"MR2_FTW - Group J's resident Stig" (MR2_FTW)

"MR2_FTW - Group J's resident Stig" (MR2_FTW)

05/14/2014 at 21:28 • Filed to: MR2, toyota, project, supercharged

1

1

0

0

"MR2_FTW - Group J's resident Stig" (MR2_FTW)

"MR2_FTW - Group J's resident Stig" (MR2_FTW)

05/14/2014 at 21:28 • Filed to: MR2, toyota, project, supercharged |  1 1

|  0 0 |

5/7/14

OK well looks like the high comp pistons idea may not work out. Turns out I can't get them through my dealership, and to get them from the main online source would be twice as expensive. And take 4-6 weeks for shipping. So I think I'll save like $300 and over a month of downtime and just keep my current pistons, and be happy with the flywheel and TRD headgasket for performance gains (maybe look into cams if I really feel ambitious). The machine shop says my crank journals are mint, and my block is basically perfect so they are going to give it a basic hone and resurface and that should do it. I'll be ordering main bearings, rod bearings, thrust washers, and piston rings today. If everything goes really well, the car may be up to race at the test & tune in June. Maybe.

EDIT: haha yeah I just got rings, rod bearings, main bearings, and thrust washers all combined for less than just the new pistons would have been online. Yeah I'm ok with that.

5/8/14

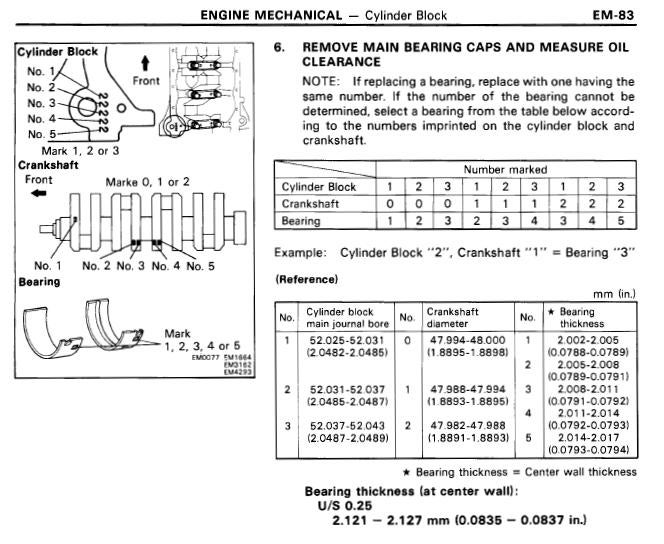

Turns out I ordered the wrong size main bearings (the parts catalog at work can be super confusing), so those will get returned when they come in. Apparently when you look up the full set in the catalog it's "U/S" for undersize journals if you had to get the crank machined. What I need to do now is look for numbers stamped on the block and crank and match them up through a little chart in the repair manual to determine what bearing size I need. Fortunately I have a picture of said markings on the block from a few years ago (mine is 33332). Unfortunately, my crank is still at the machine shop and I can't get it till Monday.

Here's the chart for reference.

5/13/14

Got off work early today because I had to go to some kind of inventory class training thing, and stopped by the machine shop to have a look at the numbers on the crank so I could order main bearings. I was delighted with some good news. 1. Giving the crank a light polish won't effect the bearing tolerances in any kind of significant amount2. Everything should be done tomorrow or Thursday3. The bill will be significantly less than I anticipated

Anyways, the marks on the crank read 00001. Using the chart posted previously that works out to all 5 main bearings in size "3". They should be here Monday at the latest I think. I have also ordered appropriately sized plastigauge (every kind you can get readily in the US doesn't go to tight enough tolerances) from a guy on MR2OC that has some he presumably got from a UK supplier. I'm so psyched to start putting this thing back together!

5/14/14

Got everything back from the machine shop today.

They washed everything, honed & resurfaced block, resurfaced the head, polished the crank, and cleaned the pistons. The guy that did the work (Frank) said that there was some pretty good pitting between the cylinders and the water jacket on the gasket surface which were most likely the cause of my issues. He says he sees it a lot on iron block/aluminum head old Toyotas. So, mystery solved.

I got to work cleaning the burnt carbon off the pistons this evening. Fine wire wheel on the dremel with a very light touch and a steady hand did the trick. I need to get a fresh wheel to get down in the ring lands better, but I'm pretty happy with how they turned out.

Before:

After:

Before:

After:

I also wire wheeled (big one on a power drill this time) the windage tray to get all the old RTV off it. I also straightened it out from where it got a little bent up from removal. The oil pan flange will be getting the same treatment soon.

Also also - I ordered another DIY urethane kit from McMaster to fill my side motor mounts. Yiss.