"No, I don't thank you for the fish at all" (notindetroit)

"No, I don't thank you for the fish at all" (notindetroit)

07/10/2014 at 09:33 • Filed to: shiplopnik, engine tech

5

5

4

4

"No, I don't thank you for the fish at all" (notindetroit)

"No, I don't thank you for the fish at all" (notindetroit)

07/10/2014 at 09:33 • Filed to: shiplopnik, engine tech |  5 5

|  4 4 |

Electric batteries, hydrogen power, jet engines and steam have all been used to move cars down roads. As long as someone can figure out how to make it turn an axle, it can power a car. A ship doesn't move through the water on wheels - but it does have propellers and someone just needs to figure out how to make it spin. Actually, it doesn't even really need a propeller to move forward. Pumpjets and all sorts of crazy stuff can work too, and there's always the oldest form of large ship propulsion....

Sail, oars, teams of mules pulling on ropes to push ships through canals - it's just a matter of the laws of physics let you utilize your imagination. But I'll focus on the most common forms of mechanical engine propulsion. The first of which was steam, originally coal-fired then oil-fired; then someone devised steam turbine engines in lieu of piston reciprocating engines; then someone figured out how to put a jet engine in there, and people started using diesel engines and electric motors. Then the absolute craziest thing of all happened - people figured out that if you use a combination of all of this, things get really awesome!

Single-Type Propulsion Systems

Presently, ships are going to be powered through steam turbines, gas turbines/jet engines, or diesel engines. Petrol engines are almost exclusively limited to small craft and to my knowledge no one's built a reciprocating piston steam engine ship since WWII other than for the sheer novelty of it. The simplest setup would be extending the output shaft of the steam turbine/jet engine/diesel until it pokes out the bottom of the ship and stick a propeller directly on it. Anybody who's ever seen how fast a jet engine can spool up (or for that matter a steam turbine) will realize this is sheer madness and will break a lot of things on the ship (the propeller itself, the output shaft, probably the engine and a good chunk of hull along with it) so a series of reduction gears are used. This is in effect attaching a transmission between where the output shaft sticks out of the engine and where it connects to the propeller, but for the most part stuck to a single speed. It's possible for a ship to have reverse gears, but for the most part reverse is achieved by reversing the propeller's pitch angle. Speed is controlled directly through throttle response and mostly chug along all day at cruise.

Hybrid Systems

Yes, just like a Prius; in fact hybrid systems have been used on ships long before someone thought to put it in a car. !!!error: Indecipherable SUB-paragraph formatting!!! , yet for the most part abandoned it during the Cold War for reasons I honestly don't know (please comment if you happen to know!) Back then, they didn't call it a hybrid system or a Toyota Synergy Drive(TM) or what have you; the technical term was turboelectric drive . It more or less tells you what it is - a steam turbine (turbo) supplies power to an electric motor, and it's the electric motor that's actually attached to the output shaft. From various snippets I've read around the web (mainly from enthusiast and hobby sites) the turboelectric drive was considered highly resistant to battle damage, especially regarding concussions from torpedo attacks and flooding. It was also less complex to manufacture than using reduction gears (which required complex tooling to cut, something that was increasingly a luxury during WWII) hence why it was used for everything from convoy escorts to battleships.

!!! UNKNOWN CONTENT TYPE !!!

Naturally, you can hybrid almost anything. Some of the more common hybrid combos will be discussed in greater detail below. But perhaps the most intriguing hybrid is combining mechanical propulsion with sails.

Image from !!!error: Indecipherable SUB-paragraph formatting!!!

You may also noticed that I left out nuclear propulsion from the single type setups, even though a good chunk of the US Navy runs on it. Technically nuclear propulsion more closely resembles a hybrid setup: a nuclear reactor generates steam which is then sent to a steam turbine. Other than the fact that the heat source happens to be a nuclear reactor, it's really no more technically advanced than any other steam turbine setup.

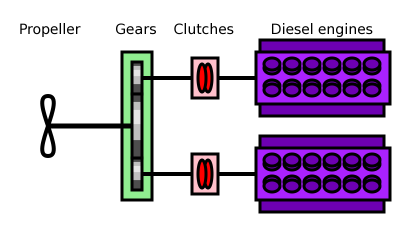

Combined Diesel and Diesel (CoDaD)

Image from Wikipedia

Wait, what ? We're putting two diesel engines together? Kind of, sort of. It just means that two engines share a reduction gear set-up, as shown in the illustration, ultimately powering the same propeller shaft. The important distinction is that multiple engines must share the same reduction gearing; it doesn't count if you have two engines on the same hull but each powers a different propeller shaft.

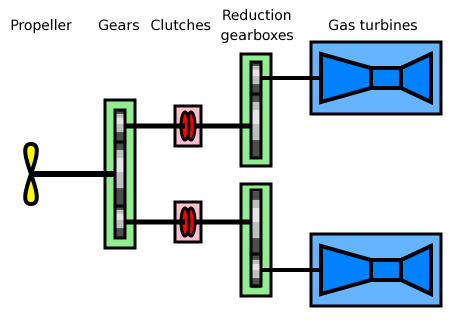

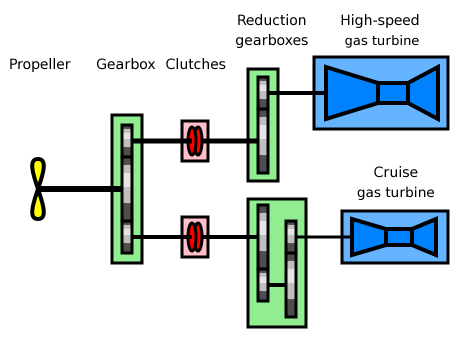

Combined Gas and Gas (CoGaG)

This is fundamentally the same as CoDaD except with jet engines instead of diesels. Because the jets spin much faster, each engine needs to have its own reduction gearbox in addition to the one on the prop shaft that all the engines share. CoDaD and CoGaG are going to be the most common engine configurations on big ships, with CoGaG especially popular on very large non-nuclear warships and

!!!error: Indecipherable SUB-paragraph formatting!!!

. A typical large warship will have four 747-sized jets with two each powering a prop shaft, for example. It's a great way to generate lots of power for high speed, especially if you can afford to not care about what it does to your fuel mileage.

!!! UNKNOWN CONTENT TYPE !!!

Combined Diesel and Gas (CoDaG)

Unfortunately not everybody has the luxury of not caring how low their MPG numbers reach. One way of achieving some sort of compromise would be to switch out some of the jets for diesels. A clutch engagement/disengagement system can add further efficiency but we'll get to that later.

Of course, you can also add a turboelectric drive to create a !!!error: Indecipherable SUB-paragraph formatting!!! .

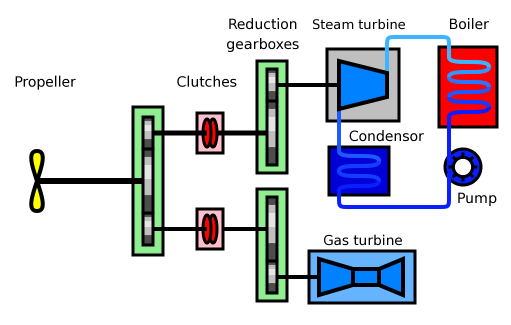

Combined Steam and Gas (CoSaG)

Same as above but with a steam turbine instead of a diesel. This setup was more common during the early days of gas turbine adoption, either to supplement one or the other or to retrofit an older vessel by replacing some of the steam turbines with gas turbines.

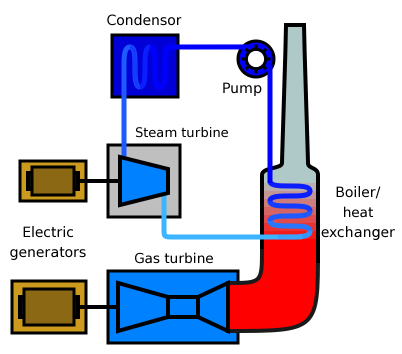

Combined Gas and Steam (CoGas)

This propulsion setup is a little tricky in its quest to be clever. Instead of an oil-fired boiler, a steam turbine is powered by water heated by the waste gasses of a jet engine which also directly contributes propulsion. The illustration actually depicts a sub-variant which throws a turboelectric drive into the mix to create a CoGES (Combined Gas-Electric-Steam) setup. So far it's primarily found on some cruise ships.

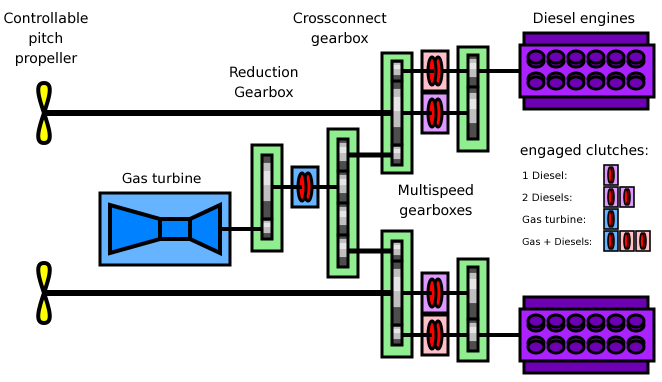

Combined Gas or Gas (CoGoG)

Another way to stretch fuel but maintain high speeds is to have one or two big jets combined with one or two smaller ones. In a CoGoG setup, clutches allow one or more of the engines to be de-coupled from the setup when not in use. Usually all engines will be fired up for flank speed, while only the smaller engines will be running at normal cruise speed. A typical setup is two 747-sized engines with two jet engine types you might find in a narrow-body/single-isle airliner or a larger business jet or turboprop. Fighter jet engines are also popular as "boost" or "flank" engines; some designs like the Pratt & Whitney J75 haven't been in front-line fighters for decades but still see service on warships.

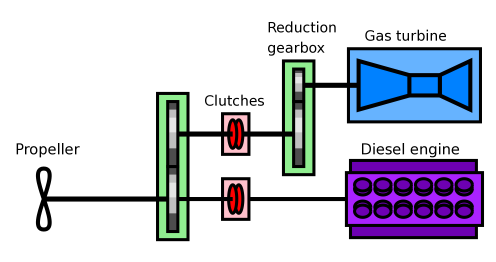

Combined Diesel or Gas (CoDoG)

Same idea, just instead of having a big jet engine and a small jet, you have a jet engine and a diesel engine. Once again, clutches can engage or disengage an engine from the setup. All engines will be running at flank but only the diesel engines will be running at cruise. Most of the world's smaller warships (frigate size or smaller, and some smaller missile destroyers) use either a CoGoG or CoDoG setup.

Combined Nuclear and Steam (CoNaS)

As you've probably figured, this means there are both oil-fired steam turbines and nuclear reactor-fed steam turbines present. Only one ship class in the world uses this setup, the

Kirov

class cruisers (as pictured above).

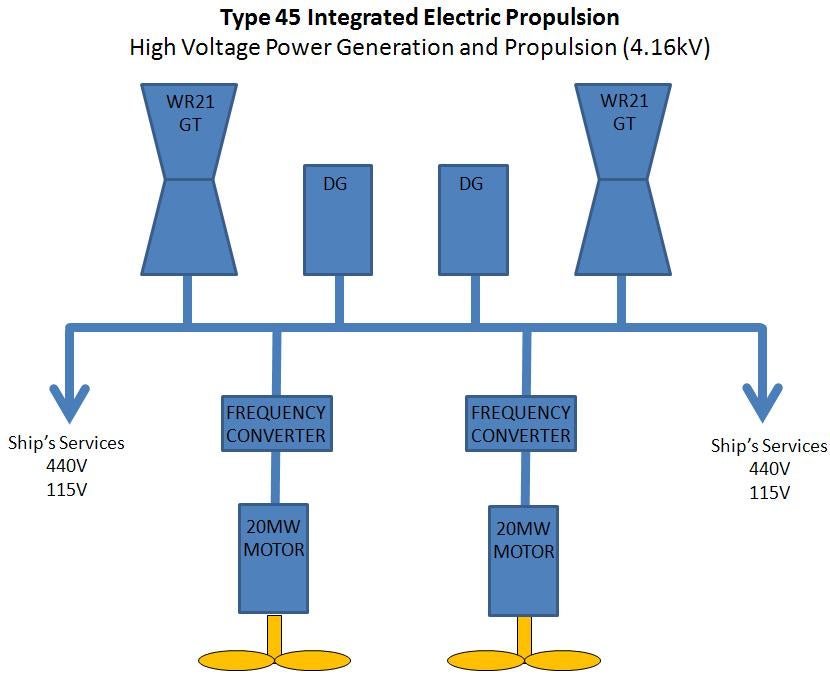

Integrated Electric Propulsion (IEP)

This one is a bit tricky; a traditional gas/diesel turboelectric setup has engines supplying power to electric motors which are directly connected to the propeller shaft. The biggest distinction between that and IEP is that in an IEP setup the engines are supplying power to this thing called an

!!!error: Indecipherable SUB-paragraph formatting!!!

which essentially combines the electric motor and propeller into a single podded unit that can rotate to provide steering. Alternatively power can be supplied to a fixed podded engine which doesn't rotate (using traditional rudders instead) which is...simply called a podded engine. They can also be used to power

!!!error: Indecipherable SUB-paragraph formatting!!!

although Voith-Schneider props can be powered by any of the above means as well. Pump jets (where an

impeller

sucks in and expels water through a narrow tube) may also use this setup, though once again it can also use any of the above.

Air-Independent Propulsion (AIP)

This reflects a relatively new trend to try to give diesel-electric submarines comparable staying power to a nuke boat, especially when submerged. The most traditional methods include closed-cycle diesels which are essentially diesels force-fed bottled air while running under the surface, and closed-cycle steam turbines which are fed steam heated by non-combustion chemical reactions or sustained/continuous combustion typically through "alternative" fuels (such as ethanol). The Swedes are currently big on using

!!!error: Indecipherable SUB-paragraph formatting!!!

; in this application, this type of engine essentially separates the "squeeze" and "bang" stages into their own cylinders with gasses being transferred through piping. Stirling engines can be powered by nothing more than a temperature differential between each cylinder (as some home and hobby applications are) but so far in the marine world are just fancy internal combustion engines in practice. That said, a truly hydrocarbon-free Stirling engine holds obvious promise for extended submarine operations.

KirkyV

> No, I don't thank you for the fish at all

KirkyV

> No, I don't thank you for the fish at all

07/10/2014 at 09:42 |

|

The world's navies really need to get back into the habit of painting ships' names on the side/back in nice, fancy letters. I mean, imagine how much cooler this would look if it had ' Daring' on the side or back.

(The post was really interesting, thanks. I had no idea combined oil/nuclear steam set-ups were a thing.)

spanfucker retire bitch

> No, I don't thank you for the fish at all

spanfucker retire bitch

> No, I don't thank you for the fish at all

07/10/2014 at 09:59 |

|

Shouldn't this be a picture of slaves and paddles?

Chuckybas

> No, I don't thank you for the fish at all

Chuckybas

> No, I don't thank you for the fish at all

11/05/2015 at 11:44 |

|

Semi-obsessed with ships. Have known about most of these systems, but not all, and have certainly never had such great illustrations to accompany the concepts. Thank you! (realize this comment comes wayyyyy after you wrote it, but can’t get enough of this stuff.

Old enough to know better

> No, I don't thank you for the fish at all

Old enough to know better

> No, I don't thank you for the fish at all

11/25/2015 at 11:08 |

|

This is a pretty comprehensive discussion of ship propulsion but there is one misstatement or at least omitted type.

There are a lot of contemporary PISTON driven ships. All you have to do is consider the huge container ships which are direct driven from massive Diesel engines. These ships make up to 25 knots at sea. These engines are typically 2 stroke low RPM engines of massive proportions. These ships are typically Post Panamax in dimensions and have only one propeller again of massive proportions.

These designs are driven from an economical point of view designed to cruise at steady speeds and are not designed to perform in any ‘tactical’ manner.