"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

06/17/2014 at 17:13 • Filed to: Spit6

6

6

7

7

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

06/17/2014 at 17:13 • Filed to: Spit6 |  6 6

|  7 7 |

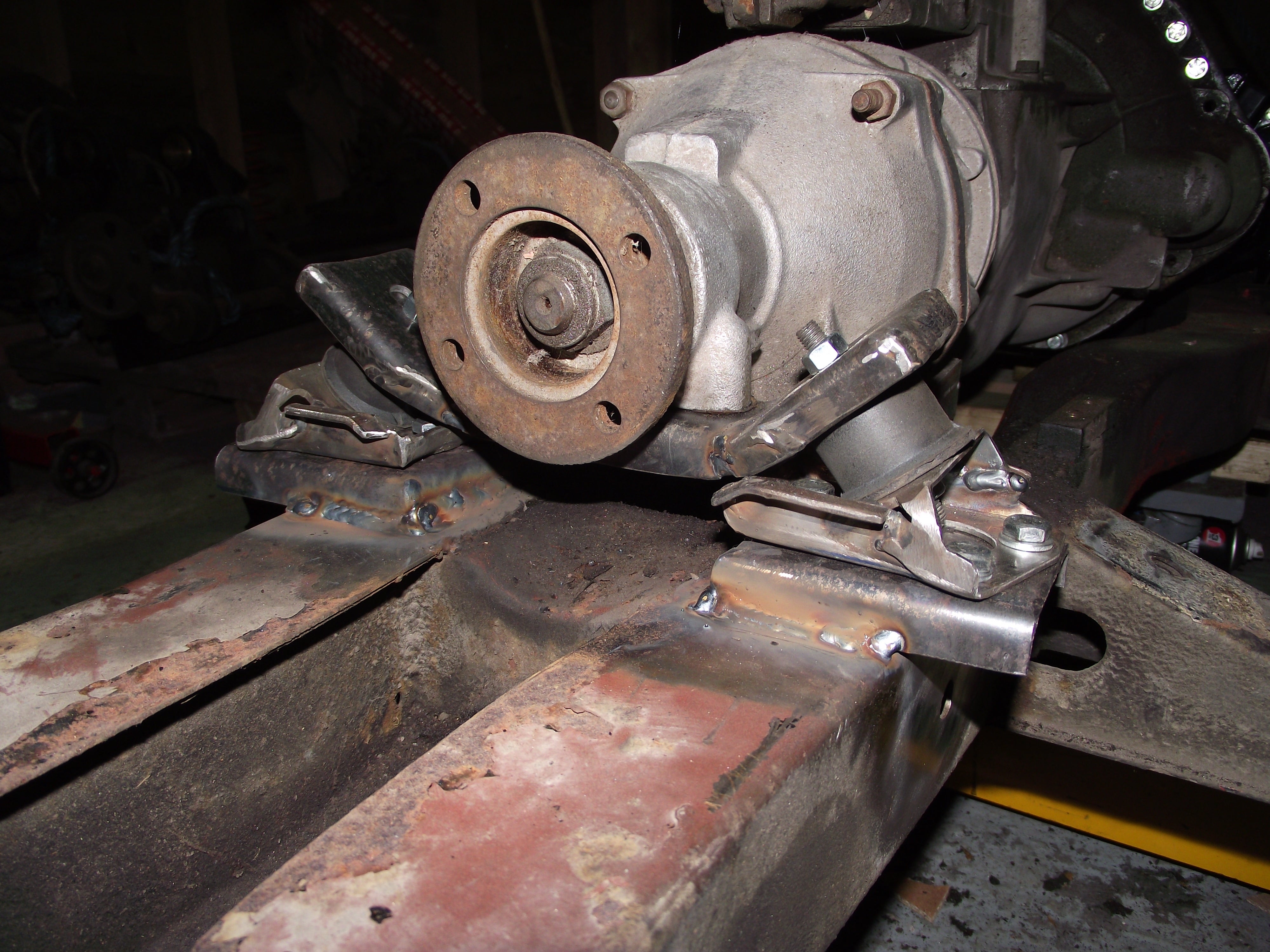

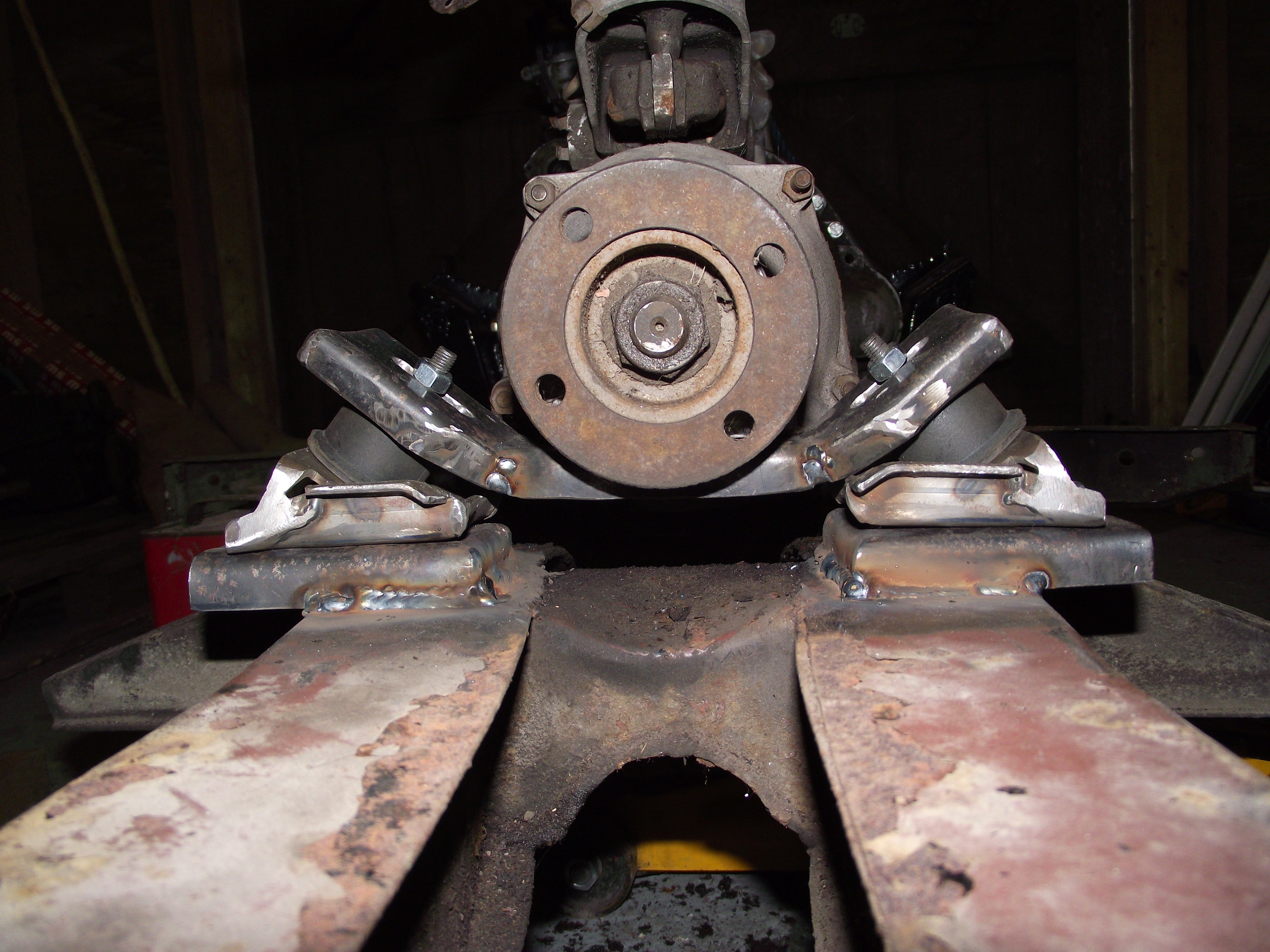

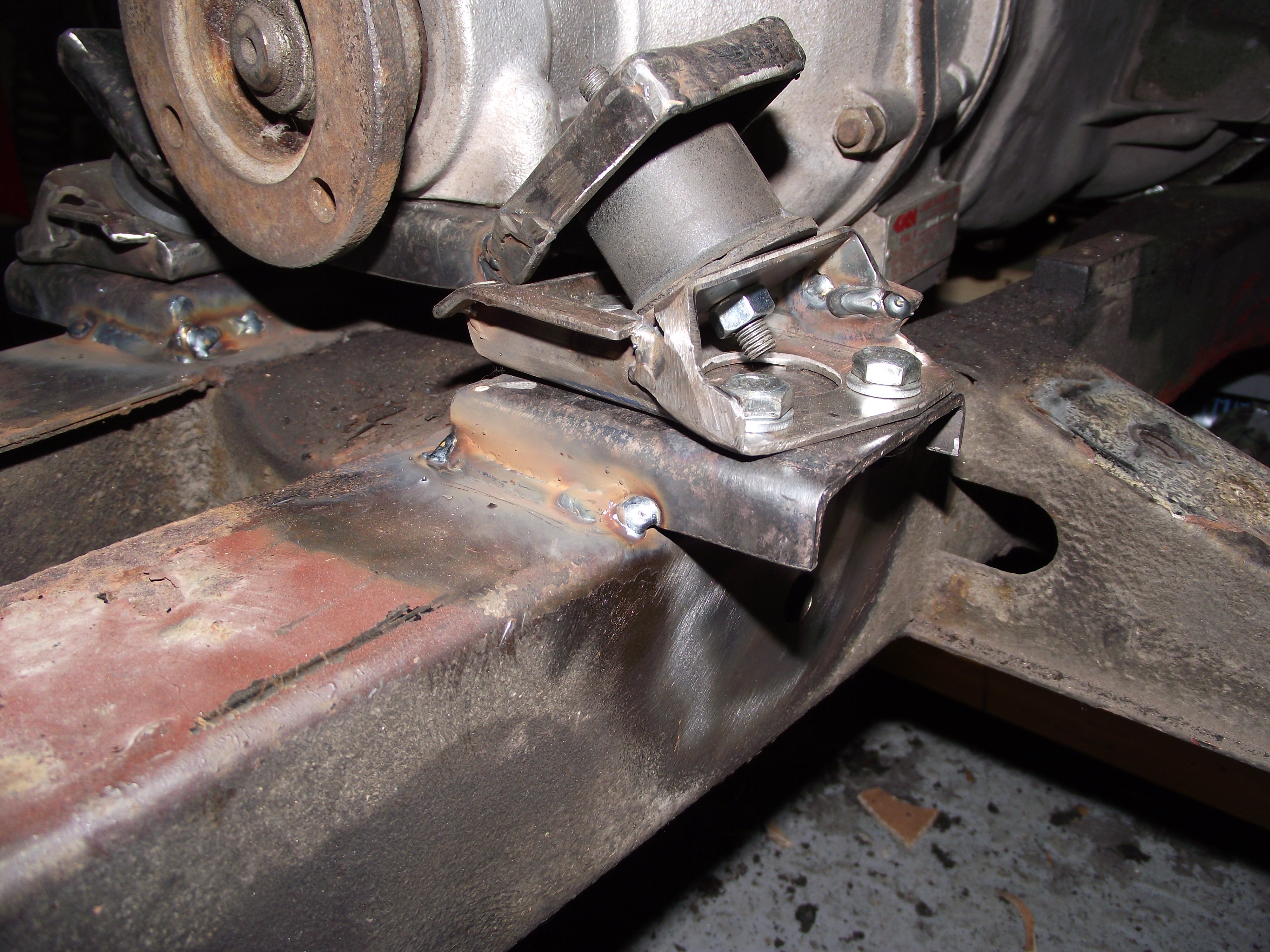

Finished off fabricating the gearbox mount brackets, and welded them onto the chassis. It's not quite finished, I need to cut away some excess metal for clearance, and weld little triangles to support the overhangs, but this is the last bit of modification I'll need to do on the chassis. After that it's just saving up for the chemical dipping, which is tricky if you go around buying Jaaags and whatnot...

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

06/17/2014 at 18:01 |

|

Did you ever nail down what you're using for the chemical dip?

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

06/18/2014 at 07:07 |

|

You know not really. This is the website of the people that are doing it, but understandably they're a bit secretive about the process itself.

Looks interesting though :)

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

06/18/2014 at 09:15 |

|

Very nice. It's effectively the same as a galvanizing prep (alkaline dip, acid dip, alkaline wash), followed by phosphating and what's very similar to a modern powdercoat process (except applied via dip). I do note that they want you to waxoyl or equivalent the frame interior, which leads me to believe that the primer itself is not a perfect coat that will reach all portions of the interior, despite best attempts. For all that, though, that's a pretty modern-car-like sort of thing to do, as is the electrophoretic primer itself.

That being said, I don't know that galvanizing is either, per se. Probably wouldn't hurt to wax the interior of our two Series frames that were dipped - zinc or no. At least we've got mass quantities of sacrifice metal if it *does* try rusting anywhere.

About how much does it all add up to? The galvanizing we got done looks lumpy and brutish in places, but cost us only about $0.95/lb of steel.

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

06/18/2014 at 12:07 |

|

Hmmm, I think you're right about the process not getting to all the nooks and crannies. I did plan to waxoyl thoroughly anyway, just for good measure.

I wish it was $0.95/lb. The whole thing was quoted at £1100, just the chassis. I haven't done any shopping around though, so I might be able to find it cheaper.

The main reason I'll still be going for it despite the price is weight gain. From the Triumph forum I'm on I've heard that galvanising the chassis adds about 10-15kg. Not a massive amount, but seeing as I'm aiming for 750kg any little helps.

Plus, it's a bugger to weld galv-ed chassis' if something eats through the protection.

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

06/18/2014 at 12:17 |

|

It's probably as much as anything that with a sane temperature of dip, unlike galvanizing, they don't have to come over all Nazi on whether your planned regimen of holes allows air gaps or not. With galvanizing, it's very high risk to have air pockets anywhere, so they make you bore holes in it until *they* are satisfied. Over the Rover stock frame, I averaged more than a hundred holes added per - and barely skated. Nobody, and I do mean nobody, would do that level of prep for a process if they didn't have to, and that likely covers this. I'd suggest that that raised the *effective* cost of the frame jobs quite a bit, as that was as you might say "a right bastard".

If you've got air in a galvanized chassis, you run the gamut from possibly blowing the skin of the chassis loose in spots violently when raising out of the dip, to having slugs of half-molten zinc expelled from holes at high velocity. Whereas air in a water-based dip amounts to... at the most Chevy Vega style rust spotting from within 5 years later, and only if not waxed.

I certainly hear you on welding galv. Fastest way to fill up the shield on a mig welder with detritus that exists, not to mention funny yellow smoke, white wisping on the work, and igniting metal.

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

06/18/2014 at 12:35 |

|

I've heard about all the nasty things that can happen without proper galv prep. If there are air pockets they can superheat and deform the chassis as well. Definitely don't want to do that after I spent ages fabricating custom gearbox mounts and welding them on :S

I've been weighing up whether to have it done for the body as well. I suppose it's best to have a look inside the boxed-in areas first. One of those little cameras on the ends of a stalk for electrical inspections should do nicely :)

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

06/18/2014 at 12:41 |

|

I'll probably have to sandblast and spray-phosphate the rockers in the Ranchero rather than trying to dip the whole thing - the empty body's far less than a ton stripped, but still rather a tricky bit of work to move around. However, since the rockers and most of the unibody are accessible from inside, I'm not as worried as I might be. Lots of boxes, but most have one side as only a web, or an entry from one end.