at all

08/03/2014 at 18:54 |

|

its why we need to replace our F15's

AuntSlappy

> No, I don't thank you for the fish at all

AuntSlappy

> No, I don't thank you for the fish at all

08/03/2014 at 20:17 |

|

I have to nitpick you on one thing. You describe fatigue by having someone bend a strip of aluminum over an over again until it breaks. That is not, in fact, fatigue. That's embrittlement by work hardening. That might sound like a minor distinction, but the mechanisms are actually different. Work hardening requires plastic deformation of the material, while fatigue occurs even though the material is being stressed under its plastic deformation limit. You are correct, though, that aluminum does not have a fatigue limit like steel does.

CountIt

> No, I don't thank you for the fish at all

CountIt

> No, I don't thank you for the fish at all

08/03/2014 at 22:04 |

|

I LOVE that you linked to the "Ship of Theseus". I had never heard of that, but obviously the idea/concept has been discussed before. A nice touch to a great article.

Ludovico Scarfiotti

> emjayay

Ludovico Scarfiotti

> emjayay

08/03/2014 at 23:20 |

|

The failure of the rear pressure bulkhead happened to a 747SR (short range) of Japan Airlines in 1985:

http://en.wikipedia.org/wiki/Japan_Air…

It wasn't the result of metal fatigue, but of the improper repair of the aft pressure bulkhead following an earlier tail strike incident.

Ludovico Scarfiotti

> kniga

Ludovico Scarfiotti

> kniga

08/04/2014 at 00:25 |

|

The MD-10 was operated only by FedEx. It was an update that gave their DC-10s the electronic, two-man glass cockpit of the MD-11.

The model number of the DC-10 in general wasn't changed to "MD-10."

Ludovico Scarfiotti

> special_k_side

Ludovico Scarfiotti

> special_k_side

08/04/2014 at 00:26 |

|

Happiness is a sopping-wet Beaver. :-)

Kevin Barrett

> No, I don't thank you for the fish at all

Kevin Barrett

> No, I don't thank you for the fish at all

08/04/2014 at 03:55 |

|

Also turbo-props!

bariki

> Newsboy

bariki

> Newsboy

08/04/2014 at 06:15 |

|

Five years is still an absurdly short amount of time for a bicycle component, especially something as expensive as carbon fiber handlebars.

Gamecat235

> pfftballer

Gamecat235

> pfftballer

08/04/2014 at 13:35 |

|

I know that NotInDetroit already chimed in with the more recent F-15 issues, but the F-111 had significant fatigue issues as well which lead at least one crash. This isn't a matter of money, but of maintaining an aging fleet.

klurejr

> No, I don't thank you for the fish at all

klurejr

> No, I don't thank you for the fish at all

08/04/2014 at 14:41 |

|

I am curious why Airplane Graveyards even exist. Once a plane is no longer viable for Service why does it sit in the Desert? Why not dismantle and recycle the aluminum?

I see the Graveyard outside of the city of Mojave when going up to visit family from time to time and that thought always occurs to me.

special_k_side

> Ludovico Scarfiotti

special_k_side

> Ludovico Scarfiotti

08/04/2014 at 19:08 |

|

Which usually means you are on the best fishing trip away from your broken down middle aged Beaver, In an old Beaver that keeps on giving! :)

VTECjustkickedinyo

> Craig Lloyd

VTECjustkickedinyo

> Craig Lloyd

08/04/2014 at 22:02 |

|

They're eerily silent (which is fantastic) if you get a seat towards the front since the engines are in the back. I flew on two recently and loved them from rows 7 and 9.

Primoz

> Newsboy

Primoz

> Newsboy

08/05/2014 at 14:04 |

|

COmposites are a b*tch because they usually have polymers (plastics) as part of the structure (the matrix, i.e. the filler that holds the fibres in their place). Said plastic is very prone to degradation, so composites can have an almost unlimited cycle life (as long as the energies aren't high enough, to heat up the sample and damage it in this way, again, plastics don't tolerate heat as well) but the general time they can be useful is not as defined. Proper care sure does help, preventing UV rays from hitting bare composite surfaces, preventing water from coming in contact and the like.

The industry is very pro composite, becuase it gives a whole new world as far as designs go (metals are quite isotropic, composites are mainly complete anisotropic, which can be useful) and can be made lighter as well. But how they react after 20, 30, 40 or 50 years isn't understood as well as it is for metals. And even with metals we have some problems (Aluminium and fatigue life and all).

Making bikes out of CF is easy, since the average life of a bike is... 5 years? Planes have a much longer lifecycle.