"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

04/15/2014 at 17:50 • Filed to: Spit6

6

6

17

17

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

04/15/2014 at 17:50 • Filed to: Spit6 |  6 6

|  17 17 |

I had a crack at some chassis repair on the Spitfire today. Both of the outriggers at the front that support the bonnet hinges are rusted to buggery, and the one on the right hand side of the chassis had been pushed backwards and upwards by a minor shunt in the past.

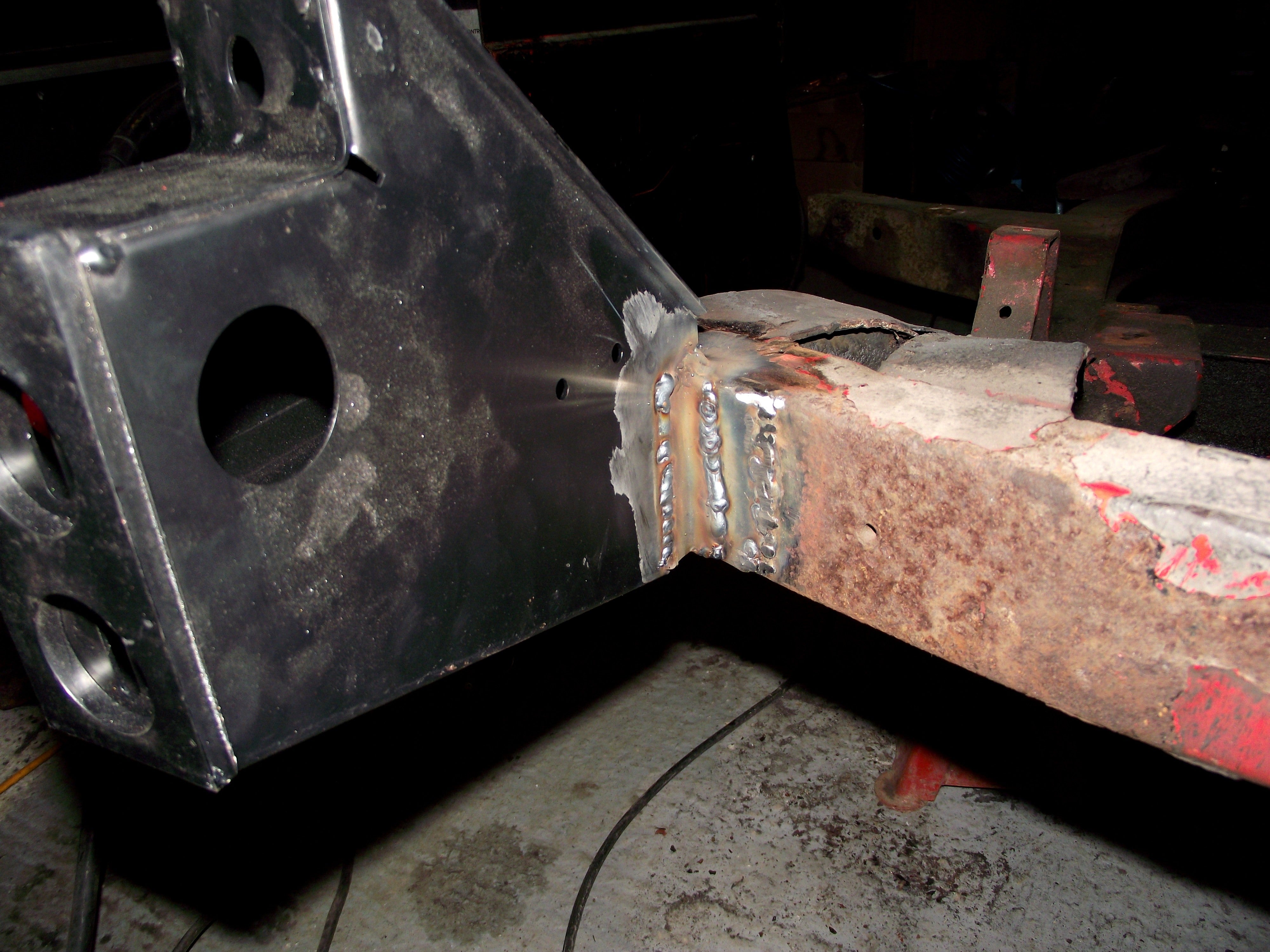

I started by chopping the old outrigger off, which really shows how rusted it had become.

Some more angle-grinding and I'd got it back to some solid metal.

Thanks to a lot of measuring beforehand, I could fab up a new bit of open box section. Just a matter of marking out, cutting, bending in a vice and offering it up to make sure it fits :)

Welding it into place...

...and grinding down the welds flush.

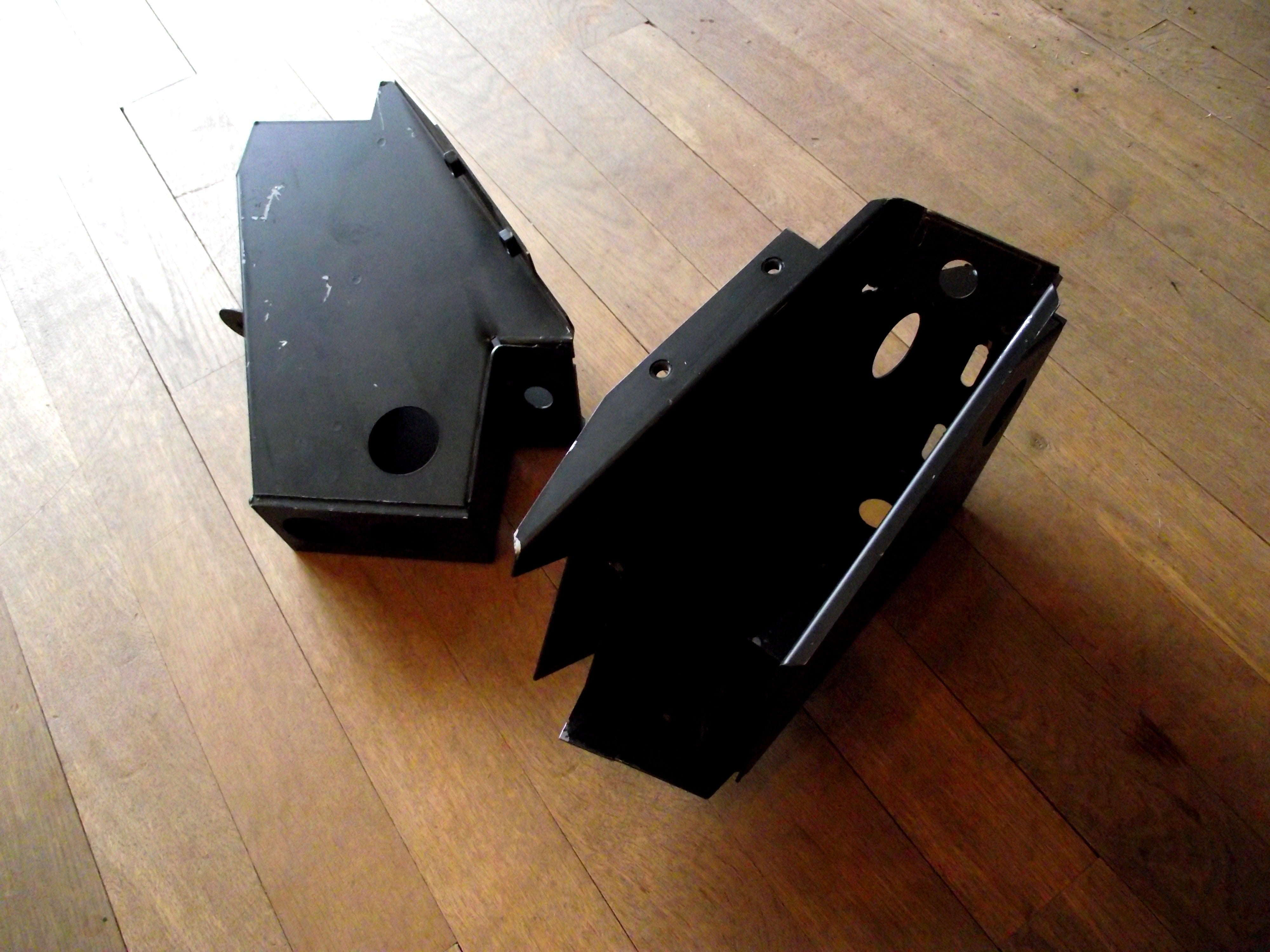

Luckily, I could order brand new front outriggers so I wouldn't have to rebuild the crusty old ones. I love parts availability :)

In order to offset the crash damage, I used a level and some 4x2 to prop it in the right place, and tacked it onto the chassis, knitting the welds up afterwards. Fingers crossed it's in the right place :S

You can see how far away I had to mount it away from the chassis with these little L-shaped extensions. A good centimetre (2/5") each side.

A quick spray of cheap zinc primer to protect it and this side's done :) I do love it when a job's finished in a day.

jkm7680

> BiTurbo228 - Dr Frankenstein of Spitfires

jkm7680

> BiTurbo228 - Dr Frankenstein of Spitfires

04/15/2014 at 18:05 |

|

Oh Noes! Glad it's gone through Surgery successfully.

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

04/15/2014 at 18:10 |

|

As I'm sure you know, this is eerily similar to Landy chassis work. In fact, I got a pair of 109SW and 88 frames back from the galvanizer just yesterday. Both of which had had bits chopped off and replaced by yours truly; in the case of the 109 making a fresh one from existing front and rear plus fresh front spring horns, fresh firewall supports, and a small raft of little braces from the defunct rear to the fresh one (SW brackets - > pickup rear frame).

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

04/15/2014 at 18:19 |

|

I was thinking about galvanising my chassis actually, but decided against it on weight principles. It adds a good few kilos, and given the effort I've made to keep the weight down it seemed a little counter-productive.

I'll be getting a company to acid-dip it and paint it with some sort of electrolysis process, so it should be nicely protected inside the box-sections as well. Seems like the best of both worlds :)

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

04/15/2014 at 18:24 |

|

In the case of the Landies, getting a proper non-galvy clean and prep to the inside of the frame would be damn tricky at this stage, due to expanse and complexity, not to mention intrinsic issues of pre-existing rust and paint residues. At this point, best to have the vast acres of sacrifice metal in case the inside of the frame decides to be clever. That, and getting it hot enough to galv will at least burn off anything within that couldn't be removed.

One Landy's a little one, so fast enough for an extra pound or two, and the other's getting a Benz turbodiesel. And, since the gearing's low and the top-speed limiter's far more the slabby face than the weight, it seemed a reasonable trade.

I think we might have picked up about 30lb-40lb a frame, if that. Not terrible, still possible to pick one up with a pair of men, so hardly a tragic hit.

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

04/15/2014 at 18:37 |

|

Yeah, I expect it's less of an issues with a Landy. Durability in adverse conditions is much higher on the agenda than with my Spit. 30-40lbs would be noticeable in such a featherweight chassis (I can stand in the middle and pick it up myself).

I'll be getting it chemical dipped beforehand, so hopefully all the crud that's developed within the box-sections should be excised.

If it turns out to be money down the drain I'll probably galvanise it. I really don't like the idea of spending tons of time painting the outside only to have it rust from the inside out.

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

04/15/2014 at 18:46 |

|

In either case, you should be prepared to drill the proverbial arseload of holes. More so if galvanizing comes into the picture, but tank-dippers of various stripes are not fans of handling lumps with cavities within that can't fill, and reserve air pockets. In the case of hot-dip, an air pocket can even make for a bomb - serious danger to workmen. I found myself putting probably 160 holes in the two chassis just to be sure they wouldn't be turned back at the gate - over an hour's drive to the plant, so any failure on that count would sting.

Recommendation sheets on galv prep in that respect should be available online, but a big thing is to drill sets of opposite corners so high spots can't exist *no matter which way the frame gets tilted*, and their opposites to ensure a drain. Much more time consuming than you might expect, when the up/down of the frame in treatment is uncertain.

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

04/15/2014 at 19:08 |

|

I have heard of the problems with galvanising an unmodified chassis. Most of the stories of galvanising warping chassis' comes from air pockets in enclosed sections becoming superheated.

I don't know if the process I'm going for is a hot one or a cold one actually. I'll have to ask the company.

Oh, have you done any work stiffening chassis' before? I'm wondering whether to seam-weld the chassis to increase rigidity, or just add some extra box-section in places to brace it a little. I'll have to weld in a new gearbox mount anyway, so I might as well put some strengthening in there while I'm at it.

desertdog5051

> BiTurbo228 - Dr Frankenstein of Spitfires

desertdog5051

> BiTurbo228 - Dr Frankenstein of Spitfires

04/15/2014 at 19:09 |

|

Glad you included pics. Could not tell what the hell you were talking about from the text. Looks like a first rate job has been done. Congrats.

BiTurbo228 - Dr Frankenstein of Spitfires

> desertdog5051

BiTurbo228 - Dr Frankenstein of Spitfires

> desertdog5051

04/15/2014 at 19:13 |

|

Thanks man :) I was rather proud of how it turned out.

Ramblin Rover - The Vivisector of Solihull

> BiTurbo228 - Dr Frankenstein of Spitfires

Ramblin Rover - The Vivisector of Solihull

> BiTurbo228 - Dr Frankenstein of Spitfires

04/15/2014 at 19:25 |

|

haven't stiffened Landy frames st all. They don't really have the power to need it. Later frames had a couple of webs or bars added for giggles, but not really anything of consequence. From factory, the 109s have an extra strip (double layer) in high-stress narrow sections - so that's as good a trick as any - but I havent done anything myself. Now, the Falcon is another matter. I'm going to be adding subframe connectors to the unibody as were present on station wagons and as people like to add to mustangs to combat body flex. Add me raising the door sills with a box section, and it should be stiff as an iron poker, regardless of me adding t-tops. Which is something I'm set to do. ;)

mrazekan

> BiTurbo228 - Dr Frankenstein of Spitfires

mrazekan

> BiTurbo228 - Dr Frankenstein of Spitfires

04/16/2014 at 01:21 |

|

You mentioned an "electrollysis process" earlier. If it is what think it is, then it is electro deposition, or ED. The process is commonly used in the bike industry as a rust prevention. The most common color is black though we recently received clear ED parts. BMX bikes are using it as a finish "paint" now that there are more collors available.

The process is a cold process. You can think of it as a cross between powder coating and electro plating. After being cleaned and prepped, the parts are dipped into a liquid which has plastic partIicles dissolved/suspended in it, I can't remember which. A current is applied to the part which causes the plastic in the solution to deposit onto the charged surface. I think the parts are then dipped into another solution which binds the plastic together.

The resulting layer is really thin and lightweight but very tough.

BiTurbo228 - Dr Frankenstein of Spitfires

> mrazekan

BiTurbo228 - Dr Frankenstein of Spitfires

> mrazekan

04/16/2014 at 07:02 |

|

Oh cool :) that sounds like what they were describing. I think I'll put a layer of chassis paint over the top, and maybe some waxoyl inside, but it certainly sounds the business.

Jobjoris

> BiTurbo228 - Dr Frankenstein of Spitfires

Jobjoris

> BiTurbo228 - Dr Frankenstein of Spitfires

04/16/2014 at 08:04 |

|

Wow, looks great! You're really lucky parts for these English cars are so easy to get. When did you plan to have it ready?

BiTurbo228 - Dr Frankenstein of Spitfires

> Jobjoris

BiTurbo228 - Dr Frankenstein of Spitfires

> Jobjoris

04/16/2014 at 08:11 |

|

I know :) you can pretty much buy a brand new Spitfire/MGB/Mini from parts if you so wished. Very lucky :)

I'm hoping it'll be finished by the end of the year, but I'm aware there's a long way to go. I've started putting things back together now, rather than take them apart, but I reckon all the little finishing bits will take an age.

BiTurbo228 - Dr Frankenstein of Spitfires

> Jobjoris

BiTurbo228 - Dr Frankenstein of Spitfires

> Jobjoris

04/16/2014 at 08:13 |

|

Oh, how's the '02 coming?

Jobjoris

> BiTurbo228 - Dr Frankenstein of Spitfires

Jobjoris

> BiTurbo228 - Dr Frankenstein of Spitfires

04/16/2014 at 09:05 |

|

Took the engine out of the donor-car this weekend, will write up a short post this week:

BiTurbo228 - Dr Frankenstein of Spitfires

> Jobjoris

BiTurbo228 - Dr Frankenstein of Spitfires

> Jobjoris

04/16/2014 at 12:30 |

|

Kickass :) look forward to it