"Moose Kitty" (moosekitty)

"Moose Kitty" (moosekitty)

05/17/2014 at 14:41 • Filed to: None

0

0

24

24

"Moose Kitty" (moosekitty)

"Moose Kitty" (moosekitty)

05/17/2014 at 14:41 • Filed to: None |  0 0

|  24 24 |

I was coming up with a balancing idea for my flat twin concept. I was wondering if there was a way to use the crankshaft to balance the rocking at higher rpms. I also had an idea of using the exhaust pressure to push a counter weight that balances out the rocking. The exhaust would still be directed to the turbo right afterwards. The intake pressure would push the cylinder back to the exhaust side of the counter weight.

I was also wondering if unequal header lengths (like subaru had there turbo EA engines) effected the boost transfer to each cylinder (It would effect the intake lenghts too right?).

BrianNutter

> Moose Kitty

BrianNutter

> Moose Kitty

05/17/2014 at 15:08 |

|

Ok, I'll bit. Look at the bolt on counterweight box driven by a centered crank gear in the ford duratec 2.5. Do you have solidworks? Keep in mind you're only masking imbalance...not fixing it...and it adds weight and requires power.

Opposite Locksmith

> Moose Kitty

Opposite Locksmith

> Moose Kitty

05/17/2014 at 15:17 |

|

subaru EJ engines!

And no it would affect "boost transfer"

Moose Kitty

> Opposite Locksmith

Moose Kitty

> Opposite Locksmith

05/17/2014 at 15:37 |

|

K good to know...thanks

Moose Kitty

> BrianNutter

Moose Kitty

> BrianNutter

05/17/2014 at 16:03 |

|

Planning on buying solidworks, and the balancing system was just me wondering if it would have any real effect with what was required to move it. The actual plan was to use two counter weights that oppose each other, and oppose the pistons while using the crankshaft to turn them. Similar to crankshaft counterweights.

BrianNutter

> Moose Kitty

BrianNutter

> Moose Kitty

05/17/2014 at 16:16 |

|

Let me ask what your goals are for the engine. Power. Where used. What vehicle. Vehicle weight. Transmission.

Moose Kitty

> BrianNutter

Moose Kitty

> BrianNutter

05/17/2014 at 18:09 |

|

I'd like to pull about 160~190 hp. Used for hillclimbs and time attacks. Home made vehicle mostly tube framing till I get more fiber glass panels and clear acrylic. It weights at 1042 lb right now and is getting lighter with speed holes. The transmission I have for the engine is a magnesium transaxle with a sequential gearbox.

BrianNutter

> Moose Kitty

BrianNutter

> Moose Kitty

05/17/2014 at 21:07 |

|

Are there any weight breaks or displacement breaks that will affect the class you run in or is it open and you are showing self restraint towards displacement.?

Moose Kitty

> BrianNutter

Moose Kitty

> BrianNutter

05/18/2014 at 01:16 |

|

I'm running in open class and yes I'm keeping the displacement low in attempt to keep the engine from killing itself. As much as I'd love to have a 2.2 liter flat twin it would be too heavy for one (setup for rear engine, and the piston size i was using before it would be too difficult to get a clean burn (flame speed wouldn't be quick enough for a 5.1 inch piston at the rmps I'm starting to want to get too).

briannutter1

> Moose Kitty

briannutter1

> Moose Kitty

05/19/2014 at 10:23 |

|

The big thing is to differentiate piston speed from RPM. Piston speed really isn't an issue. I do piston design and we turn 4" stroke parts 10k plus rpm all the time. RPM isn't determined by a "short stroke" but rather by the cylinder heads airflow and the ability of the valvetrain to remain stable past the point where it runs out of air.

The reason people associate 'short stroke" with rpm is based on some misunderstood ideas. Consider a small block Chevy where the factory and aftermarket put a 3, 3.250, 3.48, and 3.75 stroke under a given sbc cylinder head that flowed 200cfm. The piston speed where max horsepower achieved will be the same on all 4 combinations. Say 400hp was achieved, it would be at 8000 rpm on the 302, 7400 on the 327, 6900 on the 350, and 6400 on the 383 all with piston speeds of roughly 3900 fpm. So if all 4 of those engines made the same peak horsepower, but the smaller stroke engines all lack the torque (302 versus 383ci) of the largest stroke; why bother with a shorter stroke at all if you're not racing is a specific displacement class? If a lesser RPM means a given valvetrain can cope better, the longer stroke engine will have a tendency to make more peak horsepower because the valves are still in control. A cylinder heads airflow is mostly dictated by the intake valve size which is dependent on the bore size. Torque per displacement is a cool exercise (think BMW S1000rr or Ferrari 458), but in the end -it's ricer math to a racer and the guy with larger displacement wins and has more valvetrain reliability to boot. Put more stroke in either of those two engines and they will make more useable power.

Getting back to your requirements, if you need your naturally aspirated twin to produce 200hp, that's going to require about 400cfm of air. http://www.wallaceracing.com/Calculators.ht… That's a bit over simplified, but pretty easy to achieve out of a 2v or a 4v head depending on the bore you've decided on. A 4.5 bore and 4.0 stroke would yield a 2.1 liter twin and the RPM to hit 200hp wouldn't be much. There's enough stroke there that you can achieve a high compression ratio easily. Think of it as a 509 bb Chevy only needing to produce 800 hp. Piston speed is relatively low for your hp target and it would be a walk in the park for the valvetrain. Larry Meaux has some interesting work out there. Heywood has some very good books out that explain the science.

Moose Kitty

> briannutter1

Moose Kitty

> briannutter1

05/19/2014 at 10:37 |

|

Thank you i mostly had a short stroke because it thought it was going to be too wide...then I remembered the mount is rear engined. Thankfully I haven't started building just yet so I can't express my full gratitude for your help.

briannutter1

> Moose Kitty

briannutter1

> Moose Kitty

05/19/2014 at 11:23 |

|

ok, getting further into the idea of using "off the shelf" standards; here's how we'd go about determining a proper deck height. 4" stroke with a 6.125 rod and .927 pin and 1.110 compression height (common chevy Ls 427 combination) has a stackup height of 9.235" The rod could be shortened to 6" or even 5.850 depending on how much heavy metal needs to added to the counterweights to compensate for a shorter counterweight (to clear the underside of the piston). The piston could be shortened up even further with a 22mm pin diameter and 1" compression height (similar to a NHRA Pro Stock engine style piston). This means deck could theoretically be shortened to 8.850". A Subaru deck height is 7.913 in comparison. Crank's Rod journals could be 2" for good bearing availability (or even Honda journal sized), but you would have a pretty stout crank in terms of journal overlap with a 2" rod journal.

So let's talk about engine package size. ohc adds a lot of weight, complexity and width to the engine. If you didn't mind bumping it up to a 4.600 bore, you could run one of these 507 cfm BBC heads http://www.brodix.com/heads/big-bloc… . Those heads usually produce 1200 naturally aspirated horsepower on a BBC, so a 300hp twin is possible. You would be hardly working things if you only needed 200hp. Frankly, you could by one head and chop it up and use the two middle cylinders with plates welded onto each side of the water jacketing. Off the shelf rocker shaft, pushrod, and cam lobe (billet shaft) availability solves some problems too. Then there's the fact that blueprints/solidmodels for that engine are easy to come by and you would have a "known" reliability. Really you could get a model for a bbc and chop off 1,2,3,4,5,6 off the front and use the model for cylinder 7/8 for the thrust bearing and rear flange/seal design and use the front of cylinders 1/2 for the front accessory drive pieces. Changing the solid model to a "flat" configuration would be pretty easy.

So, you've got some choices...go wild or go mainstream. You may want to consider this as a starter engine. Either way is fun, but your budget and timeline will usually make your decision for you.

briannutter1

> briannutter1

briannutter1

> briannutter1

05/19/2014 at 11:28 |

|

Also, run the cam off a gear drive on the top of the engine with pushrod tubes above the crank for minimal chance of leakage. A little "block" on top of the engine with the cam in the middle would accommodate .904" diameter off the shelf roller lifters.

briannutter1

> briannutter1

briannutter1

> briannutter1

05/19/2014 at 12:24 |

|

Also thinking you now have easy easy crank and cam triggers placement for your injection.

Moose Kitty

> briannutter1

Moose Kitty

> briannutter1

05/19/2014 at 12:53 |

|

Never thought to use a BBC head. If anything going with chopping up a model would be the easiest in the sense of time in shop. Luckily the summer is getting close and I'll have more time to spend working on the engine. If i could get 300hp out of this thing I would dominate against racers of the same weight (got the car to just above 900 lb yesterday dry).

briannutter1

> Moose Kitty

briannutter1

> Moose Kitty

05/19/2014 at 12:56 |

|

Yes and the best part it the reliability. If you build this, it's going to get a lot of attention and you may want to think about getting into the UAV business :)

briannutter1

> Moose Kitty

briannutter1

> Moose Kitty

05/19/2014 at 13:10 |

|

This is a Top fuel 4 cylinder billet engine we worked on when I was at CJ Batten's in the late 90's. Bob Norwood does some incredible builds and CJ's 4v DOHC BBC heads (and many other projects) were amazing. He also designed V12's that were based on a mix of BBC, BBF bottom end design standards along with his 4v head designs.

http://www.bobnorwood.com/Max-4%20Techni…

http://www.turbomagazine.com/tech/0202tur_n…

http://www.hotrod.com/techarticles/i…

This last engine is a 509 4v dohc conversion.

Moose Kitty

> briannutter1

Moose Kitty

> briannutter1

05/19/2014 at 13:39 |

|

UAV? Unmanned aerial vehicle? I've been gathering materials recently, and I'm hoping that all that cash doesn't end up in a cracked block or thrown rod. Anyways it's awesome that you've been helping especially since I would have even tried a lot of the stuff proposed on thought alone (was planning on chopping up a EJ head and hope it would work).

briannutter1

> Moose Kitty

briannutter1

> Moose Kitty

05/19/2014 at 13:57 |

|

yeah, UAV (drone) business is big right now for lightweight high output reliable engines.

It might be too simple, but how about a lightly boosted Buell 1125 or 1190 engine? http://www.erikbuellracing.com/motorcycles/11… The 1190 is 175 out of the box.

Moose Kitty

> briannutter1

Moose Kitty

> briannutter1

05/19/2014 at 14:01 |

|

Nice to know. I was considering using one, but I'd never created an engine (design, construction, etc.) and wanted to try my hand at it. If anything, if my engine were to fail I would go through with the 1190.

Reigntastic

> Opposite Locksmith

Reigntastic

> Opposite Locksmith

05/21/2014 at 10:47 |

|

Opposite Locksmith

> Reigntastic

Opposite Locksmith

> Reigntastic

05/21/2014 at 10:59 |

|

Want.

Reigntastic

> Opposite Locksmith

Reigntastic

> Opposite Locksmith

05/21/2014 at 11:07 |

|

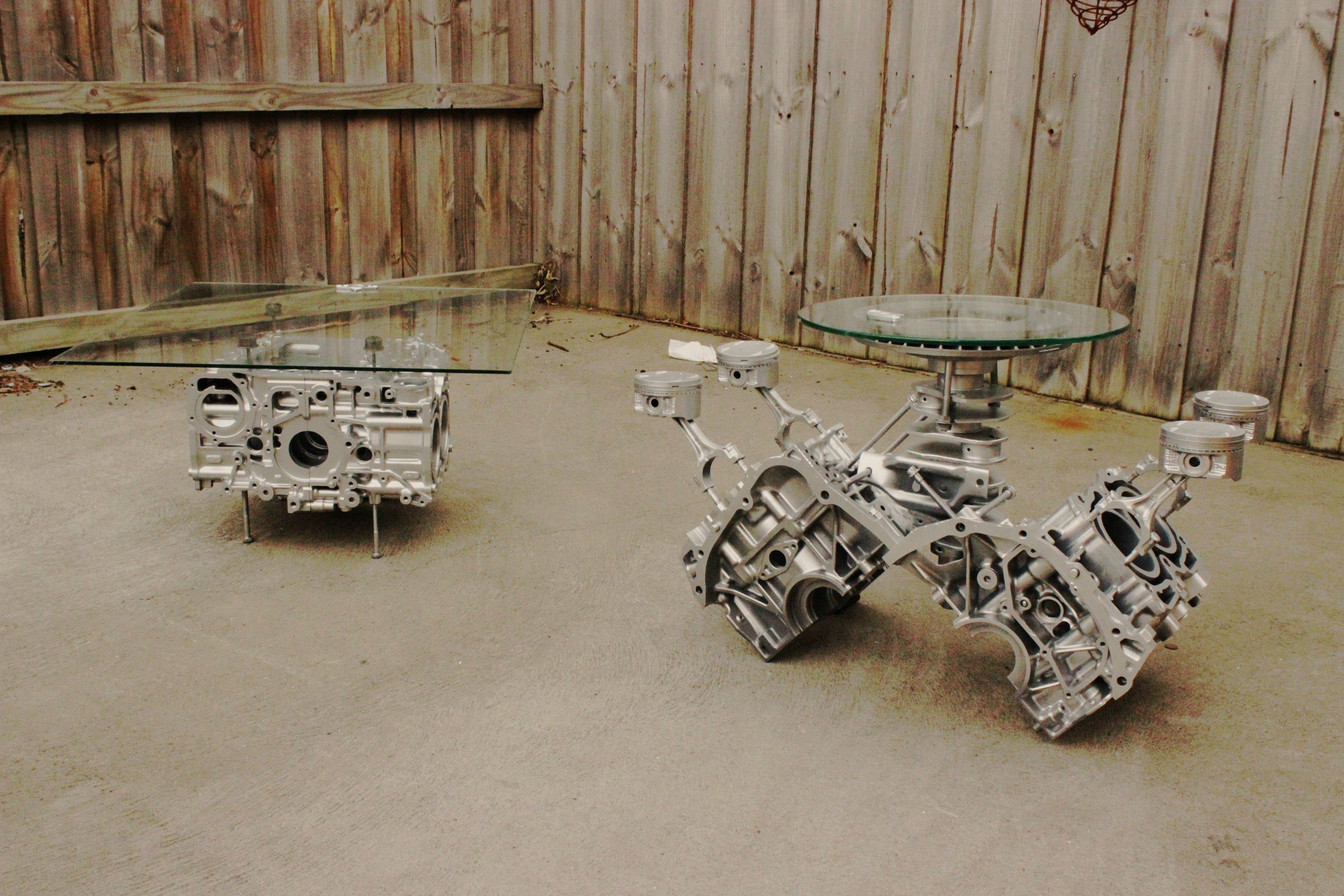

Which one do you like more? I like the one on the right more myself, but I wish they had used the pistons for the glass top instead of what looks like a rotor (flywheel?) on a crankshaft for more surface area.

Opposite Locksmith

> Reigntastic

Opposite Locksmith

> Reigntastic

05/21/2014 at 12:41 |

|

the leftmost one you magnificent bastard.

I don't understand what the pistons are doing on the other

Reigntastic

> Opposite Locksmith

Reigntastic

> Opposite Locksmith

05/21/2014 at 12:43 |

|

Love you too ;)

They're bolted on to the block where the head would be, kind of like Kevin's V8 table.